Cav Rotodiesel DPA Pumps Service Test Data

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Explanatory Notes

CAV Roto Diesel

DPA Pump Test Data

THIS PUBLICATION DIRECTLY SUPERSEDES

PUBLICATION LEX 3750. ANY REFERENCE IN ANY

OTHER PUBLICATION TO LEX 3750 MUST

THEREFORE BE TAKEN AS REFERRING TO THIS

PUBLICATION.

PUBLISHED BY SERVICE PUBLICATIONS DEPARTMENT

CAV PARTS and SERVICE

©1983 Lucas CAV Limited

ALL RIGHTS RESERVED

EXPLANATORY NOTES

0 COPYRIGHT 1983

1 of 9

CAV

LONDON W3 7SS

ROTO DIESEL DPA — SERVICE TEST PLANS

Issue I

SECTION 1 - GENERAL TEST INSTRUCTIONS

A. Scope of Test Plan Instructions

A-1 These instructions apply to all DPA pumps unless

otherwise stated in the test plans. They are not

mentioned on each test plan, but must be referred to

separately for each test whenever required.

A-2 References are made in test plans to RotoDiesel Service

Instruction Notes. These must be read before each test

whenever they are mentioned in 'Requirement& column.

B. Test Bench Equipment and preparation of Pump for test

To ensure the accuracy of pump settings on the test

bench, certain equipment and conditions must exist. These

general instructions, specified below, apply to all types of

DPA pumps. Certain types require special conditions for

testing and these are recorded on individual test plans.

B.1. Test Bench and Equipment

1. Speed range of machine to be between 70 rpm and

3000 rpm.

2. Drop in speed of the motor under load to be as

little as possible (choice of motor).

3. Fuel tank 0,6m above pump. Capacity 5 to 6 litres.

4. Paper fuel filter (element 7111-296) to be fitted

between tank and pump.

.5. Minimum fuel delivery at the pump inlet to be

1000 cm3 per minute.

NOTE: If this cannot be obtained under gravity, a feed

pump can be used giving a maximum pressure of 0,15 bar

(2 lbf/in2) to give the prescribed delivery.

6. High pressure pipe:

Length 865m m.

Outside diameter 6mm

Bore diameter 2mm

7. Nozzle holder BKB5OSD19b or BKB5OSD533b.

8. Nozzles RDN12SDC6399R or RDN12SD12R (balanced

for delivery). Setting pressure 177 bar (175 atm).

9. Delivery values - see Section 2 A-2.

10. Back leakage connection from pump. Nylon tube

6mm x one metre long.

11. Measuring glasses - grOuations not to exceed 0,2 cm

3 .

Capacity 0 to 10 cm- 5 and 10 to 50 cm 3 .

12. Immersion heater with temperature controller providing

constant temperature of 32

0

± 2 ° C for the test oil at the

pump inlet. Temperature measurement by thermometer.

13. Pressure Gauge - transfer pressure 0 to 15 bar

- vacuum 0 to 76 cmHg.

B-2 Test 011

SHELL LUB 203 B or equivalent CAV approved oil (viscosity 6,7 to

7,2 cSt at 32 °

C). The oil should be changed after testing 150

pumps.

-17,7, 0 C (0 ° F)

- 65,5 - C (150 ° F).

- mg KOH/g max. 0,1.

- IP154 (Procedure b) - classification

1 max.

- 25-30 mN/rn

- 6,5-7,1 cSt at 21 ° C (70 F).

The viscosity at 106 sec.

-1 shear

h u a , 11 20 7 t e o x o c F e ). e d 30 cSt at

- Information if required, available

upon request.

IP135 24 hours distilled water at

60 ° C (140 ° F). No corrosion.

_ IP114 30 hours at 110°C (230

° F) -

0,3mg KOH/g max.

*This viscosity may be measured directly if suitable equipment is

available. Alternatively, the maximum viscosity may be obtained by

extrapolation from at least two measurements made above the cloud

point using a REFUTAS or similar chart.

B-3. High Pressure Outlets

B3a. Rump outlet connections. Unless stated on the test plans all

tests are to be made using radial connections part number 7123-501,

irrespective of the type of connection supplied with the pump.

NOTE: The original connections must be re-fitted to the pump on

completion of test.

CAV OIL SPECIFICATIONS

Pour point, max.

Flash point, open cup, min.

Acid value

Sulphur active

Surface tension

Viscosity* (a)

(b)

Choking tendency

Corrosion resistance

Oxidation resistance

PUBLISHED BY SERVICE PUBLICATIONS DEPARTMENT

EXPLANATORY NOTES

0 COPYRIGHT

1983

2 of 9

CAV

LONDON W3 7SS

ROTO DIESEL DPA — SERVICE TEST PLANS

Issue

B3b. For this type of pump it is ESSENTIAL to make the test

with the original connections fitted (see test plan).

B-4. Position of the Stop Lever

There is a risk of seizure if the pump is run for a long time

without fuel oil feed. In order to prevent the stop lever

accidentally moving to the stop position, it should be fixed by

means of a spring attached to the backleak return pipe.

B-5. Drive Shaft

Certain pumps are supplied with drive shafts of non-standard

length which, on the test bench, are liable to make a poor

connection with the drive.

In this case, it is advisable to use drive shaft 7123-610C for the

test.

NOTE: The original shaft must be replaced before proceeding to

the timing.

B-6. Drive Shaft Screw

On mechanically governed pumps, remove the pump from the

test machine after testing and slacken and retighten the drive

shaft screw to the required torque three times to avoid the

possibility of the screw slackening in service. Refer to the

DPA Workshop Manual for the correct torque value.

B-7. Comments on the Components of the Test Bench

1. High pressure pipes.

To be solid drawn steel 6mm x 2mm x 865mm (34in)

long. Maximum tolerance on bore size to be IF: 0,08mm.

Pipe bore ends must be not less than 0,2mm below

nominal size for at least 60mm after forming nipples (use

2mm drill). Any bends are to be not less than 50mm

radius.

Fuel delivery can be seriously affected by restrictions in

the bore or length of pipe. Regular checks should be

made to ensure that no closure of the bore occurs in use

and that the bore ends are maintained at not less than

0,2mm below the nominal size. Shortening of the pipe

(to reform a nipple), from the specified 865mm is

permissible down to 840mm without affecting fuel

delivery. The length of the pipe can be readily checked

by inserting a thin wire of the correct length through the

bore. If it is less than 840mm the pipe must be

scrapped.

2. Fuel pump drive.

Fuel deliveries can be substantially affected by flexion in the

pump drive. It is therefore important to keep backlash to a

minimum in order to maintain accurate fuel settings and

reduce line to line scatter. Either a flexible disc coupling or

an Oldham type coupling should be used to connect pump to

test machine. The fibre disc in the Oldham coupling should

be a good sliding fit on the dogs. The coupling should be

renewed if backlash exceeds TI

.-" (e.g. 0,2mm on a 90mm

diameter coupling). Total backlash between the drive shaft or

quill shaft of the Rump and the test machine output shaft

must not exceed 2 and wherever possible this should be kept

down to 14 °

. On no account must flexible rubber couplings

be used to drive the pump.

SECTION 2 - SETTING OF DPA PUMPS

A. General Test Instructions

A-1. Leaks.

All pumps must be completely free from leaks both

while running and when stationary.

A.2. Delivery values.

All setting and checking values are for 200

strokes except where otherwise stated. It is essential that the test

is taken over the stated number of strokes, otherwise incorrect

delivery values will result.

The delivery value does NOT vary in direct proportion to the

number of strokes due to the effect of the oil already present in

the glass at the start of each reading.

IMPORTANT:

In order to maintain the necessary viscosity of the

tst oil, it is important to use the recommended test oil at 32

0

t

2'C (unless otherwise stated) for the setting of ALL CAV RD DP A

PUMPS. Before starting the tests, it is necessary to have the pump

running for a few minutes at average speed for the pump to reach

this temperature.

A-3. Throttle and Shut-Off Levers

Throttle and shut-off levers to be fully open unless otherwise stated.

Before commencing tests unscrew the maximum stop and the idling

stop screws to allow full movement of the throttle arm.

Do NOT run the pump for long periods with the shut off lever

closed.

Do NOT run the pump for long periods at high speed with low

delivery.

PUBLISHED BY SERVICE PUBLICATIONS DEPARTMENT

CAV

LONDON W3 7SS

EXPLANATORY NOTES

0 COPYRIGHT

1983

3 of 9

ROTO DIESEL DPA — SERVICE TEST PLANS

Issue

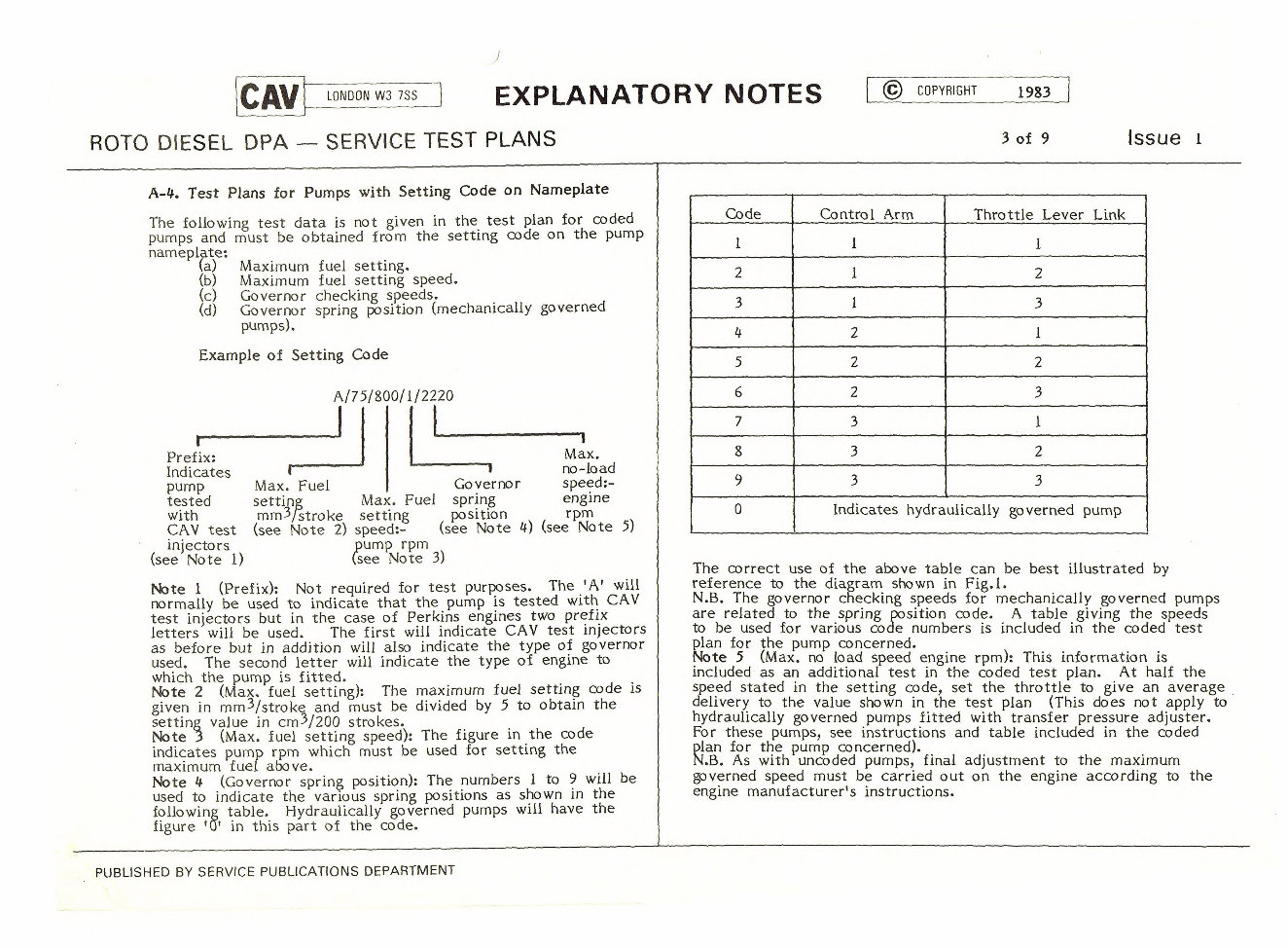

A-4. Test Plans for Pumps with Setting Code on Nameplate

The following test data is not given in the test plan for coded

pumps and must be obtained from the setting code on the pump

nameplate:

(a) Maximum fuel setting.

(b)

Maximum fuel setting speed.

(c) Governor checking speeds.

(d)

Governor spring position (mechanically governed

pumps).

Example of Setting Code

Prefix:

Indicates

Max.

no-load

pump Max. Fuel

Governor speed:-

tested setting Max. Fuel spring engine

with mm 3 /stroke setting position

rpm

CAV test (see Note 2) speed:-

(see Note 4) (see Note 5)

injectors rpm ,pump

(see Note 1) (see Note 3)

Note 1

(Prefix): Not required for test purposes. The 'A' will

normally be used to indicate that the pump is tested with CAV

test injectors but in the case of Perkins engines two prefix

letters will be used

The first will indicate CAV test injectors

as before but in addition will also indicate the type of governor

used. The second letter will indicate the type of engine to

which the pump is fitted.

Note 2

(Max. fuel setting): The maximum fuel setting code is

given in mm 3 /stroke and must be divided by 5 to obtain the

setting value in cm 3 /200 strokes.

Note 3 (Max. fuel setting speed): The figure in the code

indicates pump rpm which must be used for setting the

maximum fuel above.

Note 4

(Governor spring position): The numbers 1 to 9 will be

used to indicate the various spring positions as shown in the

following table. Hydraulically governed pumps will have the

figure '0' in this part of the code.

Code Control Arm Throttle Lever Link

1 1 1

2 1 2

3 1 3

4 2 1

5 2 2

6 2 3

7 3 1

8 3 2

9 3 3

0 Indicates hydraulically governed pump

The correct use of the above table can be best illustrated by

reference to the diagram shown in Fig.l.

N.B. The governor checking speeds for mechanically governed pumps

are related to the spring position code. A table giving the speeds

to be used for various code numbers is included in the coded test

plan for the pump concerned.

Note 5 (Max. no load speed engine rpm): This information is

included as an additional test in the coded test plan. At half the

speed stated in the setting code, set the throttle to give an average

delivery to the value shown in the test plan (This does not apply to

hydraulically governed pumps fitted with transfer pressure adjuster.

For these pumps, see instructions and table included in the coded

-plan for the pump concerned).

N.B. As with uncoded pumps, final adjustment to the maximum

governed speed must be carried out on the engine according to the

engine manufacturer's instructions.

A/75/800/1/2220

I

PUBLISHED BY SERVICE PUBLICATIONS DEPARTMENT

IDLING THROTTLE

SPRING SHAFT

1 2

GUIDE GOVERNOR LINK

SPRING

WPM' )

2 t

t

GOVERNOR

ARM

3

23

4 5 6

- 7 8 9

CODE

Locate code number in table. The

vertical and horizontal lines from

this number to the pump compon-

ents gives the correct numbered hole

in the throttle shaft link and the

governor arm for assembling the

governor spring, eg code No 8 = No 2

hole in throttle shaft link and No 3

hole in governor arm.

General Notes on Coded Test Plans

The positions in the coded test plan where reference to the

setting code is required are marked thus*.

Test plans for coded pumps are identified by the mark against

the words "Setting code on nameplate" printed on the front page

next to the pump type, engine make and application.

Where the same test plan covers both coded and uncoded pumps

the difference in procedure will be indicated in the text for the

relevant tests, care should be taken to follow the correct

instructions for a given case.

B. Procedure to follow for particular operation

B-1. Roller to Roller Dimension

The setting given in the test plan is approximate and is for use

when assembling the pump. Final adjustment of maximum fuel

must be carried out on the test machine. If a substantial

alteration is required, then the pump cannot be functioning

correctly, e.g., plungers sticking, incorrect governor link setting,

etc.

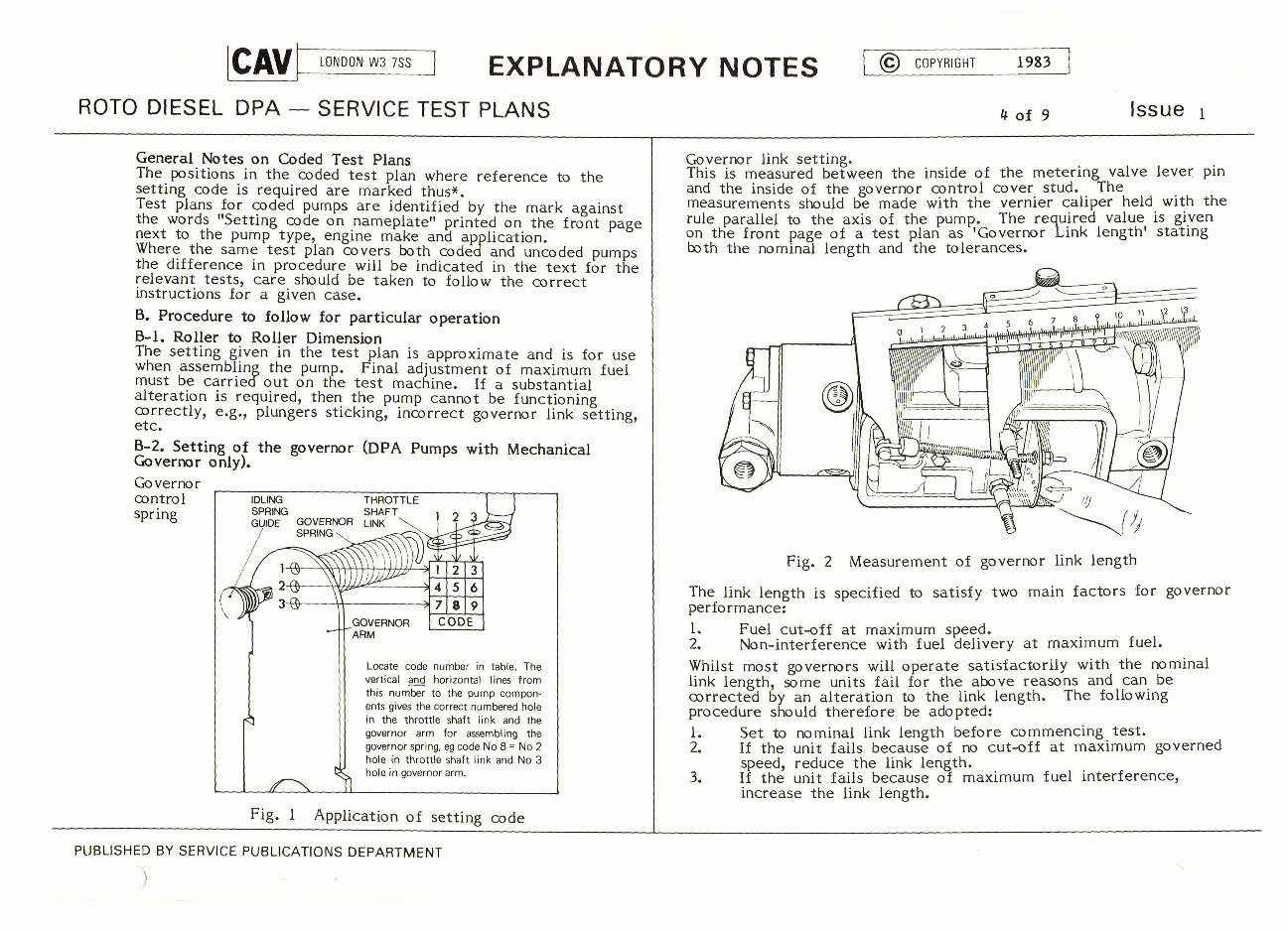

B-2.

Setting of the governor (DPA Pumps with Mechanical

Governor only).

Governor

control

Spring

Fig. 1 Application of setting code

Governor link setting.

This is measured between the inside of the metering valve lever pin

and the inside of the governor control cover stud. The

measurements should be made with the vernier caliper held with the

rule parallel to the axis of the pump. The required value is given

on the front page of a test plan as 'Governor Link length' stating

both the nominal length and the tolerances.

Fig. 2 Measurement of governor link length

The link length is specified to satisfy two main factors for governor

performance:

1. Fuel cut-off at maximum speed.

2. Non-interference with fuel delivery at maximum fuel.

Whilst most governors will operate satisfactorily with the nominal

link length, some units fail for the above reasons and can be

corrected by an alteration to the link length. The following

procedure should therefore be adopted:

1. Set to nominal link length before commencing test.

2. If the unit fails because of no cut-off at maximum governed

speed, reduce the link length.

3. If the unit fails because of maximum fuel interference,

increase the link length.

CAV

LONDON W3 7SS

EXPLANATORY NOTES

ROTO DIESEL DPA — SERVICE TEST PLANS

0 COPYRIGHT 1983

4 of 9

Issue

PUBLISHED BY SERVICE PUBLICATIONS DEPARTMENT

Spring Linkage

Retainer Spring

Linkage Hook

2

--.1 r•-

7mm

EXPLANATORY NOTES

© COPYRIGHT 1983

5 of 9

CAV

LONDON W3 7SS

ROTO DIESEL DPA — SERVICE TEST PLANS Issue 1

Note, however, that incorrectly machined, worn or wrongly

assembled parts can produce the same faults, and alteration to

link length, which may be correct, will not necessarily effect a

solution. Should adjustment to the link setting fail to correct

the fault, then the link should be reset to the nominal length

and the cause looked for elsewhere. Where adjustments to the

governor link length have been made, the sequence of governor

setting must be repeated and the test requirements satisfied.

Adjustments must NOT be made beyond the specified tolerance.

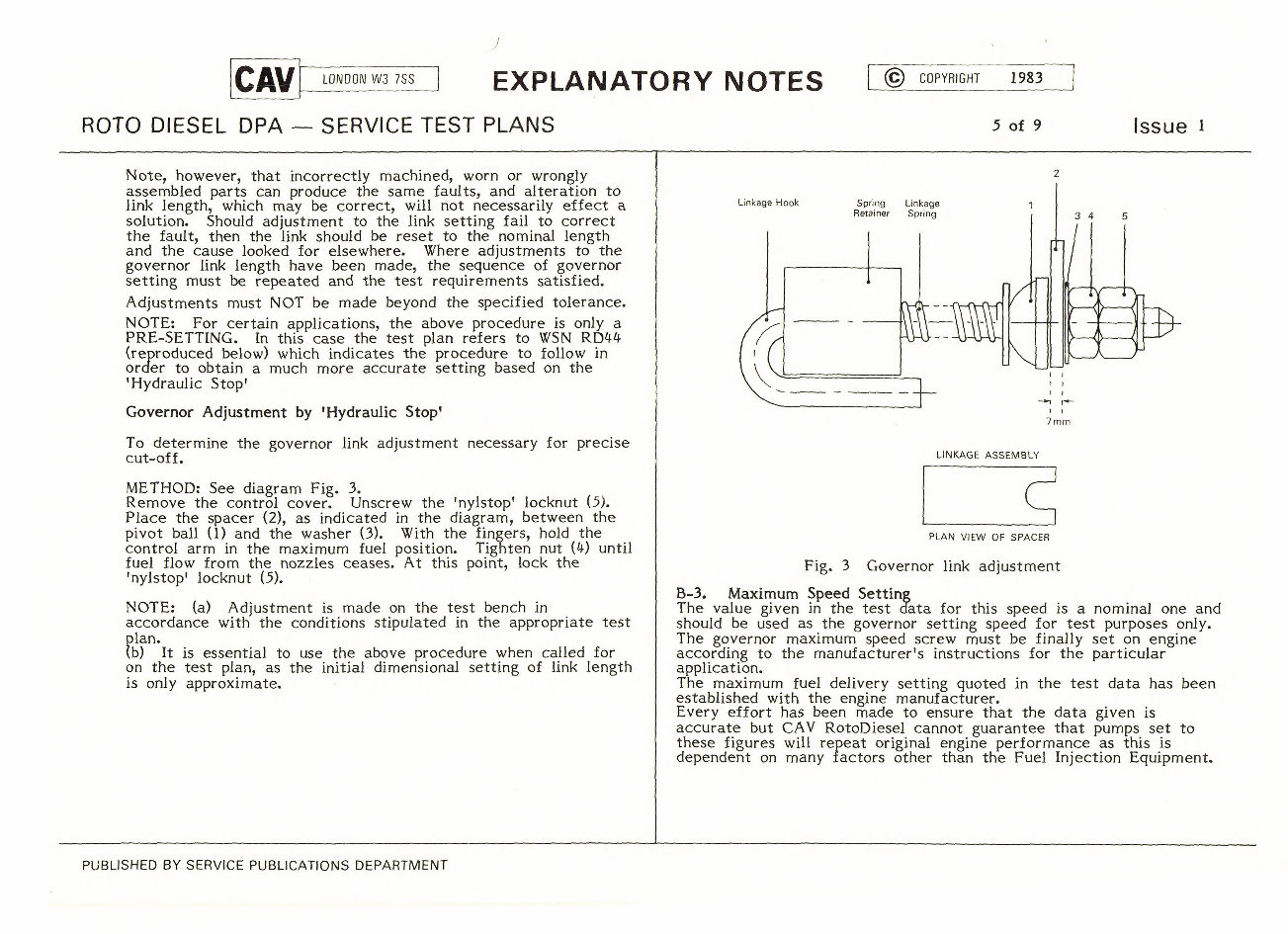

NOTE: For certain applications, the above procedure is only a

PRE-SETTING. In this case the test plan refers to WSN RD44

(reproduced below) which indicates the procedure to follow in

order to obtain a much more accurate setting based on the

'Hydraulic Stop'

Governor Adjustment by 'Hydraulic Stop'

To determine the governor link adjustment necessary for precise

cut-off.

METHOD: See diagram Fig. 3.

Remove the control cover. Unscrew the 'nylstop' locknut (5).

Place the spacer (2), as indicated in the diagram, between the

pivot ball (1) and the washer (3). With the fingers, hold the

control arm in the maximum fuel position. Tighten nut (4) until

fuel flow from the nozzles ceases. At this point, lock the

'nylstop' locknut (5).

NOTE: (a) Adjustment is made on the test bench in

accordance with the conditions stipulated in the appropriate test

plan.

(b) It is essential to use the above procedure when called for

on the test plan, as the initial dimensional setting of link length

is only approximate.

LINKAGE ASSEMBLY

PLAN VIEW OF SPACER

Fig. 3 Governor link adjustment

B-3. Maximum Speed Setting

The value given in the test data for this speed is a nominal one and

should be used as the governor setting speed for test purposes only.

The governor maximum speed screw must be finally set on engine

according to the manufacturer's instructions for the particular

application.

The maximum fuel delivery setting quoted in the test data has been

established with the engine manufacturer.

Every effort has been made to ensure that the data given is

accurate but CAV RotoDiesel cannot guarantee that pumps set to

these figures will repeat original engine performance as this is

dependent on many factors other than the Fuel Injection Equipment.

PUBLISHED BY SERVICE PUBLICATIONS DEPARTMENT

CAI/1

LONDON W3 7SS

EXPLANATORY NOTES

0 COPYRIGHT 1983

6 of 9

ROTO DIESEL DPA — SERVICE TEST PLANS

Issue

B-4. Vacuum Test

It will sometimes be found that, due to the flexible pipe

connecting the vacuum gauge to the pump being partially filled

with air, an incorrect reading will result. To correct this,

slacken the pipe connection at the gauge end with the fuel

supply turned on. Wait until fuel flows from this pipe then re-

tighten the union.

C.

Precautions to be taken when testing the pump on the

test bench.

C-1. Fitting the Pump on the Test Bench

Under the nuts to secure the pump to the test bench use the

Spacers 9003-310B fitted on the pump originally. These have

the correct bearing surface and avoid marking the faces of the

pump housing flange.

C-2. Priming and Venting

Correct consistent operation of the auto advance is dependent

upon the exclusion of air from the auto-advance housing. This

may be sometimes improved by the removal of the advance

gauge before priming. Venting itself should be carried out at

the vent screws whilst running the pump at 100 rpm.

C-2a Pumps with Hydraulic Governor and Combined Automatic

Speed and Light Load Advance.

Besides the information given in paragraph C-2 operate the

throttle lever, press inwards and release the advance indicator

pin several times to ensure venting.

NOTE: This must be repeated after each adjustment of the

auto-advance.

C-3. Measuring the Deliveries

Where marked thus use 30 seconds glass draining time and

allow fuel to settle for 15 seconds before taking reading.

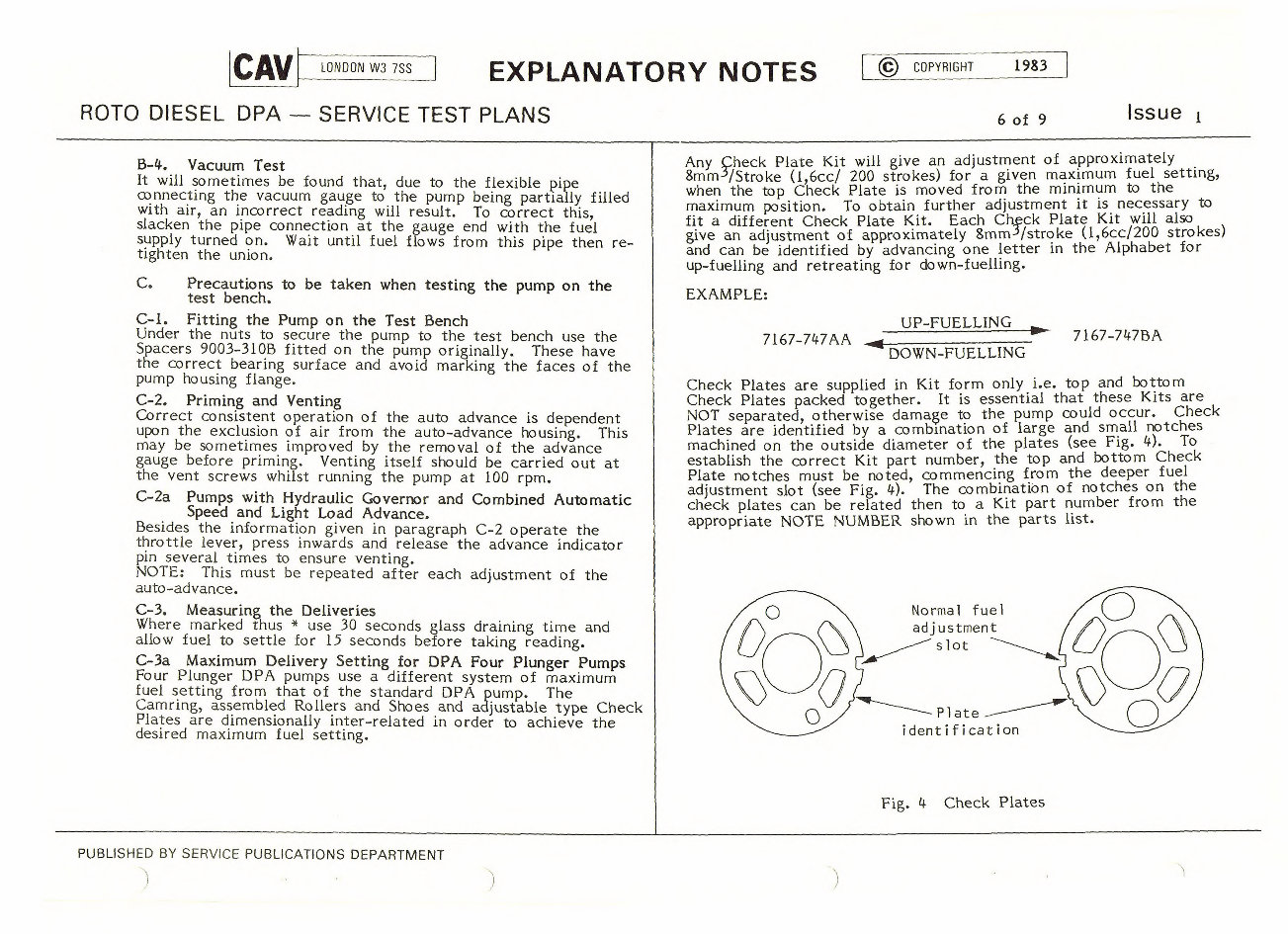

C-3a Maximum Delivery Setting for DPA Four Plunger Pumps

Four Plunger DPA pumps use a different system of maximum

fuel setting from that of the standard DPA pump. The

Camring, assembled Rollers and Shoes and adjustable type Check

Plates are dimensionally inter-related in order to achieve the

desired maximum fuel setting.

Any Check Plate Kit will give an adjustment of approximately

8mm-5 /Stroke (1,6cc/ 200 strokes) for a given maximum fuel setting,

when the top Check Plate is moved from the minimum to the

maximum position. To obtain further adjustment it is necessary to

fit a different Check Plate Kit. Each Ch_eck Plate Kit will also

give an adjustment of approximately 8mm- 5 /stroke (1,6cc/200 strokes)

and can be identified by advancing one letter in the Alphabet for

up-fuelling and retreating for down-fuelling.

EXAMPLE:

UP-FUELLING

7167-747AA

7167-747BA

DOWN-FUELLING

Check Plates are supplied in Kit form only i.e. top and bottom

Check Plates packed together. It is essential that these Kits are

NOT separated, otherwise damage to the pump could occur. Check

Plates are identified by a combination of large and small notches

machined on the outside diameter of the plates (see Fig. 4). To

establish the correct Kit part number, the top and bottom Check

Plate notches must be noted, commencing from the deeper fuel

adjustment slot (see Fig. 4). The combination of notches on the

check plates can be related then to a Kit part number from the

appropriate NOTE NUMBER shown in the parts list.

Normal fuel

adjustment

slot

Plate

i dent i f icat ion

Fig. 4 Check Plates

PUBLISHED BY SERVICE PUBLICATIONS DEPARTMENT

CAV

LONDON W3 7SS

EXPLANATORY NOTES

0 COPYRIGHT

1983

7 of 9

ROTO DIESEL DPA — SERVICE TEST PLANS

Issue

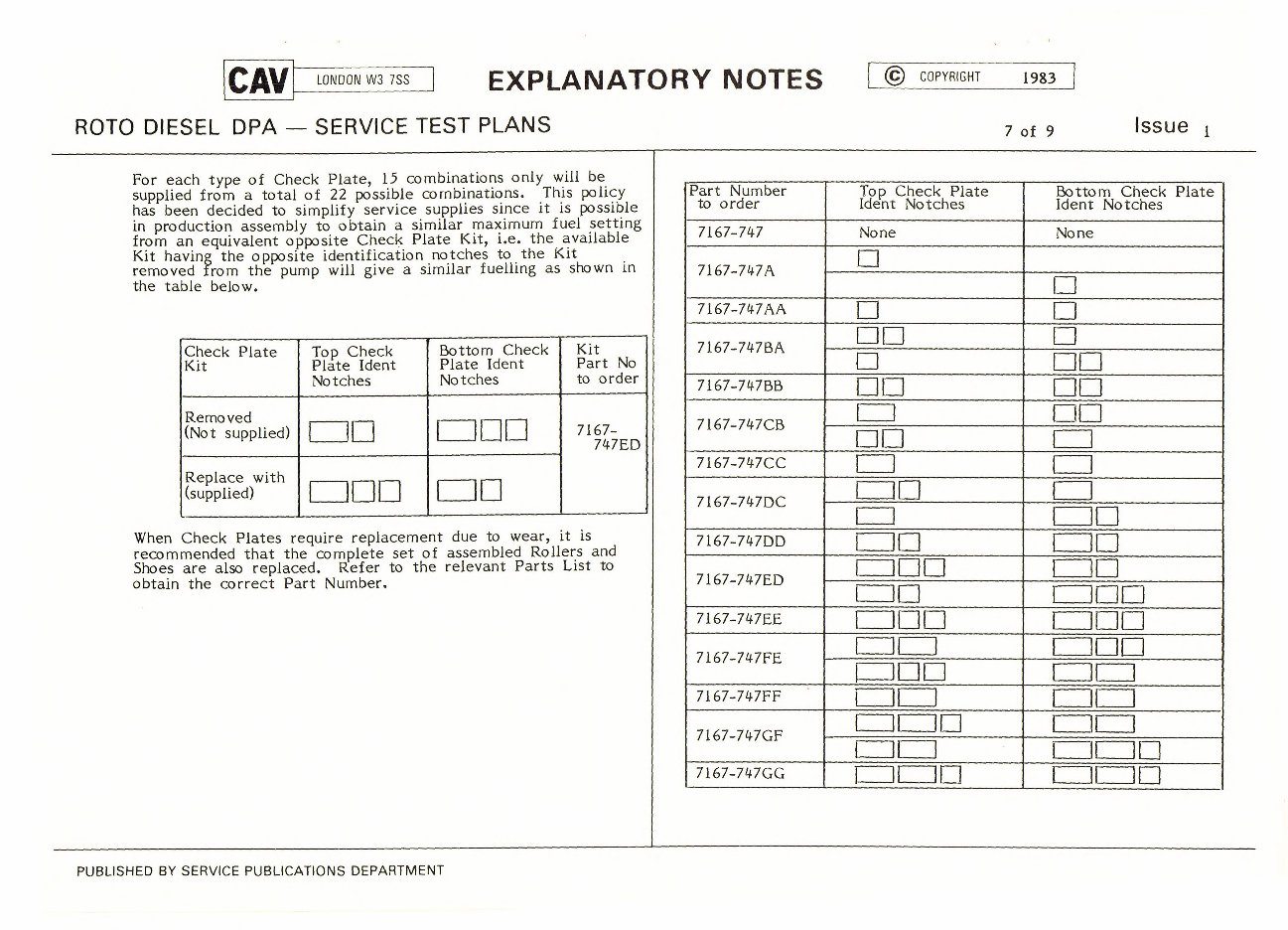

For each type of Check Plate, 15 combinations only will be

supplied from a total of 22 possible combinations. This policy

has been decided to simplify service supplies since it is possible

in production assembly to obtain a similar maximum fuel setting

from an equivalent opposite Check Plate Kit, i.e. the available

Kit having the opposite identification notches to the Kit

removed from the pump will give a similar fuelling as shown in

the table below.

Check Plate

Kit

Top Check

Plate !dent

Notches

Bottom Check

Plate Ident

Notches

Kit

Part No

to order

Removed

(Not supplied)

1- 11 11 1

7167-

747ED

I

Replace with

(supplied)

I II I I IL I

When Check Plates require replacement due to wear, it is

recommended that the complete set of assembled Rollers and

Shoes are also replaced. Refer to the relevant Parts List to

obtain the correct Part Number.

Part Number

to order

Top Check Plate

Ident Notches

Bottom Check Plate

Ident Notches

7167-747 None None

7167-747A

I

I

7167-747AA

1 1 I

7167-747BA

II I I

I II I

7167-747BB

1 11 1 I 11 1

7167-747CB

1 I I

R I

7167-747CC

I I

7167-747DC

11 1 1

1 If I

7167-747DD

III

II I

7167-747ED

11 11 1 11 1

II I I II I

7I67-747EE

1 11-11 I 11 II 1

7167-747FE

I 11 1 11 It 1

I II 11 11 1

7167-747FF

11 I I 1

I II II 1 1i i

7167-747GF

I I II In

7167-747GG

LJI R I LJI II I

PUBLISHED BY SERVICE PUBLICATIONS DEPARTMENT

C-4 Measuring the Advance (General)

Fit auto-advance device and set scale to zero before

commencing test.

C-5 Measuring the Advance on Pumps with Hydraulic Governor

with Combined Automatic Speed and Light Load Advance Device

For this type of pump, the pin of the advance gauge should

come back under the action of the inner plunger, for a value

equal to:

C-5a between 3° and 3 1 z °

C-5b between 4

0

and 4-1°.

C-6 Setting of the Advance (for all Pumps)

It is imperative NEVER to remove the shim (0,5mm) in the

piston spring cap.

In order to obtain the advance values indicated in the test

plans, it might be necessary to add or to remove shims in the

piston spring cap. The maximum acceptable thickness of the

shims must not be greater than

C-6a: 2,0mm (0,5mm shim not included)

C-6b: 2,4mm

C-6c: 2,8mm

C-6d: 3,0mm

C-6e: 3,5mm

C-7 Setting of the Advance (for Pumps with Combined

Automatic Speed and Light Load Advance Device)

For these pumps the maximum acceptable thickness of the shims

for the inner advance piston must not be greater than:

C-7a: 1,2mm

C-7b: 2,4mm

D.

Particular Characteristics of Certain Pump Types

D-1. Pump with Manual Locking Device

0-la. Unless otherwise stated in the Test Plan, the Manual

Locking Device should be open during the tests

D-lb. For this type of Pump, remove the Manual Locking

Device 7139-2C and replace by screw 7139-561B

D-2. Pump with Delivery Valves

The tests must be made with the banjo assemblies fitted with

delivery valves mounted on the pump, unless otherwise stated in

the test plan.

D-3. Pump with Non-Return Valve

The tests must be made with the non-return valve mounted on the

pump in order to maintain a residual pressure of bar (3,51bf/inh) in

the pump housing.

0-4. Pump with Pressurising Valve.

For the tests on the test bench, the pump should be fitted with

banjos 7123-503A with pressurising valves as referred to in the spare

parts list.

D-5. Pump with Transfer Pressure Adjusting Screw

Before testing, the transfer pressure adjusting screw in the

regulating valve should be fully unscrewed and then screwed in 21

to 3 turns.

D-6. DPA Pumps with Anti-Stall Screw

D-6a. Pumps with hydraulic governor

In this case, this device should be fully unscrewed before testing in

order to prevent the end of the screw from interfering with the

action of the metering valve. The device should be set when the

engine is warm.

D-6b. Pumps with mechanical governor

The anti-stall screw should be fully unscrewed before testing. This

screw must be finally set on a warm engine.

D-7. Pump fitted with a Road Speed Limiter Solenoid

Certain DPA Pumps are fitted with a solenoid controlling a road

speed limiting system. The correct working of this solenoid must be

checked at the beginning of the pump tests.

Voltage:

12 volt.

Current: 0,9 amps.

Connection:

Red lead to + of battery,

Black lead to the earth.

This solenoid should be energised during all tests unless otherwise

stated on the test plan (see CAV World Service News Letter RD12).

0-8. Pump fitted with a Fuel Shut-off Solenoid

Some DPA Pumps are fitted with a Fuel Shut-off Solenoid whose

operation enables stopping and starting of the engine through

'ignition key' operation. (See S.I. Note CAV/RDPPumps 30).

ICAV

LONDON W3 7SS

EXPLANATORY NOTES

© COPYRIGHT

1983

ROTO DIESEL DPA — SERVICE TEST PLANS

8 of 9 Issue 1

PUBLISHED BY SERVICE PUBLICATIONS DEPARTMENT

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 42 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Cav Rotodiesel DPA Pumps Service Test Data provides comprehensive plans for servicing Rotodiesels. These manuals offer valuable instructions for professionals and DIY enthusiasts alike.

- Section One General Test Instructions

- Test Bench Preparation

- Cav Oils Specifications

- Setting Up DPA Pumps

- Procedures to follow

- Setting DPA Pumps with mechanical Governors

- Governor Adjustment

- Speed settings

- Fitting pump to test bench

- Priming and Venting

- Hydraulic Governors combined Automatic and light load

- Delivery settings

These manuals contain nine pages of test plan notes dating back to 1983, offering a complete set-up guide for the DPA Pump.

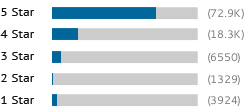

We're currently collecting product reviews for this item. In the meantime, here are some reviews from our past customers sharing their overall shopping experience.

4.5

Out of 5.0

Overall Rating

89%

of customers that buyfrom this merchant give

them a 4 or 5-Star rating.

Verified Buyer

November 7, 2025 by Bill Q. (United States)

“I'm looking at buying a used 7 Series. I bought this software first so I can study the common fault codes and diagnostic procedures. It's helping me build a checklist of things to look for when I go see the car.”

Verified Buyer

November 7, 2025 by Daniel H. (New South Wales, AU)

“it’s was quick”

Verified Buyer

November 7, 2025 by Wesley Y. (United States)

“The download was instant, the file is perfect and my computer didn't explode. So, yeah, this is legit. Pleasantly surprised.”

Verified Buyer

November 7, 2025 by David H. (United States)

“After trying to find specs on forums that were 90% ads for garbage parts, this clean, professional website was a nice change. The fact that this is the actual OEM software is also very nice.”

Verified Buyer

November 7, 2025 by Rosie J. (United States)

“The kids' quad died the night before a long weekend camping trip. This site was clean, simple, and I had the manual on my iPad in about 90 seconds. Exactly what I needed, when I needed it.”

Verified Buyer

November 7, 2025 by Beth J. (United States)

“I bought this just to have a digital reference on my boat's tablet. If something ever does go wrong on the water, I'll have the diagnostic charts right there with me. Very handy.”

Verified Buyer

November 7, 2025 by Renee W. (United States)

“The garage told me I needed a new transmission for $2,000. I bought this, read the diagnostic section, and went back to ask them if they tested the main relay first. Suddenly, the repair cost dropped. Money well spent.”

Verified Buyer

November 7, 2025 by Martin H. (United States)

“I'm restoring a 71 coupe and use the manual to ensure I bring it back exactly as it left the factory... At least I'm trying lol Manual is very good.”

Verified Buyer

November 7, 2025 by Fernando V. (United States)

“Before buying, I used their contact form to ask a specific question. I was testing them. A tech replied in about an hour with such a detailed answer, I knew it wasn't some scam site. I bought it immediately.”

Verified Buyer

November 7, 2025 by Howard R. (US)

“Ben easy so far...I hope it has everything I need”