Toyota Diesel Forklift Truck 7FDAU50, 7FDKU40, 7FDU35, 7FDU45, 7FDU60, 7FDU70, 7FDU80 Workshop Service Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

FOREWORD

This manual covers the service procedures of the TOYOTA FORKLIFT

7FGU17FDU35 - 80 series and 7FGCU35 - 70 series. Please use this manual

for providing quick, correct servicing of the corresponding forklift models.

This manual deals with the above models as of December 2000. Please

understand that disagreement can take place between the descriptions in the

manual and actual vehicles due to change in design and specifications. Any

change or modifications thereafter will be informed by Toyota Industrial Equip-

ment Parts & Service News.

For the service procedures of the mounted engine, read the repair manuals

listed below as reference together with this manual.

(Reference)

Repair manuals related to this manual are as follows:

TOYOTA G4 (GM6-262) ENGINE

REPAIR MANUAL (No. C4630)

TOYOTA 11Z,12Z,13Z,14Z ENGINE

REPAIR MANUAL (No. C4615)

TOYOTA MOTOR CORPORATION

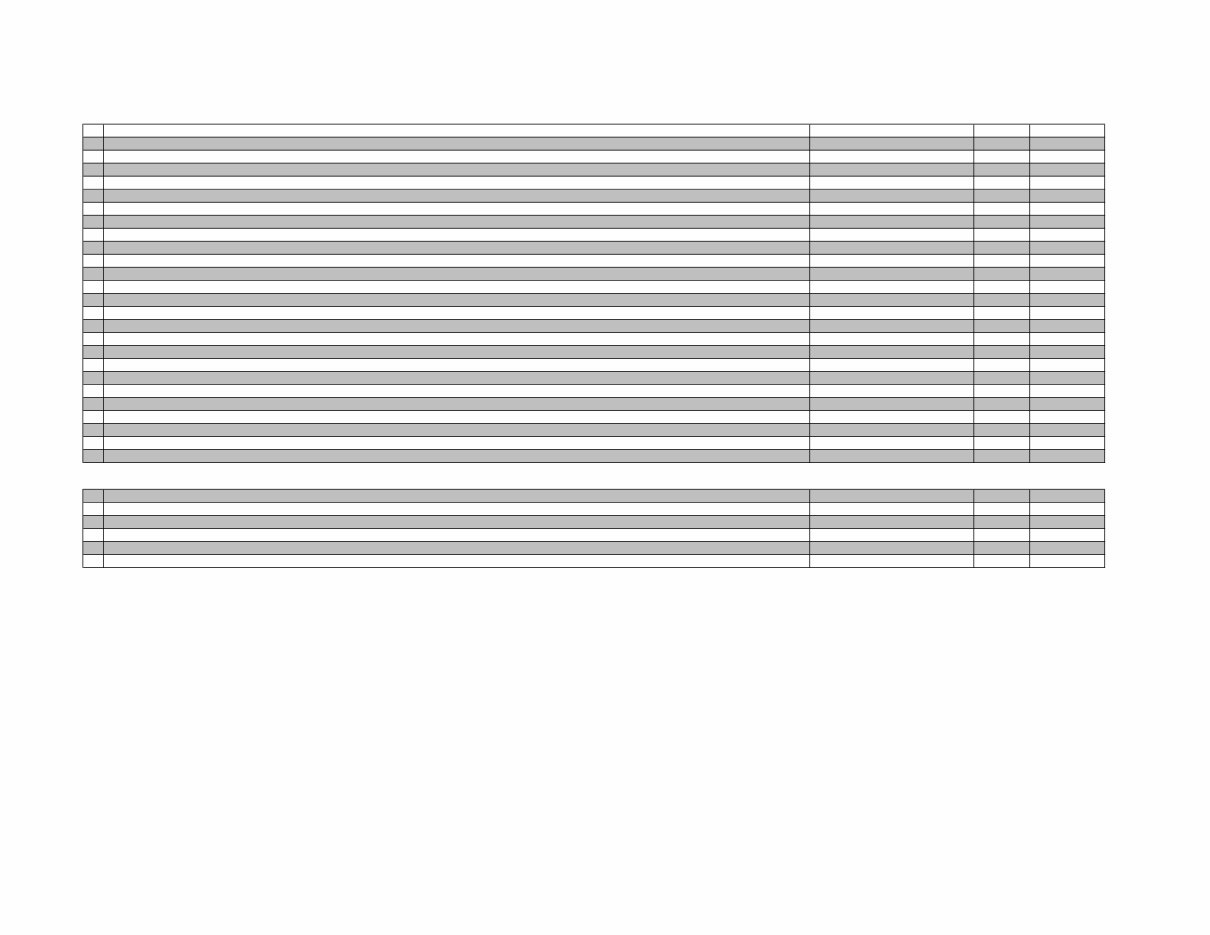

Service Information Bulletins affecting Models 7FG(D)U35-80 and 7FGCU35-70 REV: 2/29/08

Title File File Size Modified On

1 SIB MA04-001 Revision of Repair Manual for 7FG/DU35-80 & 7FGCU35-70 ma04-001.pdf 2739 KB 4/26/2006

2 SIB MA02-001 GM 6-262 Timing & Idle Adjustment Procedure Change ma02-001.pdf 237 KB 5/3/2006

3 SIB FS06-001 13Z Updated Fuel System Components fs06-001.pdf 278 KB 5/8/2006

4 SIB FS06-002 LPG Pre-Filter Service Parts fs06-002.pdf 62 KB 5/8/2006

5 SIB CE05-004 Starter Motor Engagement Delay (All I.C. Units) ce05-004.pdf 1018 KB 5/25/2006

6 SIB BR06-001 Stiffer Inching Pedal Spring br06-001.pdf 77 KB 6/1/2006

7 SIB EN04-004 13Z Injection Pump Changes en04-004.pdf 505 KB 6/7/2006

8 SIB MA05-003 Change to Periodic Replacement Parts (4Y & GM6-262) ma05-003.pdf 45 KB 6/7/2006

9 SIB EN04-001 EPA Compliant Three Way Catalyst System Identification & New SST en04-001.pdf 210 KB 6/7/2006

10 SIB EN03-004 Exhaust Y-Pipe Cracking en03-004.pdf 323 KB 6/7/2006

11 SIB CE01-005 Combination Meter Membrane Grease ce01-005.pdf 385 KB 6/8/2006

12 SIB FA06-001 Changes to Reamer Bolt Torque Specification fa06-001.pdf 82 KB 10/18/2006

13 SIB MA07-001 Caution During Oil Filling ma07-001.pdf 126 KB 1/31/2007

14 SIB FS07-001 New Fuel System for GM6-262 fs07-001.pdf 175 KB 1/31/2007

15 SIB MA07-001R Caution During Oil Filling ma07-001r.pdf 190 KB 6/27/2007

16 SIB FS07-002 MIL Strategy Change fs07-002.pdf 75 KB 6/27/2007

17 SIB FS07-003 ECM calibration revisions and DTC updates fs07-003.pdf 163 KB 7/12/2007

18 SIB CE07-002 Wiring Diagrams for Spectrum Fuel System ce07-002.pdf 3247 KB 9/25/2007

19 SIB ST07-002 Recommended Service Tools for a Field Service Technician st07-002.pdf 84 KB 9/25/2007

20 SIB FS07-004 New Spectrum DTC 652 and 653 fs07-004.pdf 87 KB 10/26/2007

21 SIB FS07-008 New Spectrum DTC 9999 and 1151 fs07-008.pdf 53 KB 10/26/2007

22 SIB FS07-005 New Spectrum DTC 627, 628, and 629 fs07-005.pdf 141 KB 10/26/2007

23 SIB CE07-006 Introduction of VSCS Vehicle Speed Control System ce07-006.pdf 741 KB 10/26/2007

24 SIB FS07-006 Spectrum Fuel System Relay Change fs07-006.pdf 77 KB 11/16/2007

25 SIB BF08-002 Product Improvement for 7FGU/7FDU35-80, 7FGCU35-70 bf08-002.pdf 2504 KB 2/12/2008

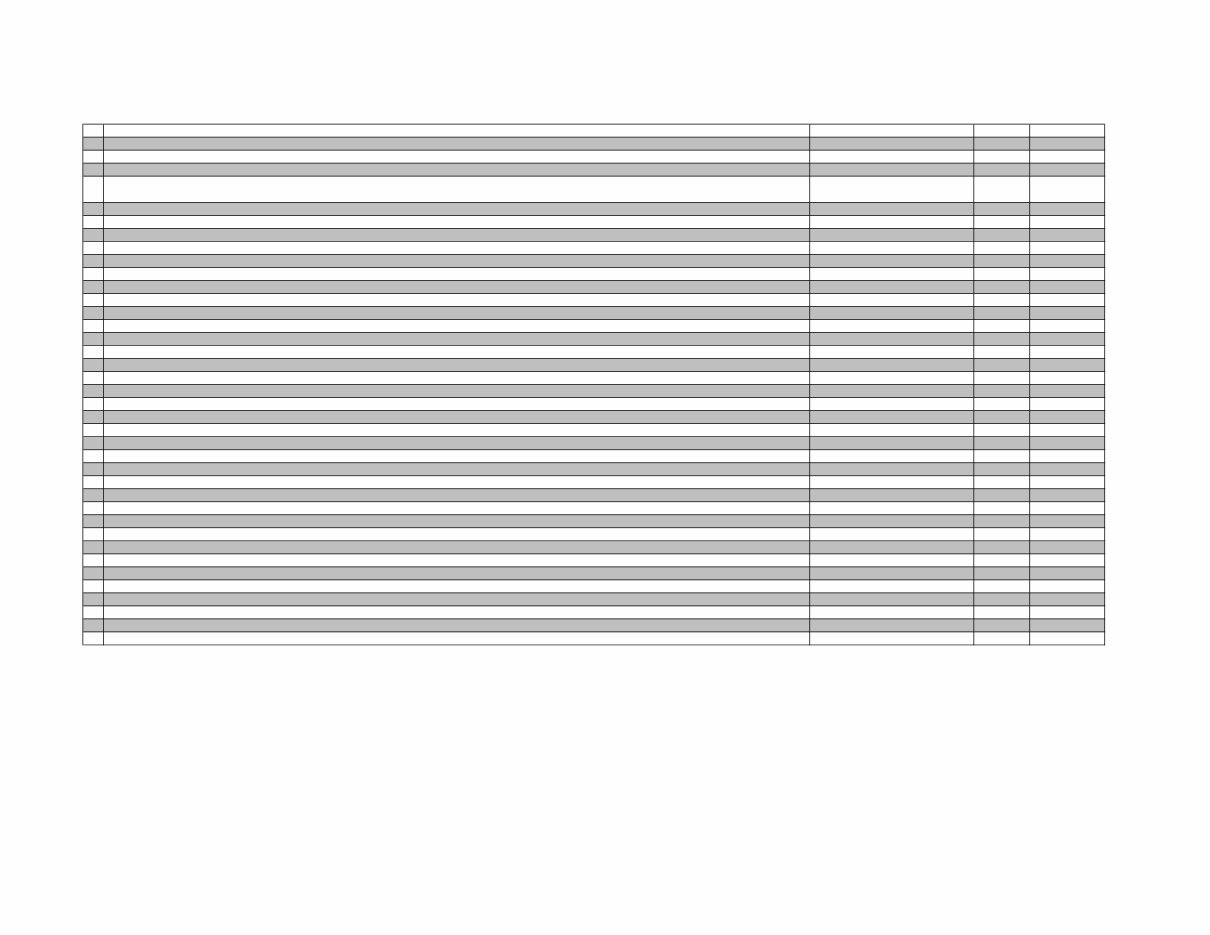

Technical New Briefs affecting Models 7FG(D)U35-80 and 7FGCU35-70

1 TNB-2007-08 Troubleshooting 13Z Diesel Exhaust Smoke tnb-2007-08.pdf 71 KB 10/26/2007

2 TNB-2005-04R2 Guidelines for Cleaning a Contaminated Hydraulic System tnb-2005-04-r2.pdf 77 KB 10/26/2007

3 TNB-2007-02 Chassis Lubrication Clarification tnb-2007-02.pdf 71 KB 4/9/2007

4 TNB-2007-01 Use of Torque Adapter for SSC FL06-007 tnb-2007-01.pdf 88 KB 4/9/2007

5 TNB-2003-03 7FGU35 – 80, 7FGCU35 – 70 Poor Engine Performance When Cold tnb-2003-03.pdf 156 KB 11/29/2005

6 TNB-2005-03 Quick Reference Sheet for 13Z Diesel Pump Timing tnb-2005-03.pdf 294 KB 11/29/2005

Hotline Tech Tip Articles affecting Models 7FG(D)U35-80 and 7FGCU35-70 REV: 2/29/08

1 HTT-11-2004 - V-6 hard start; Hydraulic valve sticking: Excessive brake wear & noise; Axle plate mounting bolts loose hotline tech tips-2004-11.pdf 114 KB 2/6/2006

2 HTT-12-2004 - GMV6 Timing; Strobe Light Failures; V6 hard start; Drive Train Noise; Hydraulic pump failures hotline tech tips-2004-12.pdf 130 KB 2/6/2006

3 HTT-1-2005 - Rotten Egg Smell, Retrieving TWC Error Codes, Flame Retardant Hydraulic Oil, GM V-6 Crank Pulley hotline tech tips-2005-01.pdf 119 KB 7/5/2006

4 HTT-2-2005 - LP Pre-filter Parts, Retrieving TWC Error Codes, Hydraulic Pump Change hotline tech tips-2005-02.pdf 153 KB 2/20/2006

5 HTT-3-2005 - “Rotten Egg” Smell; Driveline Vibration; Aisin LPG Regulator Rich/Lean Air/fuel Ratio; Abnormal Brake Noise; Diesel Engine Smoke;

Overheating

hotline tech tips-2005-03.pdf 121 KB 2/6/2006

6 HTT-4-2005 - Lean LPG Main Path, Engine Compression Check; Key Switch Change hotline tech tips-2005-04.pdf 94 KB 2/6/2006

7 HTT-5-2005 - Seat Switch Testing, Premium GM V-6 Engine; GM V-6 Crankshaft Bolt hotline tech tips-2005-05.pdf 168 KB 7/5/2006

8 HTT-6-2005 - Injector Harness Test Light; Cascade House Valves hotline tech tips-2005-06.pdf 326 KB 2/6/2006

9 HTT-7-2005 - TWC Initial Setting for Injector Period, Improvements to the new key switches, Operator Prescence System hotline tech tips-2005-07.pdf 118 KB 3/13/2006

10 HTT-8-2005 - TWC Initial Setting for Injector Period, Improvements To The New Key Switches, Operator Presence System hotline tech tips-2005-08.pdf 112 KB 3/13/2006

11 HTT-9-2005 - 13Z Diesel Injection Timing hotline tech tips-2005-09.pdf 323 KB 2/6/2006

12 HTT-10-2005 - 13Z Diesel Injection Timing hotline tech tips-2005-10.pdf 97 KB 2/2/2006

13 HTT-11-2005 - TWC Analyzer Tips, GM V6 Hot Soak Engine Shut Down hotline tech tips-2005-11.pdf 74 KB 2/6/2006

14 HTT-12-2005 - OPSS Component Information hotline tech tips-2005-12.pdf 278 KB 4/9/2007

15 HTT-1-2006 - TWC Trouble Shooting Tips, Metal Clad Wiper Seals on Rear Lift Cylinders hotline tech tips-2006-01.pdf 71 KB 2/2/2006

16 HTT-2-2006 - O.P.S.S. Error Code 1, TWC Light Strobing & Adjustments, Hood Vents, Replacement Radiators, GM V-6 Y Pipe Update hotline tech tips-2006-02.pdf 185 KB 3/2/2006

17 HTT-3-2006 - 7Series Starter Delay Circuit hotline tech tips-2006-03.pdf 249 KB 4/3/2006

18 HTT-4-2006 - LPG Regulator Air Testing, Home Depot Options, LPG Pre-Filter Service Parts hotline tech tips-2006-04.pdf 84 KB 4/27/2006

19 HTT-5-2006 -7FDU Oil Filing, Cotton Core Radiator, LPG Oil Contamination hotline tech tips-2006-05.pdf 279 KB 6/20/2006

20 HTT-6-2006 - V-Mast Rear Cylinders, Wire Harness Repair, SAS Code 63, Axle Mount Bolts hotline tech tips-2006-06.pdf 344 KB 7/11/2006

21 HTT-7-2006 - GM6-262 Exhaust Y-Pipe Breaking hotline tech tips-2006-07.pdf 131 KB 4/9/2007

22 HTT-8-2006 -Engine Shutdown Option, Extreme Environment Radiator hotline tech tips-2006-08.pdf 268 KB 9/6/2006

23 HTT-9-2006 - V-Mast Cylinder Spacer, GM6-262 Timing Chain Tensioner, TWC Tamper Resistant Plug hotline tech tips-2006-09.pdf 134 KB 10/3/2006

24 HTT-10-2006 - GM6-262 Hard/Impossible to Start, SAS L-Off hotline tech tips-2006-10.pdf 257 KB 4/9/2007

25 HTT-11-2006 - Ultra-Low Sulfur Diesel, 7FGCU35-45 Brake Noise, TWC Emission Warranty hotline tech tips-2006-11.pdf 99 KB 11/27/2006

26 HTT-12-2006 - Travel Speed Measurement, Clogged LP injector, New Fuel System SST hotline tech tips-2006-12.pdf 308 KB 4/9/2007

27 HTT-1-2007 - GM6-262 Spectrum Fuel System hotline tech tips-2007-01.pdf 136 KB 4/9/2007

28 HTT-2-2007 - Spectrum MIL Strategy change, Chassis Lubrication, USB adapter for Spectrum hotline tech tips-2007-02.pdf 519 KB 4/9/2007

29 HTT-3-2007 - IC Radiator Offerings hotline tech tips-2007-03.pdf 154 KB 4/9/2007

30 HTT-4-2007 - Spectrum Adapter hardware change hotline tech tips-2007-04.pdf 381 KB 5/10/2007

31 HTT-5-2007 - Spectrum Fuel System Terminology hotline tech tips-2007-05.pdf 216 KB 9/24/2007

32 HTT-6-2007 - New Active Radiator, Troubleshooting Smoke hotline tech tips-2007-06.pdf 162 KB 9/24/2007

33 HTT-7-2007 - New Hydraulic Oil, Troubleshooting Overheating, Spectrum III LP and/or Gasoline hotline tech tips-2007-07.pdf 600 KB 9/24/2007

34 HTT-9-2007 - Spectrum Fuel System Calibration hotline tech tips-2007-09.pdf 502 KB 9/24/2007

35 HTT-10-2007 - LP Lockoff Solenoid Orientation hotline tech tips-2007-10.pdf 303 KB 10/30/2007

36 HTT-11-2007 - Spectrum Calibration changes, Spectrum DTC 1152 hotline tech tips-2007-11.pdf 155 KB 11/19/2007

37 HTT-12-2007 - Spectrum hard start, Engine Block Heaters hotline tech tips-2007-12.pdf 490 KB 12/12/2007

38 HTT-1-2008 - Threshold Voltages hotline tech tips-2008-01.pdf 363 KB 1/28/2008

39 HTT-2-2008 - Proper Wheel Torque hotline tech tips-2008-02.pdf 204 KB 2/28/2008

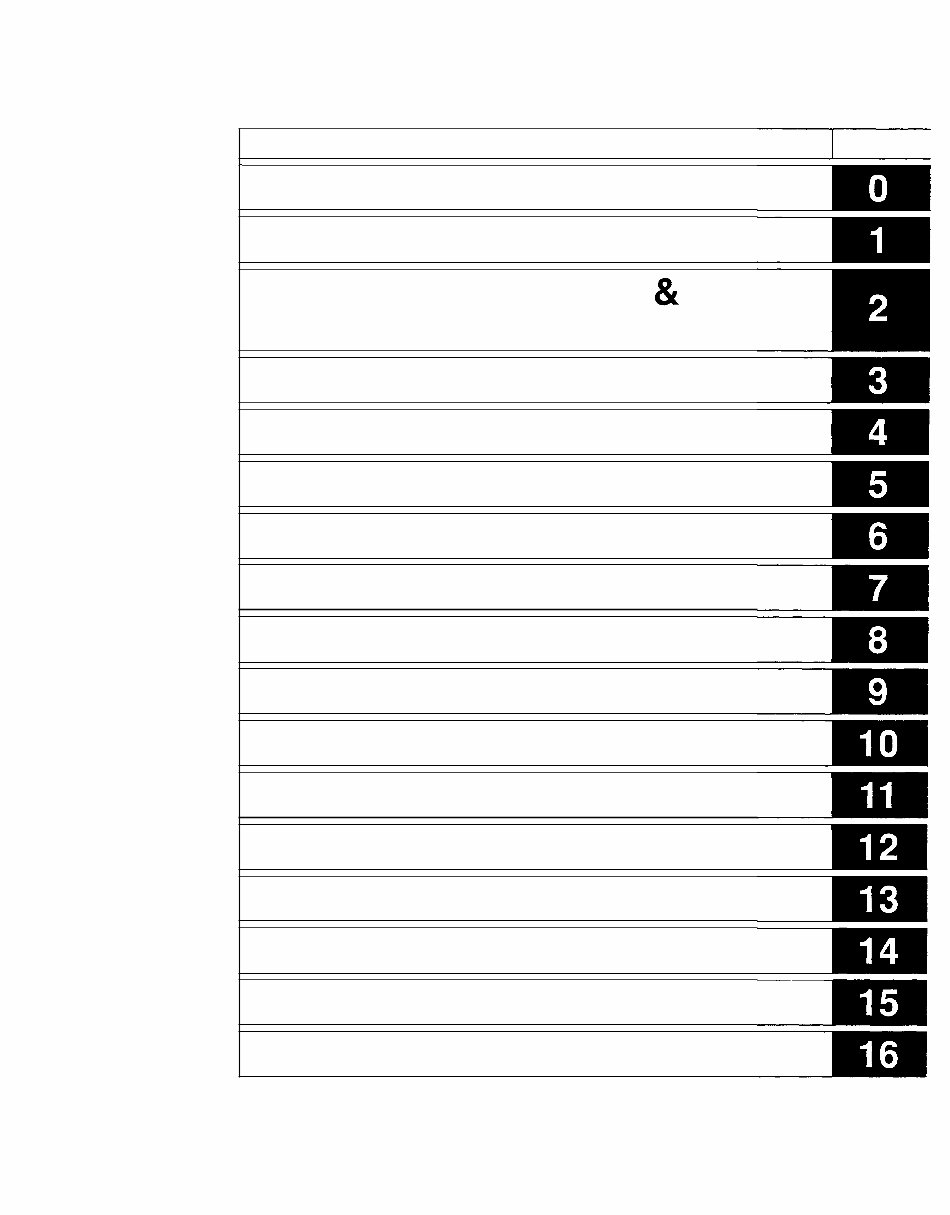

SECTION INDEX

NAME SECTION

I GENERAL

ENGINE

TORQUE CONVERTER &

TRANSMISSION

PROPELLER SHAFT

DIFFERENTIAL

FRONT AXLE

REAR AXLE

STEERING

BRAKE

BODY

MATERIAL HANDLING SYSTEM

MAST

CYLINDER

OIL PUMP

OIL CONTROL VALVE

SAS

APPENDIX

GENERAL

Page

EXTERIOR VIEWS ......................................................... 0-2

.......................................................... VEHICLE MODEL 0- 3

FRAME NUMBER .......................................................... 0- 4

.................................... HOW TO USE THIS MANUAL 0 - 5

EXPLANATION METHOD ................................................. 0 - 5

TERMINOLOGY .............................................................. 0- 6

............................................................. A6BR EVl ATIONS 0 - 6

.................................................... OPERATIONAL TIPS 0 - 7

HOISTING THE VEHICLE ........................................ 0 - 7

ATTENTIVE POINTS ON SAS .................................... 0 - 8

.................................................. CIRCUIT TESTER 0 - 9

STANDARD BOLT & NUT TIGHTENING

TORQUE ........................................................... 0-11

BOLT STRENGTH TYPE IDENTIFICATIONMETHOD ...... 0 - 11

........................................ TIGHTENING TORQUE TABLE 0 - 12

......................................................... PRECOAT BOLTS 0 - 13

HIGH PRESSURE HOSE FITTING

............................................ TIGHTENING TORQUE 0 - 13

WIRE ROPE SUSPENSION ANGLE LIST ............... 0 - 14

SAFE LOAD FOR EACH WlRE ROPE

............................................... SUSPENSION ANGLE 0 - 14

............................................. COMPONENTS WEIGHT 0 - 15

RECOMMENDED LUBRICANT

QUANTITY & TYPES ................................................. 0 - 16

................................................. LUBRICATION CHART 0 - 17

.......................................... PERIODIC MAINTENANCE 0-20

PERIODIC REPLACEMENT OF PARTS AND

............................................................... LUBRICANTS 0-26

EXTERIOR VIEWS

Pneumatic tire model

Cushion tire model

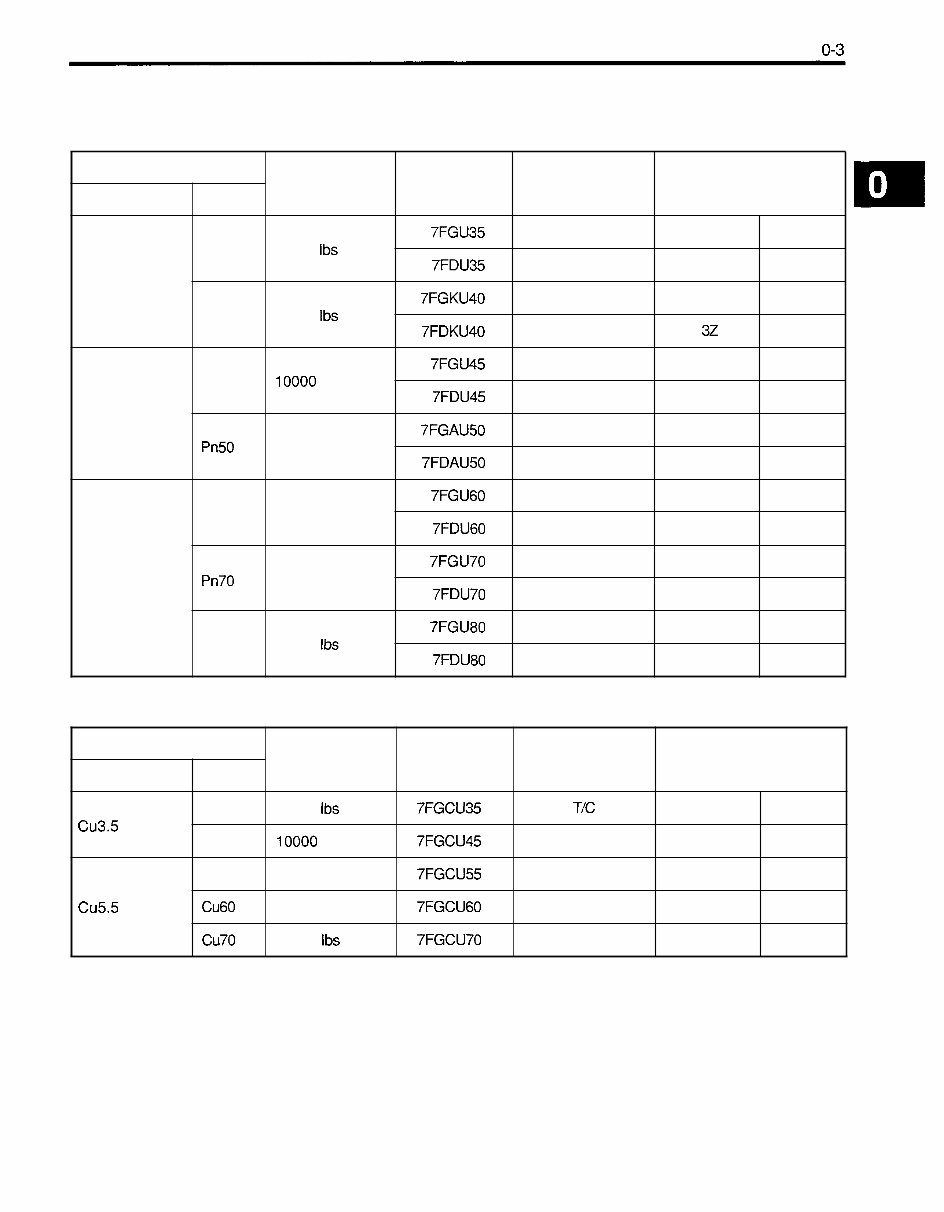

VEHICLE MODEL

Pneumatic Tire Models (Pn)

Cushion Tire Models (Cu)

Note:

The G4 engine is the same as the GM6-262 engine except for the nomenclature.

Vehicle Model

7FGU35

7FDU35

7FGKU40

7FDKU40

7FGU45

7FDU45

7FGAU50

7FDAU50

7FGU60

7FDU60

7FGU70

7FDU70

7FGU80

7FDU80

Load Capacity

8000 Ibs

9000 lbs

10000lbs

11000 Ibs

13500 Ibs

15500 Ibs

17500 Ibs

Classification

Series

Pn3.5 ton series

Pn4.5 ton series

Pn6.0 ton series

Model

Pn35

Pn40

Pn45

Pn50

Pn60

Pn70

Pn80

Transmission Type

TIC

TIC

TIC

TIC

TIC

TIC

TIC

TIC

TIC

TIC

TIC

TIC

TIC

TIC

Transmission Type

TIC

TIC

TIC

TIC

TIC

Engine

Classification

G4 (GM6-262)

G4 (GM6-262)

G4 (GM6-262)

G4 (GM6-262)

G4 (GM6-262)

Engine

Load Capacity

8000 Ibs

10000lbs

12000 Ibs

13500 Ibs

15500 Ibs

Series

Cu3.5 ton series

Cu5.5 ton series

Gasoline

Gasoline

Gasoline

Gasoline

Gasoline

G4 (GM6-262)

132

G4 (GM6-262)

1 32

G4 (GM6-262)

132

G4 (GM6-262)

132

G4 (GM6-262)

132

G4 (GM6-262)

132

G4 (GM6-262)

132

Vehicle Model

7FGCU35

7FGCU45

7FGCU55

7FGCU60

7FGCU70

Model

Cu35

Cu45

Cu55

Cu60

Cu70

Gasoline

Diesel

Gasoline

Diesel

Gasoline

Diesel

Gasoline

Diesel

Gasoline

Diesel

Gasoline

Diesel

Gasoline

Diesel

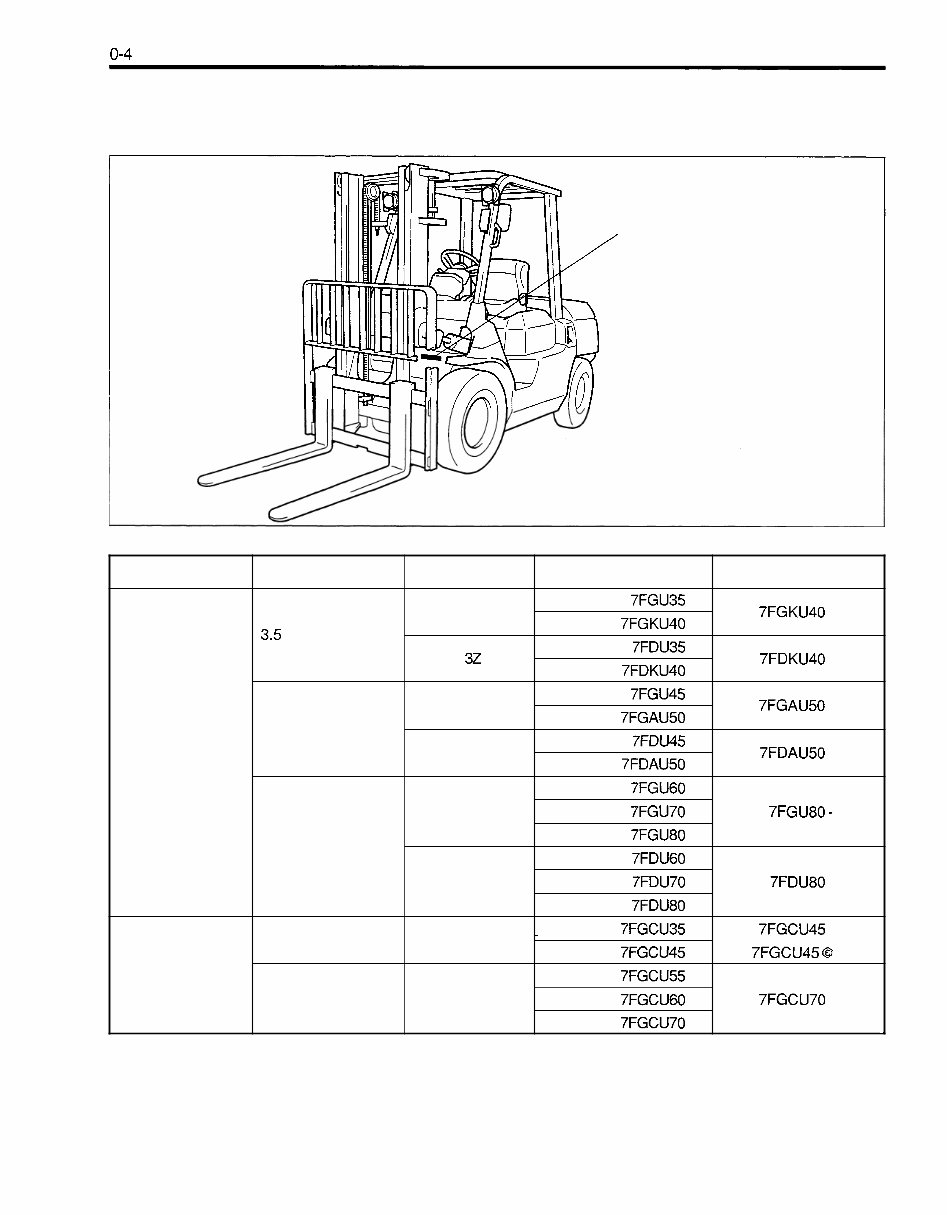

FRAME NUMBER

Frame No. Punching Position

Punching position

*: EEC spec.

Pneumatic tire

Cushion tire

Series

3.5 ton series

4.5 ton series

6.0 ton series

3.5 ton series

5.5 ton series

Engine

G4 (GM6-262)

1 32

G4 (GM6-262)

132

G4 (GM6-262)

132

G4 (GM6-262)

G4 (GM6-262)

Vehicle model

7FGU35

7FGKU40

7FDU35

7FDKU40

7FGU45

7FGAU50

7FDU45

7FDAU50

7FGU60

7FGU70

7FGU80

7FDU60

7FDU70

7FDU80

-

7FGCU35

7FGCU45

7FGCU55

7FGCU60

7FGCU70

Punching format

7FGKU40 - 6001 1

7FDKU40 - 6001 1

7FGAU50 - 6001 1

7FDAU50 - 6001 1

7FGU80 - 6001 1

7FDU80 - 6001 1

7FGCU45 - 6001 1

* 7FGCU45 O 6001 1

7FGCU70 - 6001 1

-

HOW TO USE THIS MANUAL

EXPLANATIONMETHOD

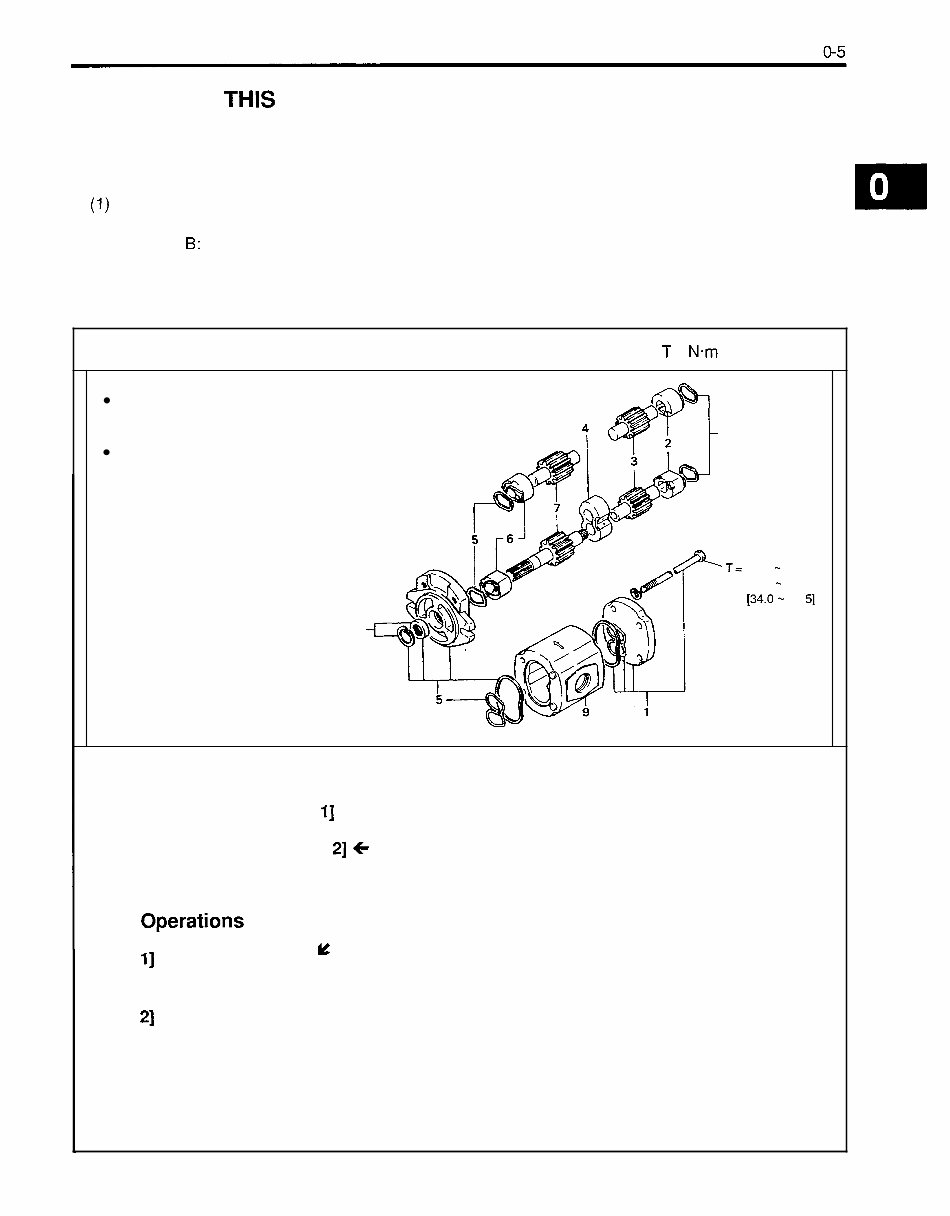

1. Operation procedure

(1) The operation procedure is described in either pattern A or pattern B below.

Pattern A: Explanation of each operation step with illustration.

Pattern 6: Explanation of operation procedure by indicating step numbers in one illustration, fol-

lowed by explanation of cautions and notes summarized as point operations.

Example of description in pattern B

DISASSEMBLY-INSPECTION-REASSEMBLY Tightening torque unit T = N-m (kgf-cm) [ft-lbf]

Step Nos. are partially sometimes

omitted in illustrations.

1

When a part requiring tightening

torque instruction is not indicated in

the illustration, the part name is de-

scribed in the illustration frame.

T= 46.1 - 48.1

(470 - 490)

[34.0 - 35 51

8

Disassembly Procedure

1 Remove the cover. [Point 11

2 Remove the bushing [Point 21 C Operation explained later

3 Remove the gear.

Point Operations Explanation of key point for operation with an illustration

[Point 11

LL

Disassembly: Put a match mark when removing the pump cover.

[Point 21

Inspection: Measure the bushing inside diameter.

Limit: 19.12 mm (0.7528 in)

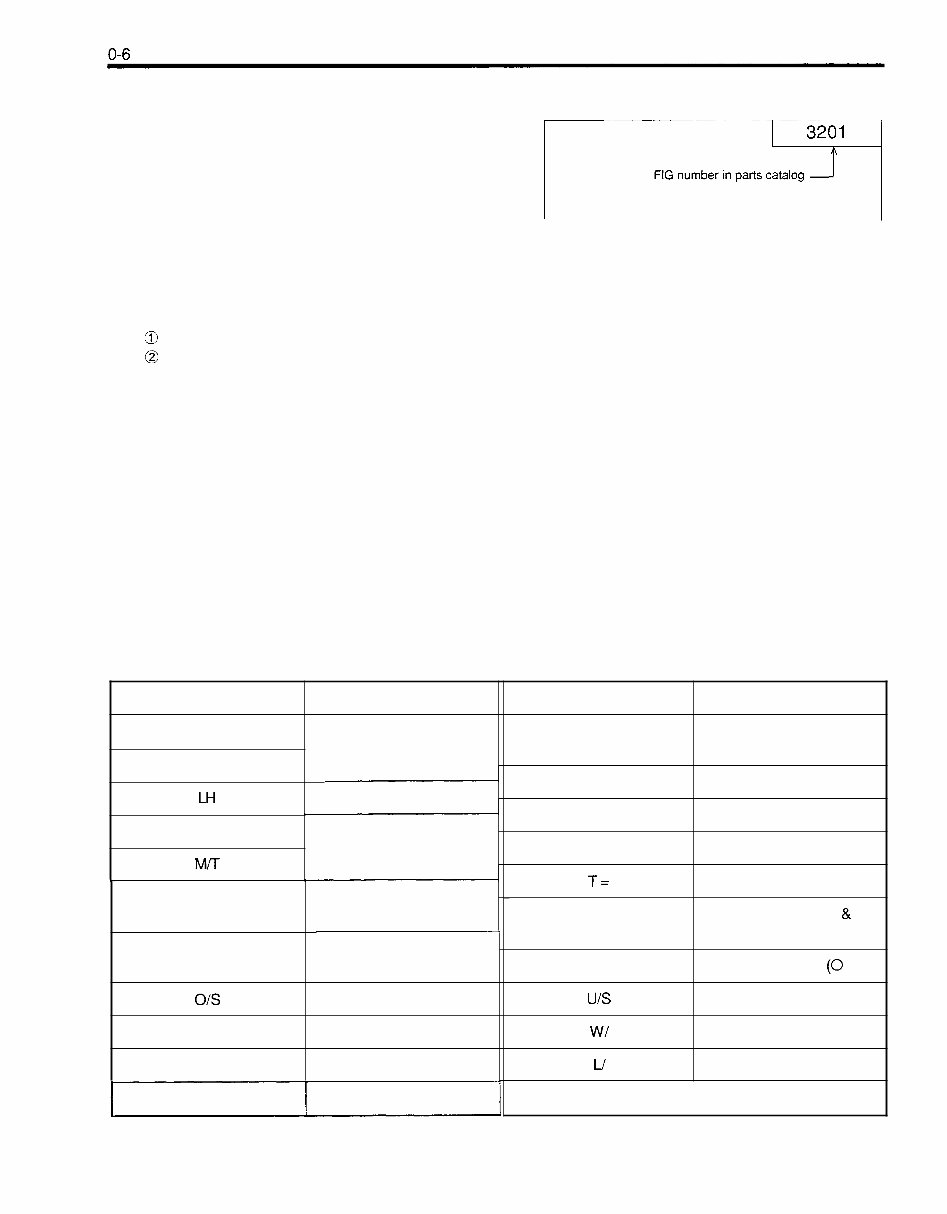

2. How to read components figures (Example)

(1) The components figure uses the illustration

in the parts catalog for the vehicle model.

Please refer to the catalog for checking the

part name.

The number at the right shoulder of each

components figure indicates the Fig. num-

ber in the parts catalog.

FIG number in parts catalog

I

3. Matters omitted in this manual

(1) This manual omits description of the following jobs, but perform them in actual operation:

@

Cleaning and washing of removed parts as required

@ Visual inspection (partially described)

TERMINOLOGY

Caution:

lmportant matters of which negligence may cause hazards on human body. Be sure to ob-

serve them.

Note:

lmportant items of which negligence may cause breakage or breakdown, or matters in opera-

tion procedure requiring special attention.

Standard: Values showing allowable range in inspection and adjustment.

Limit: Maximum or minimum allowable value in inspection or adjustment.

ABBREVIATIONS

Meaning

Society of Automotive

Engineers (USA)

System of active stability

Special service tool

Standard

Tighteningtorque

Torque converter &

transmission

Number of teeth (0 0)

Undersize

With

Less

RH Right hand

Abbreviation(code)

SAE

Abbreviation(code)

ASSY

Cu

Meaning

Assembly

- -

Cushion tire models

SAS

SST

STD

T=

-

TIC

OOT

UIS

WI

U

U-l Left hand

LLC

M/T

Long life coolant

- -

Manual transmission

NMR

OPT

01s

Pn

PS

No-load maximum

speed

Option

Oversize

Pneumatic tire models

Power steering

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$32.99

Viewed 47 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$32.99

Illustrated Factory Workshop Service Manual for Toyota Diesel Forklift Truck Type 7FD. This manual contains high-quality images, circuit diagrams, and instructions to assist in the operation, maintenance, and repair of your truck. It is useful for both professional mechanics and DIY enthusiasts. The manual is printable, contains searchable text, and navigation bookmarks for easy access.

Covered models:

- 7FDAU50

- 7FDKU40

- 7FDU35

- 7FDU45

- 7FDU60

- 7FDU70

- 7FDU80

Language: English

Contained Set of Manuals:

- Main Service manual, 596 Pages, December 2000 - This manual covers the service procedures of the TOYOTA FORKLIFT 7FGU/7FDU35 - 80 series and 7FGCU35 - 70 series. Please use this manual for providing quick, correct servicing of the corresponding forklift models.

- Update for Main Service manual, 134 Pages, September 2005 - This manual covers the service procedures of the TOYOTA FORKLIFT 7FGU/7FDU35 - 80 series and 7FGCU35 - 70 series. Please use this manual for providing quick, correct servicing of the corresponding forklift models.

- Wiring Diagrams, 26 Pages

- Wiring Diagrams, 26 Pages

Contents of main manual:

- GENERAL

- ENGINE

- TORQUE CONVERTER &

- TRANSMISSION

- PROPELLER SHAFT

- DIFFERENTIAL

- FRONT AXLE

- REAR AXLE

- STEERING

- BRAKE

- BODY

- MATERIAL HANDLING SYSTEM

- MAST

- CYLINDER

- OIL PUMP

- OIL CONTROL VALVE

- SAS

- APPENDIX

Contents of update manual:

- GENERAL

- OPS

- BODY

- OIL CONTROL VALVE

- SAS

- APPENDIX