Allison 1000 & 2000 Transmission Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

INDEX

Copyright © ATSG 2000 May, 2000

ALLISON 1000/2000 SERIES

CAUTION: ATSG service manuals are intended for use by professional,

qualified technicians. Attempting repairs or service without the proper

training, tools and equipment could cause injury to you or others and damage

to the vehicle that may cause it not to operate properly.

CLUTCH AND SOLENOID APPLICATION CHART ........................................................................................... 4

TRANSMISSION IDENTIFICATION TAG INFORMATION .............................................................................. 5

GENERAL DESCRIPTION AND OPERATION .................................................................................................... 6

ELECTRICAL OPERATION ................................................................................................................................... 9

THROTTLE POSITION SENSOR .............................................. ........................................................................... 10

NEUTRAL START BACK UP SWITCH ................................................................................................................. 11

TRANSMISSION CONTROL MODULE CONNECTOR IDENTIFICATION .................................................... 12

DIAGNOSTIC TROUBLE CODE IDENTIFICATION ......................................................................................... 14

SOLENOID IDENTIFICATION AND OPERATION ............................................................................................. 16

INTERNAL WIRING HARNESS SCHEMATIC AND RESISTANCE CHART ................................................... 18

EXTERNAL WIRING HARNESS SCHEMATIC AND TERMINAL IDENTIFICATION ................................... 19

PRESSURE SWITCH ASSEMBLY IDENTIFICATION AND OPERATION ....................................................... 20

RETRIEVING DIAGNOSTIC TROUBLE CODES ................................................................................................ 22

LINE PRESSURE TESTS ................................................... ................................................................................... 23

BELL HOUSING OIL PASSAGE IDENTIFICATION ......................................................................................... 24

MAIN CASE "FRONT" OIL PASSAGE IDENTIFICATION .............................................................................. 26

MAIN CASE "REAR" OIL PASSAGE IDENTIFICATION ................................................................................. 27

OIL PUMP COVER OIL PASSAGE IDENTIFICATION ..................................................................................... 29

SHIFT VALVE BODY OIL PASSAGE IDENTIFICATION ................................................................................. 31

MAIN VALVE BODY "TOP VIEW" OIL PASSAGE IDENTIFICATION .......................................................... 32

MAIN VALVE BODY "BOTTOM VIEW" OIL PASSAGE IDENTIFICATION ................................................ 33

MAIN CASE "BOTTOM VIEW" OIL PASSAGE IDENTIFICATION ............................................................... 35

TRANSMISSION DISASSEMBLY PROCESS ...................................................................................................... 36

COMPONENT REBUILD

TRANSMISSION CASE ASSEMBLY .............................................................................................................. 53

OIL PUMP AND BELLHOUSING ASSEMBLY ............................................................................................ 55

FOUR DIFFERENT BELL HOUSINGS IDENTIFICATION ...................................................................... 66

C1/C2 CLUTCH HOUSING ASSEMBLY ....................................................................................................... 68

C1/C2 CLUTCH HOUSING SNAP RING IDENTIFICATION ..................................................................... 72

VALVE BODY ASSEMBLY ............................................................................................................................. 80

SOLENOID AIR CHECKS ............................................................................................................................... 83

EXTENSION HOUSING ASSEMBLY ............................................................................................................. 91

GEAR TRAIN PARTS ....................................................................................................................................... 96

CASE CLUTCH PARTS .................................................................................................................................... 100

FINAL TRANSMISSION ASSEMBLY PROCESS ................................................................................................ 102

BOLT IDENTIFICATION CHART ........................................................................................................................ 119

TORQUE SPECIFICATION CHART .................................................................................................................... 120

AUTOMATIC TRANSMISSION SERVICE GROUP

18639 S.W. 107TH AVENUE

MIAMI, FLORIDA 33157

(305) 670-4161

BACK

BACK

BACK

GO TO PAGE

INTRODUCTION

ALLISON 1000/2000 SERIES

1

No part of any ATSG publication may be reproduced, stored in any retrieval system or transmitted in any form or

by any means, including but not limited to electronic, mechanical, photocopying, recording or otherwise,

without written permission of Automatic Transmission Service Group. This includes all text illustrations,

tables and charts.

Beginning at the start of production for the 2000 model year, General Motors introduced two new Allison

automatic transmissions referred to as the 1000 Series and the 2000 Series, for light duty (8600-19850 GVW)

and medium duty (19850-3000 GVW) commercial trucks.

The 1000 and 2000 Series transmissions both have helical cut planetary gear systems to minimize noise

concerns and come in two different gear ratio configurations. The 1000 Series uses closer steps to improve the

shift quality that we now expect from an automatic transmission. The 2000 Series uses wider steps to

accommodate the greater vehicle weights associated with the 2000 Series. The gear ratios for both of the new

units are shown in this Manual.

The 1000 and 2000 Series transmissions have a Park position, Reverse, Neutral and five forward speeds with

5th gear being overdrive, and are completely electronic shift controlled. Notice that the standard General

Motors case connector has been utilized, and the Park/Neutral switch is exactly the same switch used currently

on the THM 4L60-E transmission. Two different bottom pan configurations are also provided to make these

units even more versitile. The 1000 and 2000 Series transmissions utilize five clutch packs (No Bands-No

Freewheels) to obtain the five forward gears and reverse. This manual will cover the dis-assembly, rebuild of all

components and re-assembly of both the 1000 and 2000 Series units.

Updated

October, 2003

DALE ENGLAND

FIELD SERVICE CONSULTANT

ED KRUSE

TECHNICAL CONSULTANT

WAYNE COLONNA

TECHNICAL SUPERVISOR

PETER LUBAN

TECHNICAL CONSULTANT

JIM DIAL

TECHNICAL CONSULTANT

GREGORY LIPNICK

TECHNICAL CONSULTANT

JERRY GOTT

TECHNICAL CONSULTANT

JON GLATSTEIN

TECHNICAL CONSULTANT

DAVID CHALKER

TECHNICAL CONSULTANT

MIKE SOUZA

TECHNICAL CONSULTANT

ROLAND ALVAREZ

TECHNICAL CONSULTANT

GERALD CAMPBELL

TECHNICAL CONSULTANT

"Portions of materials contained herein have been reprinted under

license from General Motors Corp, Service & Parts Operations."

The information and part numbers contained in this booklet have

been carefully compiled from industry sources known for their

reliability, but ATSG does not guarantee its accuracy.

Copyright © ATSG 2000

AUTOMATIC TRANSMISSION SERVICE GROUP

18639 S.W. 107TH AVENUE

MIAMI, FLORIDA 33157

(305) 670-4161

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

3

Copyright © 2000 ATSG

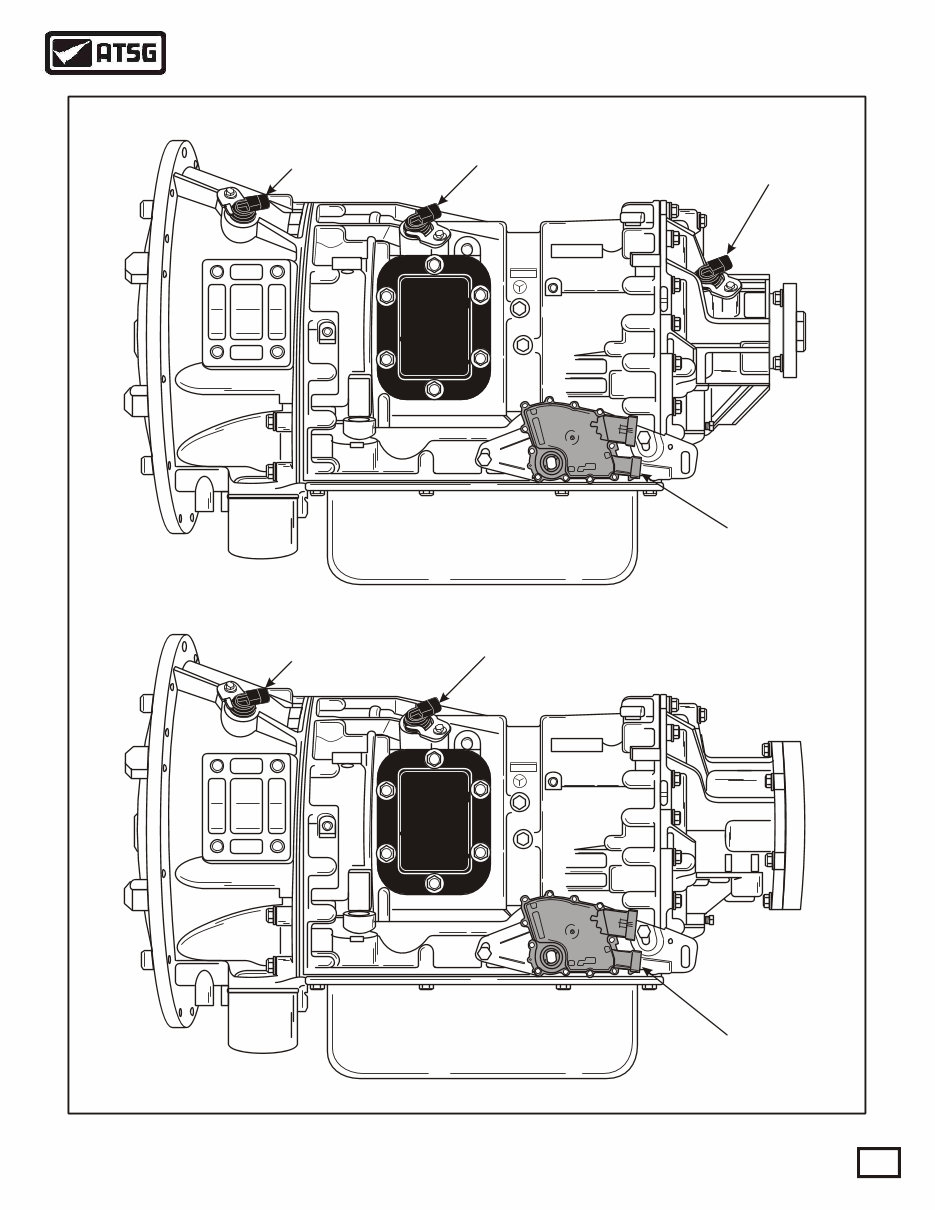

Allison Allison

Allison Allison

ALLISON 1000/2000 SERIES

TWO WHEEL DRIVE

FOUR WHEEL DRIVE

Engine Speed

Sensor

Engine Speed

Sensor

Turbine Speed

Sensor

Turbine Speed

Sensor

Neutral Start

Switch

Neutral Start

Switch

Output Speed

Sensor

Figure 1

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

4

Copyright © 2000 ATSG

**

Range

Ratios

1000 2000

C2

Clut

C3

Clut

C4

Clut

C5

Clut

Sol

"A"

Sol

"B"

Sol

"C"

Sol

"D"

Sol

"E"

Sol

"F"

C1

Clut

Park

Reverse X

X X ON

ON

ON ON

ON ON

ON

ON ON

ON

ON ON

ON

ON

X

4.49

3.10

1.81

1.41

1.00

0.71

5.09

3.51

1.90

1.44

1.00

0.74

*

*

*

* **

**

**

**

**

**

**

**

**

**

**

**

**

**

**

**

X

X

X

X

X

X

X

X

X

Neutral

OD-1st

OD-2nd

OD-3rd

OD-4th

OD-5th

X = Electrical Power Applied To Solenoid

= Apply Solenoid "F" To Apply Converter Clutch

= Solenoids "A" and "B" are "Trim" solenoids used to control oncoming, off-going, and

holding pressure to the five clutch packs.

*

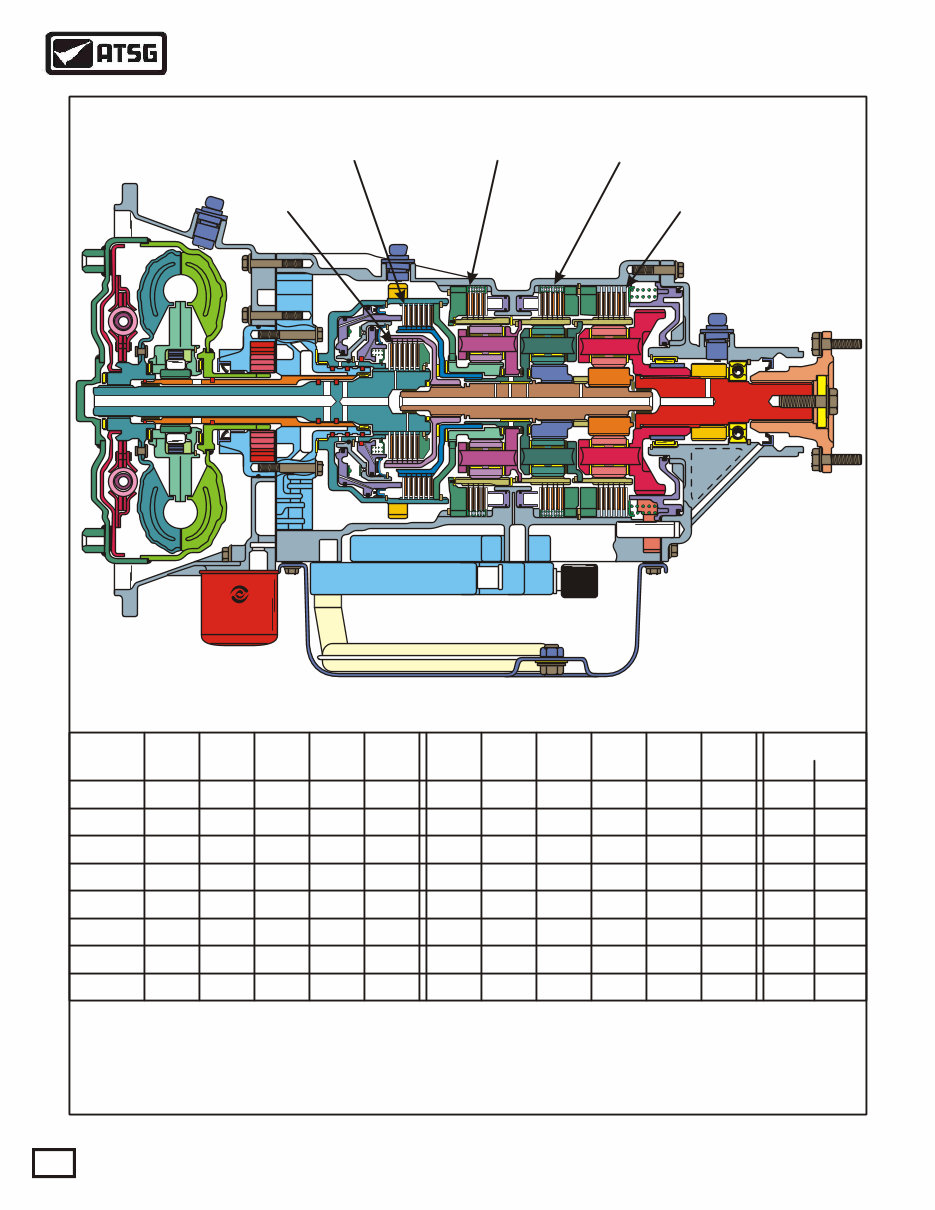

ALLISON 1000/2000 SERIES TRANSMISSION

"C5" CLUTCH

"C4" CLUTCH "C3" CLUTCH "C2" CLUTCH

"C1" CLUTCH

Figure 2

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

5

Copyright © 2000 ATSG

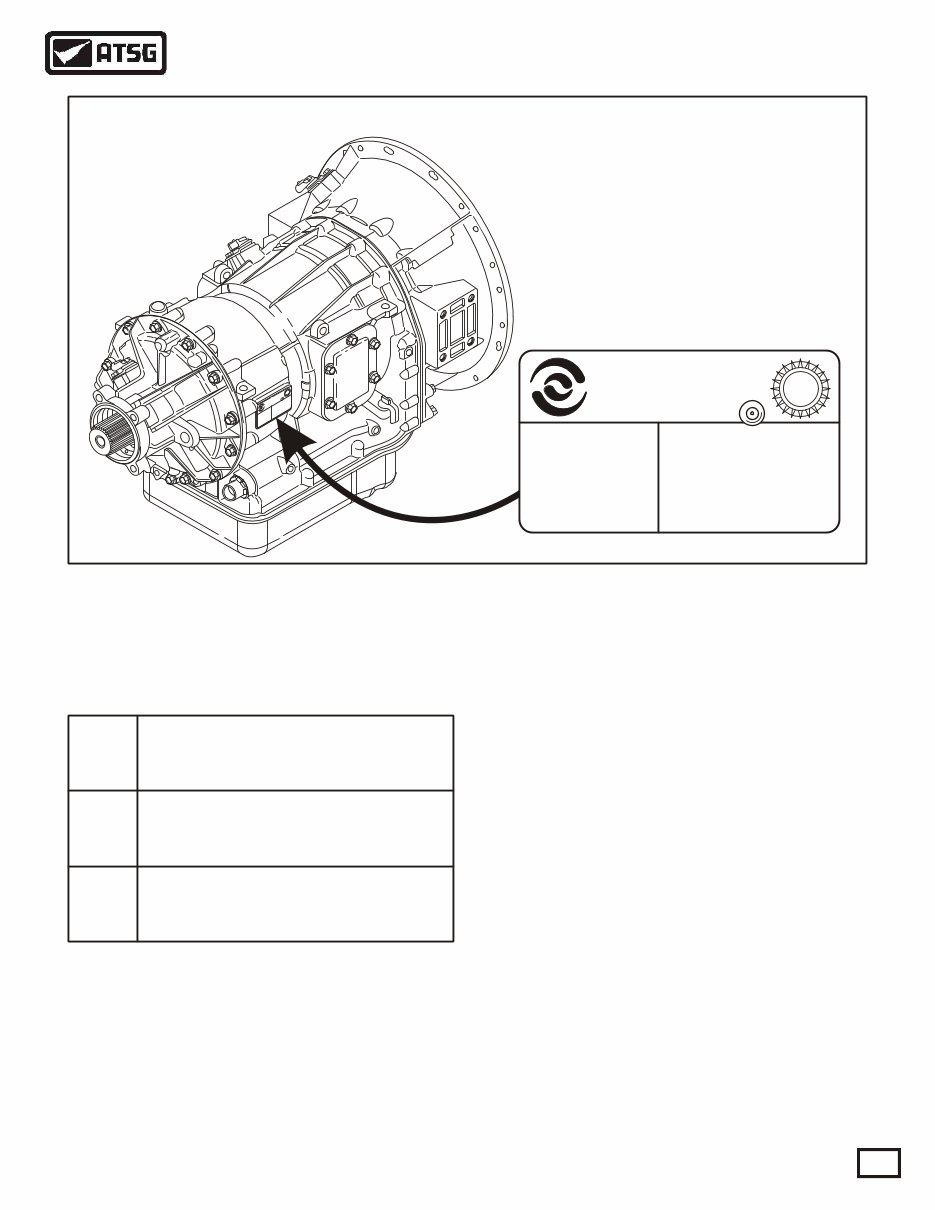

Allison

Transmission

Allison

Transmission Transmission

D I V I S I O N O F G E N E R A L M O T O R S C O R P .

INDIANAPOLIS, INDIANA

MODEL

UAW

933

1000 SERIES

DATE

99F21 X X

X X X X X X X X X X

X X X X X X X X X

X X - X X X X X X - X X X X

X X - X X X X X X - X X X X

X X - X X X X X X - X X X X

X X - X X X X X X - X X X X

X X - X X X X X X - X X X X

TID

SERIAL NO.

EFCN

ALLISON IDENTIFICATION TAG LOCATION

TRANSMISSION IDENTIFICATION TAG

Figure 3

Several different transmission configurations are

available within the 1000/2000/2400 Series. The

different models are identified as follows:

1000

Series

2000

Series

2400

Series

Heavy-duty automatic transmission

with parking pawl.

Maximum GVW = 19850 lb.

Heavy-duty automatic transmission

with parking pawl.

Maximum GVW = 26000 lb.

Heavy-duty automatic transmission

without parking pawl.

Maximum GVW = 30000 lb.

Each transmission is identified by a model

designation, group numbers, and serial number. This

information is included on the transmission

identification tag located on the right rear side of the

transmission case, as shown in Figure 3.

This information must be used when discussing

specific service issues, or when parts replacement is

necessary. The transmission identification tag also

includes the date of manufacture, and also the

transmission identification number used with the

diagnostic systems.

Special Note:

Allison Series 1000/2000/2400 transmissions are

designed and manufactured to metric standards, and

metric tools are required for service.

The cooler ports and the main line pressure tap are

the only non-metric fittings on the transmission

case. The output flange/yoke retaining bolt is also

non-metric.

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

6

Copyright © 2000 ATSG

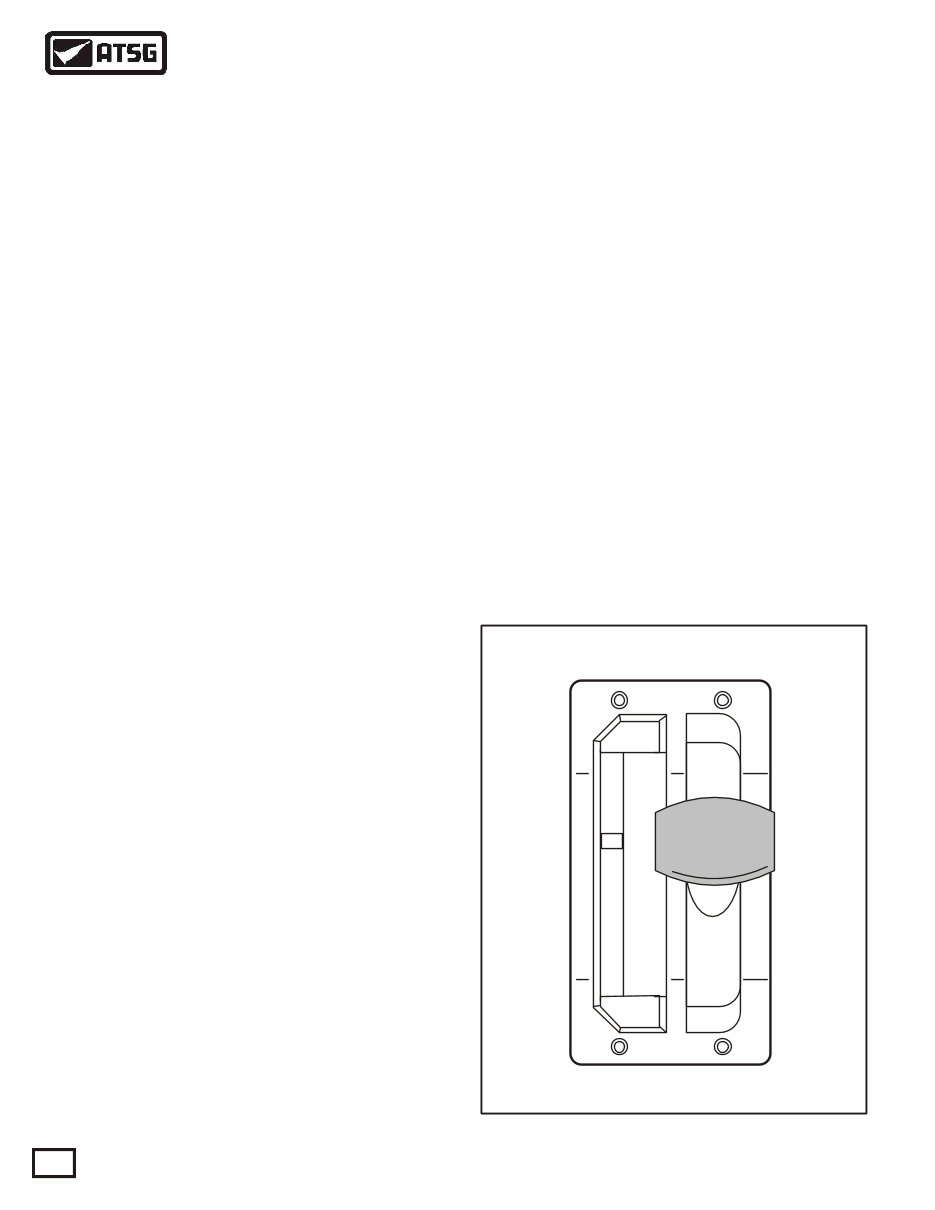

Figure 4

GENERAL DESCRIPTION AND OPERATION

TYPICAL MANUAL SHIFT TOWER

Allison 1000/2000/2400 Series transmissions are

torque converter driven fully automatic units. All

models have neutral, reverse, and up to 5 forward

speeds, with 5th gear being overdrive. Refer to

Figure 2 for the different gears ratios available in the

different models.

The torque converter housings of these units mate

directly to SAE No. 2, SAE No. 3, or direct to the

engine block in some cases. Flexplate drive is used

for all engine to transmission torque transfer.

Several different torque converters are available to

match the transmissions to a wide variety of diesel

and gasoline engines. The torque converter is a single

stage, three element unit, consisting of a pump, stator,

and turbine, with the addition of a converter clutch to

provide direct drive from the engine to the

transmission. The converter clutch is applied and

released electronically, and changes the direction of

fluid flow in the converter as in most typical

converters today.

Internally these units contain 2 rotating clutches (C1

and C2), and 3 brake clutches (C3, C4 and C5), to

direct the flow of torque through the unit. All clutch

packs are hydraulically applied and spring released,

with automatic wear compensation, and their

locations in the transmission are shown in the cut-

away in Figure 2.

The Transmission Control Module (TCM) signals

six different solenoids, located on the valve body, to

apply and release clutches based on vehicle speed and

power combinations, and the range selected by the

operator.

The planetary gear train consists of three constant

mesh, helical gear planetary sets, refered to as P1, P2,

and P3. By the engagement of the 5 clutch packs in

various combinations, the planetary gear sets react

singly or together to provide 5 forward speeds,

neutral, and reverse.

A common hydraulic system provides fluid for all

hydraulic operations, lubrication, and cooling. The

front oil pump, driven by the converter, provides the

pressure needed for the hydraulic system, and comes

from the common sump in the bottom pan.

A suction filter, located in the bottom pan provides

general protection to the entire hydraulic system, and

a spin-on filter provides full time protection for the

control solenoids and multipass protection for the

entire system.

The spin-on filter is located externally on the

converter housing at the lower left front of the

transmission.

Some 1000/2000/2400 Series transmissions are

available with an optional extension housing that

accommodates an OEM installed two shoe,

expanding type, drum parking brake.

The 1000/2000/2400 Series transmissions use lever

type shift selectors, as shown in Figure 4. The vehicle

may be equipped with one or two shift selectors,

depending on the number of operator stations for

driving the vehicle and/or operating a variety of

chassis mounted equipment. The shift positions on

the shift selector can vary according to the shift

selector installed in the vehicle.

P

R

N

D

4

2

1

DO NOT

SHIFT

DO NOT

SHIFT

NOTE: Refer to Figure 5 for the various Shift

Selector positions, and corresponding ranges that

can be attained for all 1000/2000/2400 Series

models.

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

7

Copyright © 2000 ATSG

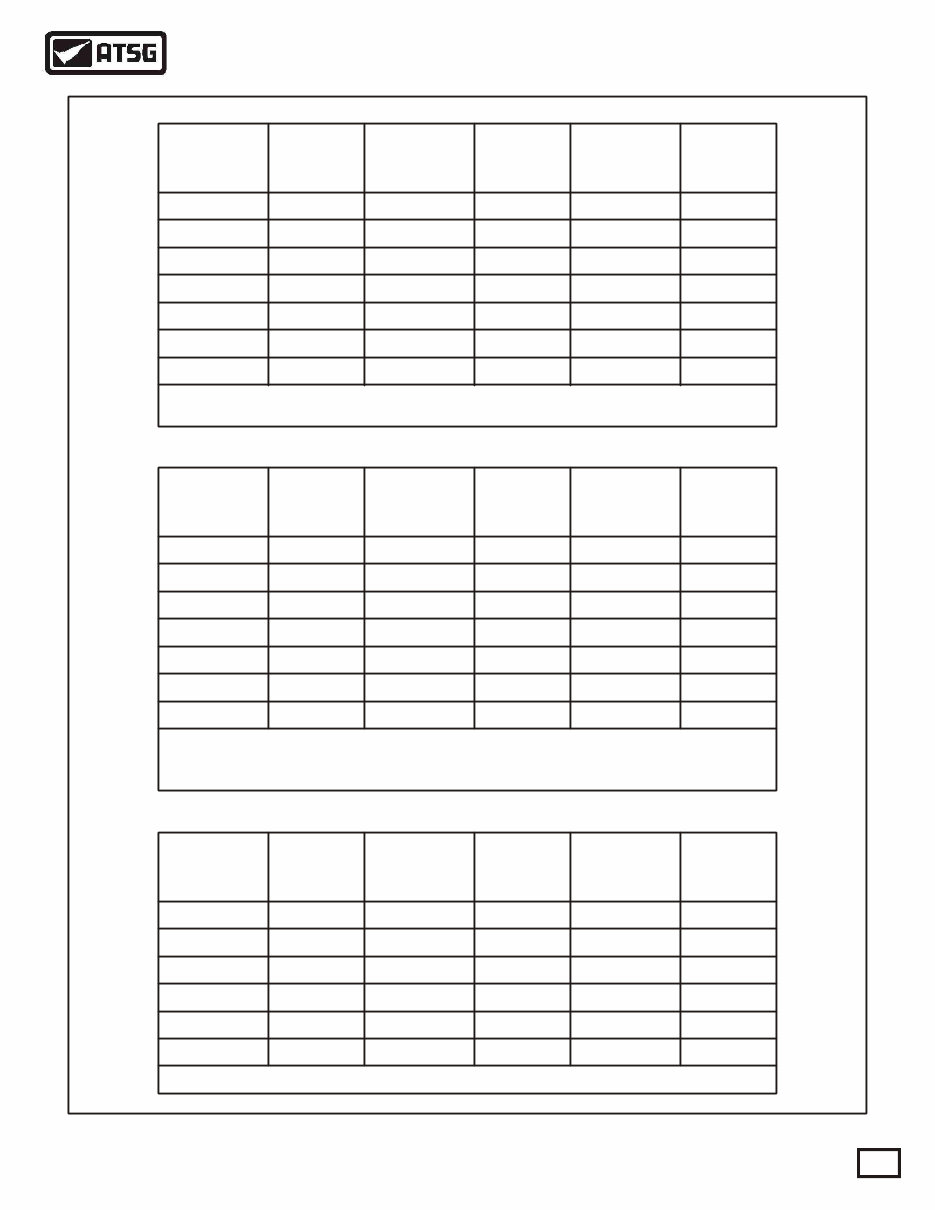

ALL 1000 AND 2400 SERIES

ALL 2000 SERIES "WITH" AUTO-APPLY PARKING BRAKE

ALL 2000 SERIES "WITHOUT" AUTO-APPLY PARKING BRAKE

Figure 5

Shift

Selector

Position

Shift

Selector

Position

Shift

Selector

Position

Shift

Selector

Position

Shift

Selector

Position

Shift

Selector

Position

Shift

Selector

Position

Shift

Selector

Position

Shift

Selector

Position

Gears

Available

Gears

Available

Gears

Available

Gears

Available

Gears

Available

Gears

Available

Gears

Available

Gears

Available

Gears

Available

P (Park)

PB = (Park)

P (Park)

PB = (Park)

P (Park)

PB = (Park)

R (Reverse)

R (Reverse)

R (Reverse)

R (Reverse)

R (Reverse)

R (Reverse)

R (Reverse)

R (Reverse)

R (Reverse)

N (Neutral)

N (Neutral)

N (Neutral)

N (Neutral)

N (Neutral)

N (Neutral)

N (Neutral)

N (Neutral)

N (Neutral)

D (Drive)

D (Drive)

D (Drive)

D (Drive)

D (Drive)

D (Drive)

D (Drive)

D (Drive)

D (Drive)

4 (Fourth)

4 (Fourth)

4 (Fourth)

4 (Fourth)

4 (Fourth)

4 (Fourth)

3 (Third)

3 (Third)

3 (Third)

2 (Second)

2 (Second)

2 (Second)

2 (Second)

2 (Second)

2 (Second)

3 (Third)

3 (Third)

3 (Third)

1 (First)

1 (First)

1 (First)

1 (First)

1 (First)

1 (First)

1 (First)

1 (First)

1 (First)

Neutral*

Neutral*

Reverse

Reverse

Reverse

Neutral

Neutral

Neutral

1-5

1-5

1-5

1-5

1-5

1-5

1-5 (1-4)**

1-5 (1-4)**

1-5 (1-4)**

1-4

1-4

1-4

1-4

1-4

1-4

1-3

1-3

1-3

1-3

1-3

1-3

1-2

1-2

1-2

1-2

1-2

1-2

1st

1st

1st

1st

1st

1st

1st

1st

1st

Neutral

Neutral

Neutral

Neutral

Neutral

Neutral

Reverse

Reverse

Reverse

Reverse

Reverse

Reverse

Neutral*

Neutral*

Neutral*

Neutral*

* With Park Pawl Engaged

* With Auto-Apply Parking Brake Engaged

** 4 Speed Calibration or Trailering Mode

** 4 Speed Calibration or Trailering Mode

PB = Auto-Apply Parking Brake

** 4 Speed Calibration or Trailering Mode

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

8

Copyright © 2000 ATSG

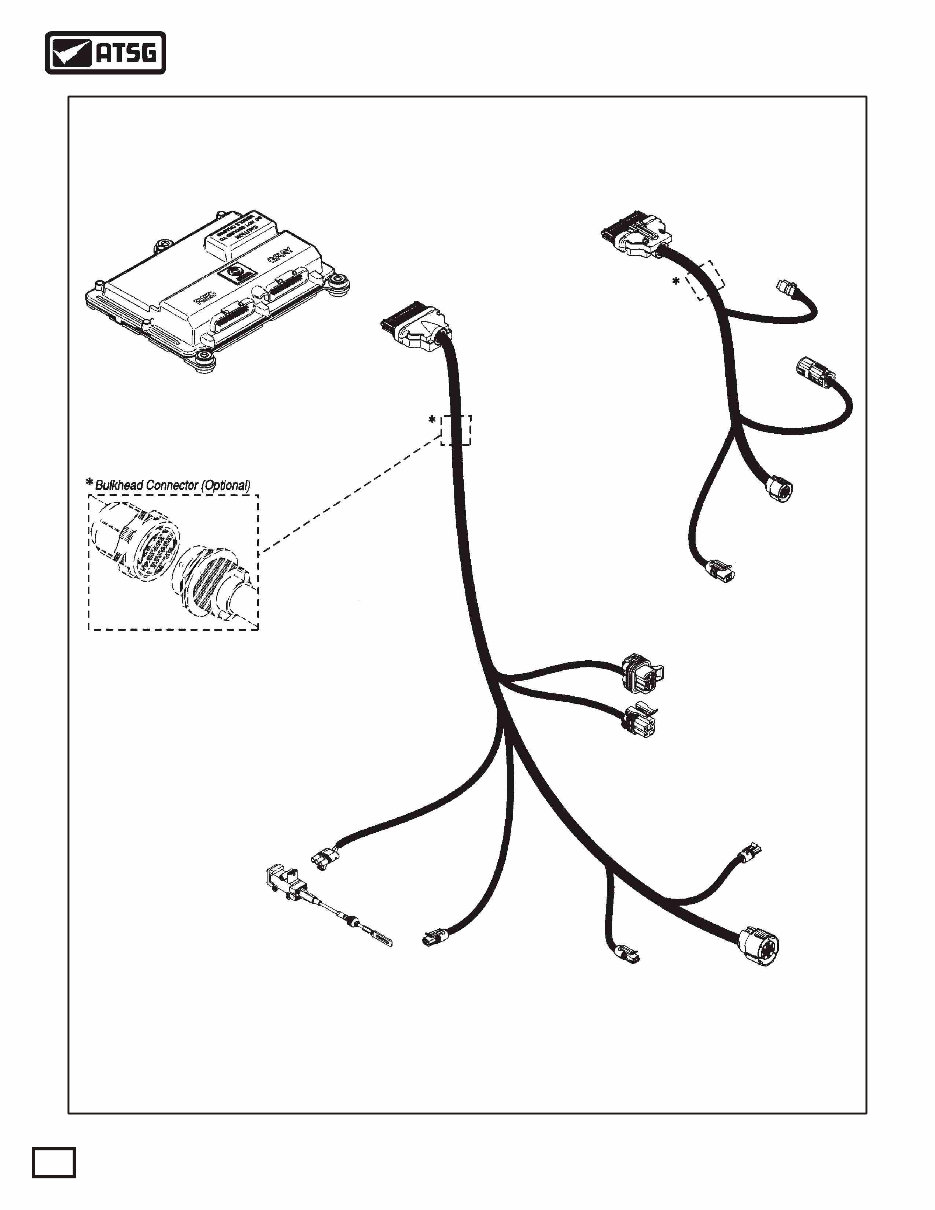

Figure 6

TYPICAL TRANSMISSION CONTROL MODULE

AND VEHICLE HARNESS

TRANSMISSION CONTROL

MODULE (TCM)

TRANSMISSION (J2)

HARNESS

VEHICLE (J1)

HARNESS

"J1"

CONNECTOR

(GRAY)

J 1939

CONNECTOR

(OPTIONAL)

VIW "X"

CONNECTOR

VIW "Y"

CONNECTOR

GP 19

CONNECTOR

NSBU SWITCH

CONNECTORS

OUTPUT

SPEED SENSOR

CONNECTOR

ENGINE

SPEED SENSOR

CONNECTOR

TURBINE

SPEED SENSOR

CONNECTOR

TPS

CONNECTOR

THROTTLE

POSITION

SENSOR (TPS)

7 PIN

4 PIN

"J2"

CONNECTOR

(RED)

Actual harness configuration may differ from this illustration.

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

9

Copyright © 2000 ATSG

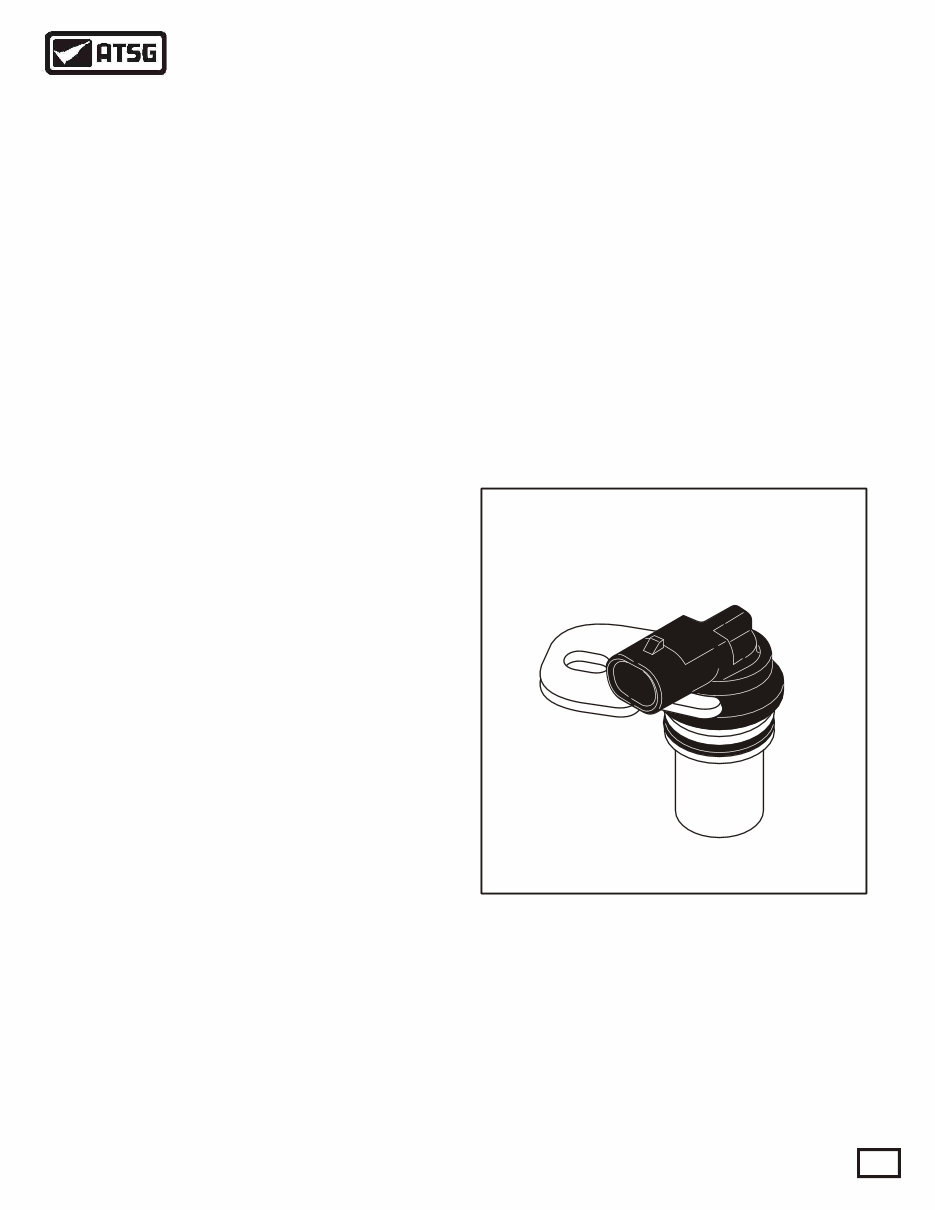

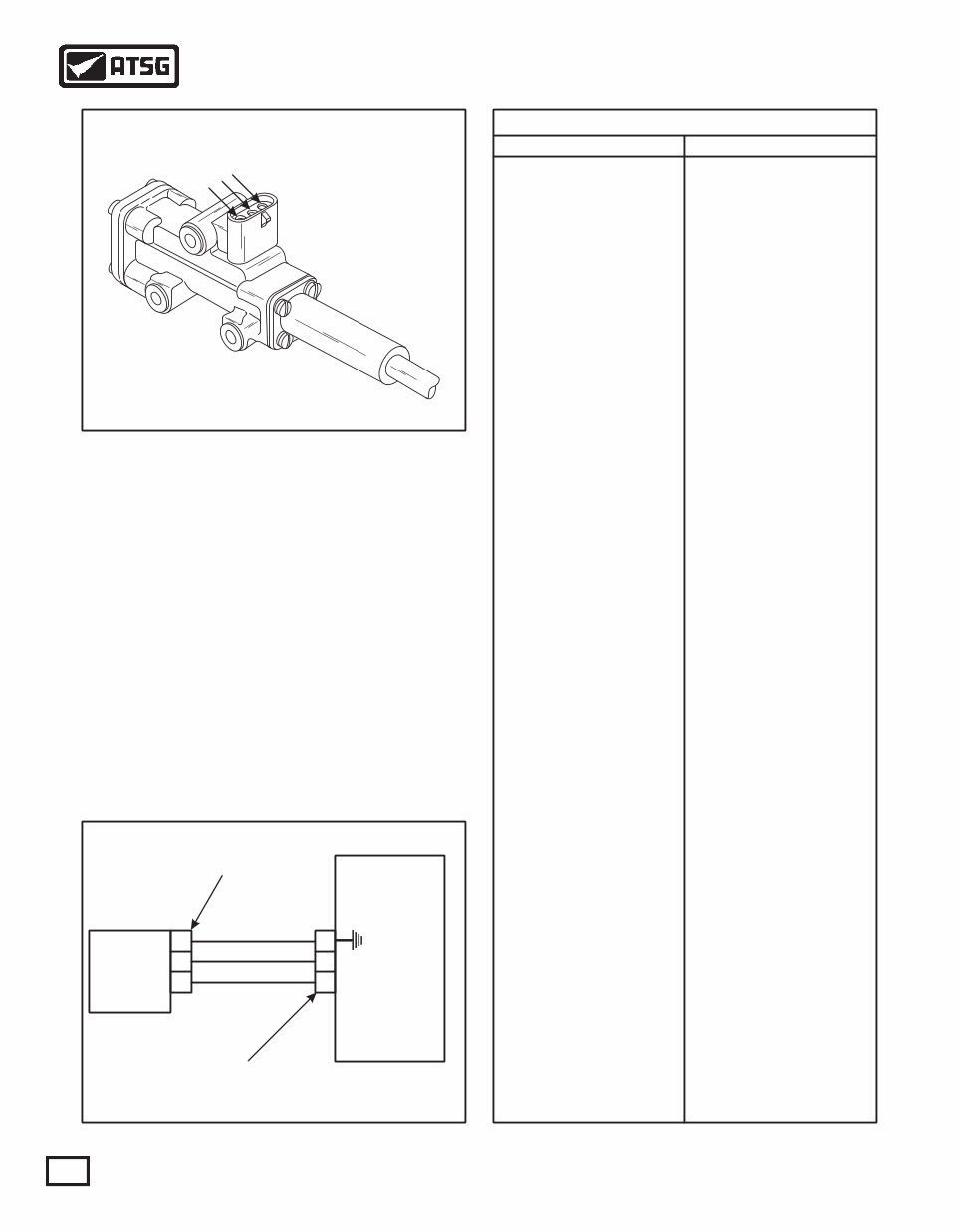

ELECTRICAL OPERATION

EXTERNAL COMPONENTS

SPEED SENSORS

TYPICAL SPEED SENSOR

ENGINE SPEED SENSOR

TURBINE SPEED SENSOR

OUTPUT SPEED SENSOR

Figure 7

The electronic control of the transmission is

performed by the Transmission Control Module

(TCM). Transmissin Control Modules are available

in both 12V and 24V configurations, to match the

configuration of the vehicle electrical system.

The TCM, shown in Figure 6, recieves and processes

signals from various switches and sensors. The TCM

determines shift sequences, shift timing, and clutch

apply and release pressures. The TCM uses this

information to control solenoids and valves, supply

system status, and provide diagnostic information for

service technicians.

The speed sensors are variable reluctance devices

which convert mechanical motion to an AC voltage.

Each sensor consists of a wire coil wrapped around a

pole piece that is adjacent to a permanent magnet.

These elements are contained in a housing which is

mounted adjacent to a rotating ferrous member, such

as a gear tooth. Two signal wires extend from one end

of the housing and an exposed end of the pole piece is

at the opposite end of the housing. As a ferrous object,

such as a gear tooth approaches and passes through

the gap at the end of the pole piece, an AC voltage

pulse is induced in the wire coil. The TCM calculates

the frequency of these AC pulses and converts it to a

speed value. The AC voltage generated varies from

150mV at low speed to 15V at high speed. The signal

wires from the sensor are formed as twisted pairs to

cancel magnetically induced fields. The cable is also

shielded to protect from voltage-related fields. The

typical speed sensor is shown in Figure 7. Noise from

other sources is eliminated by using two-wire

differential inputs at the TCM.

The Engine Speed Sensor is externally mounted in

the torque converter housing, and directed at the ribs

protruding from the torque converter as shown in

Figure 1.

The Turbine Speed Sensor is externally mounted in

the main transmission case, and directed at the tone

wheel or PTO drive gear attached to the C1/C2 clutch

housing as shown in Figure 1.

The Output Speed Sensor is externally mounted in

the extension housing and directed at the teeth of a

tone wheel splined to and rotating with the output

shaft as shown in Figure 1.

AUTOMATIC TRANSMISSION SERVICE GROUP

Technical Service Information

10

Figure 8

Figure 10 Figure 9

THROTTLE POSITION SENSOR

THROTTLE POSITION SENSOR

Copyright © 2000 ATSG

mm/inch

(TPS) Distance of Travel Versus Volts

0/0

1/.039"

2/.079"

3/.118"

4/.157"

5/.197"

6/.236"

7/.275"

8/.314"

9/.354"

10/.394"

11/.433"

12/.472"

13/.511"

14/.551"

15/.590"

16/.629"

17/.669"

18/.708"

19/.748"

20/.787"

21/.826"

22/.866"

23/.905"

24/.945"

25/.984"

26/1.023"

27/1.063"

28/1.102"

29/1.142"

30/1.181"

31/1.220"

32/1.260"

33/1.299"

34/1.339"

35/1.378"

36/1.417"

37/1.457"

38/1.496"

39/1.535"

40/1.575"

41/1.614"

42/1.654"

43/1.693"

44/1.732"

45/1.772"

46/1.811"

Volts

0

0.11

0.22

0.33

0.44

0.55

0.66

0.77

0.88

0.99

1.10

1.20

1.30

1.43

1.54

1.65

1.76

1.87

1.98

2.08

2.19

2.30

2.41

2.52

2.63

2.74

2.85

2.96

3.07

3.18

3.29

3.40

3.51

3.62

3.73

3.84

3.95

4.06

4.17

4.28

4.39

4.50

4.61

4.72

4.83

4.94

5.05

The Throttle Position Sensor (TPS) can be mounted to

the engine, chassis, or transmission. The TPS

contains a pull actuation cable and a potentiometer.

One end of the cable is attached to the throttle lever

and the other end, inside a protective housing, to the

potentiometer. Output voltage from the TPS is

directed to the Transmission Control Module (TCM)

through the external harness. The voltage signal will

vary and indicates the throttle position and in

combination with other input data will determine shift

timing. Refer to the chart provided in Figure 10 for

approximate voltages at various throttle openings. It

is basically the same as most current GM models with

0.5 volts at idle, to 5.0 volts at wide open throttle.

A

B

C

Transmission

Control Module

(TCM)

Throttle

Position

Sensor

(TPS)

20

9

19

A

B

C

TCM "J2" (RED)

Connector

Pink, 5V Supply

Green, Ground

Blue, Signal Ret.

TPS

Connector

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 88 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

The Allison 1000 & 2000 Transmission Master Workshop Manual provides comprehensive guidance for repairing and maintaining these transmissions. Whether you're a professional mechanic or a DIY enthusiast, this manual equips you with the necessary technical information.

It comes in a file format that is compatible with all versions of Windows, Mac, and Linux. The manual is printable and can be viewed with Adobe Reader. With clear and crisp content, it is easy to understand and navigate, making it a valuable resource for anyone working with these transmissions.