mikuni carb manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

4th - Edition

TTLE VAL \

- ----- - - - - -

IllbOduclion

Sudco International IS America's leading

source for Mikuni aftermarket carburetors, parts,

accessories, and information. Sudco has been selling

Mikuni products to the powersports industry for

over twenty five years and continues

to provide the most comprehensive service

available for Mikuni aftermarket products.

The Sudco / Mikunj tuning manual is a compilation

of official Mikuni techuical manuals combined with

years of hands on experience setting up, tunjng, and

troubleshooting Mikuni products. All information

contained within this manual is specific to Mikuni

aftennarket carburetor designs only. The Milami

aftermarket division does not represent the exact

Mikuni products which may have been supplied by

the Original Equipment Manufacturer. In most cases,

the parts from aftermarket carb designs are not inter-

changeable with OEM carburetors.

Please take the time to read the chapter

on general carburetor theory and operation.

Sudco has o~n been called upon to troubleshoot

carburetor pr9blems. Many types of problems can

be identi. fied and solved with an understanding of

carburetor fuddamentals. Motorcycle perfonnance

does not have to be compljcated if you have the

basic knowledge.

It is our hope that you will use this mauual

as a guide and reference tool as do many schools and

race mechanics.

! ,.,_ .. ,e

1I81E 01 CONIENTS

Basic slide carburetor theory and operation.

General Mikuni carburetor circuitry

and tuning for motorcycle applications.

Ttoubleshooting, general procedures,

and techniques to determine rich from lean.

Carburetbr synchronization -

VM Smoothbores, RS and others.

Carburetors and related parts charts

A. ~Roundslide

B. Throttle Valves

C. VM29 Smoothbore

D. VM33 Smoothbore

E. TM Flatslide

F. TMX Flatslide

G. TM33 Flatslide

H. HS40 (TM40) Flatslide

1. HSR42J45J48 Smoothbore

J. RS Smoothbore

General Mikuni tuning parts - motorcycle carbs

A. Main & Pilot Jets

B. Needle Jets

C. Jet Needles

D. Ma nifolds and Adapters

E. Fuel Pumps

F. Carburetor Accessories

G. Carb Kits

H. Pingel Products

I. K&N Filters & Flame Arresters

Watercraft Carburetors

Tools

Reading Spark Plugs

~

2

3

9

13

15 - 57

15-23

24-25

26-27

28~29

30-33

34-38

39

40-44

45-52

53-57

58-70

58-59

60 .. 62

63-1'0

71

72

73

74

75

76-77

78-90

91

92

1

2

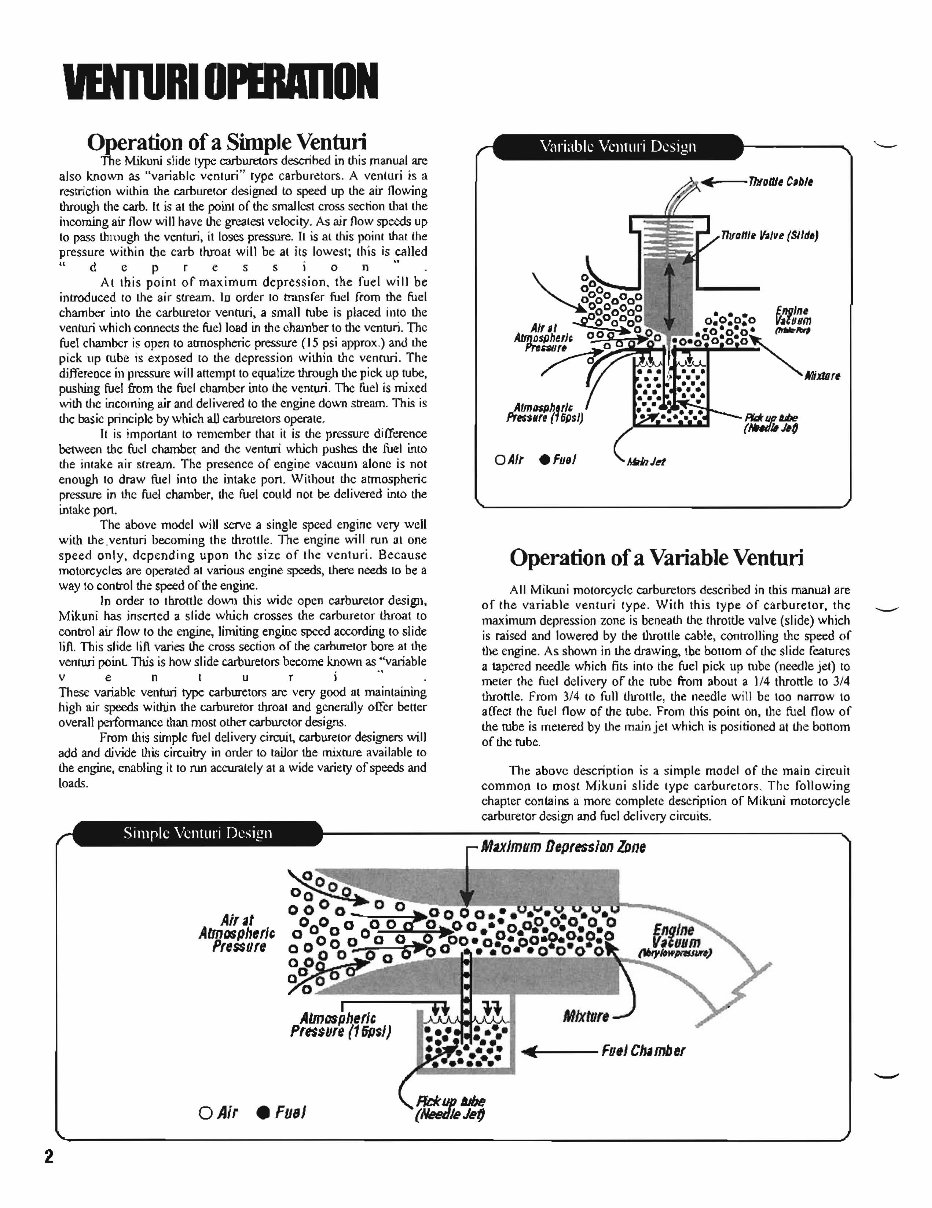

VENlURIOPBUDlON

Operation of a Simple Venturi

The Mikuni slide type carburetors descrihed in this manual are

also known as "variable venluri" type carburetors. A venturi is a

restriction within the carburelor designed to speed up the air flowing

through Ihe carbo It is al the poinl of the smaJ. lcst cross section thai the

incoming air flow will have thc greatesl velocity. As air /low spe.xls up

10 pass thmugh the venturi, il loses pressure. It is at this poinl that the

pressure within the carb thIoa! will be at its lowest; this is called

"d cpr e s s ion"

At Ihis point of maximum depression. the fuel will be

introduced 10 the air stream. ID order to transfer fuel from the fuel

chamber inlo the carburelor venturi, a small tube is placed into the

venturi which connects the fuel load in the chamber 10 dle venturi. The

fue! chamber is open 10 atmospheric pressure (J 5 psi approx.) and the

pick up rube is exposed 10 the depression within thc vennui. The

differeoce ill pressure will attempt to equalize through Lhe pick up tube,

pushing fuel from the fuel chamber into the venturi. The fuel is mixed

with the incoming air and delivered to the engine down stream. This is

the basic principle by which all carburelors opera Ie.

It is important to remember thai it is the pressurc difference

between thc fuel chambe( and the venturi which pushes the fuel into

the intake air slream. The presence of engine vacuum a!one is not

enough to draw fuel into the intake pon. Wilhout thc atmospheric

pressure in thc fuel chamber, the fuel could not be delivered into the

inlake pon.

The above model will serve a single speed engine very weI!

with the .venturi becoming Ihe throttle. The engine will run alone

speed only, dcpending upon Ihe size of Ihe venturi. Because

motorcycles are operated al various engine speeds, there needs 10 be a

way 10 conb"ol the speed of the engine.

In order to throttle dow'1) this wide open carburetor design,

Mikuni has inserted a slide which crosses the carburetor throat to

conb"ol air flow to the engine, limiting engine speed according 10 slide

lift . This slide lift varies the cross section of the carburetor bore III the

venturi painl llJ.is is how slide carburetors become known as dvariable

ve n I uri .,

These variable ventwi type carburetors are very good at maintaining

high air speeds within the carburetor throal and generally olIer better

overall perfonnancc than most other carburelor designs.

From this simple fuel delivery circuit, carburetor designers will

add and divide this circuitry in oruer 10 tailor the mixture available to

the engjne, enabling it 10 run aCCUr.llely at a wide variety of speeds and

loads.

Air ~t

Atmospht:rJ,

Pressure

I

Almaspht:rJ,

Pressure (15fJ$/)

o Air • FilS!

AIm/)$fJhl'"

Pre$slIre ( 6Psl)

o AIr .FIJel

Operation of a Variable Venturi

MixltJrf

All Mikuni motorcycle carburelors described in tbis manual are

of the variable venturi type. With Ihis Iype of carburelor, the

maximum depression zone is beneath the throttle valve (slide) which

is raised and lowered by the Ihrollie cable, conrrolling the speed of

the engine. As shown in the drawing, Ibe bOllom of the slide features

a tapered needle which fits into tbe fuel pick up tube (needle jet) 10

meter the fuel delivery of the tube from about a 1/4 throttle to 3/4

throttle. From 3/4 to full lhrollle, the needle will be 100 narrow to

affeCI (he fuel flow of the tube. From this point on, the fuel now of

the rube is metered by the main jel which is positioned at the bonom

of the tube.

The above description is a simple model of the main circuil

common 10 most Mjkuni slide type carburetors, Tile following

chapter contains a more complete descriplion of Mikuni motorcycle

carburelor design and fuel delivery circuits.

M~Jmum Depression lDne

..... 1---- fuel Chlmbet

-

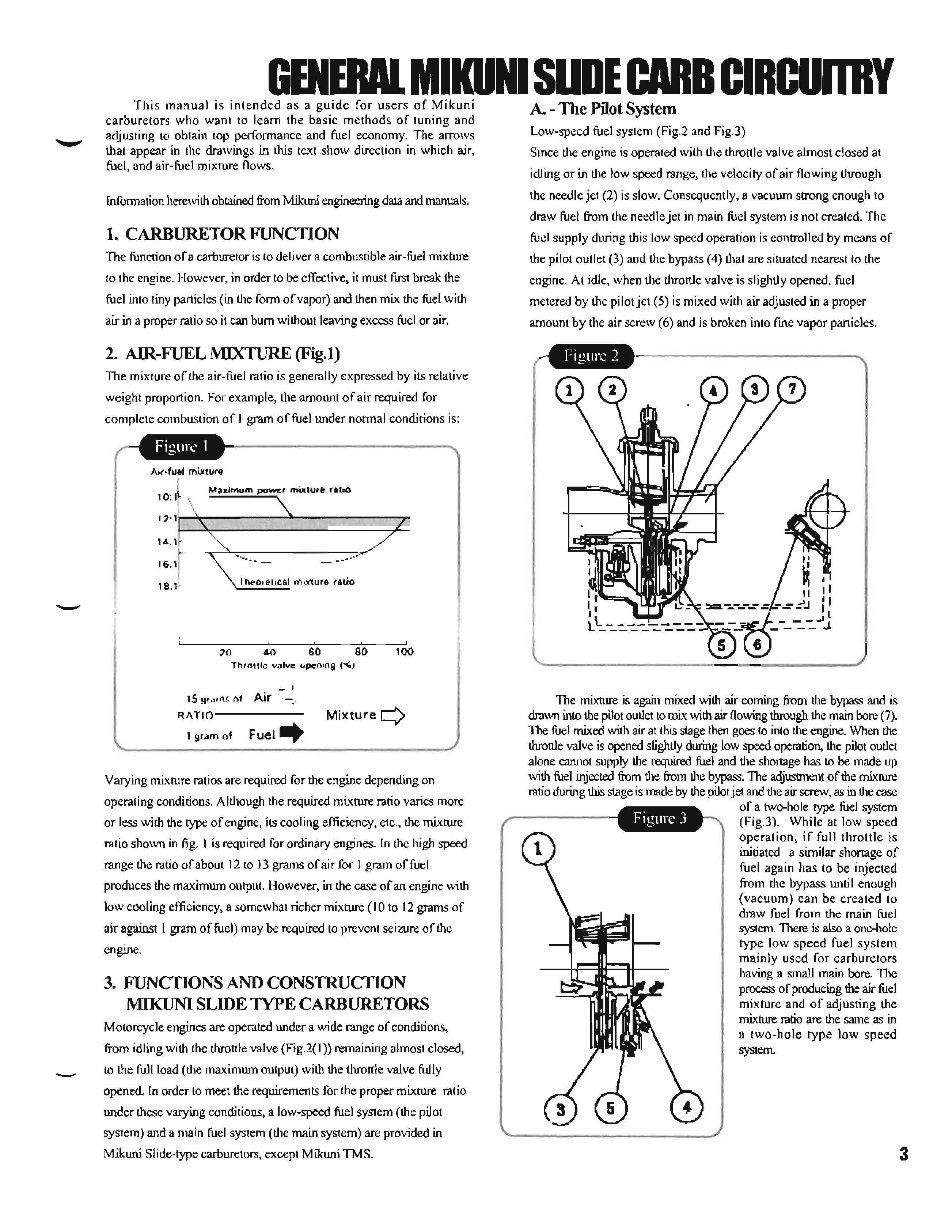

GENERAl. MIKUNI SUDE CARB CIRCURRY

This manual is intended as a guide for users of Mikuni

carburetors who want to learn the basic methods of tuning and

adjusting to obtain top performance and fuel economy. The aJTOWS

that appear in the drawings in this tcxt show direction in which air,

fuel, and air-fuel mixrure flows.

[nfonnation herewith obtained from Mikuni engineering daJa and manuals.

1. CARBURETOR FUNCDON

The function ofa carbUTetor is to deliver a combustible air-fuel mixture

10 the engine. However, in order to be effective, it must first break the

fuel into !iny particles (in the form of vapor) and then mix the fuel with

air in a proper ralio so il can bum without leaving excess fuel or air.

2_ AIR-FUEL MIXTURE (Fig.I)

The mixture of the air-fuel ratio is generally expressed by its relative

weight proportion. For example, the amounl of air required for

compiete combustion of I gram of fuel under nonnal conditions is:

A,(·fu6i mLllwro

14 .. 1

16.1

18.1 '

,-~,~ .. -.--------------- .. ,~

1I\ .. O,&I,C61 O"i),)((ure (11;0

-'

15 ~,~,J\< ,,1 Air .-:

100

RA TlO-------

MixtureQ

1 9r~m of Fuel ~

Varying mixrure ratios are required for the engine depending on

operating conditions. Although the required mixture rario varies more

or less with the type of engine, its cooling efficiency, etc .. the mixture

ratio shown in fig, I is required for ordinary engines. In the high speed

range the ratio of about 12 to 13 grams of air for I gram of fuel

produces the maximum output. However, in the case of an engine with

low cooling efficiency, a somewhat richer mixture (10 to 12 grams of

air against I gram of fuel) may be required to prevent seizure of the

engine.

3. FUNCflONS AND CONSTRUCIlON

MIKUNI SLIDE lYPE CARBURETORS

Motorcycle engines are operated under a wide range of conditions,

from idling with the throttle valve (Fig.2( I)) remaining almost elosed,

to the full load (the maximum output) with the throttle valve fully

opened. In order to meet the requirements for the proper mixrure ratio

under these varying conditions, a low-speed fuel system (the pilol

system) and a main fuel system (the main system) arc provided in

Mikuni Slide-type carburetors, except Mikuni TMS.

A. - The Pilot System

Low-speed fuel system (Fig.2 and Fig.))

Since lhe engine is operated with the throttle valve almost closed at

idling or in the low speed range, the velocity ofaiT flowing through

the needle jet (2) is slow. Consequently, a vacuum strong enough to

draw fuel from the needle jet in main fuel system is not created. The

fuel supply during this low speed operation is controlled by means of

the pilot outlet (3) aud the bypass (4) that arc situated nearest to the

engine. At idle, when lhe throttle valve is slightly opened. fuel

metered by the pilot jet (5) is mixed with air adjusted in a proper

amount by the air screw (6) aud is broken into fme vapor panicles.

I'

~ .

11 II

~-:.--;; -_.:-=~ J ~

-..:C!)---- j.

The mixture is again mixed with air coming from the bypass and is

drown into the pilot outlet to mix with air flowing through the main bore (7).

The fuel mixed with air at this stage then goes 10 into the engine. When the

thronle valve is opened slighLly during low speed operation. the pilot ouLiet

alone cannot supply the required fuel and the shortage has to be made up

with fuel injected from L1le from the bypass. The adjustment of the mixrure

ratio during this stage is made by the pilot jet and the air screw. as in the case

of a two-hole type fuel system

(Fig.3). While lit low speed

operation, if full throttle is

initiated a similar shortage of

fuel again has to be injected

from me bypass until enough

(vacuum) can be created to

draw fuel from the main fuel

system. There is also a one-hole

type low speed fuel system

mainly used for carburetors

having a smaJJ main bore. TI'tC

process of producing the air fuel

mixture and of adjusting the

mixture ratio are the same as in

a two-hole type low speed

system.

3

4

GENERAl. MIKUNI SUOE CARB CIRCURlY

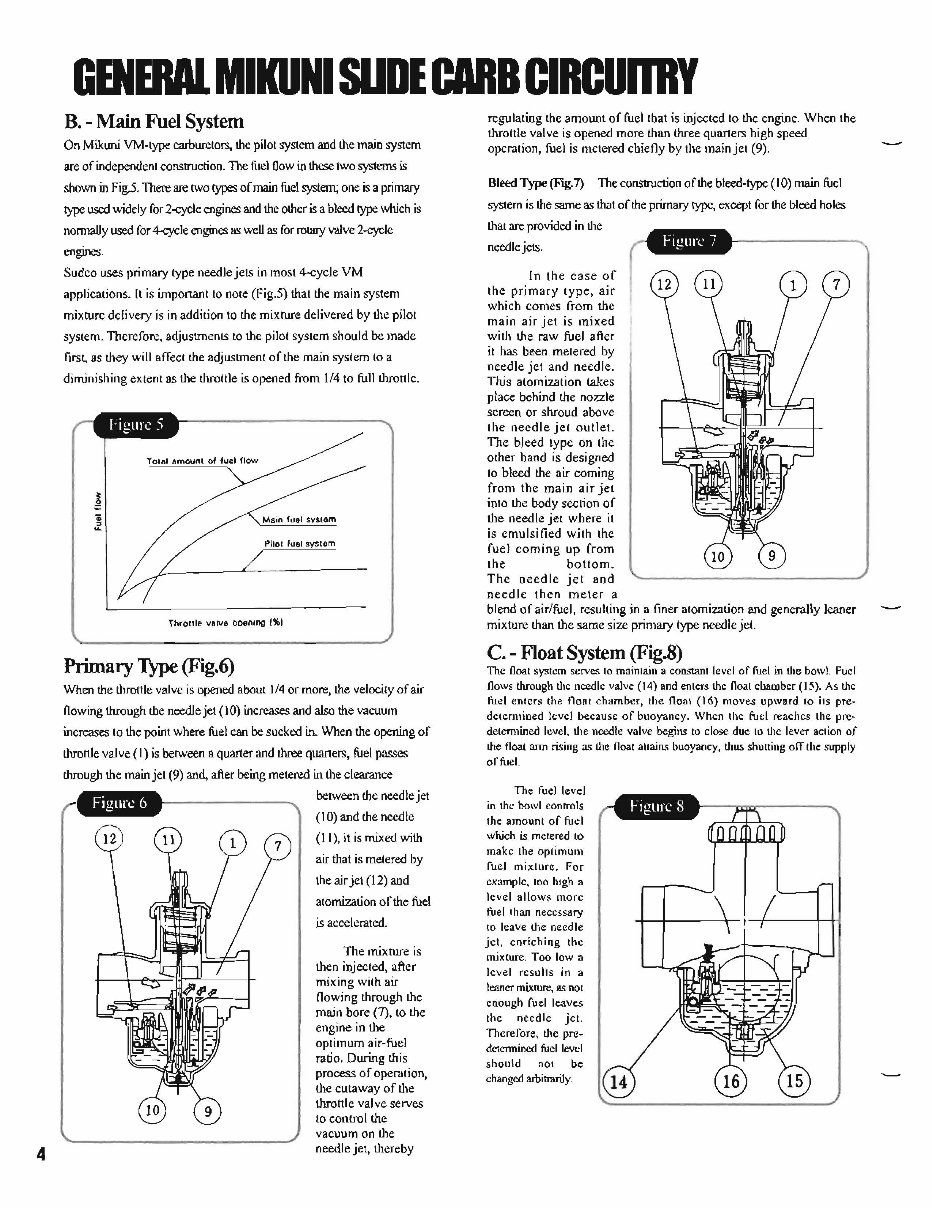

B. - Main Fuel System

On Mikuni YM-type carburetors, the pilot sy&tem and the main system

are of independent construction. TIle fild Oow in these two systems is

shown in Figj. There are two types of main fuel system; one is a primary

!)pC used widely for 2-cycle engines and the other is a bleed type which is

nonnaUy used for 4-cycle engines !IS weU as for rotaIy valve 2-cycle

engines.

Sudeo uses primary type needle jets in most 4-cycle VM

applications. [t is important to note (Fig.S) that the main system

mixture delivery is in addition to the mixture delivered by the pilot

system. Therefore, adjustments to the pilot system should be made

first. as they will affect the adjustment of the main system to a

diminishing extent as the throttle is opened from 114 to full throttlc.

10Iai amount 01 fuel flow

Plio' fuel system

Throttle valve ooenlllg t'lbl

Primary Type (Fig.6)

When the throttle valve is opened about 1/4 or more, the velocity of air

flowing through the needle jet (10) increases and also the vacuum

increases to the point where fuel can be sucked in. When the opening of

throttle valve (I) is between a quarter and three quaners, fuel passes

through the main jet (9) and, after being metered in the clearance

between the needle jet

(10) and the needle

(J I), it is mixed with

air that is metered by

the air jet (12) and

atomization of the fuel

is accelerated.

The mixrure is

then injected, after

mixing with air

/lowing through the

main bore (7), to the

engine in the

optimum air-fuel

ratio. During this

process of operation,

the cutaway of the

throttle valve serves

10 control the

vacuum on the

needle jet, thereby

regulating the amount of fueltbat is injected to the engine. When the

throttle valve is opened more than three quarters high speed

operation, fuel is metered chiefly by the main jet (9).

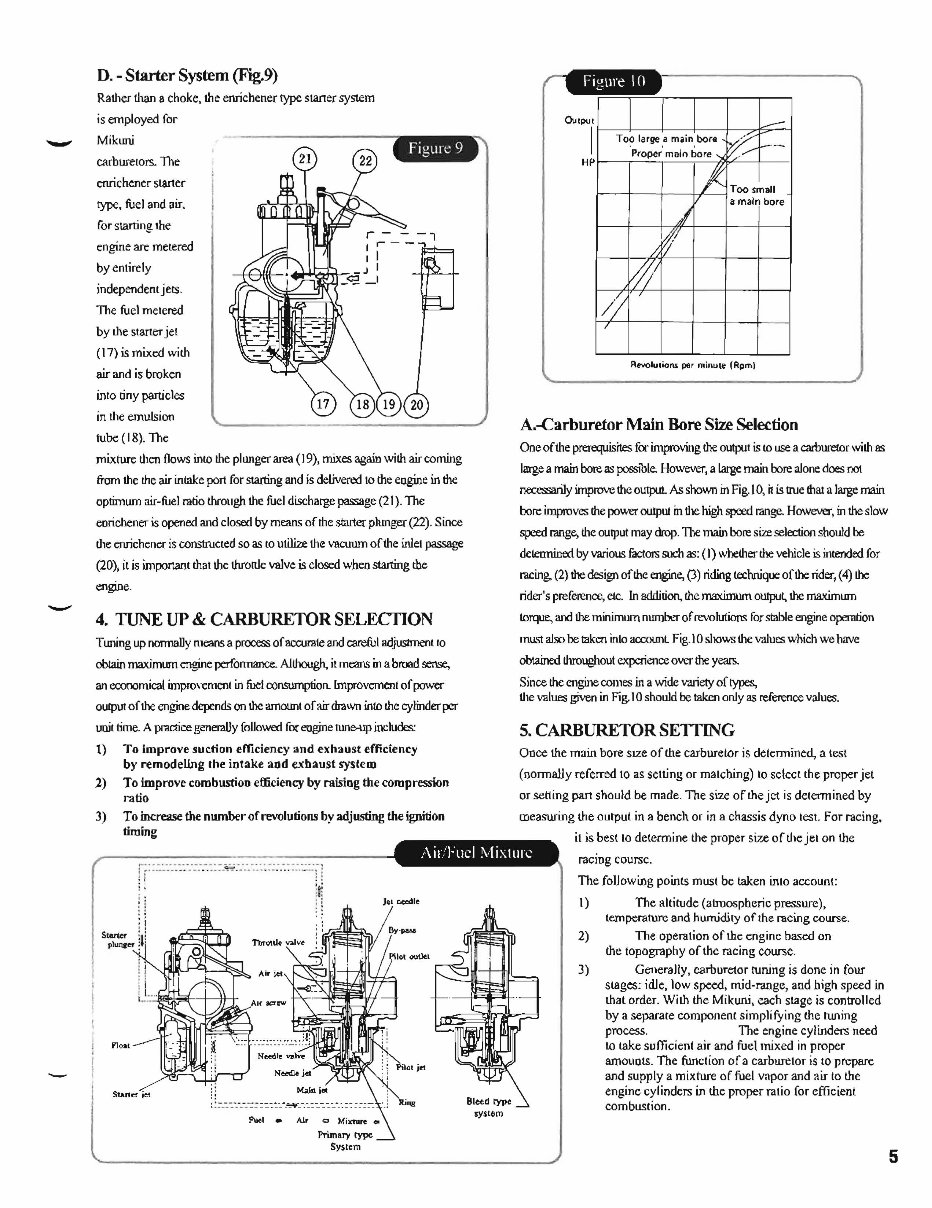

Bleed Type (Fig.7) The construction of the bleed-type (10) main fuel

system is the same as trot of the pri.rnaJy type, except for the bleed holes

that are provided in the

need Ie jets.

In the case of

the primary type, air

which comes from the

main air jet is mixed

with the raw fuel after

it has been metered by

needle jet and needle.

nus atomization takes

place behind the nozzle

screen or shroud above

the needle jet outlet.

The bleed type 00 the

other hand is designed

to bleed the air coming

from the main air jet

into the body seclion of

the needle jet where it

is emu lsi (jed with the

fuel coming up from

the bollorn.

The needle jet and

needle then meter a

blend of air/fuel, resulting in a finer atomization and generally leaner

mixture than the same size primary type needle jet.

C. - Float System (Fig.8)

The float system serves to main lain a constant level of fuel in the bowl. Foci

flows through tlte needle valve (14) and enters the float ebalDbcr (15). As the

fu<!1 enters the float chamber, the floal (16) moves upward 10 ils pre-

delemtined level because of buoyancy. When the fuel reaches the pre-

detemlined level. the needle valve begins to close due to Ihe lever aClion of

the float:mn rising as the float 3ltains buoyancy, thu:; shuning olTthe st.rpply

of fuel.

The fuel level

in the bowl eonrrols

the amount of fuel

which is metered to

makc the optimUl'l

fuel mi;dure. For

examplc, too high a

level allow~ morc

fuel than necess.ary

10 leave the needle

jet. enrichillg the

mixture. Too Iowa

level resu Its in :I

leaner mixture, as not

enough fuel leaves

the need Ie jet.

Therefore, the pre-

dctcnnincd fuel level

should nOI be

changed arbitrarily.

-

-

D. - Starter System (Fig.9)

Ralher than 8 choke, the enrichener type staner system

is employed. for

Mikuni

carburetors. The

enrichenerstaner

type, fuel and air.

for starting the

engine are metered

byenlirely

independent jets.

The fuel melered

by the starter jel

(17) is mixed with

air and is broken

into tiny particles

in Ihe emulsion

tube (18). The

mixture Ihen flows inlD the plunger area (19), mixes again with air coming

from the the air intake port for starting and is delivem.:llo the eogine in the

optimum air-fuel ratio through the fuel discharge passage (21) . ThE:

eorichener is opened and closed by means of the starter phmger (22). Since

Ihe enrichener is constructed so as to Ulilize the Vllcuum of the inlel passage

(20), it is important thaI the throttle valve is closed when starting the

engJJIe.

4. TUNE UP & CARBURETOR SELECTION

T lUling up nonnaIJy means a process of IICCUrBte and careful adjuslmeot 10

obtain maximum engine performance. Although, it means in a broad sense,

an economical improvement in fuel consumption. Improvement of power

oulput of the engine depends on the amOWlt of air drawn into the cylinder per

unil time. A practice generally followed for engine rune-up inchldes:

1) To improve suction efficiency and exhaust efficiency

by remodeling the intake aod exhaust system

Z) To improve combustion efficiency by raising the compression

ratio

3) To increase the number of revolutiollli by adjusting the ignition

timing

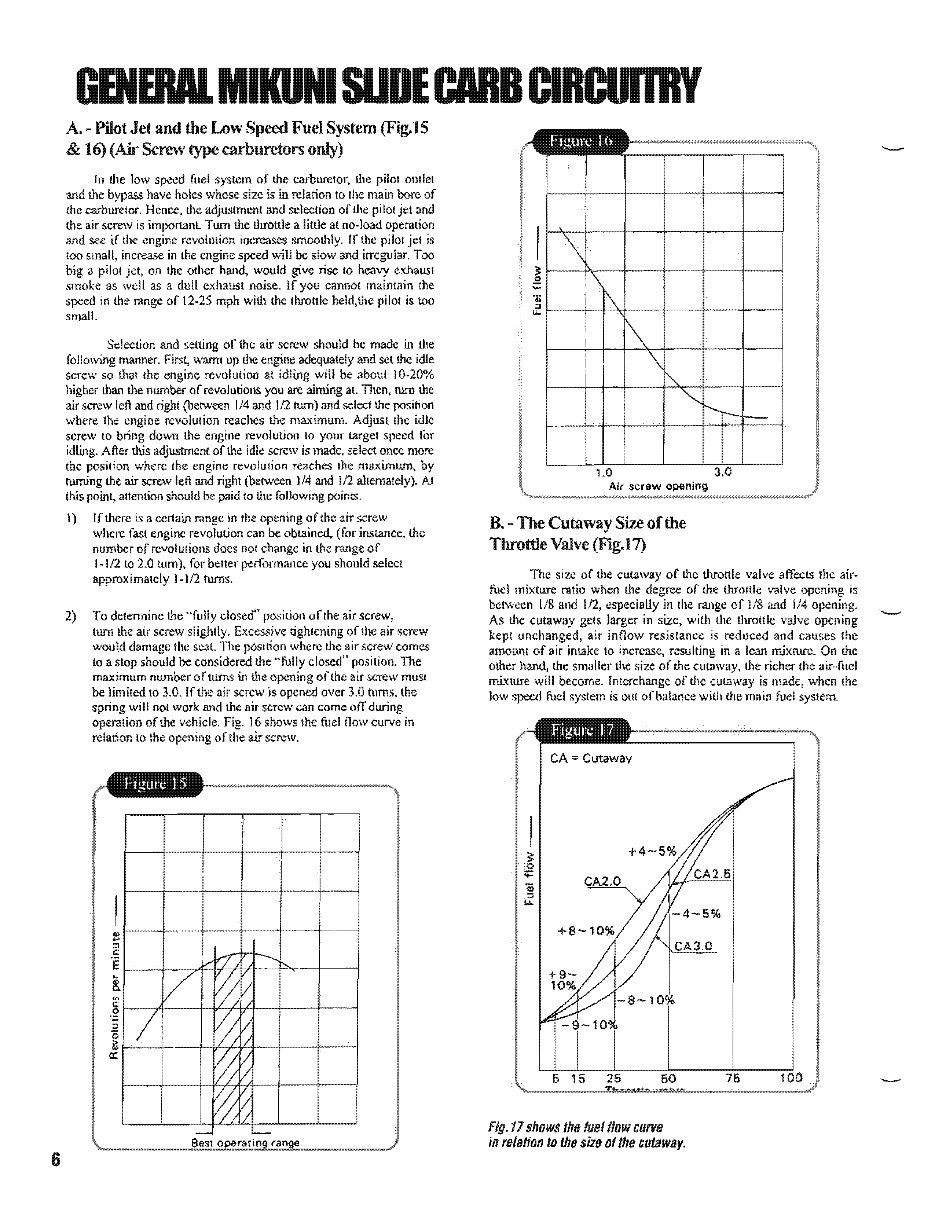

Output

I f------+----+--+-----+------::>-7--j

HPr---r-~,---.-~~~~---1

Revolutions per m~rlUle (Apm)

A.-Carburetor Main Bore Size Selection

One of the prerequisites [or improving !he output is to use a carburetor with as

large a main bore. as posstble. However, a large main bore alone does not

nec=IDJy improve the output. As shown in Fig.J 0, it is \rue thal a large main

bore improves the power output in dlC high speed range. However, in the slow

speed range, the output may drop. TIle main bore size selection should be

deletmined by variouc; fuctors such as: (I) whether the vehicle is intended for

racing. (2) the design of the engine, (3) riding technique of the rider, (4) the

rider's preference, etc. In addition, the maximum output, the maximum

torque, and the minimum numb..'T of rcvolutionc; for stable engine operation

must also be taken into accounL Fig. 1 0 shows the values which we h3Ve

obtained throughout experience over the years.

Since the engine comes in a wide variety of types.,

the values given in Fig. I0 should be taken only as reference values.

5. CARBURETOR SETTING

Once the main bore SIZe oflhe carburetor is detennined, a lest

(llonnaUy referred 10 as selting or matching) 10 select the proper jet

or setting pan should be made. The size of the jet is determined by

lDeaswing the output in a bench or in a chassis dyno lest. For racing.

Air,Fuel MiXll11-:

il is best 10 detennine the proper si7..e of the jel on the

racing course.

ri: =.:: -:.-.~: -::.-.-.-.: -: ~~ :~~:~ ~~::: :::: .: ~ :.::.::: -i

i: ~

'. : . i: . '

: I

Start<r !:

PI_ .. :I:

I·

!l

1i

:. '::' .::i " l!£IoJl.;;iI--1--1t+

~ :

: =- _ .. :~.-----::. ::::.::. -.'"=¥--.:.::.. -. :.:..-.-.:: : :.:::

FUel • Al.r

Jel ocrdte

81eed type

systom

The following points must be taken inlo account:

I) The altitude (atmospheric pressure),

lemperature and humidity of the racing course.

2) The opera lion of the eng inc based on

the topography of the racing wurse.

3) Generally, carburetor tuning is done in four

SLages: idle, low speed, mid-range, and high speed in

thai order. With the Mikuni, each stage is controlled

by a separare componenl simplifying the tuning

process. The engine cylinders need

to take sufficient air and fuel mixed in proper

amOllots . The function of a carburelor is 10 prepare

and supply a mixture of fuel vapor and air to the

engine cyl inders in the proper ralio for efficient

combustion.

5

6

GENERAl CARB

A. ~ Pilot Jet and the Low Speed Fuel

& 16) (Air Screw type carburetors only)

of the carburetor, the pHo! mulel

size is in relation 10 Ihe main bore of

the and selection of 11lC pi 10\ jet and

Im,,,,n"l11 Tum the throttle a little at no-load operation

and see if the revolution iocreases smoothly. if the pilot is

too small, increase in the engine speed will be slow and irregular.

a on the other hand, would give rise 10 heavy exhaust

smoke as well as a dull exhauSI noise. If you cannol maintain the

in the range of 12·25 mph with the throttle pilot is too

small.

Selection and of the air screw should be made in Ihe

foJlowmg manner. warm up the adequately and set the idle

screw so thai the revolutioQ at will be about 10-20%

than 1l1C of revolutions you are aiming at. TIlen, rum the

screw left and (between 1/4 and 1121um) and select the position

wbere the revolution reaches the maximum. Adjust the idle

screw to down the engine revolution 10 your targel for

idling. After adjustment of the idle screw is made, select once more

the position where tne engine revolution reaches the maximwn,

turning the air screw left and right (bet'Ween 1/4 and 112 AI

this poin!, attention should be paid to the following

I)

2)

of the air screw

where fast can obtained, (for instance. the

nwnber ofrevolulions does no! change in the range of

1-112 LO 2.0 for you should select

1-1/2 turns.

To determine the "fully closed" position oflne air screw,

tum the air screw slightly. Excessive tighlening of the air screw

would damage the scal. TIle where the air screw comes

10 a Slop should be closed" The

maximum nwnber of turns in the of the

be limited 10 3.0. If the air screw is over 3.0 films,the

spring will nol work and the air screw can come ofT during

operation of the vehicle. 16 shows Ihe fuel now curve in

relation 10 the a.tr screw.

.e!

:::J

c:

'E 1- ....... ~f---Ac.r.,t~II----F"'-+---j

&

'"

.g l--cA---+-Ij,L.,,4,4-+----+~____I

:::J

'0

i; I---~+----I-

a::

1.0

Air screw opening

B. - The Cutaway of the

Throttle (Fig.l7)

The size of 1l1e cutaway of the t.hrottle valve affects Ihe air-

fuel mixture ralio when the degree of the throttle valve is

between 1/8 and 112, especially in the range of 118 and 1/4 UIJC;,,"'I!..

As lhe cutaway gelS in size, with the IllfOttie valve

kepI unchanged, air resistance is reduced and causes

amoUIlI of air intake 10 resulting in a lean mixture. On the

olher hand, the smaller !lIe size of the cutaway, tlle richer the air-fuel

mixture will become. of tllC cutaway is made, when Ine

low speed fuel system is CUI of balance with the main fuel system.

CA Cutaway

Fig. 17 shows the fuelliow curve

in relation to the size of the liULilIWlj!!f.

-

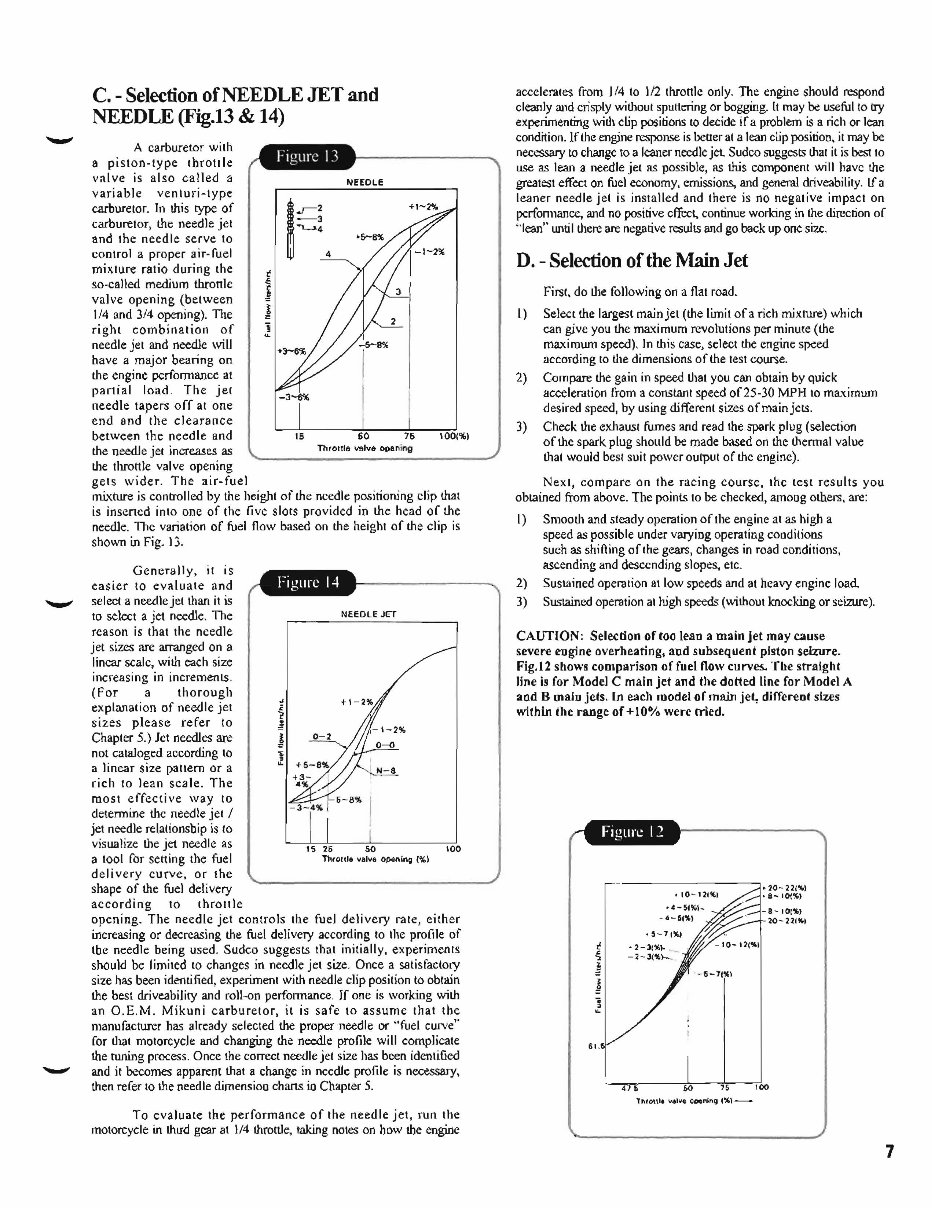

C. - Selection of NEEDLE JET and

NEEDLE (Fig.13 & 14)

A carburetor with

a piston-type tbroll Ie

val ve is also called a

variable venturi-type

carburetor. In this type of

carburetor, the needle jet

and the needle serve to

control a proper air- fuel

mixture ratio during the

so-called medium thtonk

valve opening (between

1/4 and 3/4 opening). 11le

rigbt combination of

needle jet and needle will

have a major bearing on

the engine performance at

partial load. The jet

needle tapers off at one

end and the clearance

between the needle find

.

...

-3

""L.J.4

~

~2

16

NHOLE

4

60 76

the needle jet increases as Throttle ""Ive op&ning

the throttle valve opening

gets wider . The air-fuel

1001%)

mixture is controlled by the height of the needle positioning clip that

is insened into one of the live slots provided in the head of the

needle. The variation of fuel flow based on the height of the clip is

shown in Fig. 13 .

Generally, it is

easier to evaluate and

select a needle jet than it is

to select a jet needle. The

reason is that the needle

jet sizes are arranged on a

linear scale, with each size

increasing in increments .

(For a thorough

explanation of needle jet

sizes please refer to

Chapter 5.) let needles are

not cataloged according to

a linear size pattern or a

rich to lean scale. The

most effective way to

determine the needle jet /

jet needle relationsbip is to

visualize the jet needle as

a tool for setting the fuel

del i very curve, or the

shape of the fuel deli very

according to throllie

NEEDLE JET

100

opening. The needlc jet controls the fuel delivery rate, either

increasing or decreasing the fuel delivery according to the pro(i]e of

tbe needle being used. Sudco suggests that initially, experiments

should be limited to changes in needle jet size. Once a satisfactory

size has been identified, experiment with needle clip position to obtain

the best driveabililY and roll-on performance. If one is working with

an O.E.M. Mikuni carburetor, it is safe to assume that tbe

manufacturer has already selected the proper needle or "fuel curve"

for that motorcycle and changing the needle profile will complicate

the runing process. Once the correct needle jet size has been identified

and if becomes apparent that a change in needle profile is necessary,

then refer to the needle dimensiou chans in Chapter 5.

To evaluate the performance of the needle jet, run the

motorcycle in thl!d gear at 1/4 throttle, taking notes on how the engine

accelerates from 1/4 to 1/2 throttle only. The engine should respond

cleanly and crispLy without sputtering or bogging. It may be useful 10 try

experimenting witll clip positions to decide if a problem is a rich or lean

condition. If the engine response is \)coer at a lean clip position. it may be

necessary to change to a leaner needle jet Sudco suggests that it is best to

use as lean a needle jet as possible, as this component will have the

greatest effect on fuel economy, emissions, and general driveability. Lf a

leaner needle jet is installed and there is no negative impact on

perfonnancc, and no positive cffect. continue working in the direction of

"lean" Wltillhere are negative results and go back up one size.

D. - Selection of the Main Jet

First. do !lIe following on a flat road.

I) Select the largest main jet (the limit ofa rich mixture) which

can give you the ma'Cimum revolutions per minufe (the

maximum speed) , In this case, select the engine speed

according to the dimensions of the test course.

2) Compare the gain in speed that you can obtain by quick

acceleration rrom a constant speed of25-30 MPH to ma'"(imum

desired speed, by using different sizes of main jets .

3) Check the exhaust fumes and read the spark plug (selection

of the spark plug shonld be made based on the thermal value

that would best suit powcr oU'1>ut of the engine).

Next, compare on the racing course, the test results you

obtained from abovc. The points to be checked, amoug others, are:

I) Smooth and steady operation of the engine at as high a

speed as possible under varying operatiug couditions

sueh as shifting of the gears, changes in road conditions,

ascending and desccnding slopes, etc.

2) Sustained operation 8t low speeds and at heavy engine load

3) Sustained operation at high speeds (without knocking or seizure).

CAUTION : Sel~don of too lean a main jet may C41use

severe engine overheating, and subsequent pIston seizure.

Fig.12 shows comparison of fuel flow cu rYes. The straight

line is for Model C main jet and the dotted line for Model A

aDd B main jets. In each model of main jet, different sizes

within the range of +10% were tried.

61.

-----------:J.20 - 22/'41

,10-12."'. ·S-I()(lIl

-8 - 101%1

20- 211'41

,00

7

(I

SUDECARB

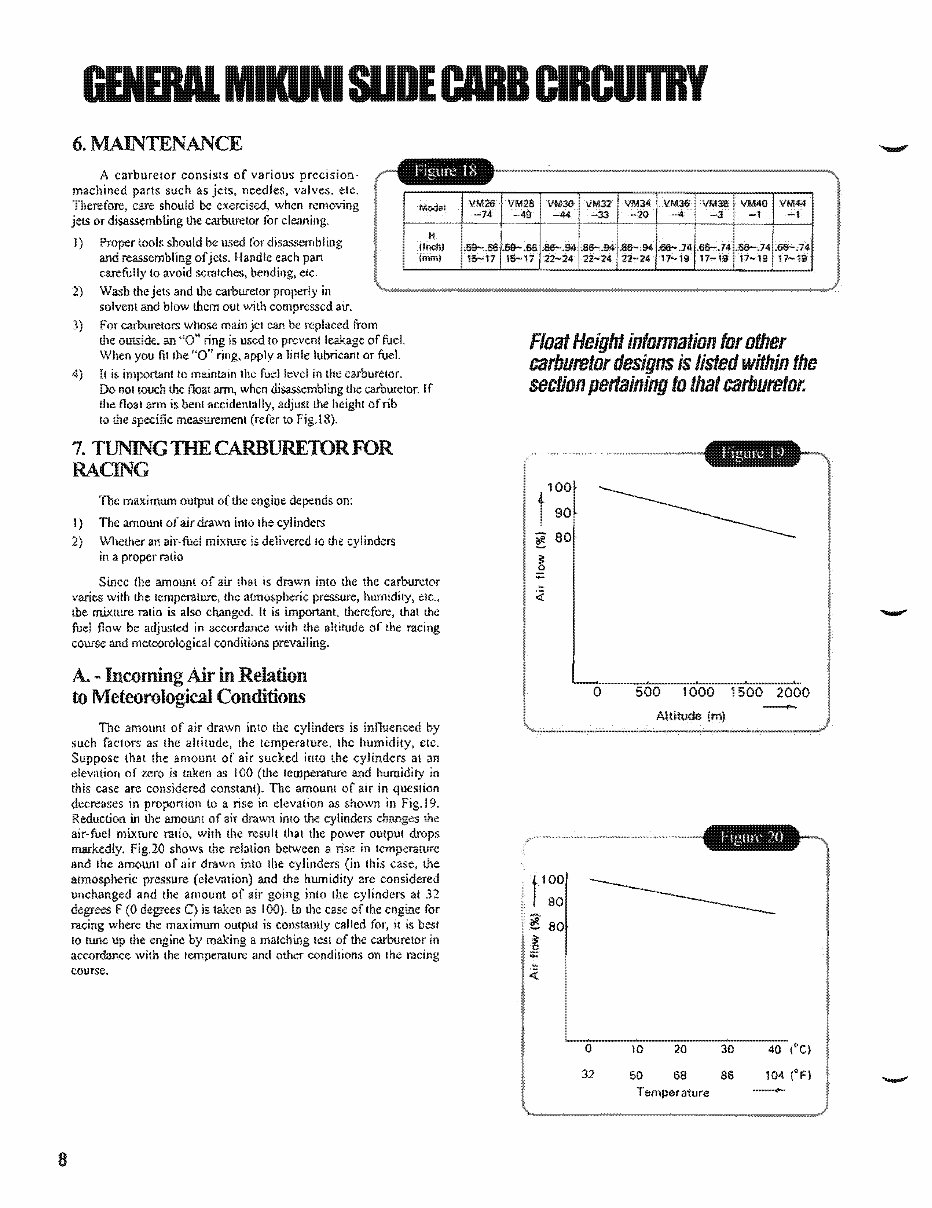

6. MAINTENANCE

A carburetor cOllsisls of various precision-

machined parts such as jets, needles, valves, ele,

lIell"""'<:;, care should be exercised, when removing

or disassembling !l1l: carburetor for

I) Proper tools should be used for 1'1\.<1.<, ... ,,1,,1 OM''''

and reassembling Handle each part

carefully 10 avoid scralches, elc.

2) Wash the jets and the carburetor

solvent and blow them out with ... "'m .... ,..,.·<r>rI alf.

3) For carburetors whose mainjel can be replaced from

the oUlSide.. an "0" is used 10 leakage of fuel.

Wllen you fil the "0" apply a lubricant or fuel.

4) II is importanllo maintain the fuel level in the carhurelor.

J:)() nOI touch the noat ann, when the carburetor. [f

the Aoat arm is benl accidentally, of rib

10 the specific measurement (refer to

TUNlNGlHE CARBURElORFOR

RACING

'n)e maximum output o(the engioe depends on:

1) The amount of air drawn into Ihe cylinders

2) Wlu:ther an air-fuel mix\l..!re is delivered to the

in iii proper ratio

Since the amount of air that is drawn inlo the the carburetor

varies with the temperature, the pressure, humidity, eIC.,

Lbe IJ"I.ixmre ralio is also II is therefore, thaI the

fuel flow be adjusted in accordance the altitude of the racing

course and meteorological condilions

A. - in Relation

to Meteorological Conditions

The amount of air drawn inlo the cylinders is innuenced by

such factors as the altitude, Ihe temperature, the clc.

that the amount of air sucked into the

elevation of zero is taken as 100 (the teillperarure humidity in

this case are considered The amount or air in question

decreases in proportion to a rise elevation as shown in Fig.19.

Reduction in tllC amount of air drawn into the cylinders changes the

air-fuel mixture ralio, with the result that the power output drops

m!lfkedly. Fig.20 shows the relation between II rise in lemperature

and the amount of air drawn into Ihe cylinders (in this case, the

and the humidi!y are considered

the amount of air going into the cylinders al 32

C) is taken as 100). lo the case of the for

where maximum output is constantly called best

10 tUIlc up the engine by making a lesE of the carburetor in

aceordance with the lemperature and otheT conditions on [he

course.

Float Height information for other

carburetor designs listed within the

section pertaining to that carburetor.

100

t 90

~ 80

~

o

:;:

b

<t.

t

lOD

90

~ 80

~

:;:

'-

<t.

a

o

31

500 1000 1500 2000

Altitude 1m)

10

50

20

68

Temperature

30

8S

-

40

104 (oFl

-

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Viewed 13 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

If your ATV is experiencing starting issues, backfiring, stalling, or power loss at high or low RPM, it may be time to give some attention to the carburetor. This article focuses on the maintenance of the Keihin CVK32 carburetor, but the principles discussed are applicable to other models as well.

Whether you are a professional mechanic or a DIY enthusiast, these manuals provide valuable insights and instructions for maintaining and troubleshooting your ATV's carburetor.