Hyster N005 (H80FT, H90FT, H100FT, H110FT, H120FT) Forklift Service Repair Workshop Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

COOLING SYSTEM

S30FT, S35FT, S40FTS [E010]; H1.6FT, H1.8FT, H2.0FTS

(H30FT, H35FT, H40FTS) [F001]; S2.0-3.5FT (S40-70FT,

S55FTS ) [F187]; H2.0-3.5FT (H40-70FT) [L177]; S4.0,

4.5, 5.50FT; S5.5FTS (S80, 100, 120FT; S80, 100FTBCS;

S120FTS; S120FTPRS) [G004]; H4.0FT5/FT6; H4.5FTS5,

H4.5FT6; H5.0-5.5FT (H80, 90, 100, 110, 120FT) [N005,

P005]; S6.0FT, S7.0FT (S135FT,S155FT) [D024, E024];

H6.0FT, H7.0FT (H135FT, H155FT) [H006, J006]

PART NO. 1580505 700 SRM 1123

Cooling System Table of Contents

TABLE OF CONTENTS

General ............................................................................................................................................................... 1

Cooling System Checks...................................................................................................................................... 1

Exhaust Leaks Into Cooling System ............................................................................................................ 1

Water Flow Restrictions in Radiator ............................................................................................................ 1

Radiator Hoses ............................................................................................................................................... 1

Water Pump ................................................................................................................................................... 1

Flushing the Cooling System ............................................................................................................................ 2

Cooling System, Clean................................................................................................................................... 2

Radiator Replacement ....................................................................................................................................... 3

Radiator, Remove for Lift Trucks Models S30FT, S35FT, S40FTS (E010); H1.6FT, H1.8FT,

2.0FTS (H30FT, H35FT, H40FTS) (F001); S2.0-3.5FT (S40-70FT, S55FTS) (F187); H2.0-3.5FT

(H40-70FT) (L177), S4.0, 4.5, 5.5FT, S5.5FTS, (S80, 100, 120FT; S80, 100FTBCS; S120FTS;

S120FTPRS) (G004) and H4.0FT5/FT6; H4.5FTS5, H4.5FT6; H5.0-5.5FT (H80, 90, 100, 110,

120FT) (N005, P005) ..................................................................................................................................... 3

Radiator, Remove for Lift Truck Models S6.0FT, S7.0FT (S135FT, S155FT) (D024, E024) ...................... 11

Radiator, Remove for Lift Truck Models H6.0FT, H7.0FT (H135FT, H155FT) (H006, J006) ................... 12

Radiator, Install for Lift Truck Models S30FT, S35FT, S40FTS (E010); H1.6FT, H1.8FT,

2.0FTS (H30FT, H35FT, H40FTS) (F001); S2.0-3.5FT (S40-70FT, S55FTS) (F187); H2.0-3.5FT

(H40-70FT) (L177), S4.0, 4.5, 5.5FT, S5.5FTS, (S80, 100, 120FT; S80, 100FTBCS; S120FTS;

S120FTPRS) (G004) and H4.0FT5/FT6; H4.5FTS5, H4.5FT6; H5.0-5.5FT (H80, 90, 100, 110,

120FT) (N005, P005) ..................................................................................................................................... 14

Radiator, Install for Lift Truck Models S6.0FT, S7.0FT (S135FT, S155FT) (D024, E024) ........................ 16

Radiator, Install for Lift Truck Models H6.0FT, H7.0FT (H135FT, H155FT) (H006, J006) ..................... 18

Fan Assembly Replacement .............................................................................................................................. 22

Fan Removal .................................................................................................................................................. 22

Inspect ............................................................................................................................................................ 26

Fan Installation ............................................................................................................................................. 28

This section is for the following models:

S30FT, S35FT, S40FTS [E010];

H1.6FT, H1.8FT, H2.0FTS (H30FT, H35FT, H40FTS) [F001];

S2.0-3.5FT (S40-70FT, S55FTS ) [F187];

H2.0-3.5FT (H40-70FT) [L177];

S4.0, 4.5, 5.50FT; S5.5FTS (S80, 100, 120FT; S80, 100FTBCS;

S120FTS; S120FTPRS) [G004];

H4.0FT5/FT6; H4.5FTS5, H4.5FT6; H5.0-5.5FT (H80, 90, 100,

110, 120FT) [N005, P005];

S6.0FT, S7.0FT (S135FT,S155FT) [D024, E024];

H6.0FT, H7.0FT (H135FT, H155FT) [H006, J006]

©2008 HYSTER COMPANY i

700 SRM 1123 Cooling System Checks

General

This section contains the repair and replacement in-

structions for the radiator, coolant level sensor, fan

assembly (pusher type), fan shroud, coolant hoses,

coolant recovery bottle, and optional debris screen.

Cooling System Checks

EXHAUST LEAKS INTO COOLING SYSTEM

WARNING

During engine operation, be careful not to

touch the fan, pulleys, or drive belts. Contact

with these parts can cause serious injury.

To check for exhaust leaks into the cooling system,

use a Combustion Leak Test Kit for this purpose. Fol-

low the manufacturer’s instructions when doing the

test.

WATER FLOW RESTRICTIONS IN

RADIATOR

WARNING

During engine operation, be careful not to

touch the fan, pulleys, or drive belts. Contact

with these parts can cause serious injury.

To check for water flow restrictions in the radiator,

run engine until it is warm.

WARNING

The radiator or other parts of the cooling sys-

tem may be hot or under pressure and can

cause serious injury. Wait 30 minutes for the

radiator to cool. Do a touch test by touching

the radiator with your hand. If the radiator is

still hot to the touch, wait another 30 minutes

before attempting to check or fix any part of

the cooling system.

Shut engine OFF and feel the radiator. The temper-

ature must be even across the radiator. (The radiator

will be hotter near the top radiator hose.) Cold spots

on radiator indicate restrictions.

If radiator has leaks, either replace the radiator or

have it repaired by trained personnel.

RADIATOR HOSES

WARNING

The radiator or other parts of the cooling sys-

tem may be hot or under pressure and can

cause serious injury. Wait 30 minutes for the

radiator to cool. Do a touch test by touching

the radiator with your hand. If the radiator is

still hot to the touch, wait another 30 minutes

before attempting to check or fix any part of

the cooling system.

Inspect all radiator hoses. If they feel spongy or have

visible cracks, replace hoses.

WATER PUMP

WARNING

During engine operation, be careful not to

touch the fan, pulleys, or drive belts. Contact

with these parts can cause serious injury.

WARNING

The radiator or other parts of the cooling sys-

tem may be hot or under pressure and can

cause serious injury.

Run engine until it is warm. Check the operation of

water pump by holding the top radiator hose. If the

pump is operating, there will be pressure surges in

the hose.

Check for leaks around the timing belt cover near the

base of the oil pump.

Check the weep hole where water can drain by the oil

filter. If there is a drip, check the pump shaft seal and

water pump. Replacement of the pump shaft seal or

water pump may be necessary.

1

Flushing the Cooling System 700 SRM 1123

For repair procedures for the GM 2.4L water pump,

refer to the section GM Engine Repair, GM 2.4

Liter Engine 600 SRM 1121.

For repair procedures for the Mazda 2.0L and 2.2L

water pump, refer to the section Mazda Engine,

2.0L and 2.2L 600 SRM 1122.

For replacement procedures for the Yanmar 2.6L

and 3.3L water pump, refer to the section Yanmar

Diesel Engines, 2.6L and 3.3L 600 SRM 1205.

For replacement procedures for the GM 4.3L water

pump, refer to the section GM Engines, 4.3 Liter

V-6 600 SRM 1251.

For repair procedures for the Cummins 4.5L and

QSB 3.3L water pump, contact your local Hyster

dealer or see Hyster Hypass Online.

Flushing the Cooling System

COOLING SYSTEM, CLEAN

WARNING

Compressed air can move particles so that they

cause injury to the user or to other personnel.

Make sure the path of the compressed air is

away from all personnel. Wear protective gog-

gles or a face shield to prevent injury to the

eyes.

WARNING

The radiator fins on the radiator are very

sharp and can cause serious injury. Wear

gloves while checking the radiator fins.

1. Check radiator fins. Clean exterior of radiator

with compressed air or water as needed.

WARNING

DO NOT remove the radiator cap from the radi-

ator when the engine is hot. When the radiator

cap is removed, the pressure is released from

the system. If the system is hot, the steam and

boiling coolant can cause burns.

WARNING

The radiator or other parts of the cooling sys-

tem may be hot or under pressure and can

cause serious injury. Wait 30 minutes for the

radiator to cool. Do a touch test by touching

the radiator with your hand. If the radiator is

still hot to the touch, wait another 30 minutes

before attempting to check or fix any part of

the cooling system.

CAUTION

Disposal of lubricants and fluids must meet lo-

cal environmental regulations.

2. Drain cooling system. Fill cooling system with

clean water. See the Radiator, Remove for

Lift Trucks Models S30FT, S35FT, S40FTS

(E010); H1.6FT, H1.8FT, 2.0FTS (H30FT,

H35FT, H40FTS) (F001); S2.0-3.5FT (S40-70FT,

S55FTS) (F187); H2.0-3.5FT (H40-70FT) (L177),

S4.0, 4.5, 5.5FT, S5.5FTS, (S80, 100, 120FT; S80,

100FTBCS; S120FTS; S120FTPRS) (G004) and

H4.0FT5/FT6; H4.5FTS5, H4.5FT6; H5.0-5.5FT

(H80, 90, 100, 110, 120FT) (N005, P005) section

for more information.

3. Drain cooling system. Fill cooling system with

clean water. See the Radiator, Remove for Lift

Truck Models S6.0FT, S7.0FT (S135FT, S155FT)

(D024, E024) and see Radiator, Remove for

Lift Truck Models H6.0FT, H7.0FT (H135FT,

H155FT) (H006, J006) section for more informa-

tion.

4. Install radiator cap. Run engine until top radia-

tor hose is hot. Stop engine and let engine cool.

2

700 SRM 1123 Radiator Replacement

5. Drain water from radiator. If water is dirty, fill

system with water and repeat procedure until

water is clean.

CAUTION

Follow the manufacturer’s instructions when

using a chemical radiator cleaner.

6. If water does not clean system, use a chemical

radiator cleaner.

CAUTION

Follow the manufacturer’s instructions when

using special equipment to reverse clean the

radiator.

7. If radiator or cooling system is very dirty or

has a restriction, use reverse cleaning method.

This method uses water pressure to force water

through radiator in opposite direction of normal

flow.

CAUTION

Additives may damage the cooling system. Be-

fore using additives, contact your local Hyster

dealer.

8. Fill cooling system with a mixture of 50 percent

water and 50 percent ethylene glycol boron-free

antifreeze. The 50/50 mixture will protect cool-

ing system to 37 C( 35 F). Add coolant as nec-

essary to keep level between the ADD and FULL

marks on the reservoir.

Radiator Replacement

RADIATOR, REMOVE FOR LIFT TRUCKS

MODELS S30FT, S35FT, S40FTS (E010);

H1.6FT, H1.8FT, 2.0FTS (H30FT, H35FT,

H40FTS) (F001); S2.0-3.5FT (S40-70FT,

S55FTS) (F187); H2.0-3.5FT (H40-70FT)

(L177), S4.0, 4.5, 5.5FT, S5.5FTS, (S80,

100, 120FT; S80, 100FTBCS; S120FTS;

S120FTPRS) (G004) AND H4.0FT5/FT6;

H4.5FTS5, H4.5FT6; H5.0-5.5FT (H80, 90,

100, 110, 120FT) (N005, P005)

WARNING

The radiator or other parts of the cooling sys-

tem may be hot or under pressure and can

cause serious injury. Wait 30 minutes for the

radiator to cool. Do a touch test by touching

the radiator with your hand. If the radiator is

still hot to the touch, wait another 30 minutes

before attempting to check or fix any part of

the cooling system.

1. Turn OFF truck.

2. Remove the hood and seat combination. See

the section Frame 100 SRM 1120 for S30FT,

S35FT, S40FTS (E010); H1.6FT, H1.8FT, 2.0FTS

(H30FT, H35FT, H40FTS) (F001); S2.0-3.5FT

(S40-70FT, S55FTS) (F187); H2.0-3.5FT

(H40-70FT) (L177) lift trucks, and Frame 100

SRM 1243 for S4.0, 4.5, 5.5FT; S5.5FTS (S80,

100, 120FT; S80, 100FTBCS; S120FTS, S120FT-

PRS) (G004) and H4.0FT5/FT6; H4.5FTS5,

H4.5FT6; H5.0-5.5FT (H80, 90, 100, 110, 120FT)

(N005, P005) lift trucks.

WARNING

Always disconnect the cable at the negative

terminal first. Install a tag on the battery ter-

minals so that no one connects the cables on

the terminals.

3. Disconnect the negative battery cable.

4. Disconnect the positive battery cable.

WARNING

DO NOT remove the radiator cap from the radi-

ator when the engine is hot. When the radiator

cap is removed, the pressure is released from

the system. If the system is hot, the steam and

boiling coolant can cause burns.

5. Let coolant cool to ambient temperature. Place a

drain pan with a capacity greater than the capac-

ity of the cooling system under radiator. Remove

radiator cap.

3

Radiator Replacement 700 SRM 1123

CAUTION

Disposal of lubricants and fluids must meet lo-

cal environmental regulations.

6. Open the drain plug or disconnect the bottom ra-

diator hose.

7. Lift trucks equipped with a Cummins QSB 3.3L

diesel engine: Loosen clamps and disconnect the

charge air cooler hoses from radiator. See Fig-

ure 4.

8. Cap radiator hoses.

9. Disconnect hose to auxiliary coolant reservoir

and remove reservoir.

10. Remove battery and battery tray.

11. Disconnect electrical connector to the coolant

level sensor.

NOTE: For Mazda LPG engine, the LPG converter

bracket needs to be moved for clearance of radiator.

12. Remove screws from the radiator shroud and

move shroud out of the way.

13. Remove fan, fan spacer, and pulley.

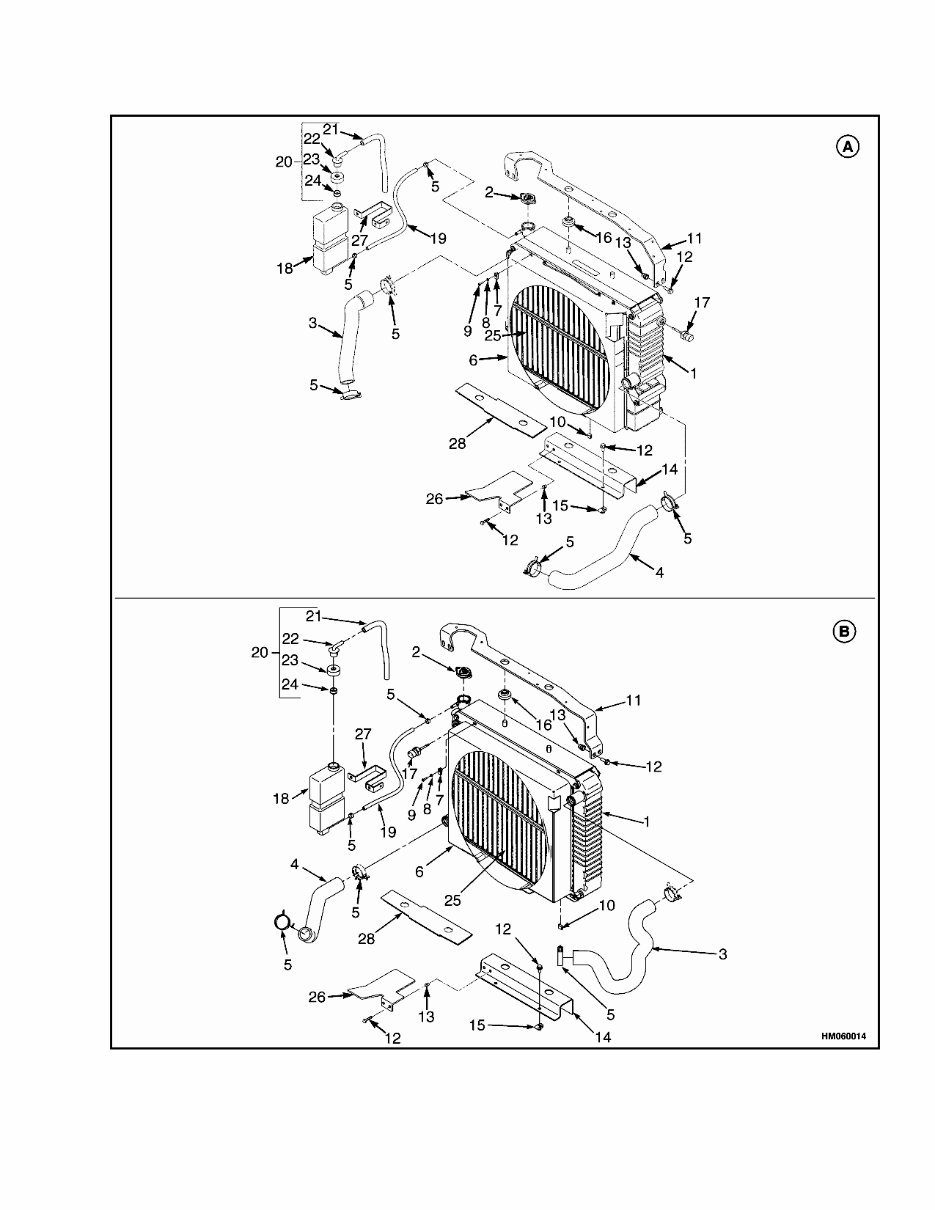

14. Remove upper radiator bracket. See Figure 1

for S30FT, S35FT, S40FTS (E010); H1.6FT,

H1.8FT, 2.0FTS (H30FT, H35FT, H40FTS)

(F001); S2.0-3.5FT (S40-70FT, S55FTS) (F187);

H2.0-3.5FT (H40-70FT) (L177) lift trucks. See

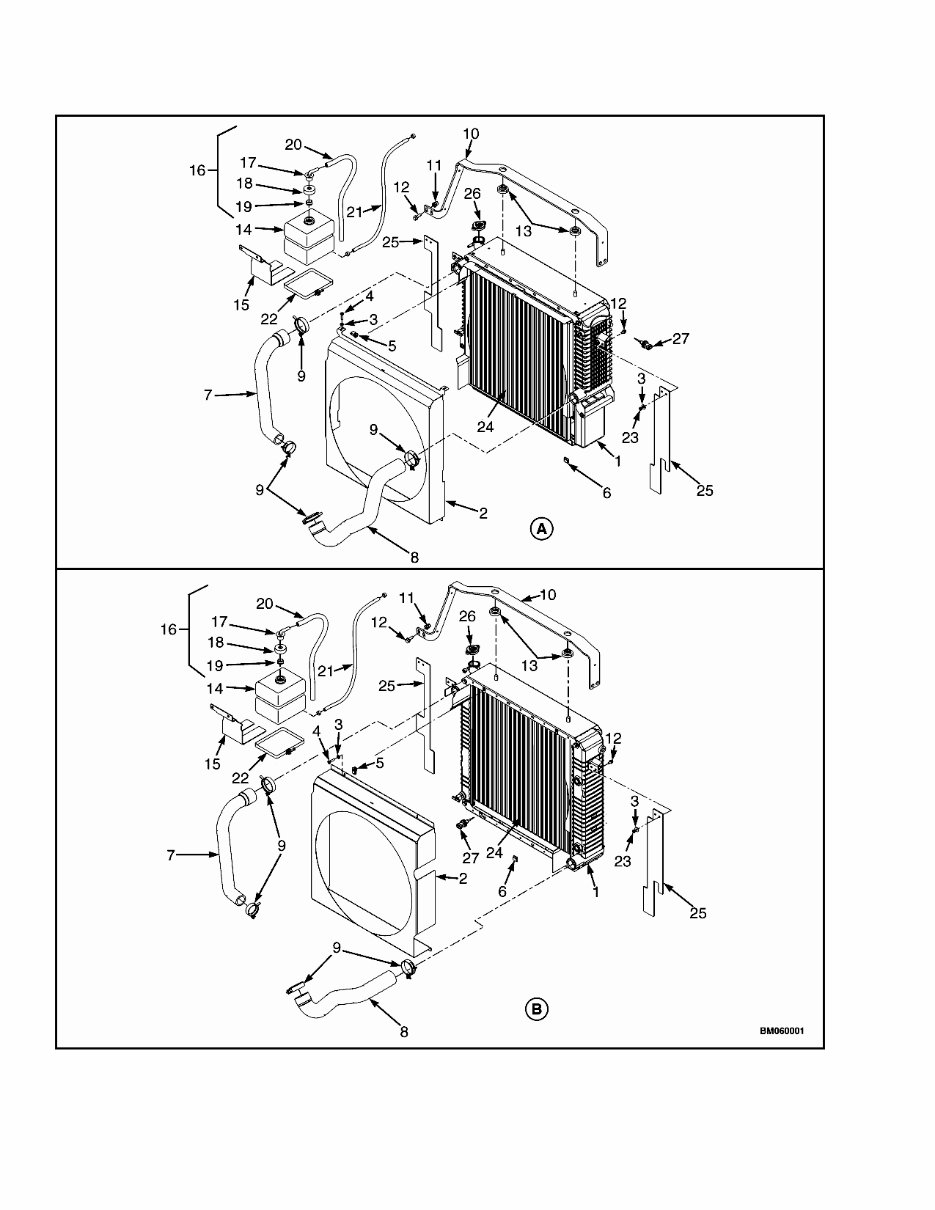

Figure 2 for S4.0, 4.5, 5.5FT, S5.5FTS, (S80, 100,

120FT; S80, 100FTBCS; S120FTS; S120FTPRS)

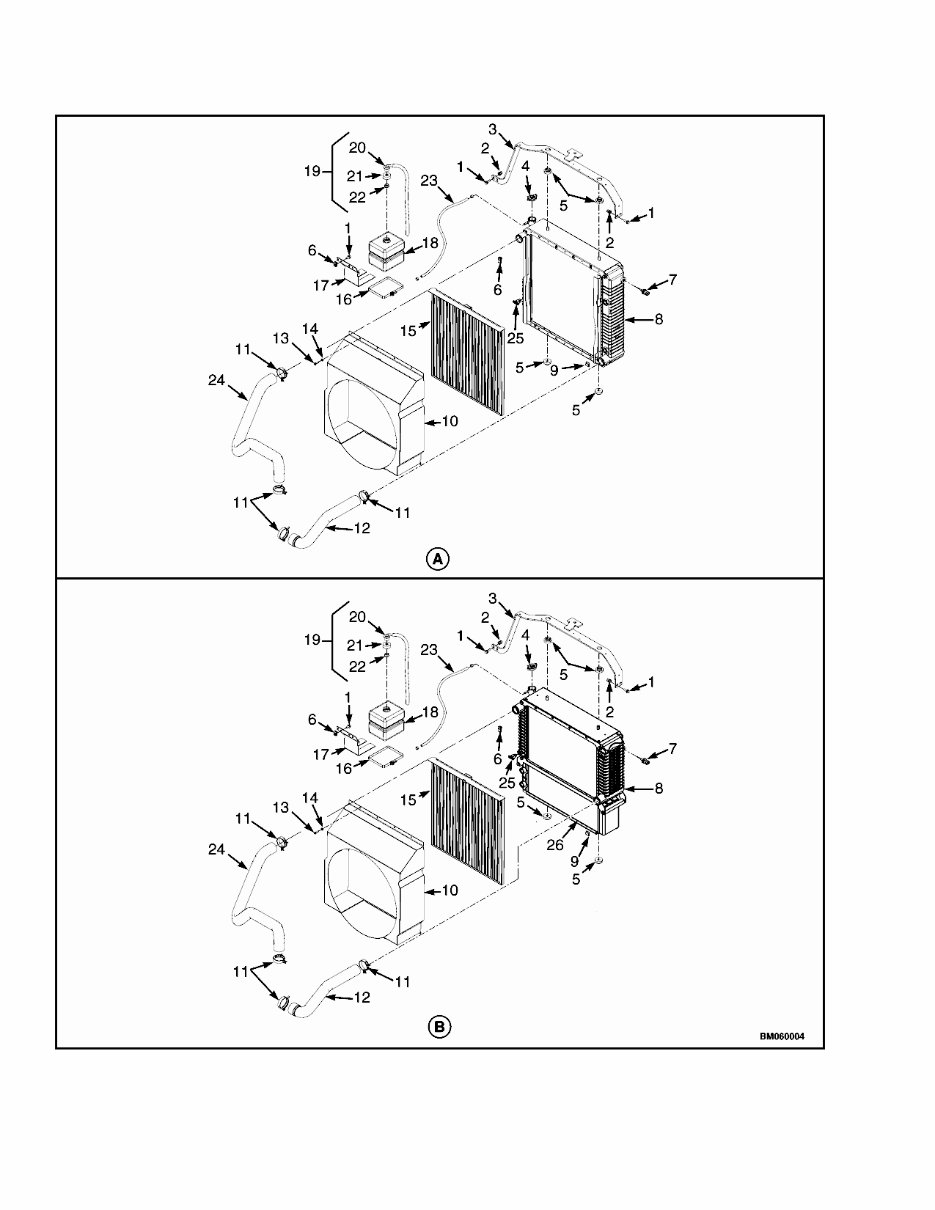

(G004) lift trucks. See Figure 3 for H4.0FT5/FT6;

H4.5FTS5, H4.5FT6; H5.0-5.5FT (H80, 90, 100,

110, 120FT) (N005, P005) lift trucks. See

Figure 4 for truck equipped with a Cummins

QSB 3.3L H4.5FT5/FT6; H4.5FTS5, H4.5FT6;

H5.0-5.5FT (H80, 90, 100, 110, 120FT) (P005),

S6.6FT, S7.0FT (S135FT, S155FT) (E024), and

H6.0FT, H7.0FT (H135FT, H155FT) (J006).

15. Remove radiator from truck.

16. If necessary, remove the coolant level sensor.

Legend for Figure 1

A. RADIATOR WITH EXTERNAL COOLER B. RADIATOR WITH INTERNAL COOLER, MODINE

SHOWN

1. RADIATOR

2. CAP

3. UPPER HOSE

4. LOWER HOSE

5. CLAMP

6. SHROUD

7. CLIP

8. WASHER

9. SCREW

10. CLIP

11. UPPER BRACKET

12. CAPSCREW, S2.0-3.5FT (S40-70FT, S55FTS)

[F187]

13. INSERT

14. LOWER BRACKET, S2.0-3.5FT (S40-70FT,

S55FTS) [F187]

15. NUT-CLIP, S2.0-3.5FT (S40-70FT, S55FTS) [F187]

16. ISOLATOR

17. COOLANT LEVEL SENSOR

18. RESERVOIR

19. TUBE

20. OUTLET ASSEMBLY

21. HOSE

22. RESERVOIR OUTLET

23. CAP

24. BUSHING

25. SCREEN ASSEMBLY (OPTIONAL)

26. HEAT SHIELD

27. RESERVOIR BRACKET

28. HEAT SHIELD, H2.0-3.5FT (H40-70FT) [L177]

4

700 SRM 1123 Radiator Replacement

Figure 1. Cooling System for S30FT, S35FT, S40FTS (E010);H1.6FT, H1.8FT, 2.0FTS (H30FT, H35FT,

H40FTS) (F001); S2.0-3.5FT (S40-70FT, S55FTS) (F187); H2.0-3.5FT (H40-70FT) (L177)

5

Radiator Replacement 700 SRM 1123

Figure 2. Cooling System for S4.0, 4.5, 5.5FT, S5.5FTS, (S80, 100, 120FT; S80, 100FTBCS; S120FTS;

S120FTPRS) (G004)

6

700 SRM 1123 Radiator Replacement

Legend for Figure 2

A. RADIATOR WITH EXTERNAL COOLER B. RADIATOR WITH INTERNAL COOLER

1. RADIATOR

2. SHROUD

3. WASHER

4. SCREW

5. CLIP NUT

6. CLIP

7. UPPER HOSE

8. LOWER HOSE

9. CLAMP

10. UPPER BRACKET

11. INSERT

12. CAPSCREW

13. ISOLATOR

14. RESERVOIR

15. RESERVOIR BRACKET

16. OUTLET ASSEMBLY

17. OUTLET

18. CAP

19. BUSHING

20. HOSE

21. TUBE

22. STRAP

23. NUT

24. SCREEN

25. BAFFLE (RH AND LH)

26. RADIATOR CAP

27. COOLANT LEVEL SENSOR

7

Radiator Replacement 700 SRM 1123

Figure 3. Cooling System for H4.0FT5/FT6; H4.5FTS5, H4.5FT6; H5.0-5.5FT (H80, 90, 100, 110,

120FT) (N005, P005)

8

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

Viewed 93 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

Get the comprehensive repair manual for the Hyster N005 (H80FT, H90FT, H100FT, H110FT, H120FT) Forklift, covering a wide range of service and repair procedures. This manual is a valuable resource for professional mechanics and DIY enthusiasts alike.

- Coverage of Cooling System, Cylinder Repair, and Diagnostic Troubleshooting Manual

- Includes detailed information on Electrical System, High Voltage Switch (HVS) Ignition, and Hydraulic Gear Pump

- Comprehensive guidance on Main Control Valve, Powershift Transmission, and Steering Axle

- Insightful details on User Interface and Wire Harness Repair

The manual is available in PDF format, compatible with all versions of Windows & Mac. It is written in English and requires Adobe Reader & Win for access. This manual is an essential tool for maintaining and repairing your Hyster N005 (H80FT, H90FT, H100FT, H110FT, H120FT) Forklift, providing cost-effective solutions and in-depth knowledge about your vehicle.