TS2470EN

Printed in the U.S.A. Copyright © 1998 General Motors Corp.

Troubleshooting

Manual

Division of General Motors Corporation

P.O. Box 894 Indianapolis, Indiana 46206-0894

May 1998

Revision 1, 199910

Allison Transmission

MD/HD/B Series Transmissions

WTEC II Controls

(Pre-TransID and TID 1)

MD 3060/MD 3066/MD 3560(P)(R)

MD 3070PT

HD 4060/HD 4560(P)(R)

B 300/B 400/ B 500(P)(R)

WTEC II ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

ii Copyright © 1998 General Motors Corp.

This manual provides troubleshooting information for Allison Transmission Division, MD/HD/B Series

Transmissions. Service Manuals SM2148EN and SM2457EN, and Parts Catalogs PC2150EN and PC2456EN may

be used in conjunction with this manual.

This manual includes:

• Description of the WTEC II electronic control system.

• Description of the electronic control system components.

• Description of diagnostic codes, system responses to faults, and troubleshooting.

• Wire, terminal, and connector repair information.

Specific instructions for using many of the available or required service tools and equipment are not included in

this manual. The service tool manufacturer will furnish instructions for using the tools or equipment.

Additional information may be published from time to time in Service Information Letters (SIL) and will be

included in future revisions of this and other manuals. Please use these SILs to obtain up-to-date information

concerning Allison Transmission products.

This publication is revised periodically to include improvements, new models, special tools, and procedures. A

revision is indicated by a letter suffix added to the publication number. Check with your Allison Transmission

service outlet for the currently applicable publication. Additional copies of this publication may be purchased from

authorized Allison Transmission service outlets. Look in your telephone directory under the heading of

Transmissions — Truck, Tractor, etc.

Take time to review the Table of Contents and the manual. Reviewing the Table of Contents will aid you in quickly

locating information.

NOTE: Allison Transmission is providing for service of WTEC II wiring harnesses and wiring harness

components as follows: (See Service Information Letter 1-WT-97 for further information.)

• Repair parts for the internal wiring harness and for wiring harness components attached to the shift selector

will be available through the Allison Transmission Parts Distribution Center (PDC). Use the P/N from your

appropriate parts catalog or from Appendix E in this manual. Allison Transmission is responsible for

warranty on these parts.

• Since January, 1998, all WTEC II external harnesses and external harness components must be obtained

from St. Clair Technologies Inc. (SCTI). SCTI provides parts to any Allison customer or OEM and is

responsible for warranty on these parts. SCTI recognizes ATD, manufacturers, and SCTI part numbers.

SCTI provides a technical HELPLINE at 519-627-1673 (Wallaceburg). SCTI has parts catalogs available.

The SCTI addresses and phone numbers for parts outlets are:

St. Clair Technologies, Inc.

1050 Old Glass Road

Wallaceburg, Ontario, Canada, N8A 3T2

Phone: (519) 627-1673

Fax: (519) 627-4227

St. Clair Technologies, Inc.

1111 Mikesell Street

Charlotte, Michigan 48813

Phone: (517) 541-8166

Fax: (517) 541-8167

St. Clair Technologies, Inc.

c/o Mequilas Tetakawi

Carr. Internationale KM 1969

Guadalajara – Nogales, KM2

Empalme, Sonora, Mexico

Phone: 011-52-622-34661

Fax: 011-52-622-34662

FOREWORD — How to Use This Manual

Copyright © 1998 General Motors Corp. iii

WTEC III ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

IMPORTANT SAFETY NOTICE

IT IS YOUR RESPONSIBILITY to be completely familiar with the warnings and cautions

used in this manual. These warnings and cautions advise against using specific service

procedures that can result in personal injury, equipment damage, or cause the equipment to

become unsafe. These warnings and cautions are not exhaustive. Allison Transmission could

not possibly know, evaluate, or advise the service trade of all conceivable procedures by which

service might be performed or of the possible hazardous consequences of each procedure.

Consequently, Allison Transmission has not undertaken any such broad evaluation.

Accordingly, ANYONE WHO USES A SERVICE PROCEDURE OR TOOL WHICH IS NOT

RECOMMENDED BY ALLISON TRANSMISSION MUST first be thoroughly satisfied

that neither personal safety nor equipment safety will be jeopardized by the service proce-

dures used.

Also, be sure to review and observe WARNINGS, CAUTIONS, and NOTES provided by the

vehicle manufacturer and/or body builder before servicing the Allison transmission in that

vehicle.

Proper service and repair is important to the safe and reliable operation of the equipment. The

service procedures recommended by Allison Transmission and described in this manual are

effective methods for performing troubleshooting operations. Some procedures require using

specially designed tools. Use special tools when and in the manner recommended.

WARNINGS, CAUTIONS, AND NOTES

Three types of headings are used in this manual to attract your attention:

NOTE: Is used when an operating procedure, practice, etc., is essential to highlight.

WARNING!

Is used when an operating procedure, practice, etc., which, if not correctly followed,

could result in injury or loss of life.

CAUTION:

Is used when an operating procedure, practice, etc., which, if not strictly observed, could

result in damage to or destruction of equipment.

The WARNINGS, CAUTIONS, and NOTES in this manual apply only to the Allison transmission

and not to other vehicle systems which may interact with the transmission. Be sure to review and

observe any vehicle system information provided by the vehicle manufacturer and/or body builder

at all times the Allison transmission is being serviced.

WTEC II ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

iv Copyright © 1998 General Motors Corp.

TRADEMARKS USED IN THIS MANUAL

The following trademarks are the property of the companies indicated:

• LPS

®

Cleaner is a registered trademark of LPS Laboratories.

• VCI #10

®

is the registered trademark for a vapor phase rust preventive manufactured by Daubert Chemical

Company, Chicago, Illinois. VCI #10 is covered by Military Specifications MIL-L-46002 (ORD) and

MIL-I-23310 (WEP) under the designation of Nucle Oil.

• Biobor JF

®

is the registered trademark for a biological inhibitor manufactured by Hammonds Fuel Additives

Corporation.

• Loctite

®

is a registered trademark of the Loctite Corporation.

• Teflon

®

is a registered trademark of the DuPont Corporation.

• Pro-Link

®

is a registered trademark of MicroProcessor Systems, Inc.

SHIFT SELECTOR TERMS AND DISPLAY INDICATIONS

Shift selector terms and displays are represented in this manual as follows:

• Button Names — ⇑ ⇓ , DISPLAY MODE, MONITOR, SELECT, etc.

• Transmission Ranges — D (Drive), N (Neutral), 1 (First), R (Reverse), etc.

• Displays — “ OL ”, “ OK ”, etc.

Copyright © 1998 General Motors Corp. v

Page

Foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

SAFETY INFORMATION

Important Safety Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Warnings, Cautions, and Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Trademarks Used in This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Shift Selector Terms and Display Indications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

SECTION 1. GENERAL DESCRIPTION

1–1. TRANSMISSION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–1

1–2. ELECTRONIC CONTROL UNIT (ECU) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

1–3. SHIFT SELECTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

A. Pushbutton Shift Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–3

B. Lever Shift Selector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1–4. THROTTLE POSITION SENSOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–4

1–5. SPEED SENSORS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–5

1–6. CONTROL MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–6

1–7. WIRING HARNESSES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

A. External Wiring Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–7

B. Internal Wiring Harness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–8

1–8. VEHICLE INTERFACE MODULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1–10

1-9. TRANSID FEATURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

SECTION 2. DEFINITIONS AND ABBREVIATIONS

2–1. DO NOT SHIFT LIGHT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2–2. DIAGNOSTIC DATA READER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–1

2–3. ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2–2

SECTION 3. BASIC KNOWLEDGE

3–1. BASIC KNOWLEDGE REQUIRED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3–2. USING THE TROUBLESHOOTING MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–1

3–3. SYSTEM OVERVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–2

3–4. IMPORTANT INFORMATION IN THE TROUBLESHOOTING PROCESS . . . . . . . . . . . . . . . 3–2

3–5. BEGINNING THE TROUBLESHOOTING PROCESS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3–3

SECTION 4. WIRE CHECK PROCEDURES

4–1. CHECKING OPENS, SHORTS BETWEEN WIRES,

AND SHORTS-TO-GROUND . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4–1

4–2. CHECKING AT TRANSMISSION CONNECTOR AND THE INTERNAL HARNESS

FOR OPENS, SHORTS BETWEEN WIRES, AND SHORTS-TO-GROUND . . . . . . . . . . . . . . . 4–2

TABLE OF CONTENTS

WTEC II ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

vi Copyright © 1998 General Motors Corp.

SECTION 5. OIL LEVEL SENSOR Page

5–1. ELECTRONIC FLUID LEVEL CHECK (SHIFT SELECTOR) . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

A. Fluid Level Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–1

5–2. ELECTRONIC FLUID LEVEL CHECK (PRO-LINK

®

9000) . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

A. Fluid Level Check Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5–4

SECTION 6. DIAGNOSTIC CODES

6–1. DIAGNOSTIC CODE MEMORY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

6–2. CODE READING AND CODE CLEARING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–1

6–3. DIAGNOSTIC CODE RESPONSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–3

6–4. SHIFT SELECTOR DISPLAYS RELATED TO ACTIVE CODES . . . . . . . . . . . . . . . . . . . . . . . 6–3

6–5. DIAGNOSTIC CODE LIST AND DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–4

6–6. DIAGNOSTIC CODE TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–17

A. Beginning the Troubleshooting Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–17

B. Solenoid Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–17

C. Diagnostic Code Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–18

D. Diagnostic Code 13 and 35 Schematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6–18

SECTION 7. INPUT AND OUTPUT FUNCTIONS

7–1. INPUT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–1

7–2. OUTPUT FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7–3

SECTION 8. GENERAL TROUBLESHOOTING OF PERFORMANCE COMPLAINTS

8–1. GENERAL NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–1

8–2. TROUBLESHOOTING PERFORMANCE COMPLAINTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8–2

APPENDICES

A. IDENTIFICATION OF POTENTIAL CIRCUIT PROBLEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . A–1

B. CHECKING CLUTCH PRESSURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B–1

C. SOLENOID AND CLUTCH CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C–1

D. WIRE/CONNECTOR CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D–1

E. CONNECTOR PART NUMBERS, TERMINAL PART NUMBERS,

TOOL PART NUMBERS, AND REPAIR INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . E–1

F. THROTTLE POSITION SENSOR ADJUSTMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F–1

G. MISCELLANEOUS ITEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . G–1

H. HYDRAULIC SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H–1

J. WT WIRING SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J–1

K. SOLENOID AND TEMPERATURE CHARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . K–1

L. EXTERNALLY-GENERATED ELECTRONIC INTERFERENCE . . . . . . . . . . . . . . . . . . . . . . . L–1

M. DIAGNOSTIC TREE — WT SERIES HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . M–1

N. PRO-LINK

®

9000 DIAGNOSTIC DATA READER INFORMATION . . . . . . . . . . . . . . . . . . . . . N–1

P. INPUT/OUTPUT FUNCTION WIRING SCHEMATICS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P–1

TABLE OF CONTENTS ( C o n t ' d)

WTEC II ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

Copyright © 1998 General Motors Corp. 1–1

WTEC II ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

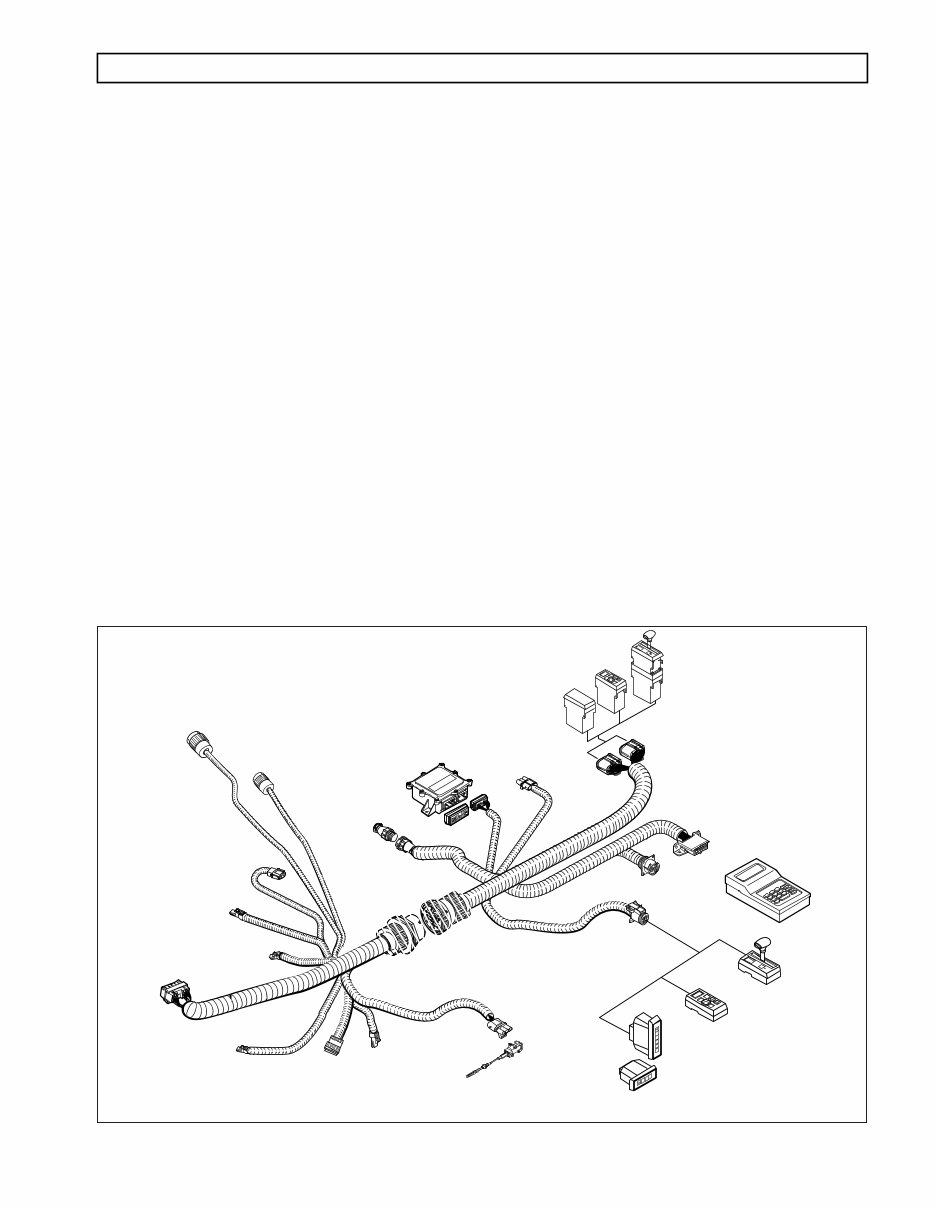

1–1. TRANSMISSION

The World Transmission Electronic Controls WTEC II system features closed-loop clutch control to provide

superior shift quality over a wide range of operating conditions. MD 3000 (except 3070), HD 4000, and B Series

configurations can be programmed to have up to six forward ranges, neutral, and one reverse range. The MD 3070

has seven forward ranges and one reverse range. Figures 1–1 and 1–2 show electronic control unit components.

WTEC II Electronic Controls consist of the following components:

• Basic or Max Feature Electronic Control Unit (ECU)

• Pushbutton or Lever Shift Selectors (remote or integral to the ECU)

• Optional Secondary Shift Selector

• Engine, Turbine and Output Speed Sensors

• Throttle Position Sensor (TPS) (or electronic engine throttle signal or PWM signal)

• Control Module (Electro-Hydraulic Valve Body)

• Wiring Harnesses

• Vehicle Interface Module (VIM)

• Optional Retarder Controls

• TransID Feature

NOTE: Model Year ’94 and earlier WT Series Electronic Controls operate on 12VDC. Vehicles with a 24VDC

system require a voltage equalizer or converter to supply 12V to the electronic control system. Model

Year ’95 and later transmissions operating on 24VDC require a 24V VIM and a 24V wiring harness

which includes shielding for the turbine and output speed sensors.

Figure 1–1. WTEC II Electronic Control Components (Units Produced Before 9/94)

7 8 9

4 5 6

1 2 3

0 ENTER =

x

–

+

–

OPTIONAL

DEUTSCH DDR

CONNECTOR

INTEGRAL ECU/

SHIFT SELECTORS

REMOTE

ECU

RETARDER

MODULATION

REQUEST (RMR)

SENSOR CONNECTOR

ELECTRONIC

CONTROL

UNIT

(ECU)

CONNECTORS

DIAGNOSTIC

DATA READER (DDR)

CONNECTOR

PRO-LINK

®

DIAGNOSTIC TOOL

J 38538-A

THROTTLE

POSITION

SENSOR

VEHICLE

INTERFACE

MODULE

(VIM)

MD/B 300/B 400

RETARDER CONNECTOR

(INCLUDES OUTPUT

SPEED SENSOR)

MD 3070

TRANSFER CASE

CONNECTOR

OUTPUT SPEED

SENSOR

*CONNECTOR

TRANSMISSION

CONNECTOR

ENGINE

SPEED

SENSOR

CONNECTOR

V01634

TPS

CONNECTOR

TURBINE

SPEED

SENSOR

CONNECTOR

(HD/B 500)

HD/B 500

RETARDER

TEMPERATURE

SENSOR

CONNECTOR

REMOTE SERIAL

INTERFACE

CONNECTOR

REMOTE

PUSHBUTTON SHIFT

SELECTOR

STRIP PUSHBUTTON

SHIFT SELECTOR

REMOTE

LEVER SHIFT

SELECTOR

RETARDER “K”

CONNECTOR

(HD/B 500)

HD/MD/B RETARDER

ACCUMULATOR “H”

SOLENOID

CONNECTOR

OPTIONAL

BULKHEAD

CONNECTOR

WIRING

HARNESS

NOTE: Illustration is not to scale.

*All HD/B 500 models

All Non-Retarder MD/B 300/B 400 models

1 2 D N R

D

N

R

VEHICLE

INTERFACE

WIRING

(VIW)

CONNECTOR

S ECTION 1 — GENERAL DESCRIPTION

WTEC II ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

1–2 Copyright © 1998 General Motors Corp.

GENERAL DESCRIPTION

Figure 1–2. WT Electronic Control Unit Components (Units Produced 9/94–12/97)

Figure 1–3 is a block diagram of the basic system’s inputs and outputs.

Figure 1–3. Electronic Control Unit Block Diagram

7 8 9

4 5 6

1 2 3

0 ENTER =

x

–

+

–

OPTIONAL

DEUTSCH DDR

CONNECTOR

INTEGRAL ECU/

SHIFT SELECTORS

REMOTE

ECU

PRO-LINK

®

DIAGNOSTIC TOOL

J 38538-A

THROTTLE

POSITION

SENSOR

MD/B 300/B 400

RETARDER CONNECTOR

(INCLUDES OUTPUT

SPEED SENSOR)

MD 3070

TRANSFER CASE

CONNECTOR

OUTPUT SPEED

SENSOR

*CONNECTOR

TRANSMISSION

CONNECTOR

ENGINE

SPEED

SENSOR

CONNECTOR

V01587

TPS

CONNECTOR

TURBINE

SPEED

SENSOR

CONNECTOR

(HD/B 500)

HD/B 500

RETARDER

TEMPERATURE

SENSOR

CONNECTOR

REMOTE SERIAL

INTERFACE

CONNECTOR

RETARDER “K”

CONNECTOR

(HD/B 500)

HD/MD/B RETARDER

ACCUMULATOR “H”

SOLENOID

CONNECTOR

OPTIONAL

BULKHEAD

CONNECTOR

WIRING

HARNESS

NOTE: Illustration is not to scale.

*All HD/B 500 models

All Non-Retarder MD/B 300/B 400 models

1 2 D N R

D

N

R

ELECTRONIC

CONTROL

UNIT

(ECU)

CONNECTORS

DIAGNOSTIC

DATA READER (DDR)

CONNECTOR

VEHICLE

INTERFACE

MODULE

(VIM)

VEHICLE

INTERFACE

WIRING

(VIW)

CONNECTOR

RETARDER

MODULATION

REQUEST (RMR)

SENSOR CONNECTOR

REMOTE

PUSHBUTTON SHIFT

SELECTOR

STRIP PUSHBUTTON

SHIFT SELECTOR

REMOTE

LEVER SHIFT

SELECTOR

SHIFT SELECTOR

RANGE AND

MODE SWITCH

TONE/DISPLAY

VIM

INPUTS OUTPUTS

ECU

SPEED SENSORS

THROTTLE POSITION SENSOR

RETARDER MODULATION

V01812

TEMPERATURE SENSOR

(SUMP/RETARDER)

SOLENOIDS

OIL LEVEL SENSOR

C3 PRESSURE SWITCH

Copyright © 1998 General Motors Corp. 1–3

GENERAL DESCRIPTION

WTEC II ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

1–2. ELECTRONIC CONTROL UNIT (ECU)

The ECU (Figure 1–4) contains the microcomputer which is the brain of the control system. The ECU receives and

processes information defining: shift selector position, throttle position, sump/retarder temperature, engine speed,

turbine speed, and transmission output speed. The ECU uses the information to control transmission solenoids and

valves, supply system status, and provide diagnostic information.

The ECU contains an Electronically Erasable Programmable Read Only Memory (EEPROM) which is

programmed with the shift calibration and other data for a specific transmission assembly, engine, and vehicle

vocation.

Figure 1–4. Electronic Control Unit (ECU)

1–3. SHIFT SELECTOR

Pushbutton and lever shift selectors are available for the WT Series. Either shift selector may be ordered attached to

(integral with), or remote from, the ECU. Both shift selectors are equipped with a digital display. However, the

strip pushbutton shift selector does not have a digital display.

On the shift selectors, between the range selected and the range monitored (attained) digits, is a MODE ON

indicator position. During normal transmission operation MODE ON indicates that a secondary or special

operating condition has been selected by pressing the MODE button. In diagnostic display mode, MODE ON

indicates the displayed diagnostic code is active. There is a SERVICE indicator icon under the MODE ON

indicator. It is illuminated when codes 21 XX, 63 00, and 66 00 are active (for ECUs programmed after 9/26/94).

When a transmission fault occurs that causes the DO NOT SHIFT light to turn on, the shift selector sounds a tone

to indicate transmission shifting is restricted.

A. Pushbutton Shift Selector (Figure 1–5)

The full-function pushbutton shift selector has six (6) buttons and a digital display. The six buttons

are: R (Reverse), N (Neutral), D (Drive), ⇑ ( Up ) , ⇓ ( Down ) , and MODE . Manual forward range

downshifts; upshifts are made by pressing the ⇑ ( Up ) or ⇓ ( Down ) arrow buttons after selecting

D (Drive). The N (Neutral) button has a raised lip to aid in finding it by touch. The digital display

on the pushbutton selector indicates the range selected on the left side and the range monitored

(attained) on the right side. The MODE button is pressed to select a secondary or special operating

condition, such as ECONOMY shift schedule. The vehicle dimmer-control changes display

brightness. Diagnostic information is obtained by pressing the ⇑ (Up) and ⇓ (Down) arrow buttons

at the same time.

V00626.01

ECU

WTEC II ELECTRONIC CONTROLS TROUBLESHOOTING MANUAL

1–4 Copyright © 1998 General Motors Corp.

GENERAL DESCRIPTION

A strip pushbutton shift selector does not have a MODE button, SERVICE icon, or diagnostic

display capability. The Pro-Link

®

9000 or a customer-furnished remote display must be used for

diagnostic purposes.

Figure 1–5. Pushbutton Shift Selectors

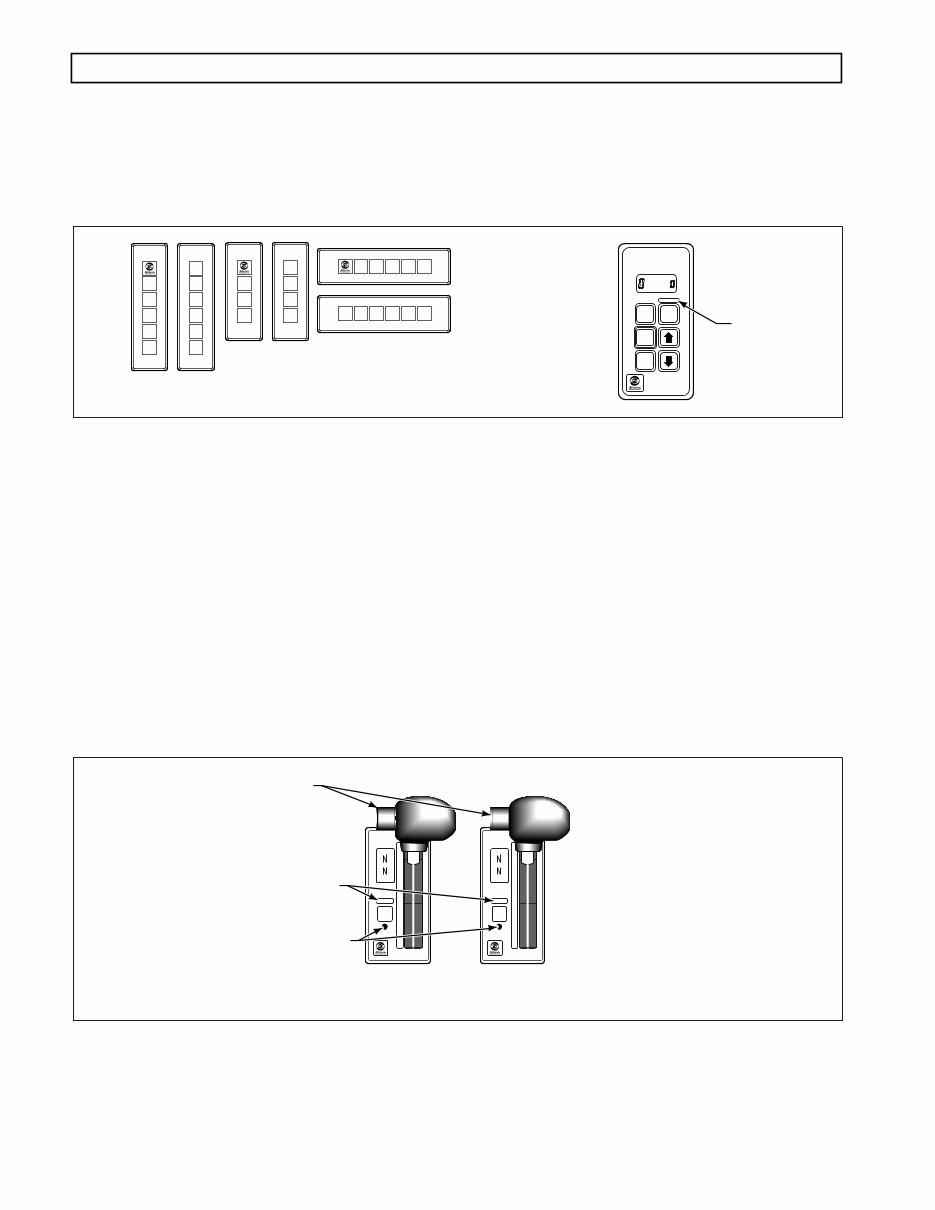

B. Lever Shift Selector (Figure 1–6)

The lever shift selector can only be ordered with as many as six forward range positions (seven for

the MD 3070), as well as R (Reverse) and N (Neutral). The shift hold mechanism is released by

pressing a button on the side of the shift handle. The range selector lever can be moved freely

between numbered forward ranges. Press and hold the shift hold button to move into or out of the

D (Drive) position or when moving into or out of N (Neutral) or R (Reverse).

The digital display on the lever selector indicates the selected range at the top and the range

monitored (attained) at the bottom. A MODE button and a recessed DISPLAY MODE button are

also on the face of the lever shift selector. The MODE button is pressed to select a secondary or

special operating condition, such as ECONOMY shift schedule. Diagnostic information is obtained

by pressing the DISPLAY MODE button. The vehicle dimmer-control changes display brightness.

Figure 1–6. Six-Speed And Seven-Speed Lever Shift Selectors

R

N

D

MODE

MODE ON

SERVICE

SELECT POSITION

1 2 D N R

1

2

D

N

R

2

1

3

D

N

R

D

N

R

1

D

N

R 2 1 3 D N R

V01588

MODE ID

PUSHBUTTON

SELECTOR

STRIP PUSHBUTTON

SHIFT SELECTORS

SELECT

MONITOR

MODE ON

MODE

1

2

3

4

5

D

N

R

SELECT

MONITOR

MODE ON

SERVICE SERVICE

MODE

1

2

3

4

5

6

D

N

R

V01589

SIX-SPEED

LEVER SELECTOR

DISPLAY MODE BUTTON

MODE ID

HOLD OVERRIDE BUTTON

SEVEN-SPEED

LEVER SELECTOR

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual