Linde Forklift Truck Type 359: H100, H120, H140, H160, H180 Service Training (Workshop) Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Viewed 35 Times Today

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$42.99

- Original Illustrated Factory Service Training (Workshop) Manual for Linde Forklift Truck Type 359.

- Original factory manuals for Linde Forklift Trucks, containing high-quality images, circuit diagrams, and instructions to help you operate and repair your truck.

- Useful for both professional mechanics and DIY enthusiasts.

- Covered models:

- H100-600

- H120-1200

- H120-600

- H140-1200

- H140-600

- H160-1200

- H160-600

- H180-600

- Format: 261 Pages, Printable

- Language: English

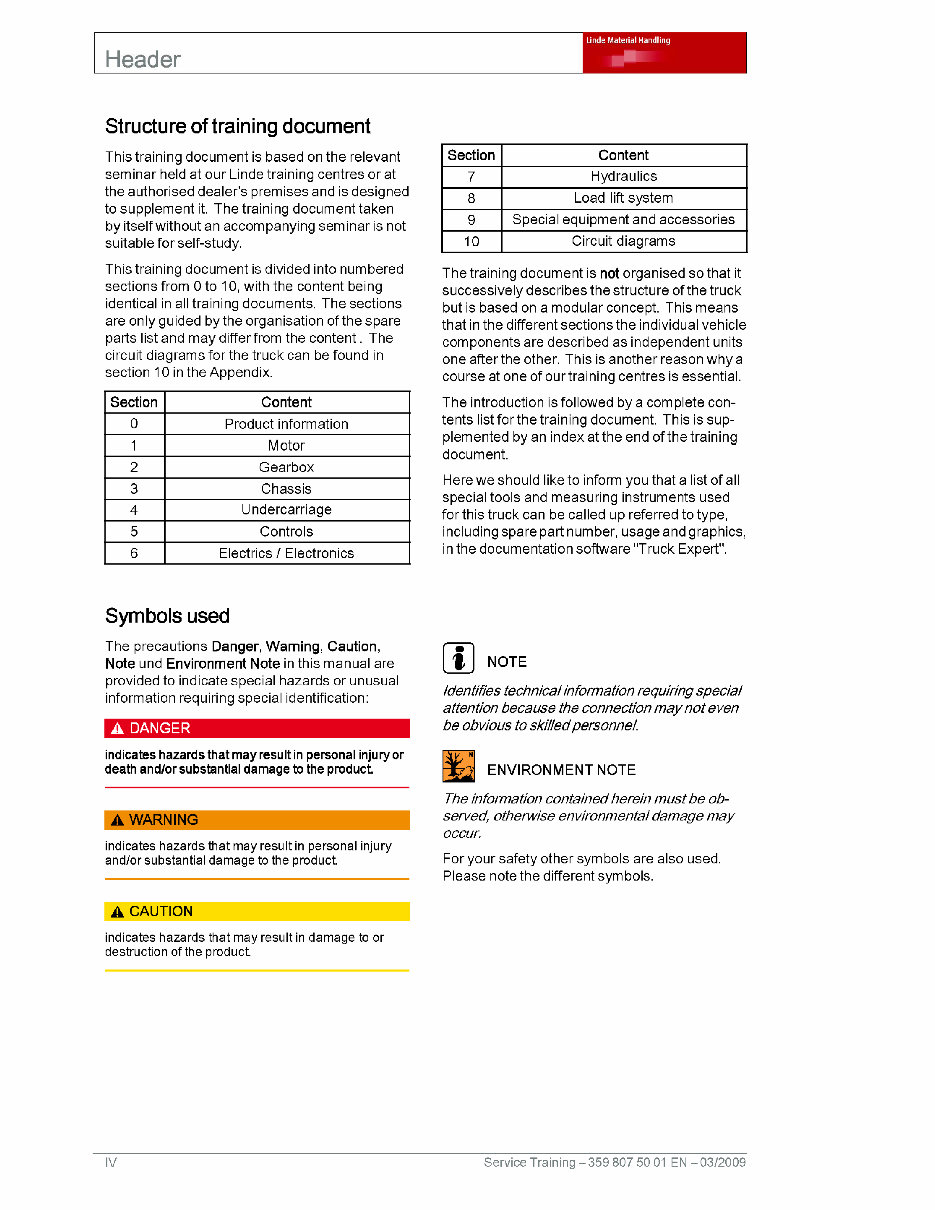

- Contents:

- Product information

- Preface

- The BR 359 truck

- Technical data

- Dimensions

- VDI datasheet H100-600, H120-600, H140-600

- VDI datasheet H150-600, H160-600, H180-600

- VDI datasheet H120-1200, H140-1200, H160-1200

- Diagnostics

- LTC basic structure

- CAN bus communication overview and installation position

- Error code lists

- Indicator unit error codes

- LTC traction control codes, versionl.X

- LTC lift control codes, 0.040 version, LTC module N1

- LTC lift control codes, Version 0.040, LTC module N2

- Cummins diesel engine fault codes

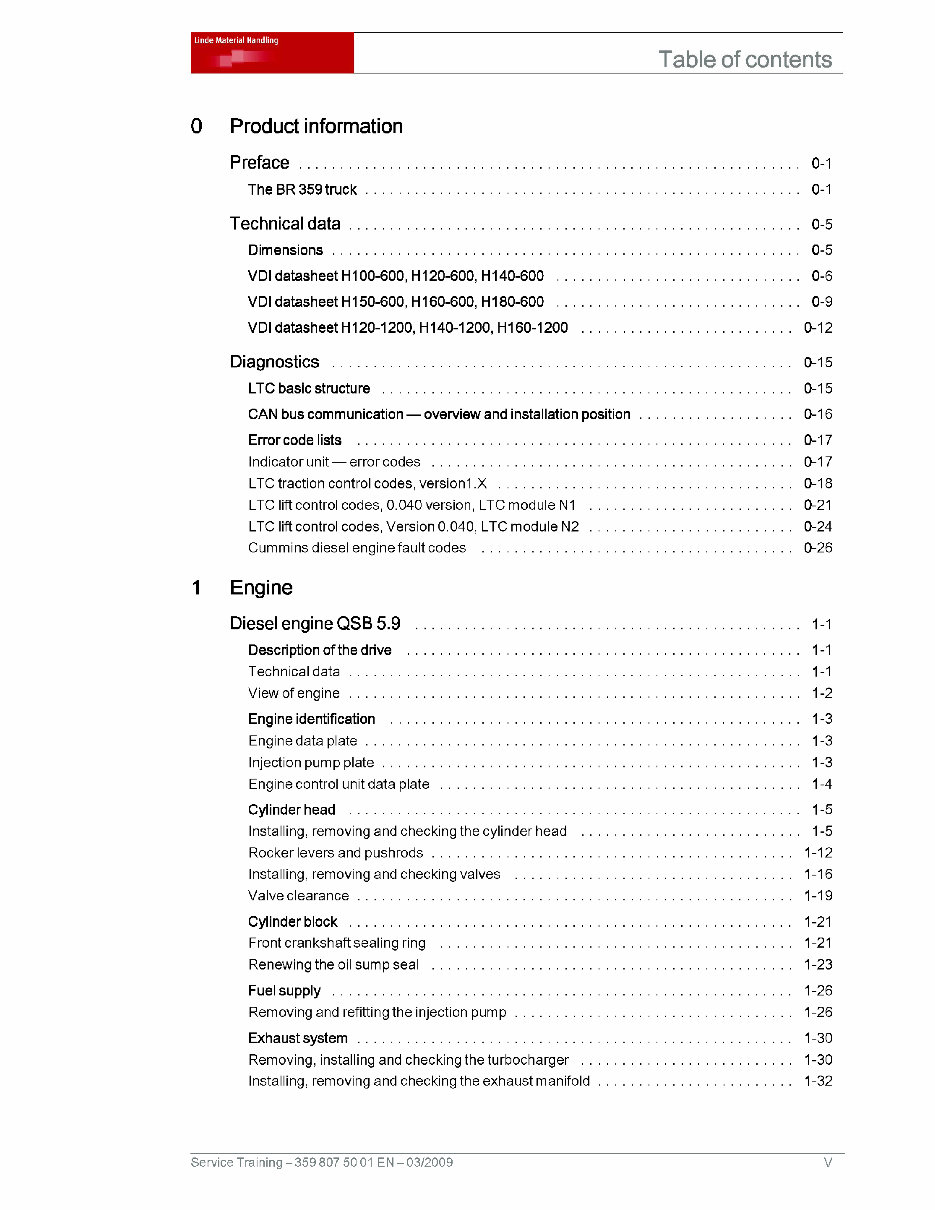

- Engine

- Diesel engine QSB 5.9

- Description of the drive

- Technical data

- View of engine

- Engine identification

- Engine data plate

- Injection pump plate

- Engine control unit data plate

- Cylinder head

- Installing, removing, and checking the cylinder head

- Rocker levers and pushrods

- Installing, removing, and checking valves

- Valve clearance

- Cylinder block

- Front crankshaft sealing ring

- Renewing the oil sump seal

- Fuel supply

- Removing and refitting the injection pump

- Exhaust system

- Removing, installing, and checking the turbocharger

- Installing, removing, and checking the exhaust manifold

- Diesel engine QSB 6.7

- Fuel supply

- Removing and installing injectors

- Checking the fuel supply

- Removing and installing the EFC actuator

- Removing and installing the high-pressure pump

- Removing and installing the rail

- Engine block

- Removing and fitting the V-ribbed belt

- Removing and installing the exhaust turbocharger

- Removing, installing, and checking the exhaust manifold

- Removing and installing the valve cover

- Adjusting the valve clearance

- Checking rocker levers and pushrods

- Removing, installing, and checking the cylinder head

- Removing, installing, and checking valves

- Changing the oil sump seal

- Diesel engine QSB 5.9

- Drive axle

- Description

- Technical data for traction drive

- Schematic view of the drive

- Linde TruckControl (LTC)

- Traction drive

- Travel drive - introduction

- Introduction

- Variable displacement pump controller

- Motor variables controller

- Pedal group

- Variable displacement pump

- HPV 210-02 variable displacement pump

- Electro-hydraulic remote control

- Variable pump advance start

- Variable motor

- Variable motor HMV210-02 and HMV 280-02

- Output unit function characteristics

- Reduction gearbox

- Reduction gearbox GR 26-01

- Brake

- Braking process - function characteristics

- Retarder valve block components

- Retarder valve block function

- Brake release valve

- Towing unit

- Checking the brake system

- Hydraulic fan drive

- Function characteristics

- Checking the hydraulic fan drive

- Chassis, bodywork, and fittings

- Steering system

- Function characteristics

- Steering axle

- Stub axle

- Wheel hub

- Adjusting the inner steering stop

- Adjusting the outer steering stop

- Removing and installing the steering cylinder

- Sealing the steering cylinder

- Controls

- Display elements

- Indicator unit

- Electrics / Electronics

- Central electrical system

- Arrangement of relays and fuses for basic equipment and special equipment

- Checks

- Testing the electronic controllers and components

- Testing the LTC (vehicle and lift controller)

- Checking wiring harness

- Testing sensors

- Checking actuators

- Testing the indicator unit

- Hydraulics

- Regulating pump HPR210-02

- Technical data for regulating pump

- HPR 210-02 regulating pump

- Load sensing regulation

- Working hydraulic

- Working hydraulic circuit diagram

- Hose layout

- Hose layout, supply, valve block, working hydraulics

- Hose layout lifting/lowering

- Tilting hose layout

- Hose layout for sideshift and fork positioner

- Measurements and settings

- Checking the maximum working pressure and LS pressure

- Checking and adjusting delta pressure P to LS

- Tilting the cab

- Cabin tilting mechanism

- Operation of the cab tilt device

- Annex

- Circuit diagrams

- Hydraulic circuit diagrams

- Hydraulic circuit diagram

- Wiring diagrams QSB 5.9

- Wiring diagram parti

- Wiring diagram Part 2

- Wiring diagram Part 3

- Wiring diagram part 4

- Wiring diagram part 5

- Wiring diagram Part 6

- Wiring diagram part 7

- Wiring diagram Part 8

- Wiring diagram part 9

- Wiring diagram part 10

- Wiring diagrams QSB 6.7

- Wiring diagram, sheet 1

- Wiring diagram, sheet 2

- Wiring diagram, sheet 3

- Wiring diagram, sheet 4 - dipped beam, sidelight, direction indicator and hazard warning light, reverse light

- Wiring diagram, sheet 5 - work lights, horn, interior light, cigarette lighter, radio

- Wiring diagram, sheet 6 - windscreen wiper motors

- Wiring diagram, sheet 7 - seat heater, flashing beacon, brake light, programmable rooflight/ beacon, mast speed limit

- Wiring diagram, sheet 8 - cabin tilting mechanism, door release, spare fuses

- Wiring diagram, sheet 9 - air conditioning

- Wiring diagram, sheet 10 - twistlocks, extend/retract, sideshift, worklights, safety override

- Circuit diagrams

- Product information