WORCESTER BOSCH GreenStar 35 HE Combi Installation And Servicing Instructions

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

6 720 610 893-01.TD

Installation and Servicing Instructions

R 30/35/40 HE plus combi

Wall mounted condensing boiler for central heating and mains

fed domestic hot water

ZWBR 7-30 R 30 HE plus GC-Number: 41 311 79

ZWBR 11-35 R 35 HE plus GC-Number: 41 311 80

ZWBR 11-40 R 40 HE plus GC Number 41 311 81

6 720 611 400 GB (03.11) TD

6 720 611 400 GB (03.11)

Contents

2

Contents

Safety precautions 3

Symbols 3

1 Details of the appliance 4

1.1 EC Declaration of Conformity 4

1.2 Standard package 4

1.3 Description of appliance 4

1.4 Accessories 5

1.5 Casing dimensions 5

1.6 Layout of appliance 6

1.7 Function 7

1.8 Electrical wiring diagram 8

1.9 Technical data 9

2 Installation regulations 10

3 Installation 11

3.1 Important remarks 11

3.2 Domestic hot water 11

3.3 Sealed systems 11

3.4 Siting the appliance 12

3.5 Wall mounting frame assembly 13

3.6 Pre-piping the system 13

3.7 Fitting the appliance 14

3.8 Checking the connections 15

3.9 Flue Systems 15

3.9.1 Siting the Flue Terminal 16

3.9.2 Installation of the flue 17

3.9.3 Flue duct preparation and assembly 19

4 Electrical connections 20

4.1 Connecting the appliance 20

4.2 Connecting TR2 Room thermostat 21

4.3 Mains Voltage external controls connections 21

5 Commissioning 22

5.1 Commissioning 22

5.2 Switching the appliance on/off 23

5.3 Switching on the central heating 23

5.4 System controls 23

5.5 Setting the domestic hot water temperature and flow

rate 24

5.5.1 Domestic hot water temperature 24

5.5.2 Hot water flow rate 24

5.6 Summer mode (hot water only) 24

5.7 Frost protection 24

5.8 Pump anti-seize function 24

5.9 Fault Condition 25

6 Text Display 26

6.1 General Description 26

6.2 Programming 26

6.2.1 Deleting a setting 27

6.2.2 Resetting all parameters to their original settings 27

6.3 Menu structure 27

6.4 Setting the time/day 28

6.4.1 Setting the time and day 28

6.4.2 Holidays 28

6.5 Heating 28

6.5.1 Heating programme 28

6.5.2 Setting Economy temperature (TR2 connected) 28

6.5.3 Manual operating mode (TR2 not connected) 29

6.6 Hot water 29

6.6.1 Hot water programme 29

6.6.2 Hot water immediately 29

6.7 i Info 29

6.8 Settings 30

6.8.1 Heating (if TR 2 is connected) 30

6.8.2 Hot Water (Storage Tank, system models only) 30

6.8.3 Service 30

6.9 Individual timer programmes 30

7 Individual settings 31

7.1 Mechanical settings 31

7.1.1 Checking the size of the expansion vessel 31

7.1.2 Setting the central heating flow temperature 31

7.2 Settings on the Bosch Heatronic 31

7.2.1 General description 31

7.2.2 Setting the anti-cycle time

(Service Function 2.4) 32

7.2.3 Setting the maximum CH flow temperature (Service

Function 2.5) 32

7.2.4 Setting the heating output

(Service Function 5.0) 32

7.2.5 Constant hot water cycle time

(Service Function 6.8) 32

7.2.6 Variable pump settings

(Service Function 7.0) 32

7.3 Setting the gas/air ratio 32

8 Converting the appliance to different

gas types 33

8.1 Setting the gas/air ratio 33

8.2 Testing combustion air/flue gas at set heat output 35

8.2.1 Testing the O2 or CO2 level in the combustion air 35

8.2.2 Testing CO and CO2 35

9 Maintenance 36

9.1 Pre-Service Check List 37

9.2 Description of servicing operations 38

9.3 Replacement of Parts 41

9.3.1 PCB control board and transformer 41

9.3.2 Fan Assembly 42

9.3.3 Pump 42

9.3.4 3-way diverter valve 43

9.3.5 3-way diverter valve motor 43

9.3.6 Sensors 43

9.3.7 Gas Valve 44

9.3.8 Domestic Hot Water Heat Exchanger 44

9.3.9 Electrode assembly 44

9.3.10 Pressure gauge 44

9.3.11 Expansion vessel 44

9.3.12 Pressure Relief Valve 44

9.3.13 Burner 44

9.3.14 Flow switch 45

9.3.15 Primary Heat Exchanger 45

10 Appendix 46

10.1 Fault Codes 46

10.2 Short parts list 47

10.3 Heating/hot water output settings R 30 HE N.G. 48

10.4 Heating/hot water output settings R 30 HE L.P.G 48

10.5 Heating/hot water output settings R 35 HE N.G. 48

10.6 Heating/hot water output settings R 35 HE L.P.G 48

10.7 Operational Flow diagrams 49

10.7.1 Domestic hot water function 49

10.7.2 Central heating function 5010.7.2Central heating

function 50

6 720 611 400 GB (03.11)

Safety precautions

3

Safety precautions

If you smell gas

B Turn off gas service cock at the meter.

B Open windows and doors.

B Do not operate any electrical switches.

B Extinguish any naked flames.

B Telephone your gas company.

If you smell fumes from the appliance

B Switch off appliance (see page 23).

B Open windows and doors.

Fitting and modifications

B Fitting of the appliance or any controls to the appli-

ance may only be carried out by a competent engi-

neer in accordance with the Gas Safety (Installation

and Use) Regulations 1998.

B Flue systems must not be modified in any ways other

than as described in the fitting instructions.

B This appliance is for use on sealed primary systems only.

Maintenance

B The user is recommended: to have the system

regularly serviced in order to ensure that it functions

reliably and safely.

B Use only original spare parts!

Combustible materials

B Do not store or use any combustible materials

(paper, thinners, paints etc.) in the vicinity of the

appliance.

Health and safety

B This appliance contains no asbestos products.

B There is no potential hazard due to the appliance

being electrically unsafe.

B There are no substances used in the construction

that are a potential hazard in relation to the COSHH

Regulations (Control of Substances Hazardous to

Health Regulations 1988).

Combustion air/Ambient atmosphere

B The combustion air/ambient atmosphere should be

kept free of chemically aggressive substances (e.g.

halogenated hydrocarbons which contain chlorine or

fluorine compounds). This will prevent corrosion.

Instructions to the customer

B Explain to the customer how the appliance works and

how to operate it.

B Advise the user that he/she must not make any modi-

fications to the appliance or carry out any repairs on it.

B These instructions are to be left with the user or at

the Gas meter.

B Important: These instructions apply in the UK only.

Unpacking

IMPORTANT HANDLING INSTRUCTIONS

B Two people should transfer the packaged appliance

from the van to the point of installation

B Open the top of the carton, remove and place the

component tray and both side bars of the wall mount-

ing frame to one side

B Lie the packaged appliance on its back. (The back

has “TRUCK HERE” printed on the carton)

B One person firmly holds the packaging while the

other straddles the boiler and slides it from the pack-

aging

B Two persons are then required to lift one end and

stand the appliance upright with the flue at the top

Additional requirements for roof space instal-

lation

B Two people should use two step ladders and share

lifting the unpacked boiler up to the loft hatch

B Where the boiler enters the loft space, tilt and slide

the boiler on its back to the point of installation

Check the contents against the packing list.

Symbols

Safety instructions in this document

are identified by a warning-triangle sym-

bol and are printed on a grey back-

ground.

i

Notes containing important information

are identified by the symbol shown on the

left. They are bordered by horizontal lines

above and below the text.

6 720 611 400 GB (03.11)

4

Details of the appliance

1 Details of the appliance

1.1 EC Declaration of Conformity

This appliance is in accordance with the applicable

requirements of the Gas Appliance Directive, Boiler Effi-

ciency Directive, Electromagnetic Compatibility Direc-

tive and the Low Voltage Directive.

1.2 Standard package

• Gas condensing combination boiler for central heat-

ing and domestic hot water

• Control panel cover

• Wall mounting frame

• Fixings (screws etc.)

• Set of documentation for appliance

• Pre-plumbing manifold

• Condensate drain pipe

• Filling loop.

1.3 Description of appliance

• Wall-mounted appliance.

• Natural gas models are low-emission appliances

• Multi function display

• Bosch Heatronic control system with integrated text

display for service functions and faults

• 3-channel - digital timer for one heating circuit

• Variable pump

• Automatic ignition

• Modulating control

• Full safety systems incorporating Bosch Heatronic

with flame ionisation monitoring, solenoid valves and

temperature sensors

• Concentric flue/air duct with testing point for

CO

2

/CO

• Regulated speed fan

• Pre-mix burner

• Temperature control for central heating

• Temperature sensor in domestic hot water

• Safety temperature limiter in 24 V electrical circuit

• Relief valve, pressure gauge, expansion vessel, Auto

air vent

• Flue gas temperature limiter (105 °C)

• Hot water priority circuit

• Motorised 3-way valve

• Plate-type heat exchange

• Condensate Trap.

PIN CE-0085 BL0507

Category UK II

2H 3P

Appliance Type C

13

, C

33

Table 1

6 720 611 400 GB (03.11)

Details of the appliance

5

1.4 Accessories

• Standard horizontal flue kit at 100 mm outside

diameter for flues up to 4 m in length (3.5m for the R

40 HE).

• Flue duct kits for horizontal (125 mm outside

diameter) for flue lengths up to 13m or 10m (R 35 &

40 HE) and vertical flue systems for flue lengths up

to 13.7m or 10.7m (R 35 & 40 HE). Fitting instruc-

tions are sent with these kits.

• TR2 Room Temperature Controller..

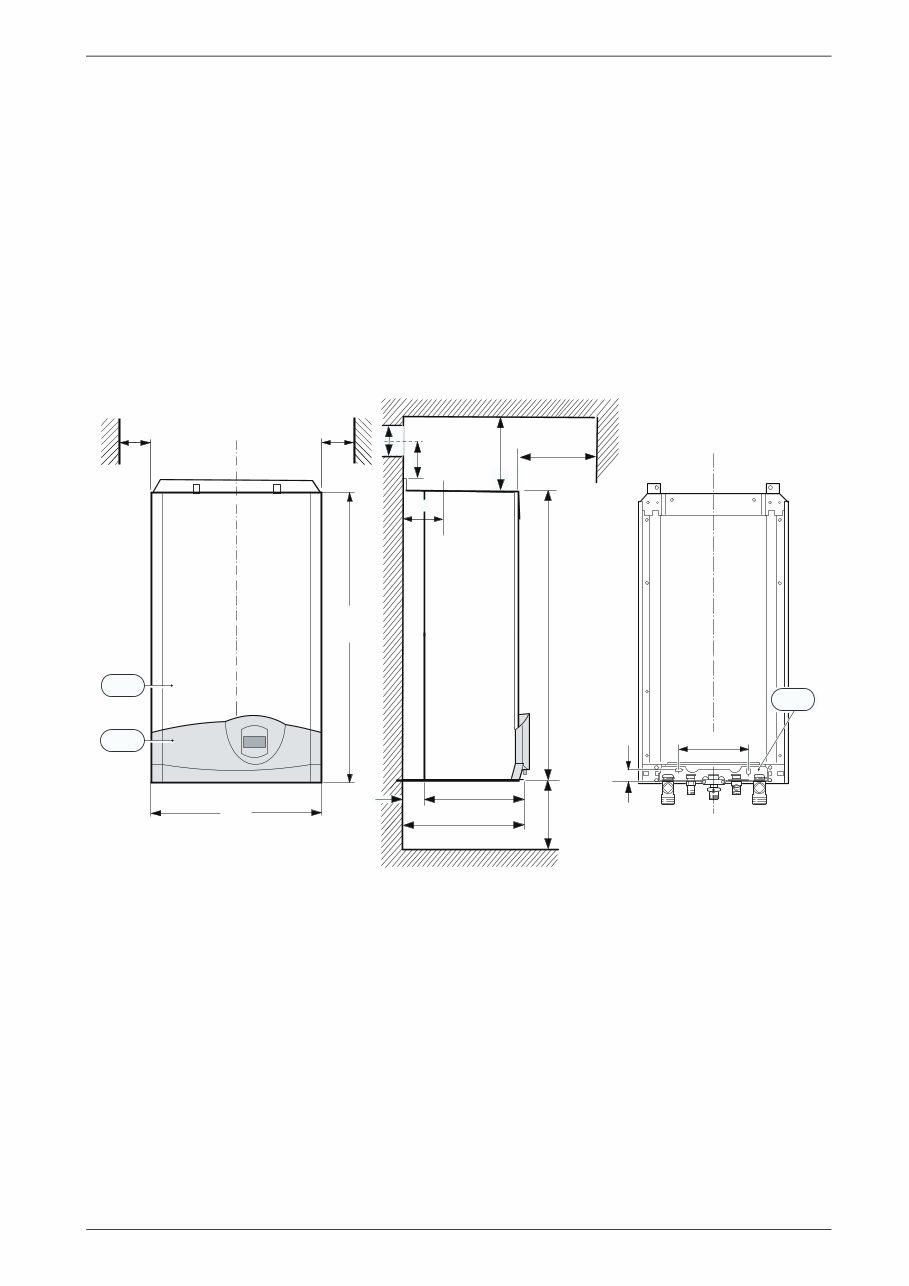

1.5 Casing dimensions

Fig. 1

13 Manifold assembly

101 Outer case

103 Facia cover

X Standard Concentric Horizontal Flue System: min. 160 mm

Alternative Concentric Flue System: min. 220 mm

Y Standard Concentric Horizontal Flue System: 40 mm

Alternative Concentric Flue System: 70 mm

Z Standard Concentric Horizontal Flue System: 105 mm

Alternative Concentric Flue System: 130 mm

* For servicing the appliance

Note: Horizontal flue only: dimension X may need to increase due

to the incline of the flue.

6 720 610 599 - 01.TD

200

30

13

395

360

850

35

X

120

Y

Z

200

*

* 600

min .

10*

min .

440

850

101

103

10*

6 720 611 400 GB (03.11)

6

Details of the appliance

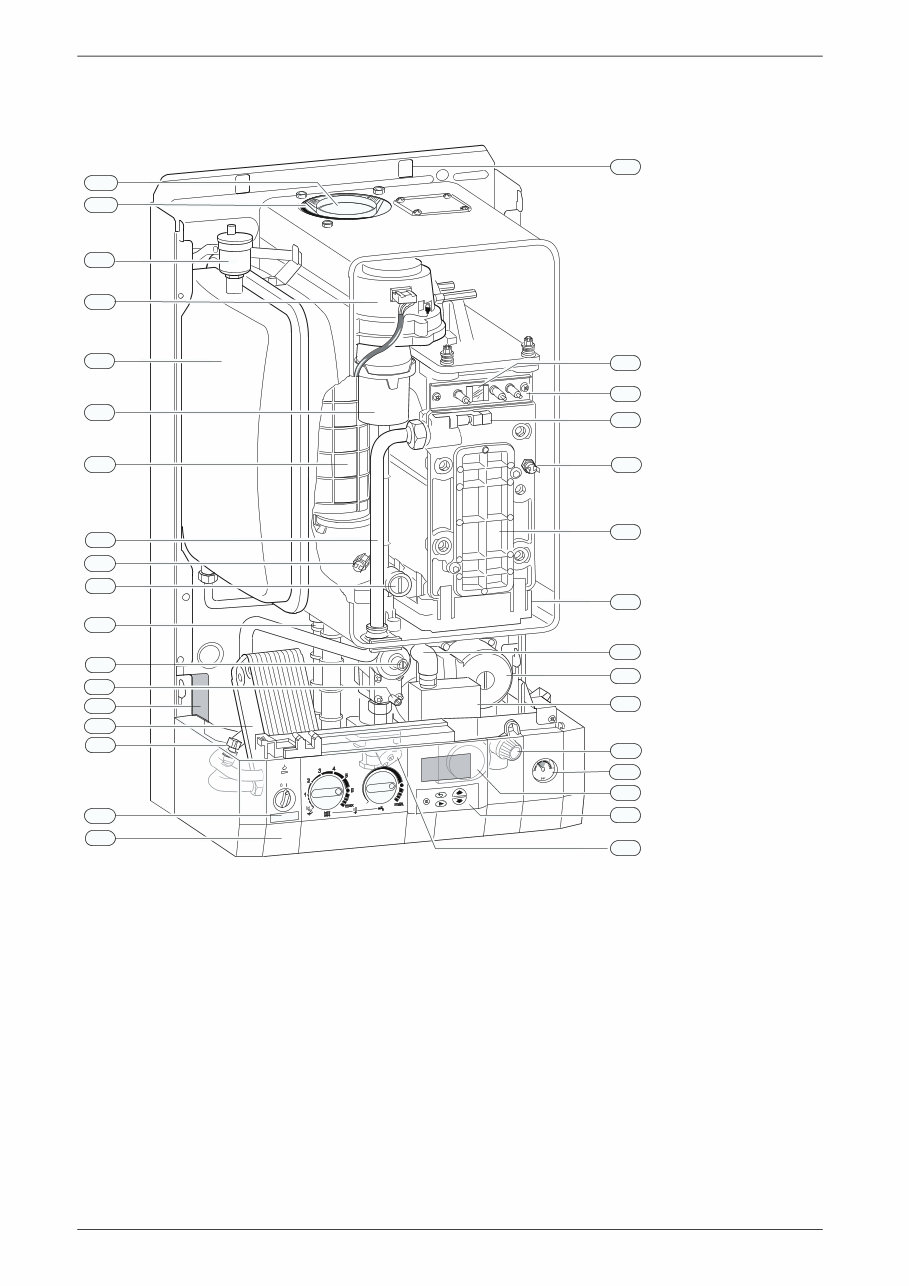

1.6 Layout of appliance

Fig. 2

4 Heatronic control

6 Heat exchanger safety temperature limiter

6.1 Hot water NTC sensor

7 Testing point for gas supply pressure

8.1 Pressure gauge

9 Flue gas temperature limiter

15 Relief valve

18 Pump

20 Expansion vessel

27 Automatic air vent

29 Air gas Mixer unit

32.1 Electrode assembly

36 Temperature sensor in CH flow

43 CH flow

63 Adjustable gas flow restrictor

64 Adjusting screw for min. gas flow volume

88 3-way valve (combi)

98 DHW flow switch (combi)

102 Inspection window

120 Fixing points

221.1 Flue duct

221.2 Combustion air intake

226 Fan assembly

295 Appliance type sticker

271 Flue duct

355 Plate-type domestic hot water heat exchanger

358 Condensate trap

396 Hose Condensate trap

400 Text display

415 Cover plate for cleaning access

416 Condensate collector

418 Data plate

423 Siphon

6 720 610 599 - 00.TD

29

98

102

226

271

416

20

43

9

63

358

64

7

355

6.1

4

415

6

36

32.1

295

8.1

18

27

88

15

120

418

400

396

423

221.1

221.2

6 720 611 400 GB (03.11)

Details of the appliance

7

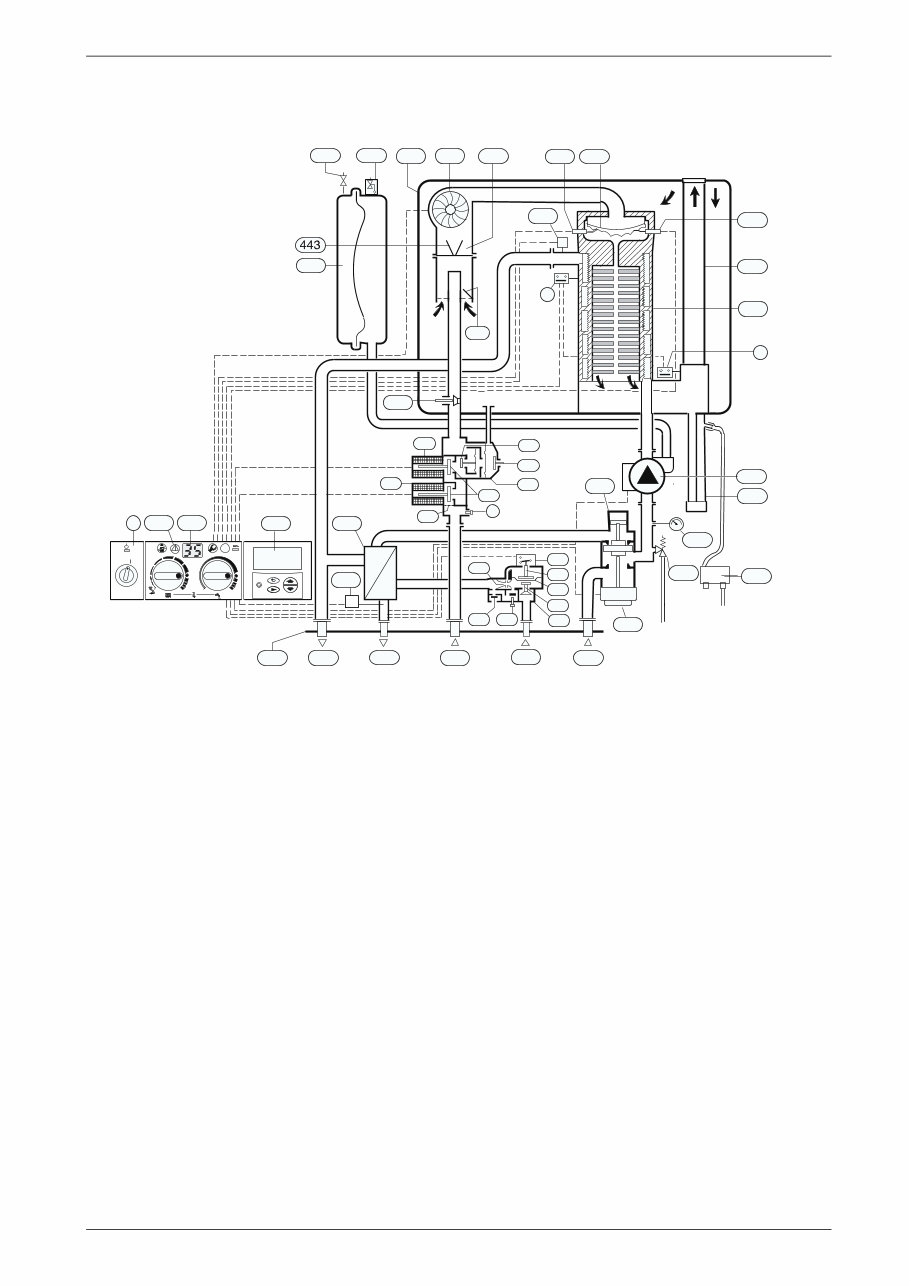

1.7 Function

Fig. 3

4 Bosch Heatronic control

6 Temperature limiter, heat exchanger

6.1 Hot water NTC sensor

7 Testing point for gas supply pressure

8.1 Pressure gauge

9 Flue gas temperature limiter

13 Manifold

15 Safety valve

18 Central heating pump

20 Expansion vessel

26 Charging valve

27 Automatic vent

29 Mixer unit

29.1 Bi-metallic thermostat for combustion air compensation

30 Burner

32 Flame sensing electrode

33 Igniter electrode

35 Heat exchanger with cooled combustion chamber

36 Temperature sensor in CH flow

43 CH flow

44 Hot water flow

45 Gas

46 Cold water inlet

47 CH return

52 Solenoid valve 1

52.1 Solenoid valve 2

55 Filter

56 Gas valve CE 427

57 Main valve disc

61 Reset button

63 Gas flow restrictor, adjustable for max. gas flow volume

64 Adjusting screw for min. gas flow volume

69 Control valve

84 Motor

88 3-way valve

90 Venturi

91 Pressure relief valve

93 Water flow regulator

94 Diaphragm

95 Pushrod with switch cam

96 Microswitch

97 Valve for hot water flow volume

98 Water valve

221 Flue duct

226 Fan

229 Air box

317 Display

355 Plate-type heat exchanger

358 Condensate trap

400 Text display

423 Siphon

443 Diaphragm

6 720 610 597-

03.2O

42

3

J

33 29 30 226 229 26

6

36

29.1

63

15

45 47

20

43 44 46 13

8.1

84

90

97 98

93

94

95

96

91

69

64

57

52.1

56 52

55

7

355

M

358

18

88

max max

1

2

3 4

5

E

ECO

0

317 61 4 400

32

9

35

221

J

27

6.1

6 720 611 400 GB (03.11)

8

Details of the appliance

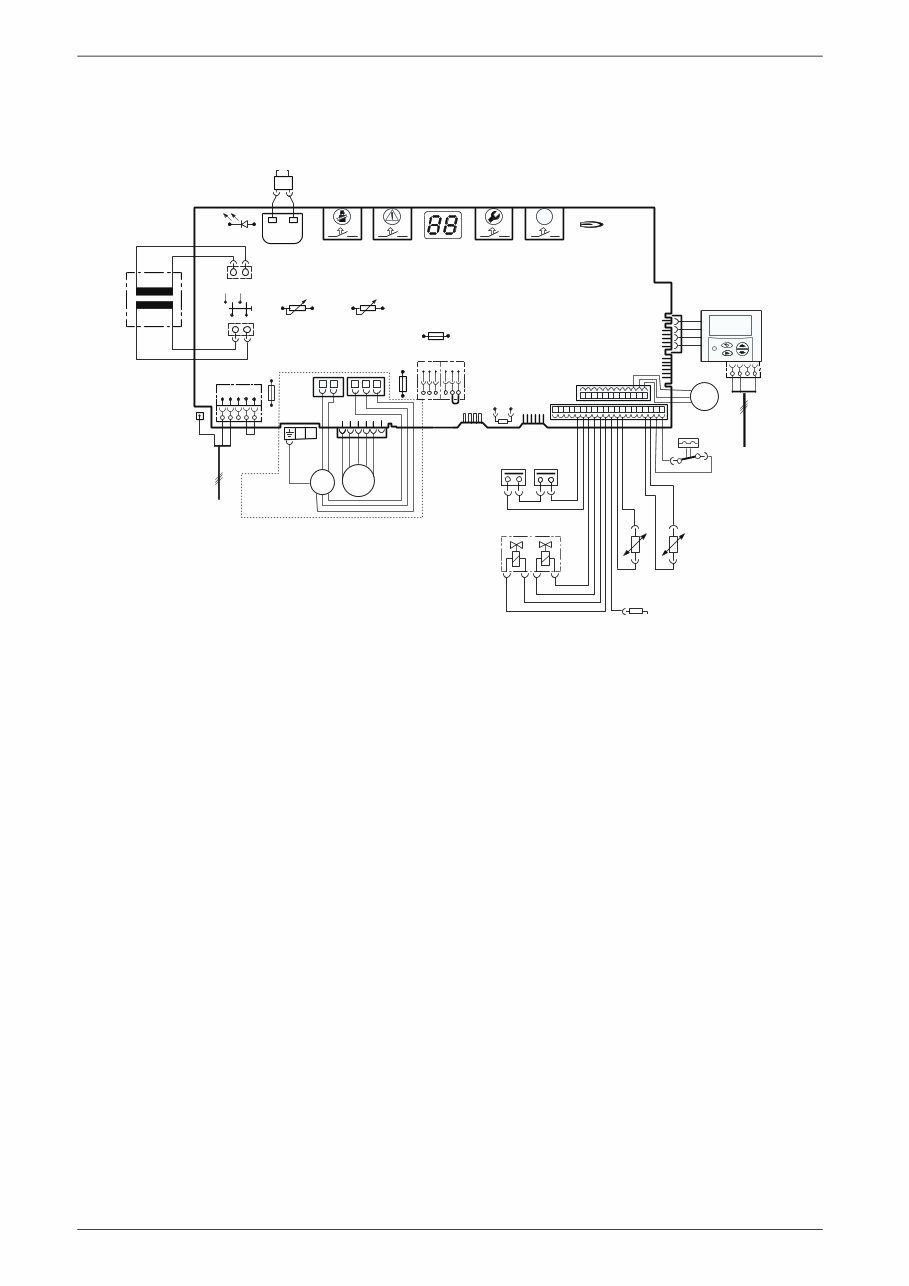

1.8 Electrical wiring diagram

Fig. 4

4.1 Ignition transformer

6 Temperature limiter, heat exchanger

6.1 Hot water NTC sensor

9 Flue gas temperature limiter

18 Pump

32 Flame sensing electrode

33 Ignition electrode

36 Temperature sensor in CH flow

52 Solenoid valve 1

52.1 Solenoid valve 2

56 Gas valve CE 427

61 Reset button

84 Motor, 3-way valve

96 Microswitch, hydraulic switch

135 Master switch

136 Temperature control for CH flow

151 Fuse, slow 2.5 A, AC 230 V

153 Transformer

161 Link

226 Fan

300 Code plug

302 Earth connection

310 Temperature control for hot water

312 Fuse, slow T 1,6 A

313 Fuse, slow T 0,5 A

317 Digital display

328 Terminal block for AC 230 V Mains supply

328.1 Link

363 Indicator lamp for burner

364 Indicator lamp for power supply

365 “Chimney sweep” button

366 Service button

367 ECO button

400 Text display

422 Connecting TR2

6 9

32

33

36

52.1 52

56

61

230 V

135

25 V

230V/AC

153

136

151

124 789

161

M 226

300

LN Ls Ns

328

LR

302

310

312

313

317 363 364 365 366

ECO

367

4.1

328.1

6.1

18

84

96

M

400

4 3 F

M

6 720 610 602 - 02.1O

mains supply

422

o - orange g - green bl - black r - red p - purple

r

r

bl

bl

bl

bl bl

o

o

o

o

g

g

p

p

p

6 720 611 400 GB (03.11)

Details of the appliance

9

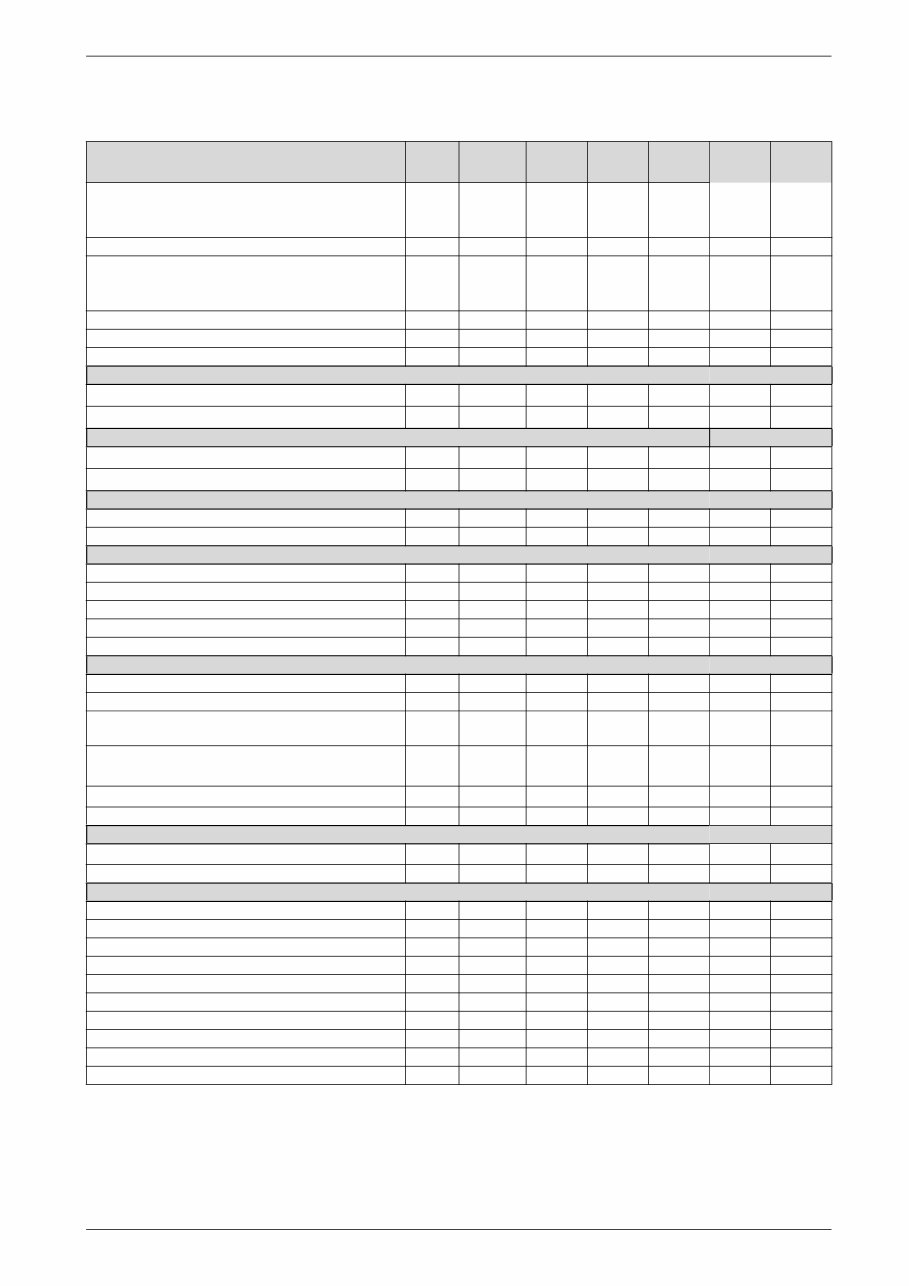

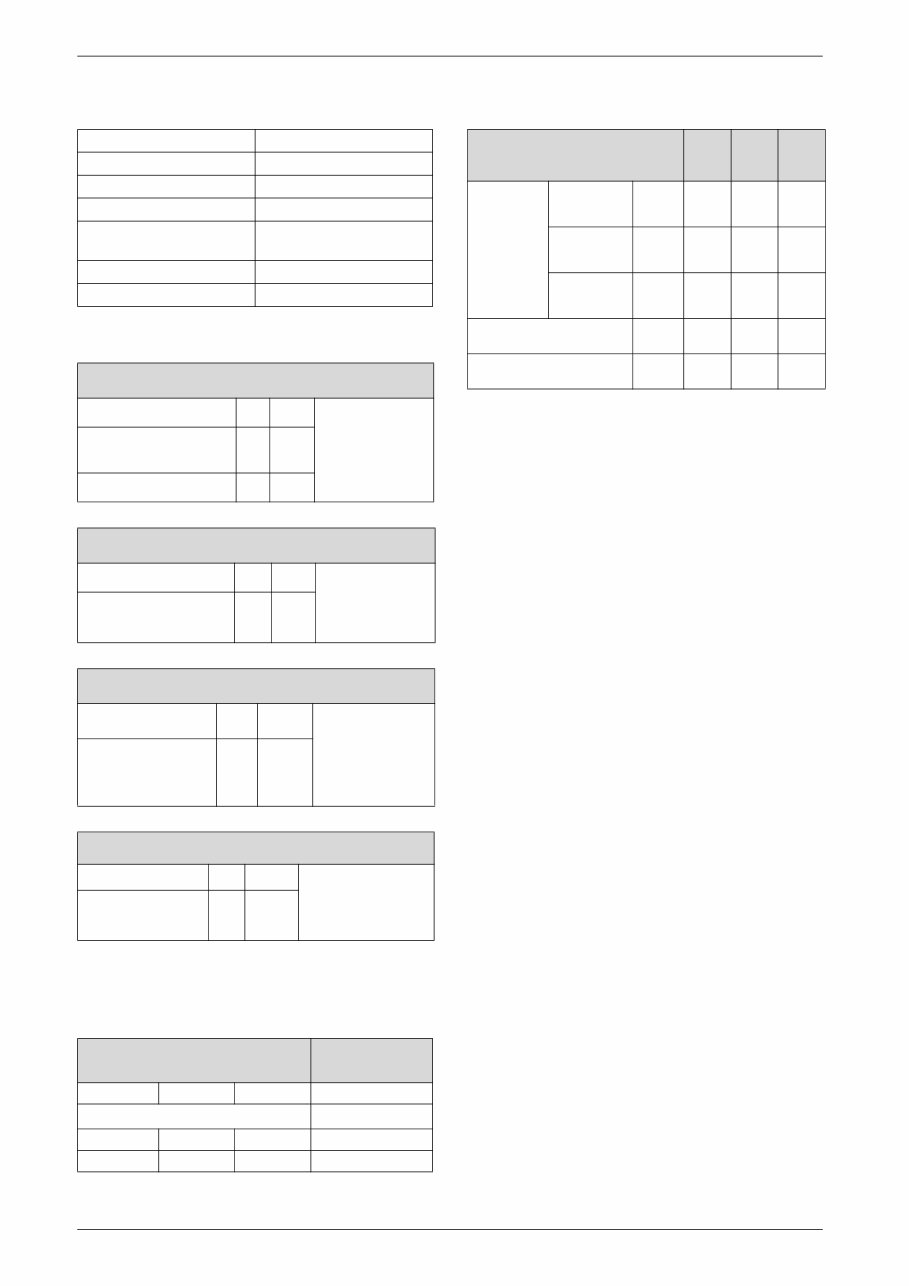

1.9 Technical data

Units

R 30 HE

NG

R 30 HE

Propane

R 35 HEi

NG

R 35 HE

Propane

R 40 HE

NG

R 40 HE

Propane

Max. rated heat output net 40/30°C central heating

Max. rated heat output net 50/30°C central heating

Max. rated heat output net 80/60°C central heating

kW

kW

kW

31.2

30.9

29.2

31.2

30.9

29.2

37.5

37.1

35.1

37.5

37.1

35.1

41.4 41.4

41.4 41.4

39.1 39.1

Max. rated heat input net kW 29.5 29.5 35.5 35.5 40.0 40.0

Min. rated heat output net 40/30°C

Min. rated heat output net 50/30°C

Min. rated heat output net 80/60°C

kW

kW

kW

8.4

8.3

7.4

11.6

11.4

10.5

12.9

12.8

11.4

16.2

16.1

14.3

12.9 16.2

12.8 16.1

11.4 14.3

Min. rated heat input net kW 7.6 10.8 11.8 14.8 11.8 14.8

Max. rated heat output net, domestic hot water kW 29.2 29.2 35.1 35.1 39.1 39.1

Max. rated heat input net, domestic hot water kW 29.5 29.5 35.5 35.5 40 40

Maximum gas flow rate – After 10 minutes from lighting

Natural gas G20 (CVnet 34.02 MJ/m

3

) m

3

/h

3.1 3.7

4.2

LPG (CVnet 88 MJ/m

3

)

kg/h 2.3

3.2

Gas supply pressure

Natural gas G20 (CVnet 34.02 MJ/m

3

)

mbar 20 - 20 -

20 -

LPG (CVnet 88 MJ/m

3

)

mbar - 37 - 37

- 37

Expansion vessel

Charge pressure bar 0.75 0.75 0.75 0.75 0.75 0.75

Total capacity l 10 10 10 10 10 10

Hot water specifications

Hot water flow rate @ 35° rise l/min 12.1 12.1 14.6 14.6 16.4 16.4

Outlet temperature range °C 40 - 60 40 - 60 40 - 60 40 - 60 40 - 60 40 - 60

Max. permissible water supply pressure bar 10 10 10 10 10 10

Min. inlet pressure for maximum flow rate bar 1.2 1.2 1.2 1.2 1.2 1.2

Specific flow rate @ 30°C l/min 13.3 13.3 16.0 16.0 18.0 18.0

Flue

Flue gas temp. 80/60°C, rated/min. load °C 67/55 67/55 87/58 87/58 87/58 87/58

Flue gas temp. 40/30°C, rated/min. load °C 43/32 43/32 65/43 65/43 65/43 65/43

Residual delivery pressure (inc. pressure drop in air

intake duct)

Pa 80 80 100 100 100 100

CO

2

level at max. rated heat output

CO

2

level at min. rated heat output

%

%

9.2

8.8

10.8

10.5

9.2

9.2

11.0

11.0

9.2

9.2

10.8

10.8

NO

x

-class 5 5 5 5

5 5

SEDBUK figure Band A A A A A A

Condensate

Max. condensation rate (t

R

= 30°C) l/h 2.5 2.5 3.0 3.0

3.5 3.5

pH-value, approx. pH 4.8 4.8 4.8 4.8 4.8 4.8

General Data

Electrical power supply voltage AC ... V 230 230 230 230 230 230

Frequency Hz 50 50 50 50 50 50

Max. power consumption W 125 125 152 152 183 183

Noise output level dB(A) 37 37 40 40 42 42

Appliance protection rating IP X4D X4D X4D X4D X4D X4D

Max. CH flow temperature °C nom. 90 nom. 90 nom. 90 nom. 90 nom. 90 nom.90

Max. permissible operating pressure (CH) bar 2.5 2.5 2.5 2.5 2.5 2.5

Permissible ambient temperatures °C 0 - 50 0 - 50 0 - 50 0 - 50 0 - 50 0 - 50

Nominal capacity of appliance l 3.75 3.75 3.75 3.75 3.75 3.75

Weight (excluding packaging) kg 46 46 46 46 46 46

Table 2

6 720 611 400 GB (03.11)

10

Installation regulations

Condensate analysis, mg/l

Flue system

Elbow - 90 ° Equivalent length 2 m

Bend - 45 ° Equivalent length 1m

Gas supply

Domestic water performance

2 Installation regulations

Gas Safety (Installation & Use) Regulations 1998: All

gas appliances must be installed by a competent per-

son. Failure to install correctly could lead to prosecu-

tion.

The manufacturers notes must not be taken, in any way,

as overriding statutory obligations.

The appliance must be installed in accordance with the

current IEE Wiring Regulations, local Building Regula-

tions, Building Standards (Scotland) (Consolidation),

bye-laws of the local Water Company, Health and

Safety Document 635 (Electricity at Work Regulations

1989) and any other local requirements.

Product Liability regulations indicate that, in certain cir-

cumstances, the installer can be held responsible, not

only for mistakes on his part but also for damage result-

ing from the use of faulty materials. We advise the

installer to avoid any risk by using only quality approved

branded fittings.

The relevant British Standards should be followed i.e.

• BS 6798: Specification for the installation of gas

fired hot water boilers of rated input not exceeding

60kW

• BS 5449: Central Heating for Domestic Premises

• BS 5546: Installation of gas hot water supplies for

domestic purposes

• BS 5440:1: Flues and ventilation for gas appliances

of rated input not exceeding 70 kW (net): Flues

• BS 5440:2: Flues and ventilation for gas appliances

of rated input not exceeding 70 kW (net): Air

Supply

• BS 6891: Installation of low pressure gas pipework

installations up to 28mm (R1).

• BS 7074:1: Code of practice for domestic heating

and hot water supply

• BS 7671: Requirements for Electrical Installation.

These instructions must be followed.

Ammonium 1.2 Nickel 0.15

Lead ≤ 0.01 Mercury ≤ 0.0001

Cadmium ≤ 0.001 Sulphate 1

Chromium ≤ 0.005 Zinc ≤ 0.015

Halogenated

hydrocarbons ≤ 0.002

Tin ≤ 0.01

Hydrocarbons 0.015 Vanadium ≤ 0.001

Copper 0.028 pH-value 4.8

Table 3

HORIZONTAL 100 mm – Standard FLUE SYSTEM

Overall Diameter of Duct mm 100

Max. 4 m

(R30 & 35 HE)

Max 3.5m

(R40 HE)

Flue Terminal / Duct

Assembly Length

mm 600

Extension Duct Length mm 1000

Table 4

HORIZONTAL 125 mm FLUE SYSTEM

Overall Diameter of Duct mm 125 Max. 13 m

(R30HE)

Max. 10m (R35 &

40 HE)

Flue Terminal / Duct

Assembly

mm 1030

Table 5

VERTICAL 100mm FLUE SYSTEM

Overall Dia. of Duct mm 100 Excl. terminal:

Max. 6.4m (R30

& 35 HE)

Max. 5.5m

(R40HE)

Flue Terminal / Duct

Assembly Length

mm 1140

Table 6

VERTICAL 125 mm FLUE SYSTEM

Overall Dia. of Duct mm 125 Excl. terminal: Max.

13.7 m (R30HE)

Max. 10.7 m

(R35 & 40HE)

Flue Terminal / Duct

Assembly

mm 1365

Table 7

Total length of gas supply pipe

(metres)

Pipe diameter

(mm)

3 6 9

Gas discharge rate (m

3

/h)

8.7 5.8 4.6 22

18.0 12.0 9.4 28

Table 8

R 30

HE

R 35

HE

R 40

HE

Domestic

Water Flow

Rate l/min

Tempera-

ture Rise

30 °C 14.2 17.0

19.2

Tempera-

ture Rise

35 °C 12.1 14.6

16.4

Tempera-

ture Rise

40 °C 10.6 12.8

14.4

Maximum Mains pressure bar 10.0 10.0

10

Minimum Mains pressure bar 0.2 0.2

0.2

Table 9

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$28.99

Viewed 14 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$28.99

Get detailed information on how to fix or maintain your boiler with the GAM Boiler Manuals. These manuals are model-specific and not generic, making them useful for both professional mechanics and DIY enthusiasts. By having this manual, you can prevent yourself from being misled by unethical repairmen and gain a full understanding of your device.

The manual contains detailed information for every owner and user alike, making it a valuable resource for anyone looking to maintain or repair their boiler. It will be made available instantly upon completion of payment, eliminating the need to wait for unreliable postal delivery. Additionally, you can print only the pages you need, making it a convenient and practical resource.