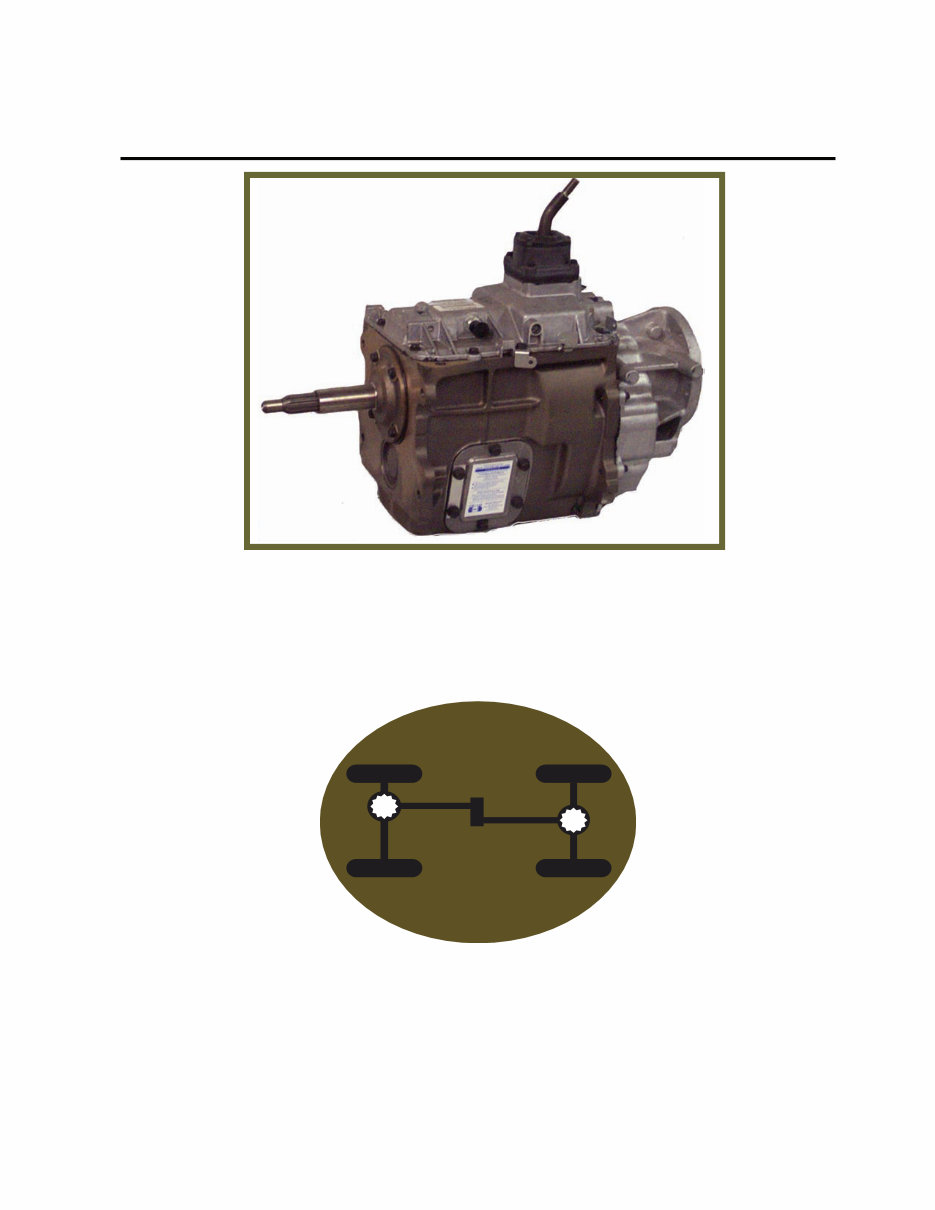

NV4500 TRANSMISSION SERVICE

DAN GUARINO

TM1003

4X4 TECHNICAL MANUAL

4x4 Tech Inc. Roberts, Montana U.S.A.

www.4x4techinfo.com

COPYRIGHT © 2005-2006 4X4 TECH INC.

UNAUTHORIZED REPRODUCTION OR DUPLICATION PROHIBITED

4X4 TECH INC.

Copyright © 2005-2006 by 4x4 Tech Incorporated. Roberts, Montana

All Rights Reserved. No part of this publication may be reproduced in any way without the ex-

press written permission of 4x4 Tech Inc..

Published by Clear Creek Publishing

Printed version is printed and Bound in the United States of America

Electronic Compact Disc version is recorded in the United States of America

Table of Contents

Disassembly 1

Inspection 23

Expanded Views 26

Gear and Shaft Guide 32

Small Parts Illustrated Guide 35

Assembly 40

Shift Cover Service 72

Torque King® Installation 85

Shop Notes 93

Specifications 98

Frequently Asked Questions 99

Fifth Gear Failures and Solutions 102

Catastrophic Manual Transmission Failures 110

Install Tips for Dodge 1994-2002 113

Special Tool List 115

This manual is intended as an aide to performing a

specific service procedure. It is not a replacement for

vehicle manufacturer service manuals.

Working on vehicles and vehicle components is dan-

gerous. It has certain inherent risks, including serious

bodily injury and death. This manual is not a substi-

tute for common sense, experience, and careful prepa-

ration. You are responsible for taking appropriate

safety precautions before and during working on your

vehicle or vehicle components. If you do not already

know how to safely work on your vehicle, please have

the work done by a professional automotive techni-

cian.

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Before starting disassembly, drain the oil by removing the lowest bolt from ei-

ther PTO cover (Early models have a drain plug on the right side).

Clean off accumulated dirt, grease and grime from exterior of transmission.

Support the transmission in a holding fixture or place on a sturdy work bench.

Have a table or cart next to your work area that you can lay out the parts you re-

move from the transmission.

Check to make sure you have the proper tools on hand.

DISASSEMBLY

1

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

The original conception of the NV4500 called for 3 ratio options plus a 6 speed, double

overdrive version. Only the medium and wide ratio 5 speed ever saw production. Dodge

used the medium ratio NV4500 from 1992 to 2004 and in a few 2005 trucks. GM used the

wide ratio from 1992-1994, then switched to the medium ratio for 1995. A number of de-

sign changes were made over the years to improve function and minimize noise, vibration,

and harshness. The last production vehicles to use the NV4500 were the 2007 Chevy Silver-

ado Classic and 2007 GMC Sierra Classic trucks with the MW3 transmission option.

ABOUT THE TRANSMISSION YOU ARE ABOUT TO SERVICE

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

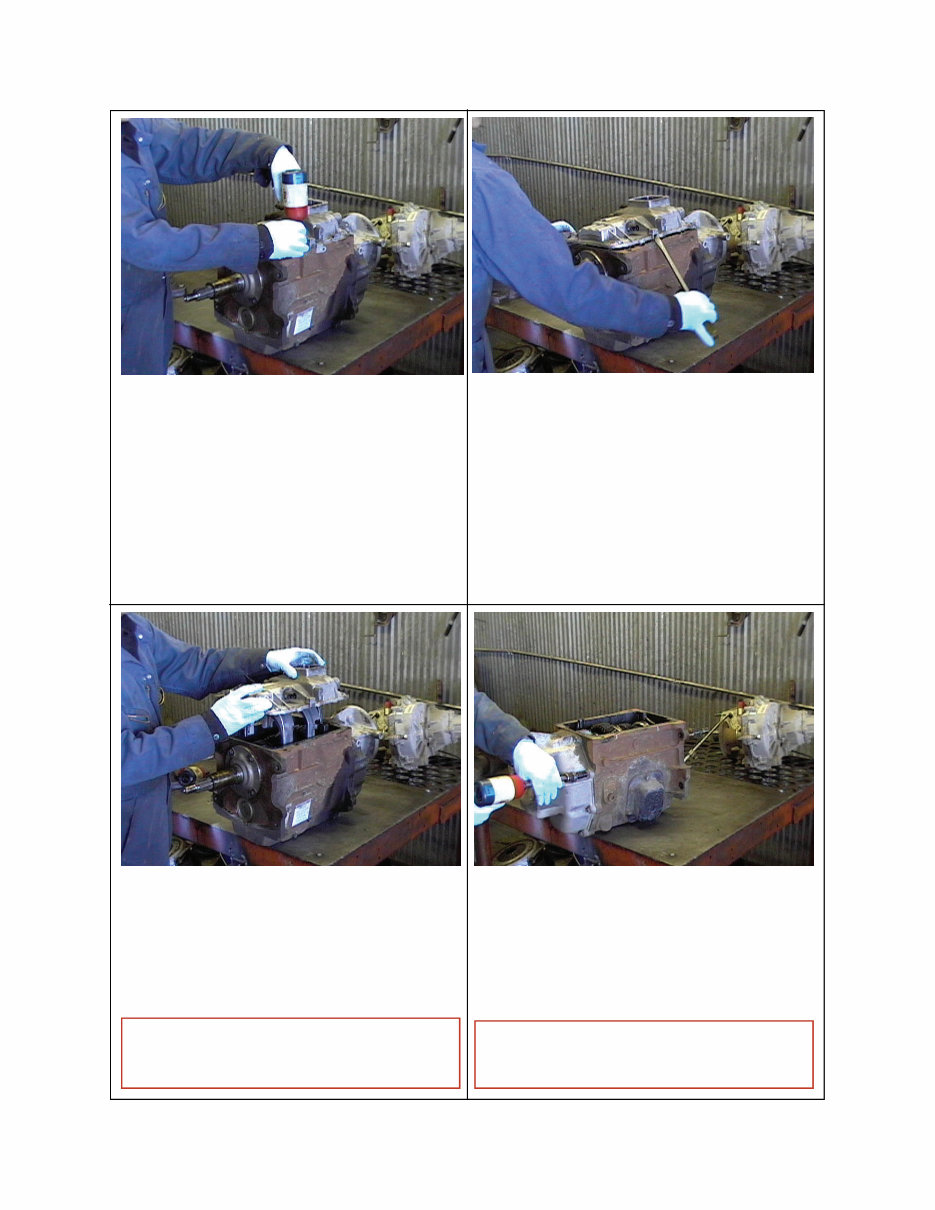

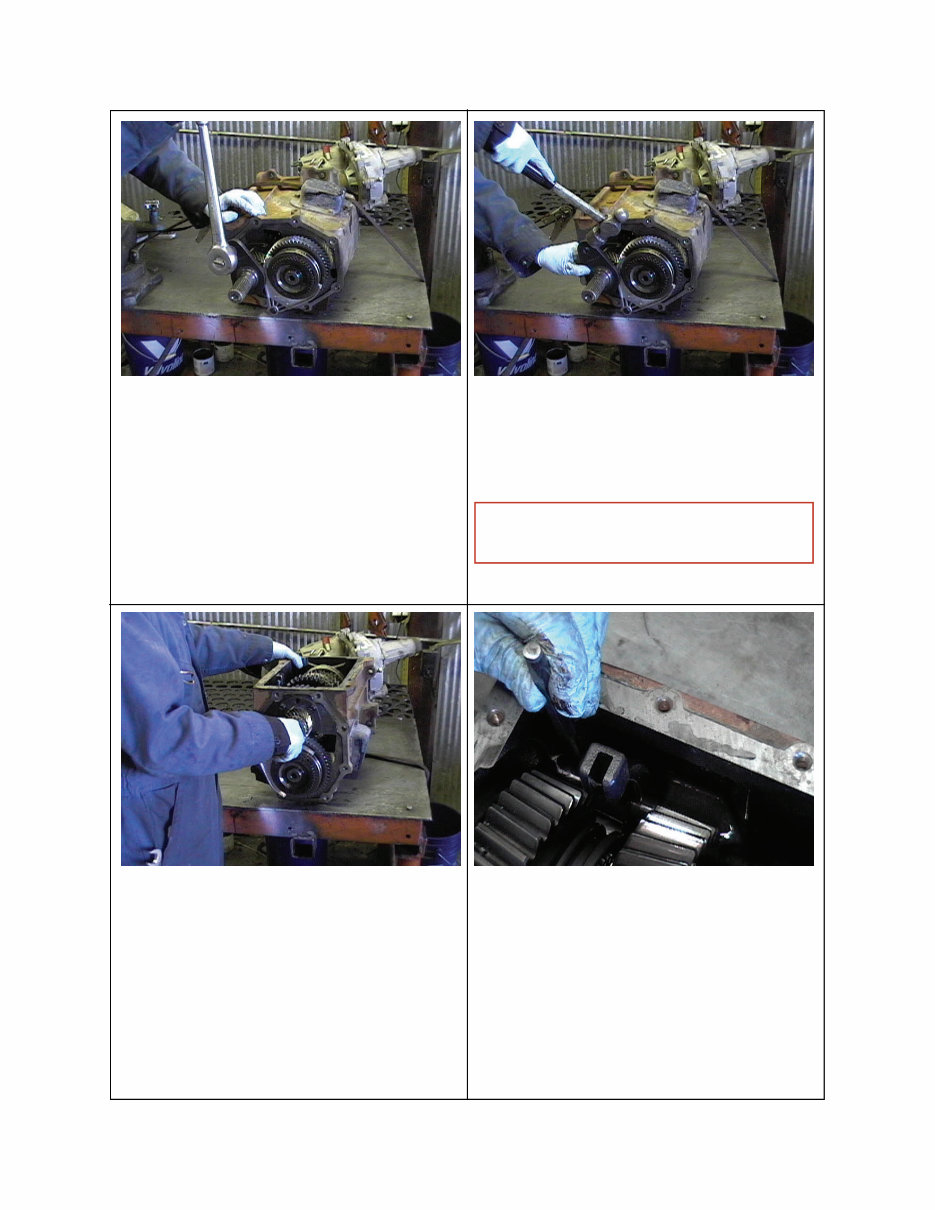

Use a ½” socket to remove the 10 top

cover bolts. Be sure to keep track of

the position and orientation of each of

the top cover clips.

Tool Recommendation:

½” Socket

Ratchet or impact wrench

Insert a suitable tool into the square

pry notches in the top cover, and pry

up cover assembly.

Tool Recommendation:

Prybar or other suitable tool

Remove cover assembly.

Position the transmission on the bench

so a drain pan can be placed under the

rear housing.

Remove the rear cover bolts.

Tool Recommendation:

QT1020 12 point impact socket

Universal Joint and 6” Extension

2

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

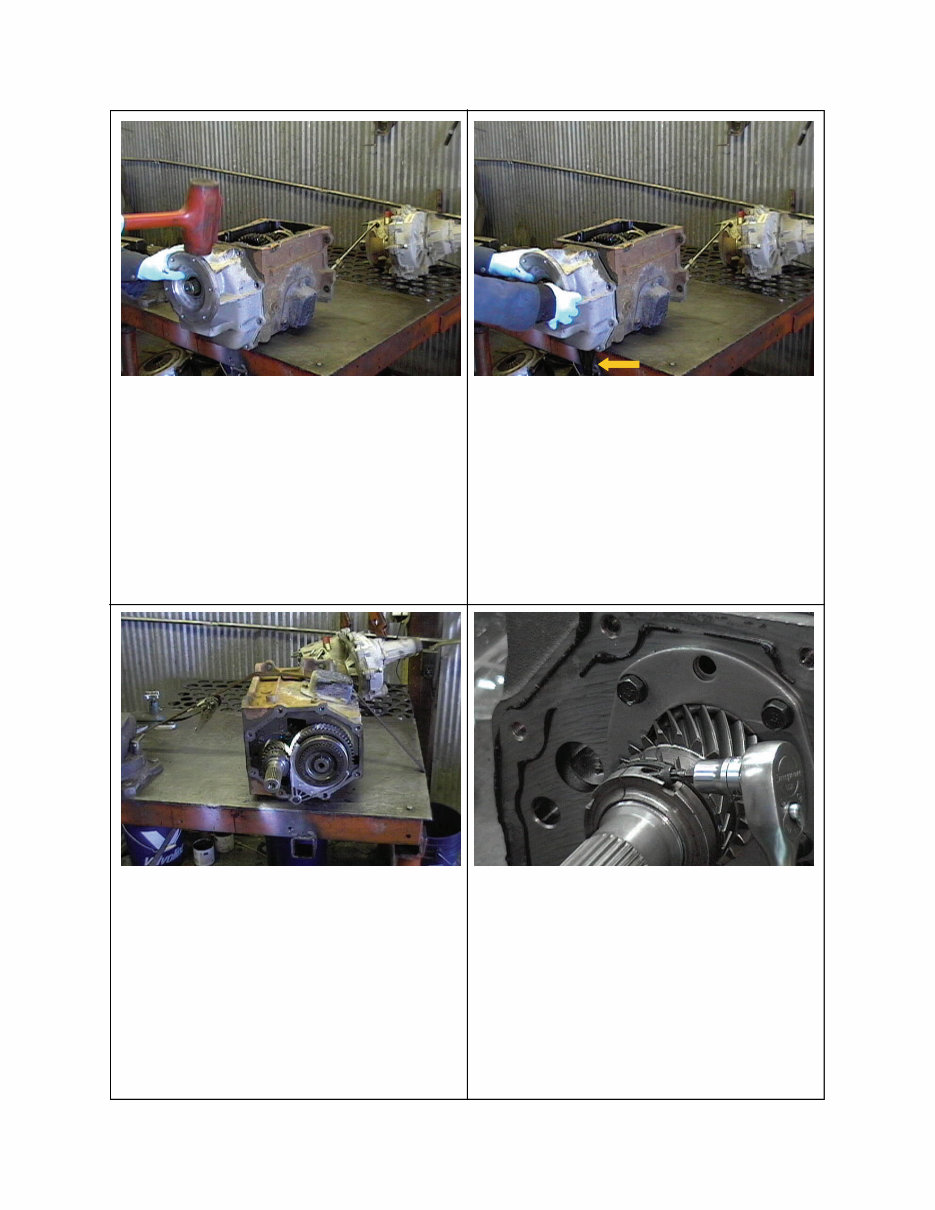

GM 4x2: Refer to Shop Note on page

95.

If the bolt heads are rounded off, refer

to Shop Note on page 95.

Use a soft-faced hammer to loosen the

sealant between the housing and trans-

mission case.

Tool Recommendation:

QT9018 5lb. Dead Blow Hammer

Pull the housing off the alignment

pins. (Arrow points to residual oil

draining from case. BE SURE to have

drain pan positioned to catch oil)

Secure the transmission to a sturdy

bench with a ratchet strap.

Tool Recommendation:

Nylon ratchet strap

Remove any lock or set screws from

the main shaft nut.

Dodge HD models with the crossbolt

(shown) require either a T27 Torx®

bit or 5/32” hex bit. Aftermarket nuts

use several different size set screws

depending upon manufacturer.

3

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Place the correct mainshaft nut

wrench or socket on the main shaft

nut and remove the nut.

T2001: Dodge HD ½ drive

T2002: Dodge LD, GM w/damper

QT2028 GM 4x4 with damper

T2036 Dodge HD ¾ drive

See Tool List on page 115 for more details

If the nut won’t break free, you can hit

the wrench with a hammer.

Place the transmission upright. Drive out the 3/16” roll pin from the

cast iron 5th gear lug.

Tool Recommendation:

QT9300 3/16”x8” Punch

16 oz. Hammer

4

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

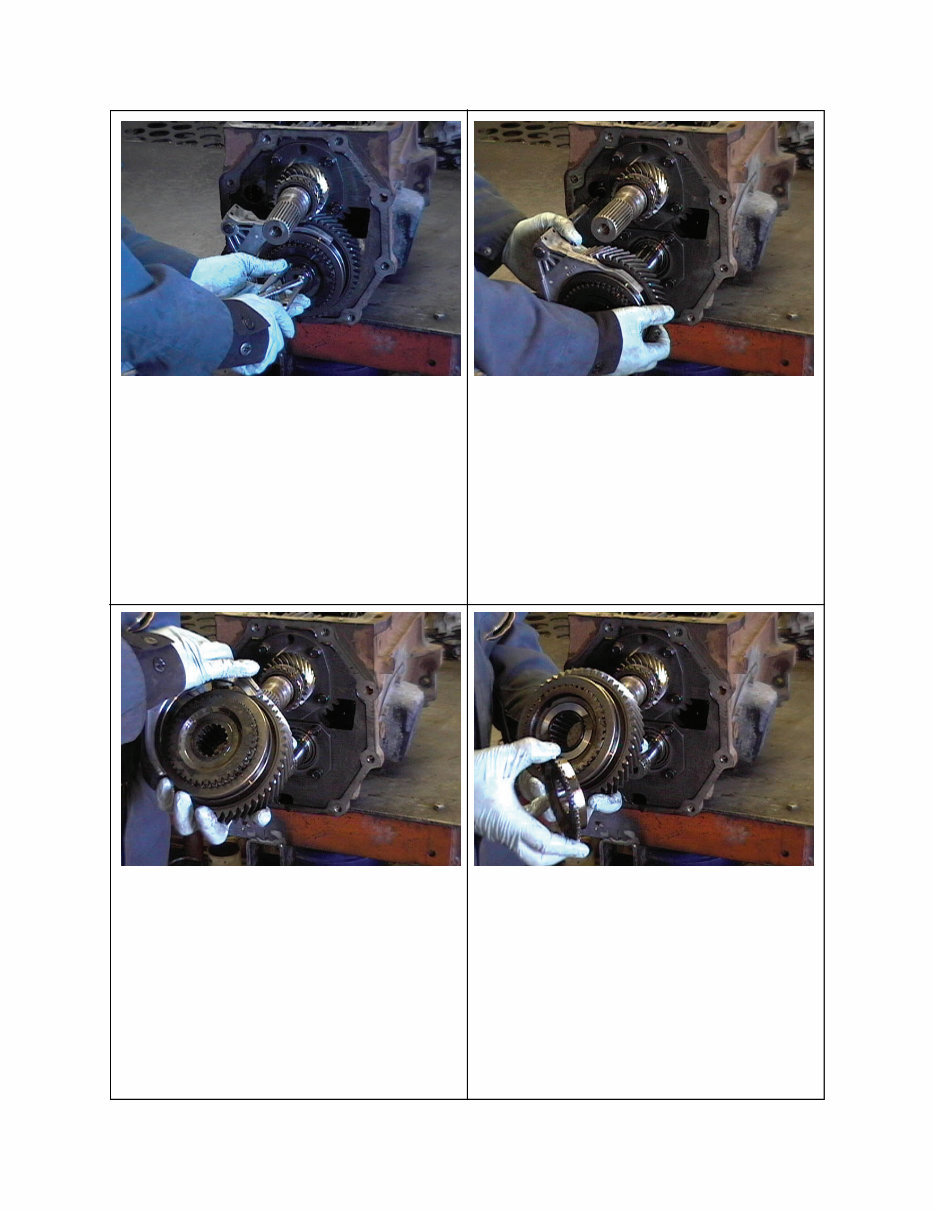

GM 4x4: Refer to Shop Note on page

95

Remove the lock ring from the back

of the countershaft.

Tool Recommendation:

QT2030 Lock Ring Pliers

Carefully work the countershaft 5th

gear assembly off the countershaft.

Simultaneously work the inner cast

iron 5th gear shift lug off the shift rail.

Remove the 5th gear shift fork. Remove 5th gear clutch.

5

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

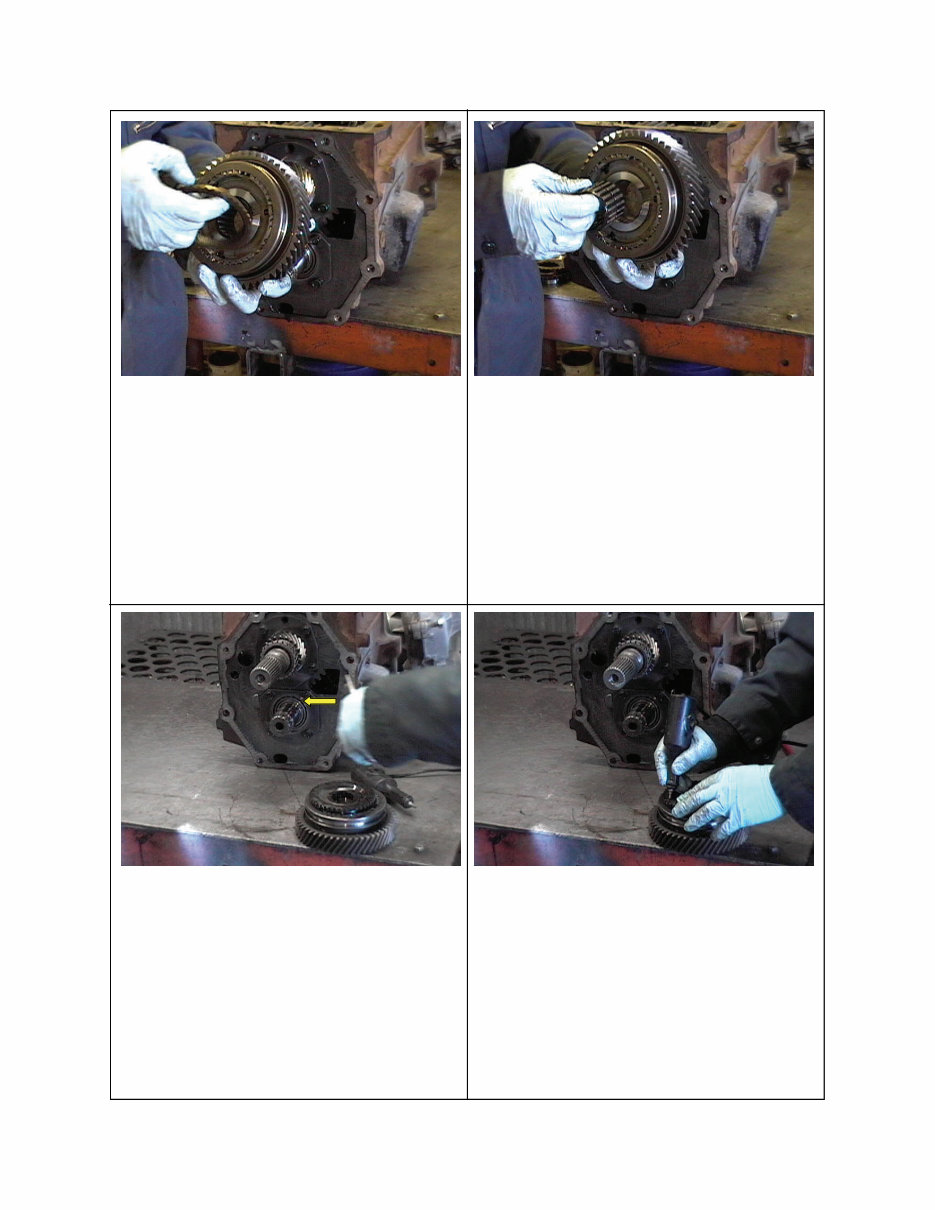

Remove the 5th gear synchronizer

ring.

Remove the 5th gear bearing.

Remove thrust washer locating pin

from countershaft.

Tool Recommendation:

Needle nose pliers

We recommend marking the matching

synchronizer and gear parts with an

engraving tool before further disas-

sembly.

Tool Recommendation:

Carbide tipped electric engraver

6

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

Copyright © 2005-2006 4x4 Tech Inc. All Rights Reserved. www.4x4techinfo.com

You're Reading a Preview

What's Included?

Lifetime Access

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual