Clark forklift c20b Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

TM 10-3930-237-35

DEPARTMENT OF THE ARMY TECHNICAL MANUAL

DS, GS, AND DEPOT MAINTENANCE MANUAL

TRUCK, LIFT, FORK, GASOLINE

SOLID RUBBER TIRED WHEELS

2000 POUND CAPACITY

ARMY MODEL MHE-192

CLARK MODEL C20B-1632032-100

FSN 3930-781-3857

CLARK MODEL C20B-1632033-127

FSN 3930-781-3858

This copy is a reprint which includes current

pages from Change 1.

HEADQUARTERS, DEPARTMENT OF THE ARMY

SEPTMEBER 1964

TM 10-3930-237-35

Changes in force: C1 C1

CHANGE HEADQUARTERS

DEPARTMENT OF THE ARMY

NO. 1 WASHINGTON, DC 25 March 1985

DIRECT SUPPORT, GENERAL SUPPORT AND

DEPOT MAINTENANCE MANUAL

TRUCK, LIFT, FORK, GASOLINE

SOLID RUBBER TIRED WHEELS

2000 POUND CAPACITY

ARMY MODEL MHE-192

CLARK MODEL C20B-1632032-100

(NSN 3930-00-781-3857)

CLARK MODEL C20B-1632033-127

(NSN 3930-00-781-3858)

TM 10-3930-237-35, September, 1964 is changed as

follows:

Title appearing on front cover and page 1 changed as

shown above:

Inside front cover add the following:

WARNING

Operation of this equipment presents

a noise hazard to personnel in the

area. The noise level exceeds the

allowable limits for unprotected

personnel. Wear ear muffs or ear

plugs which were fitted by a trained

professional.

WARNING

Compressed air, used for cleaning

purposes will not exceed 30 psi (207

kPa). Wear face shield and protective

clothing to prevent injury when using

compressed air.

WARNING

Drycleaning solvent P-D-680 is toxic

and flammable. Wear protective

goggles and gloves and use only in a

well ventilated area. Avoid contact

with skin, eyes, and clothes and don’t

breath vapors. Do not use near open

flame or excessive heat. The flash

point is 100°F - 138°F (38°C - 59°C). If

you become dizzy while using

cleaning solvent, get fresh air

immediately and get medical aid. If

contact with eyes is made, wash your

eyes with water and get medical aid

immediately.

WARNING

Cooling system is pressurized.

Remove cap slowly and only when

engine is cool or painful burns could

result.

}

TM 10-3930-237-35

C1

Page 12:

Paragraph 11, immediately following the title add the

following:

WARNING

Compressed air, used for cleaning

purposes will not exceed 30 psi (207

kPa). Wear face shield and protective

clothing to prevent injury when using

compressed air.

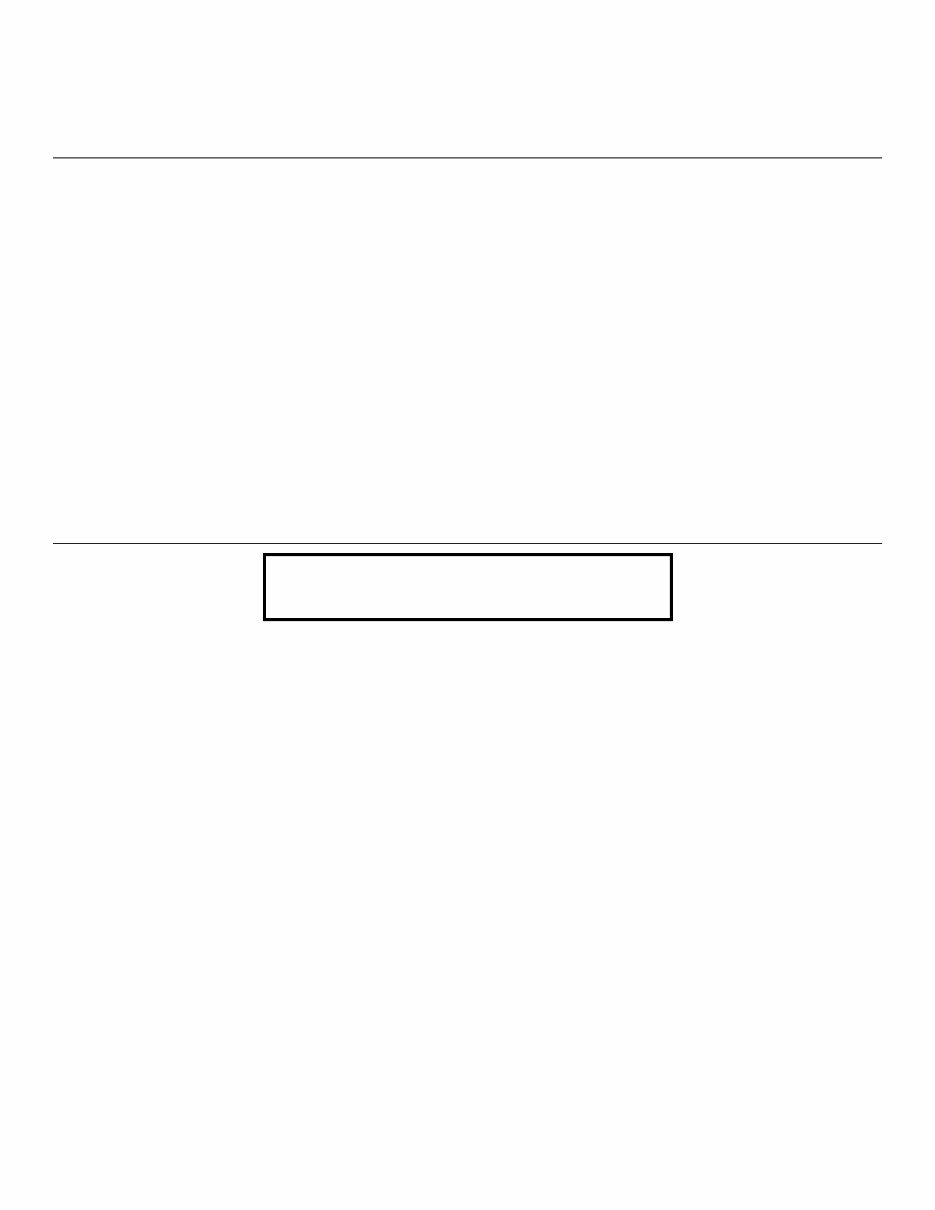

Paragraph 11.c. is superseded as follows:

c. Cylinder Head

Removal.

(1) Drain coolant from the radiator and engine.

(2) Remove hydraulic tank filler pipe and air cleaner

(fig. 4.1). Cover sump elbow to keep dirt or part

from falling in.

(3) Tag and remove high-tension and primary

distributor wire from coil (fig. 4.1).

(4) Remove nuts and lockwashers that secure

transmission oil filter and coil bracket to head

and block. Position bracket to provide clearance

to remove cylinder head.

(5) Loosen generator adjusting strap bolt (fig. 4.1).

Push generator toward engine. Remove belts

from generator pulley.

(6) Remove generator adjusting strap bolt, washer,

and lockwasher. Remove nuts and washers

securing generator to cylinder head.

(7) Remove nuts and washer securing thermostat

housing to cylinder head.

(8) Remove the bypass elbow (fig. 4.1) from the

water pump and thermostat elbow; remove the

thermostat housing.

(9) Remove nuts and washers (fig. 4.1) securing

engine oil filter to cylinder head studs.

(10) Remove distributor (see TM 10-3930-237-20).

(11) Tag and disconnect the lead from the water

temperature sending unit (fig. 4.1). Remove the

sender.

Figure 4.1. Engine compartment, left view.

TM 10-3930-237-35

C1

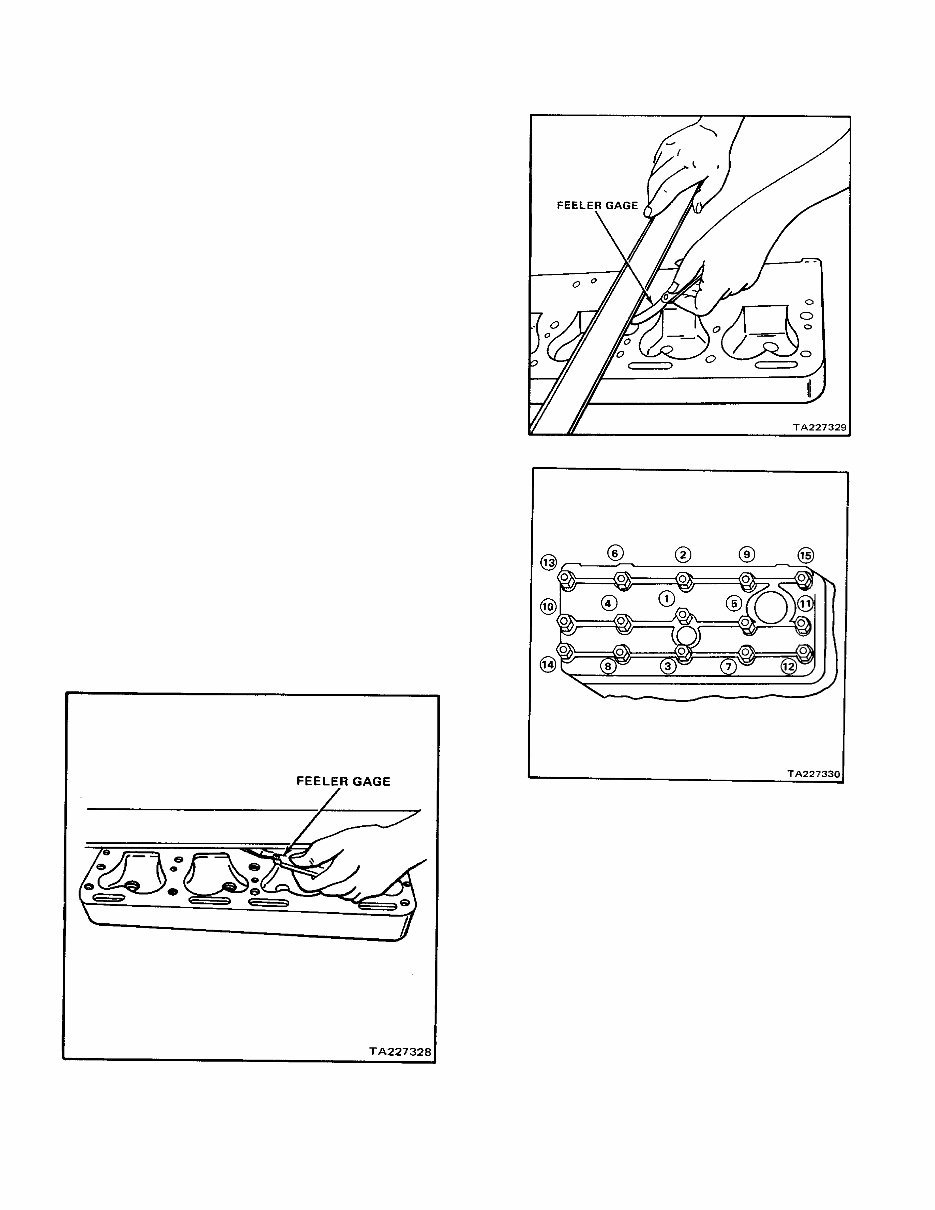

(12) Remove the nuts and washers securing the

cylinder head (fig. 4.4). Remove the cylinder

head and gasket.

c.1 Cleaning and Inspection.

(1) Remove all carbon from combustion areas with

a scraper and wire brush. Clean all remaining

residue from the cylinder head with an approved

cleaning solvent. Dry with clean, dry

compressed air.

(2) Clean the top of the cylinder block with a scraper

and a cloth dampened in an approved cleaning

solvent. Be very careful not to get dirt in the

cylinders or water jacket.

(3) Inspect the cylinder head for cracks, corrosion,

damaged threads, plugged water ports, or other

defects.

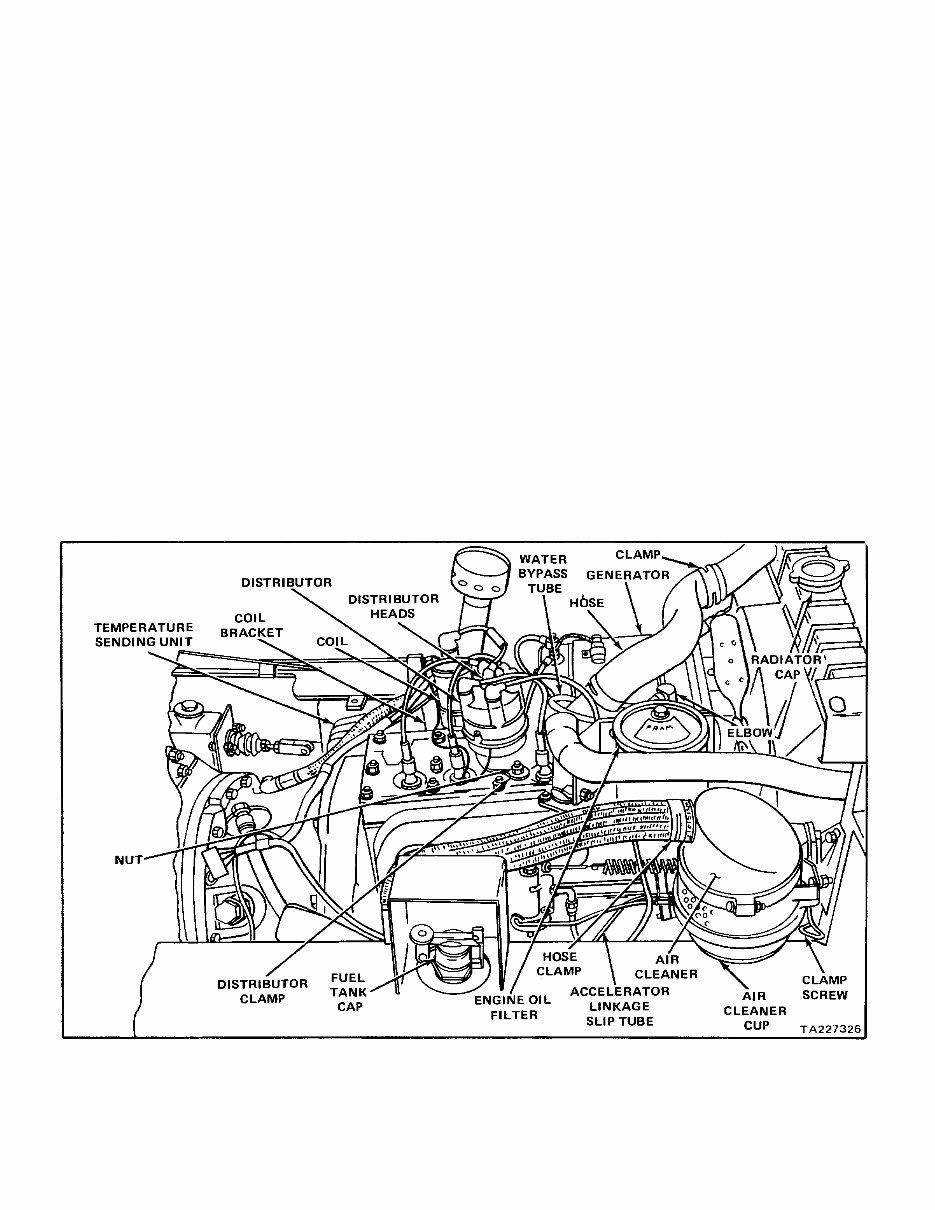

(4) Check flatness lengthwise with a straightedge

and feeler gage (fig. 4.2). The maximum

permissible low spot is 0.004 inch in the center,

gradually decreasing toward the ends. Check

flatness lengthwise at each edge and in the

middle of the head.

(5) Check flatness crosswise with a straightedge

and a filler gage (fig. 4.3). The maximum

permissible low spot is 0.003 inch in localized

areas. Check flatness crosswise at each end

and between each combustion chamber.

(6) Inspect cylinder head studs for looseness or

damaged threads.

(7) Replace the gasket hoses and defective parts.

Figure 4.2. Checking cylinder head flatness lengthwise.

Figure 4.3. Checking cylinder head flatness crosswise.

Figure 4.4. Cylinder head nut tightening sequence.

Page 22, paragraph 11.o. is superseded as follows:

o. Installation. Install head and other parts in

reverse order of removal and retime engine if necessary.

(see TM 10-3930-237-20).

TM 10-3930-237-35

C1

Page 24:

Paragraph 13.a.(1), change (TM 10-3930-237-20) to

paragraph 11.c.

Paragraph 13.a.(2), change (TM 10-3930-237-20) to

paragraph 13.c. below.

Page 27, after paragraph 13.b.(11) add the following new

section:

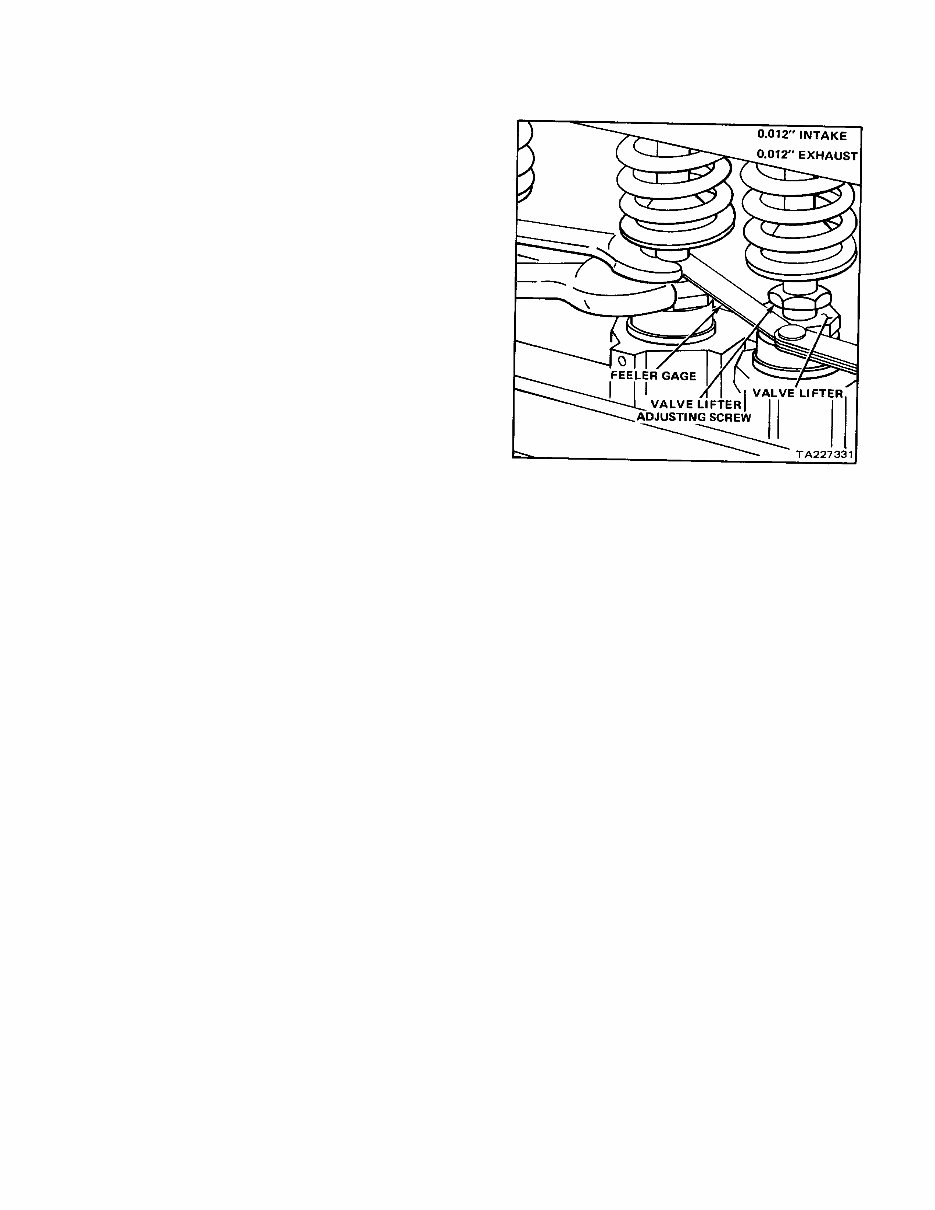

c. With the engine at operating temperature and

running at idle speed, set the valves for 0.012-inch

clearance as follows:

(1) Check for proper 0.012-inch clearance by

alternately passing a 0.01-inch and a 0.013inch

flat feeler gage between the head of the

adjusting screw and valve stem (fig. 28.1).

(2) If a 0.011-inch feeler gage moves freely back

and forth in the gap when the valve is not being

lifted and 0.013-inch feeler gage binds at all

times, the clearance requires no adjustment.

(3) If a 0.011-inch feeler gage is gripped at all times,

the clearance is insufficient.

(4) Hold valve lifter with an open end wrench while

using a second wrench to turn adjusting screw

one-quarter to one-half turn clockwise. Repeat

clearance check and adjustment until proper

clearance is obtained. The adjustable-type valve

lifters have self-locking adjusting screws that

require no locknuts.

(5) If 0.013-inch feeler moves freely when valve is

not being lifted, the clearance is too great. Hold

valve lifter with an open end wrench while using

a second wrench to turn valve lifter adjusting

screw counterclockwise one-quarter to one-half

turn. Repeat the clearance check and

adjustment until proper clearance is obtained.

(6) Repeat clearance check and adjustment for

remaining intake valves.

(7) Check exhaust valve clearance for proper 0.012-

inch clearance by alternately passing a 0.011-

and 0.013-inch flat feeler gage between the head

of the adjusting screw and the valve stem cap.

(8) If necessary, adjust the exhaust valve clearance

in the same manner as the intake valves

described in (1) through (5) above.

(9) Install the valve chamber cover using a new

gasket. Secure with two cover nuts and gaskets.

Figure 28.1. Value adjustment.

Page 27:

Paragraph 13.c. is changed to 13.d.

Paragraph 13.d.(3), change (TM 10-3930-237-20) to

paragraph 13.c.

Paragraph 13.d.(4), change (TM 10-3930-237-20) to

paragraph 11.o.

Page 28, paragraph 13.d.(5) and (6) change (TM 10-

3930-237-20) to paragraph 13.c.

WARNING

Compressed air, used for cleaning

purposes will not exceed 30 psi (207

kPa). Wear face shield and protective

clothing to prevent injury when using

compressed air.

Insert the above WARNING where indicated below:

Page 29, paragraph 15.b., after title and before (1).

Page 34, paragraph 16.b., after title and before (1).

Page 37, paragraph 20.c., after title and before (1).

Page 41, paragraph 21.c., after title and before (1).

Page 44, paragraph 23.b., after title and before (1).

TM 10-3930-237-35

C1

WARNING insertion continued:

Page 49, paragraph 27, after title and before a.

Page 47, paragraph 24.c.(8), first sentence, change of

cracks to for cracks.

Page 68, Figure 50, change callouts as follows:

21 Lockwasher 26 Cotter pin

22 Screw 27 Flat washer

23 Roller bearing 28 Shim

24 Steering knuckle 29 Setscrew

25 Nut 30 Nut

Page 72, paragraph 35.c.(2). Following the word arm

add (22), following nut (23) add torque to 40 - 50 inch-

pounds.

Page 77:

Paragraph 42.c., change title Cleaning and Inspection to

Cleaning, Inspection and Repair.

Paragraph 42.d (4), line 4, change on to an.

Page 94:

APPENDIX I REFERENCES is changed as follows:

Paragraph 1.

Line 2, change 320-5 to 310-25; following word

Terms add (Short Title)

Line 3 is superseded by:

310-50 Catalog of Abbreviations and Brevity Codes

Line 5 is deleted

Paragraph 2.

Line 7, change title to read:

Index of Army Motion Pictures and Related Audio

Visual Aids

Line 8, change title to read:

Index of Army Publications and Blank Forms

Lines 9, 10, 11 and 12 are deleted

After line 8 above add:

DA PAM 738-750, The Army Maintenance

Management System (TAMMS)

Paragraph 3.

Lines 14, 15 and 16 are deleted

Line 17, title is changed to read:

Military Symbols (Reprinted With Basic Incl C1)

After line 17 above add the following:

21-305, Manual For The Wheeled Vehicle Driver

Paragraph 4. Technical Manuals is deleted

Page 96, APPENDIX III

Line 2, change TM 10-3930-237-35P to TM 10-3930-

237-34P.

By Order of the Secretary of the Army

JOHN A. WICKHAM, JR.

General, United States Army

Chief of Staff

Official:

DONALD J. DELANDRO

Brigadier General, United States Army

The Adjutant General

Distribution:

To be distributed in accordance with DA Form 12-25A, Direct and General Support Maintenance requirements for

Warehouse Equipment.

TM 10-3930-237-35

TECHNICAL MANUAL HEADQUARTERS

DEPARTMENT OF THE ARMY

No. TM 10-3930-237-35 WASHINGTON, D.C., 24 September 1964

DS, GS, AND DEPOT MAINTENANCE MANUAL

TRUCK, LIFT, FORK, GASOLINE

SOLID RUBBER TIRED WHEELS

2000 POUND CAPACITY

ARMY MODEL MHE-192

CLARK MODEL C20B-1632032-100

FSN 3930-781-3857

CLARK MODEL C20B-1632033-127

FSN 3930-781-3858

Paragraph Page

CHAPTER 1. INTRODUCTION

Section I. General

Scope ............................................................................................................. 1 3

Appendixes ..................................................................................................... 2 3

Forms, records, and reports ........................................................................... 3 3

Orientation ...................................................................................................... 4 3

II. Description and Data

Description...................................................................................................... 5 3

Tabulated data................................................................................................ 6 4

CHAPTER 2. MAINTENANCE INSTRUCTIONS

Section I. Troubleshooting

Purpose .......................................................................................................... 7 6

Troubleshooting procedure............................................................................. 8 6

II. Engine

General ........................................................................................................... 9 9

Engine removal and replacement ................................................................... 10 9

Engine overhaul .............................................................................................. 11 12

Engine block ................................................................................................... 12 23

Valves ............................................................................................................. 13 24

III. Fuel System

General ........................................................................................................... 14 28

Carburetor ...................................................................................................... 15 28

Governor ......................................................................................................... 16 32

IV. Cooling System

General ........................................................................................................... 17 35

Radiator .......................................................................................................... 18 35

V. Electrical System

General ........................................................................................................... 19 36

Generator ....................................................................................................... 20 36

Starting motor ................................................................................................. 21 38

1

}

Paragraph Page

Section VI. Transmission and Drive System

General ........................................................................................................... 22 43

Transmission control lever and linkage .......................................................... 23 43

Transmission control valve ............................................................................. 24 44

Wheel and axle shaft ...................................................................................... 25 48

Drive wheel assembly..................................................................................... 26 49

Axle adapter and differential ........................................................................... 27 49

Transmission .................................................................................................. 28 51

VII. Steering System

General ........................................................................................................... 29 61

Steering gear .................................................................................................. 30 61

Steering axle................................................................................................... 31 66

Steering wheels .............................................................................................. 32 69

VIII. Brake System

General ........................................................................................................... 33 69

Hand brake mechanism ................................................................................. 34 70

Service brakes ................................................................................................ 35 71

Brake master cylinder ..................................................................................... 36 73

Wheel cylinder ................................................................................................ 37 74

Brake pedal and linkage ................................................................................. 38 75

IX. Seat

General ........................................................................................................... 39 76

Seat and backrest cushions ........................................................................... 40 76

X. Hydraulic System

General ........................................................................................................... 41 76

Hydraulic pump assembly .............................................................................. 42 76

Hydraulic control valve.................................................................................... 43 80

Tilt-lock valve .................................................................................................. 44 82

Control levers and linkage .............................................................................. 45 83

Hydraulic tilt cylinder....................................................................................... 46 84

Hydraulic lift cylinder....................................................................................... 47 86

Mast assembly................................................................................................ 48 88

Carriage assembly.......................................................................................... 49 91

APPENDIX I. REFERENCES ............................................................................................... -- 94

II. MAINTENANCE ALLOCATION CHART ........................................................ -- 95

III. REPAIR PARTS AND SPECIAL TOOLS LISTS ............................................ -- 96

2

CHAPTER 1

INTRODUCTION

Section I. GENERAL

1. Scope

a. This manual is published for use by personnel

responsible for direct and general support and depot

maintenance of the Fork Lift Truck, Models C26B-

1632032-100 and C20B1632033-127, manufactured by

Clark Equipment Company, Battle Creek, Michigan.

b. The direct reporting by the individual user of

errors, omissions, and recommendations for improving

this manual is authorized and encouraged. DA Form

2028 (Recommended changes to DA Publications) will

be used for reporting these improvements. This form will

be completed in triplicate using pencil, pen or typewriter.

The original and one copy will be forwarded direct to the

Commanding Officer, U. S. Army Mobility Equipment

Center, ATTN: SMOME-MM, 4300 Goodfellow Blvd., St.

Louis, Mo., 63120. One information copy will be

provided to the individual’s immediate supervisor (e.g.,

officer, noncommissioned officer, supervisor, etc.).

2. Appendixes

Appendix I is a list of current references applicable to this

manual. Appendix II, containing the Maintenance

Allocation Chart, is published in the Organizational

Maintenance Manual, TM 10-3930-237-20. Appendix III,

repair parts and special tools lists authorized for field and

depot maintenance, is published in the Field and Depot

Maintenance Repair Parts and Special Tools Lists

Manual, TM 10-3930-23735P.

3. Forms, Records, and Reports

The maintenance forms, records, and reports to be used

in the direct support, general support and depot

maintenance of this equipment are listed and described

in TM 38-750.

4. Orientation

Throughout this manual, the terms right, left, front and

rear, with respect to the engine or truck, indicate

directions from the viewpoint of the operator sitting in the

seat of the truck.

Section II. DESCRIPTION AND DATA

5. Description

a. Engine. The four-cylinder, four-stroke cycle,

L-head, water-cooled engine has a 3¼ inch bore and a

3½ inch stroke for a displacement of 116 cubic inches. It

develops a brake horsepower of 34.2 at 2800 rpm and

has a compression ratio of 6.72 to 1. The crankshaft has

three main bearings, and the engine is pressure

lubricated by positive-displacement gear pump.

b. Drive System. The unitized drive system

consists of a single-speed, forward and reverse

transmission; a differential with a pinion shaft directly

driven by transmission output; and pinion shafts which

engage the differential and transfer power to the front

wheels to propel the vehicle. Final reduction is in the

wheels.

c. Hydraulic System. The hydraulic system is

powered by a vane-type hydraulic pump mounted on and

driven by the engine. The pump capacity is 6 gpm at

1200 rpm. The working pressure of the hydraulic system

is 2000 psi maximum.

d. Steering System. The fork lift truck is steered by

the rear wheels through the use of a mechanical steering

3

system. The steering system consists of a steering

handwheel, steering gear, drag link assembly, steering

axle and tie rods.

e. Electrical System. The negatively grounded, 12-

volt electrical system employs a DC generator with a

conventional three-unit voltage regulator. The starting

circuit is actuated by the starter and ignition switch. The

starting circuit is routed through the transmission neutral

position switch to prevent cranking of the engine when

the transmission is in either drive position. By closing the

circuit through the ignition switch and neutral position

switch, the starting relay is energized which completes

the circuit to the starter motor solenoid switch. As the

solenoid energizes, it engages the overrunning clutch

with the flywheel ring gear and completes the circuit from

the battery to crank the engine.

f. Differences in Models. The two models covered

in this manual differ in the height of the mast assembly

and the addition of overhead protection for the driver in

model with the higher mast assembly. Model C20B-

1632032-100 has a 100 inch lifting capability while Model

C20B-1632033-127 has a 127 inch lifting capability and

is provided with a drivers overhead guard. General

configuration of mast assembly parts is the same; only

dimensions are different.

6. Tabulated Data

a. Engine.

Make ........................................... Continental

Model .......................................... YS 116

Number of cylinders- .................. Four

Bore ............................................ 3¼ inches

Stroke ......................................... 3½ inches

Displacement .............................. 116 cubic inches

Compression ratio ..................... 6.72 to 1

Brake horsepower ...................... 34.2 at 2800 rpm

Torque ........................................ 89 ft lb at 1200 rpm

Firing order ................................ 1-3-4-2

Weight, bare engine .................. 279 lb.

Number of main bearings ........... Three

Crankshaft:

Main bearing journal 1.7482 in. min.

diameter.

Connecting rod 1.4338 in. min.

journal diameter.

Clearance-main 0.002 in. to 0.0032 in.

bearing journals to

bearings.

End play ............................... 0.002 in. to 0.006 in.

Clearance -crank pin 0.0007 in. to 0.0031 in.

bearing journals to

connecting rod

bearings.

Flywheel:

Runout ................................. 0.008 in. max.

Eccentricity .......................... 0.008 in. max.

Flywheel housing:

Face runout ......................... 0.008 in. max.

Bore eccentricity .................. 0.008 in. max.

Camshaft:

Fan end bearing 1.8075 in. min.

journal diameter.

Middle bearing 1.7445 in. min.

journal diameter.

Drive end bearing 1.2455 in. min.

journal diameter.

Clearance-camshaft 0.002 in. to 0.004 in.

journals to fan end

and drive end

bearings.

Clearance-camshaft 0.003 in. to 0.0047 in.

journal to center

bearing.

End play............................... 0.003 in. to 0.007 in.

Clearance-camshaft 0.0015 in. max.

gear to crankshaft

gear.

Valves:

Intake valve stem 0.3128 in. max.

diameter.

Exhaust valve stem 0.3128 in. max.

diameter.

Valve guide bore 0.3133 in. max.

diameter-intake.

Valve guide bore 0.3150 in. max.

diameter -exhaust.

Valve spring tension:

Compressed to 42 pounds min.

1

3

6

3

4

in.

Compressed to 86 pounds min.

1

1

6

5

4

in.

Clearance-valve 0.005 in. max.

lifter to bore.

Valve seat angle .................. 45°

Pistons:

Piston pin hole 0.8796 in. max.

diameter.

Piston ring gap..................... 0.010 in. min. to 0.020

in. max.

Piston pin diameter ............. 0.8588 in. min.

Piston ring groove

width:

Top groove................. 0.099 in. max.

Middle grooves .................... 0.0985 in. max.

Bottom groove ..................... 0.191 in. max.

Piston ring width:

Top ring ............................... 0.0910 in. min.

Middle ring ........................... 0.0910 in. min.

Bottom ring- ......................... 0.1840 in. min.

4

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 22 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

These digital manuals are available in .PDF format, making them compatible with all versions of Windows, Mac, and Linux operating systems. They are printable and can be accessed instantly at high speed. The only requirement is Adobe Reader.