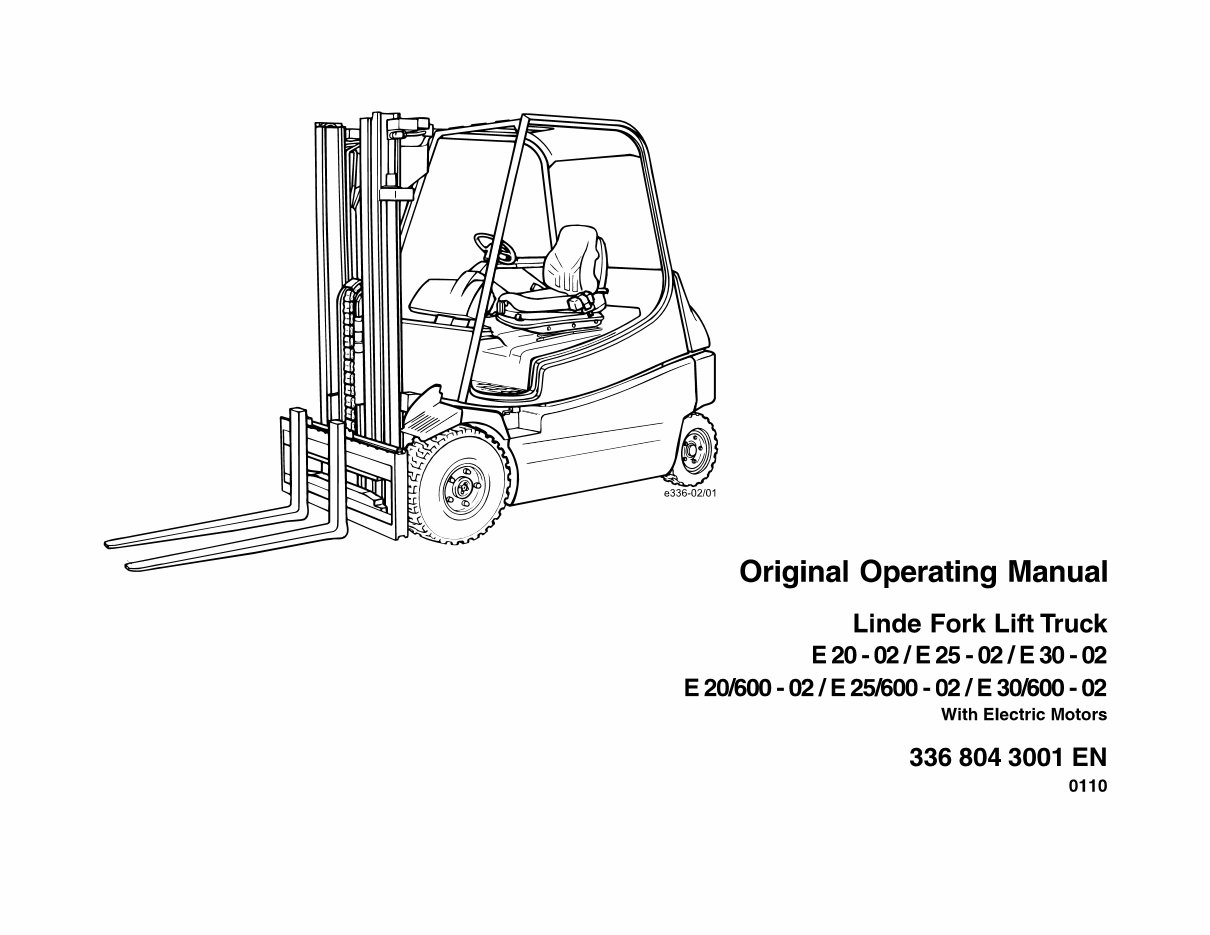

Linde Electric Forklift Truck 336-02 Series: E20, E25, E30 Operating Manual (User Manual)

These illustrated factory operating and maintenance instructions are essential for anyone working with Linde Electric Forklift Truck E336-02 Series. The manuals contain high-quality images, circuit diagrams, and detailed instructions to assist in the operation and repair of the forklift trucks.

These manuals cover the following models:

- E20-02

- E25-02

- E30-02

- E20/600-02

- E25/600-02

- E30/600-02

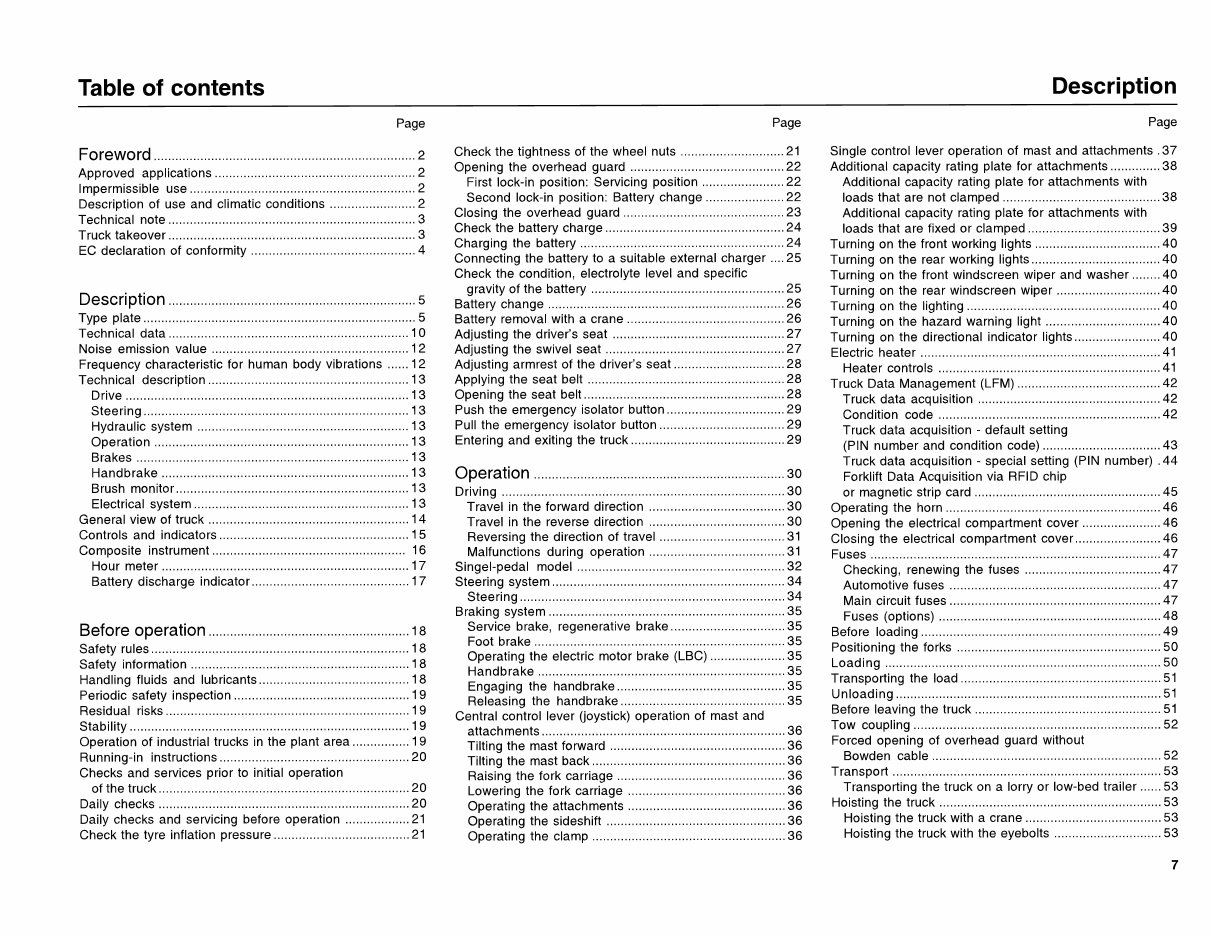

The manuals are in English and consist of 104 pages. They include a comprehensive table of contents, covering various aspects of the forklift truck's operation, maintenance, and technical specifications.

The content includes:

- Foreword, including approved applications and technical notes

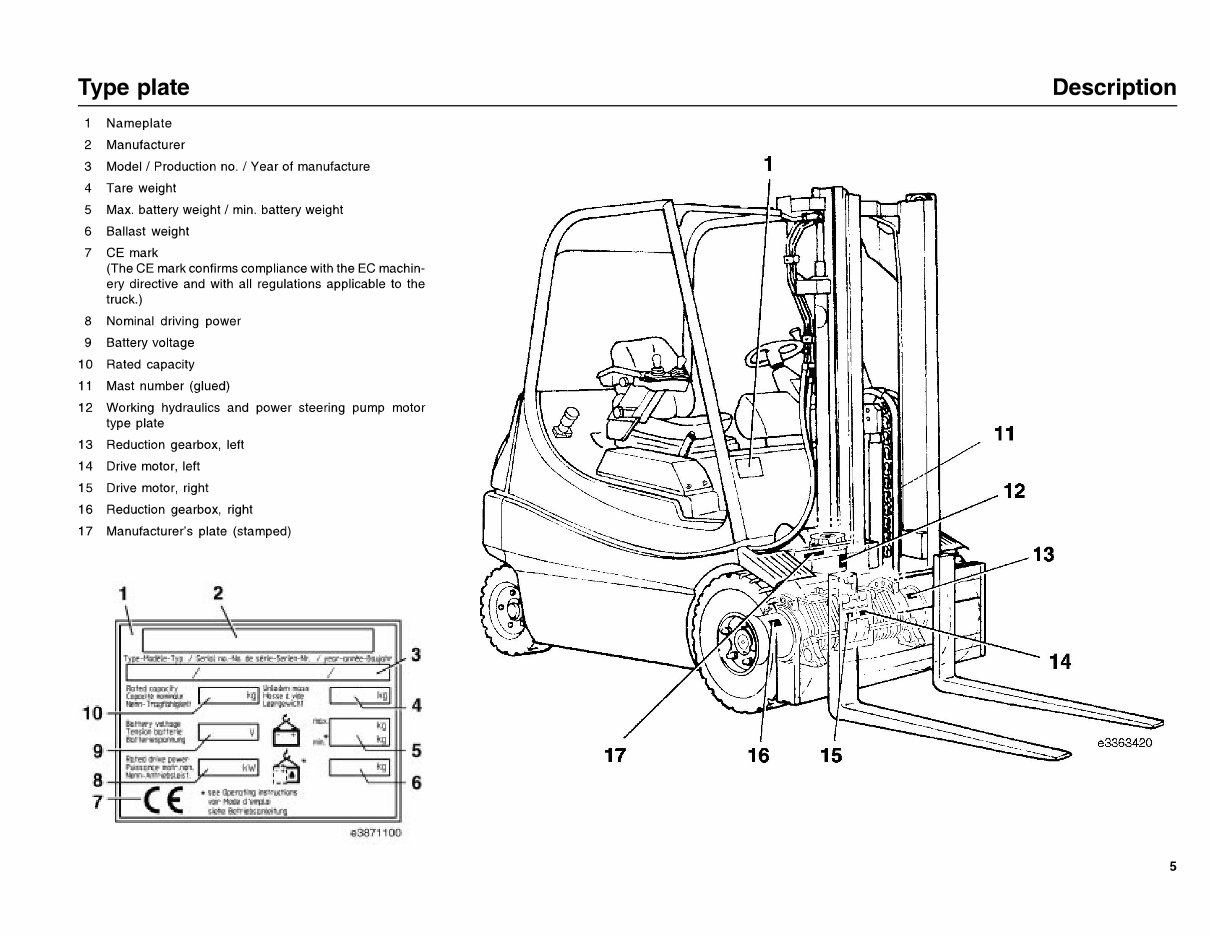

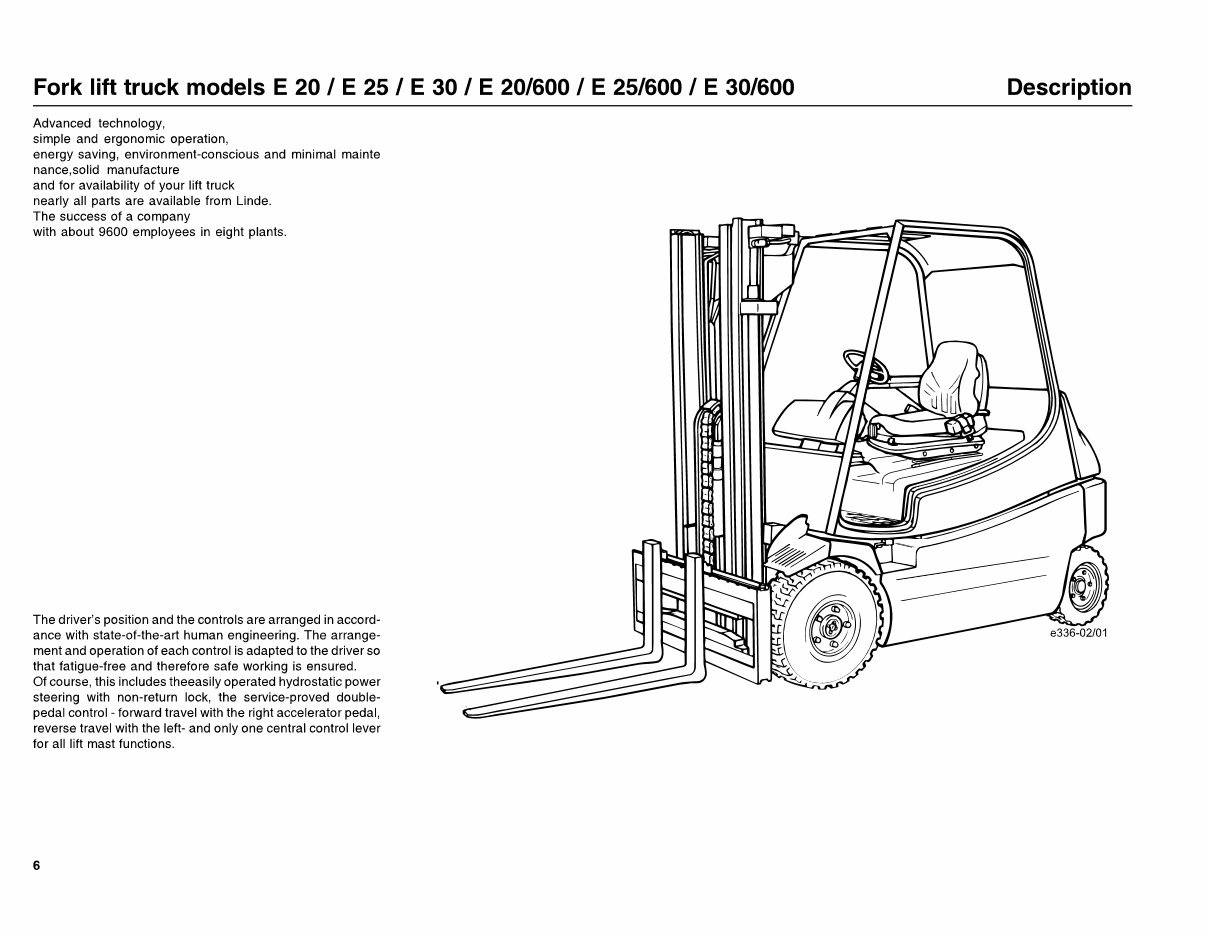

- Description, technical data, and noise emission values

- Before operation, safety rules, and periodic safety inspection

- Operation, including driving, steering, and braking systems

- Maintenance, including measures before taking the truck out of operation and disposal of old vehicles

- Inspection and maintenance as required, with detailed checklists

- Inspection and maintenance specifications, lubricant recommendations, and troubleshooting guide

- Electric and hydraulic circuit diagrams

- Index for easy reference

These manuals are invaluable resources for both professional mechanics and DIY enthusiasts, providing detailed insights into the operation, maintenance, and troubleshooting of Linde Electric Forklift Truck E336-02 Series.