Genie AWP IWP Work Platform Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Technical

Publications

First Edition, Second Printing

Part No. 31758

Service

Manual

® AWP

TM

®

IWP

TM

Service Manual - First Edition

Part No. 31758

Section 1 - Safety Rules

Safety Rules

Oanger

Failure to obey the instructions and safety rules

in this manual and the Genie IWP Operator's

Manual and the Genie AWP Operator's Manual

will cause death or serious inju叩·

Many of the hazards identified in the

operator's manuals are also safety hazards

when maintenance and repair procedures

are pertormed.

00 Not Peñorm Maintenance

Unless:

团 You are trained and qualified to perform

maintenance on this machine.

回 You read , understand and obey:

- manufacturer's instructions and safety rules

- employer's safety rules and worksite

regulations

- applicable governmental regulations

固 You have the appropriate tools, lifting

equipment and a suitable workshop.

Genie IWP & Genie AWP 111

Introduction

SAFETY RULES

Personal Safety

Any person working on or around a machine must

be aware of all known safety hazards. Personal

safety and the continued safe operation of the

machine should be your number one priority.

Read each procedure thoroughly. This

manual and the decals on the machine

use signal words to identify the following:

,南 IJ!'Ht1~:事

Indicates the presence of

a hazard that will cause

death or serious injury.

Indicates the presence of

a hazard that may cause

death or serious i时U叩·

Indicates the presence of

a hazard that will or may

cause senous InJu叩 or

damage to the machine.

Indicates special

operation or maintenance

information.

Be sure to wear protective eye wear and

other protective clothing if the situation

warrants i t.

Be aware of potential crushing hazards

such as moving parts , free-swinging or

unsecured components when lifting or

placing loads. Always wear approved steel-toed

shoes.

Service Manual - First Edition

Workplace Safety

Be sure to keep sparks , flames and

lighted tobacco away from flammable and

combustible materials like battery gases.

Always have an approved fire extinguisher within

easy reach.

Be sure that all tools and working areas

are properly maintained and ready for

use. Keep work surfaces clean and free

of debris that could get into machine components

and cause damage.

Be sure that your workshop or work area

is well ventilated and safely and

adequately iII uminated.

Be sure any forklift , overhead crane or

other lifting or supporting device is fully

capable of supporting and stabilizing the

weight to be lifted. Use only chains or straps that

are in good condition and of ample load capacity.

Be sure that fasteners intended for

one-time use (i. e. , cotter pins and

self-Iocking nuts) are not reused. These

components may fail if they are used a second

time.

Be sure to properly dispose of old oil or

other fluids. Use an approved container.

Please be mindful of the environment.

IV Genie IWP & Genie AWP Part No. 31758

Service Manual - First Edition

Part No. 31758

Section 1 - Safety Rules

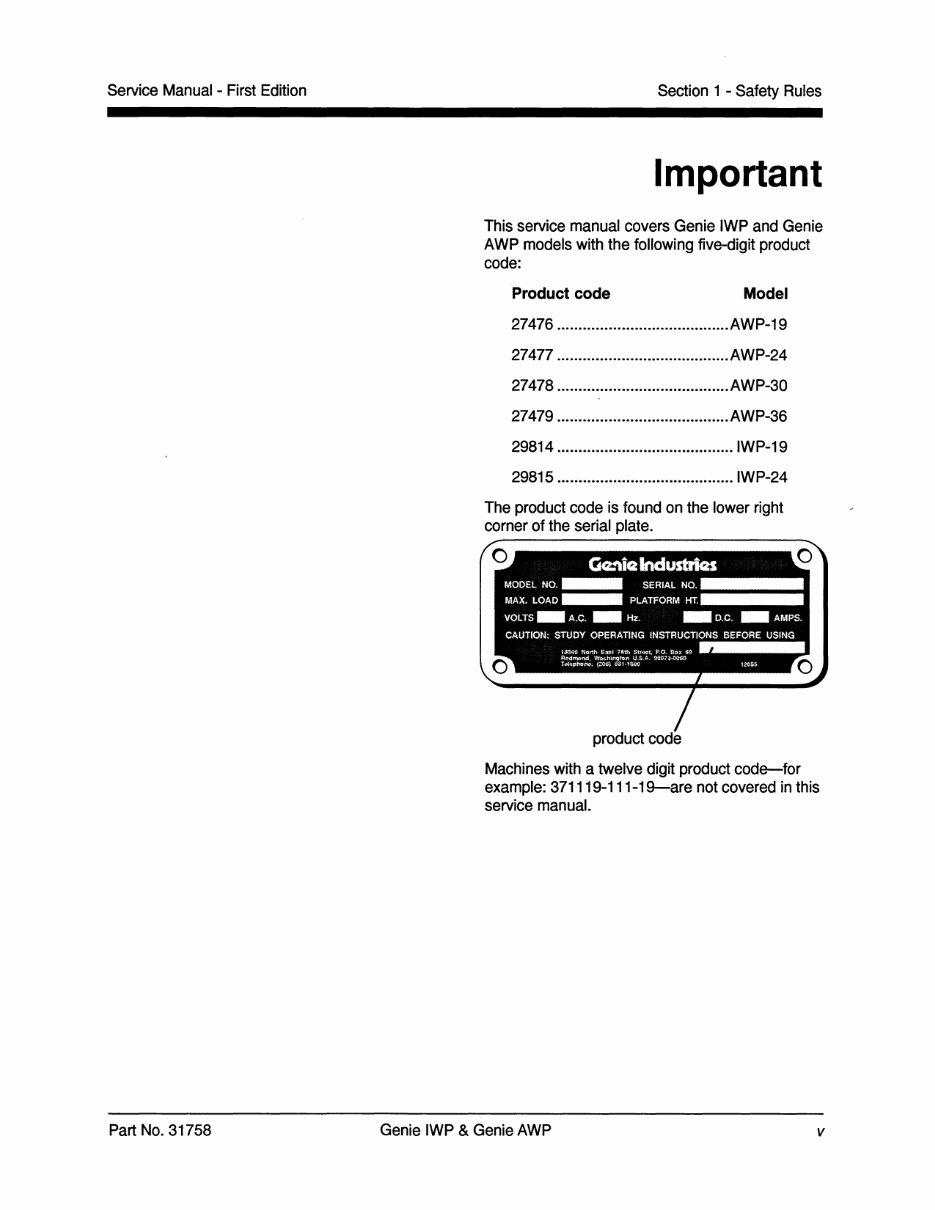

Important

This service manual covers Genie IWP and Genie

AWP models with the following five-digit product

code:

Product code Model

27476........ ………………........AWP-19

27477 …................. …………....AWP-24

27478 ….............. ……...……......AWP-30

27479............ ……………..........AWP-36

29814........…·….........................IWP-19

29815 …..……………......... …… IWP-24

The product code is found on the lower right

corner of the serial plate.

Machines with a twelve digit product code- for

example: 371119-111-1 9-are not covered in this

service manual.

Genie IWP & Genie AWP V

Service Manual - First Edition

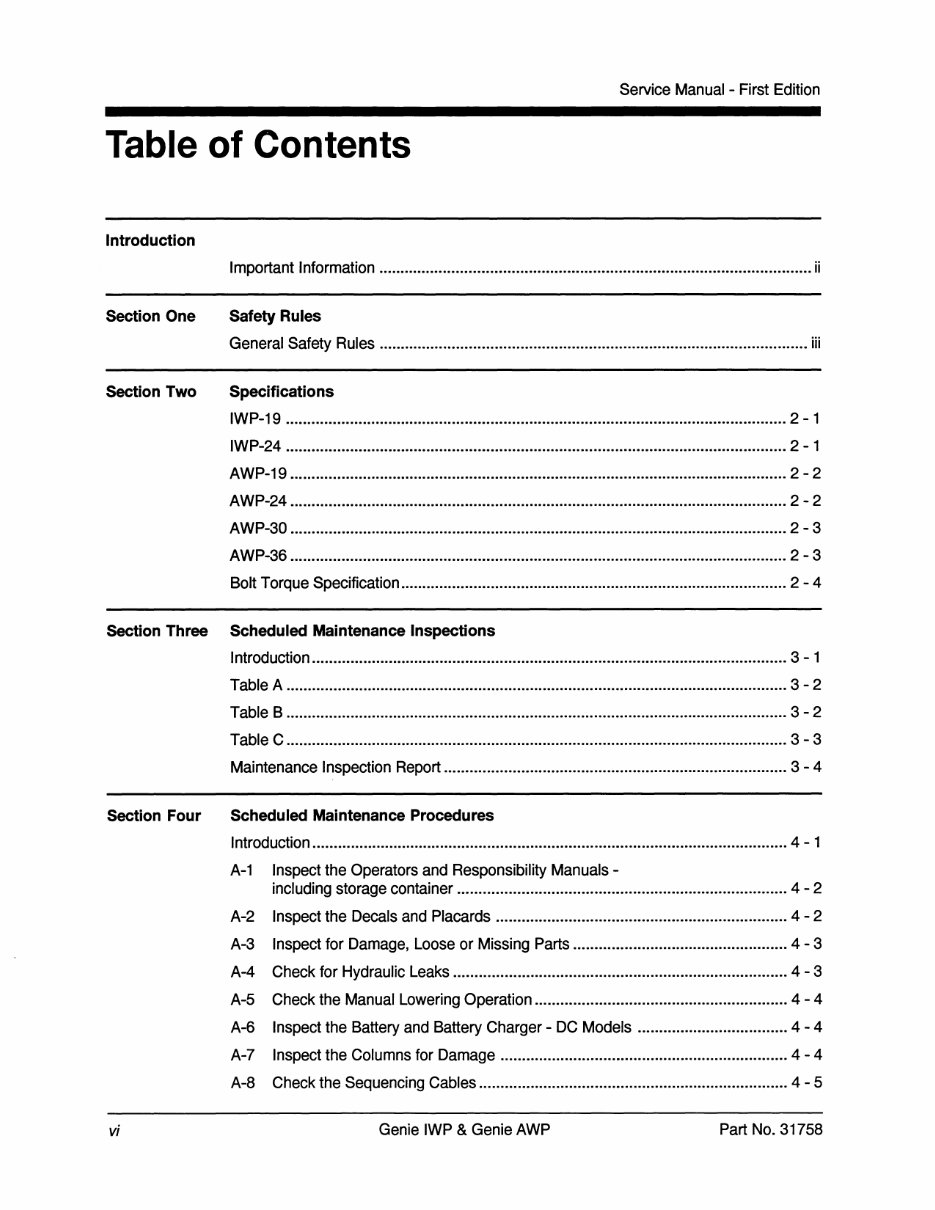

Table of Contents

Introduction

Important Information ......... …....... …..…"…….......... ……..................... …………................. ii

Section One Safety Rules

General Safety Rules ...... ………......... …….................. …"……·…......... …...... ……............. iii

Section Tw,。 4E4tnJ-ntquqUA斗吨'』nζ町'』呵'』n,』呵,』呵'』

HHnH -unu

--·‘

a ·"·户UW户UV

Hah-

s

…

HHHHHp

nHHHnuns 。

av da………………阳

c

..

9406n n9叫1233。·唱唱4IFd····FI

C--PPPP.-l 伽…WW刷刷刷刷刷

Sect ion Three Scheduled Maintenance Inspections

1 ntroduction .... ....... ........ ..... ...... .... ........... ... ...... ... ... ... ...…........................... ……......... 3-1

TableA ….............................. …...... …......... ……......... …......... ……............. …........... … 3-2

Table B............ ……......... …............... …....................................... …...... ….................. 3-2

TableC....... …..……........................ …................................. …............ …......... …"…….3-3

Maintenance Inspection Repo此…..........................................……............…......….....3-4

Section Four Scheduled MaintenanωProcedures

Introduction .............. ……...........................................................................................4-1

A斗 Inspect the Operators and Responsibility Manuals-

including storage container ............... …..................... ……................................ 4-2

A-2 Inspect the Decals and Placards ............ ….............. …........................... …...... 4-2

A-3 Inspect for Damage, Loose or Missing Parts ...………...... …...... …………........... 4-3

A-4 Check for Hydraulic Leaks ................ …......................... ….......... ……............... 4-3

A-5 Check the Manual Lowering Operation ……....... …....... ….......................... ….............. 4-4

A-6 Inspect the Ba忧e叩 and Ba忧ery Charger - DC Models ...... ……………........ …·… 4-4

A-7 Inspect the Columns for Damage ….................... ……........ …......... ………................ 4-4

A-8 Check the Sequencing Cables …........... …................................. …....... …………… 4-5

VI Genie IWP & Genie AWP Part No. 31758

Service Manual - First Edition

TA8LE OF CONTENTS

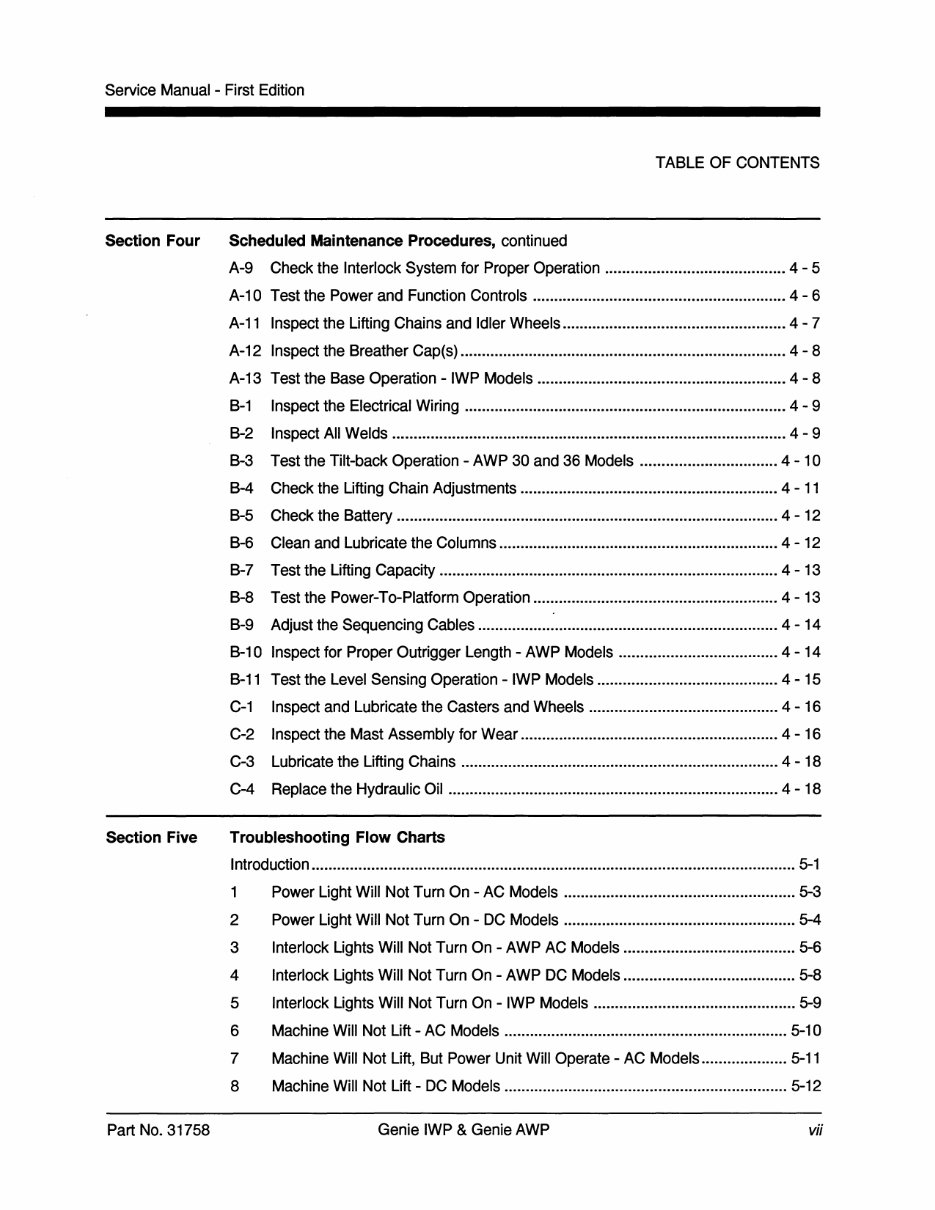

Section Four Scheduled MaintenanωProcedures, continued

Section Five

Part No. 31758

A-9 Check the Interlock System for Proper Operation ……….................. …………… 4-5

A-1 0 Test the Power and Function Controls ......... ........ ….......... …........ …............... 4-6

A-11 Inspect the Li fting Chains and Idler Wheels ......... …................. …......... …......... 4-7

A-12 Inspect the 8reather Cap(s) …"…......... ……........ …........... …............................4 - 8

A-13 Test the 8ase Operation -IWP Models ………....................... …......... …...........4 - 8

8-1 Inspect the Electrical Wiring …..…..…………....... …………………..….......4 - 9

8-2 Inspect AII Welds ……....... …….. .•. .•. ..... …………………………...................4 - 9

8-3 Test the Tilt-back Operation - AWP 30 and 36 Models ................. …............ 4-10

8-4 Check the Li fting Chain Adjustments ......... …........ …·…................. …·…......... 4- 11

8-5 Check the 8a忧e叩…………………........…..........……………........…·…...........…...4-12

8 -6 Clean and Lubricate the Columns .................... ...…..................... …............... 4- 12

8-7 Test the Li fting Capacity ……….................... …·……………......... …................... 4-13

8-8 Test the Power-To-Platform Operation ......... ………............................... …..… 4 - 13

8-9 Adjust the Sequencing Cables ... .... ……................. ……..................................4-14

8-10 Inspect for Proper Outrigger Length - AWP Models .....................................4 - 14

8-11 Test the Level Sensing Operation -IWP Models .... ……................................4- 15

C-1 Inspect and Lubricate the Casters and Wheels ……..………......... …............. 4- 16

C-2 Inspect the Mast Assembly for Wear ......................................... …......... …… 4 - 16

C-3 Lubricate the Li fting Chains ........... …........ …........... …....... …........ ……........... 4-18

C-4 Replace the Hydraulic Oil ............ ... ........ ...…..................... …........................4- 18

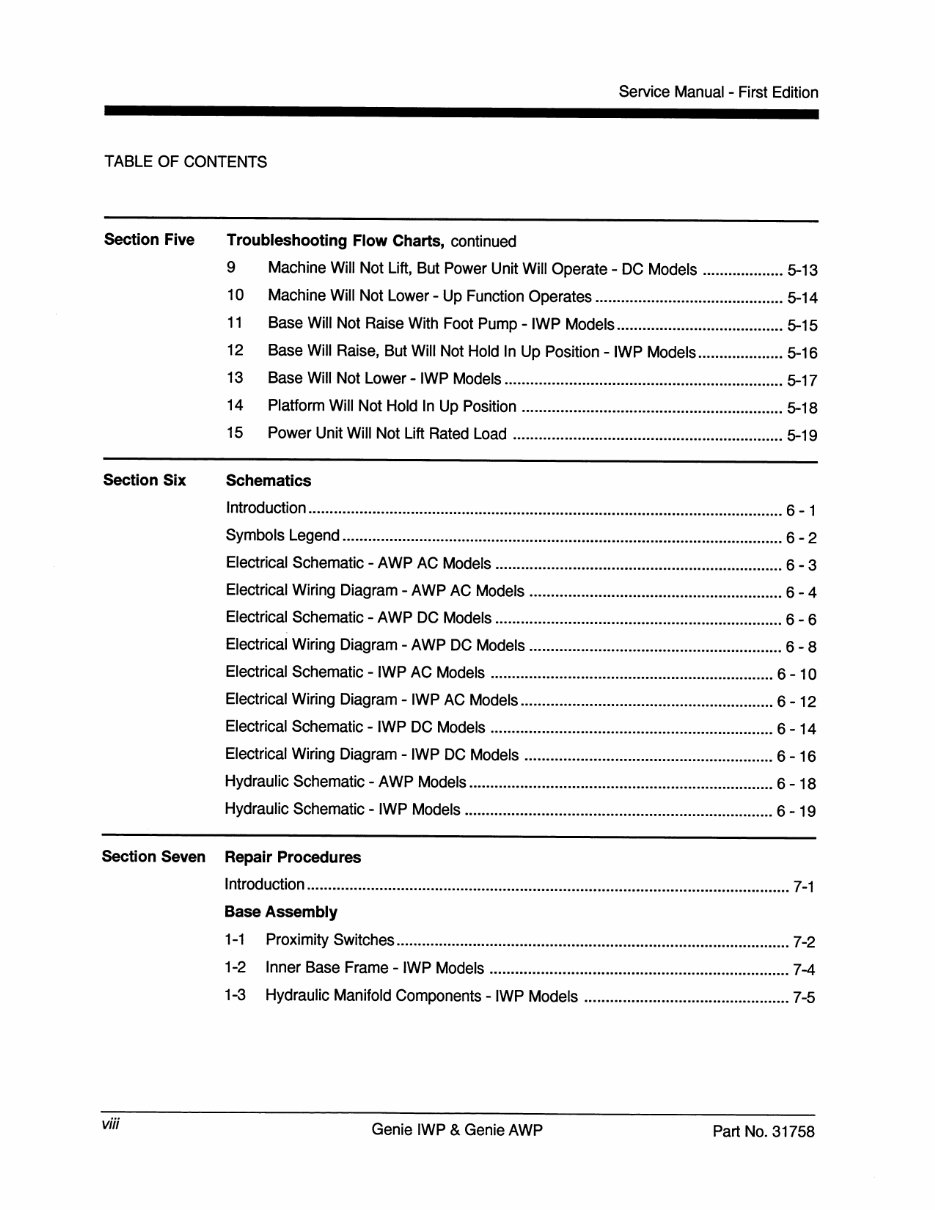

Troubleshooting Flow Charts

Introduction ........... …......... …................. …......... …...................... …·………........ ……......5-1

1 Power Li ght WiII Not Turn On - AC Models ……….......….........…… ...................5四3

2 Power Li ght WiII Not Turn On - DC Models ............................... ………............. 5-4

3 Interlock Li ghts WiII Not Turn On - AWP AC Models ........ …….......................... 5- 6

4 Interlock Li ghts WiII Not Turn On - AWP DC Models .... …........ ….....................5-8

5 Interlock Li ghts WiII Not Turn On - IWP Models .....................….........… ...........ι9

6 Machine WiII Not Li ft - AC Models ..................... …………................ …......... …..5-10

7 Machine WiII Not Li ft , 8ut Power Unit WiII Operate - AC Models ………..........5-11

8 Machine WiII Not Li ft - DC Models ... ... ... ... ...…............................... ……........... 5- 12

Genie IWP & Genie AWP VII

Service Manual - First Edition

TABLE OF CONTENTS

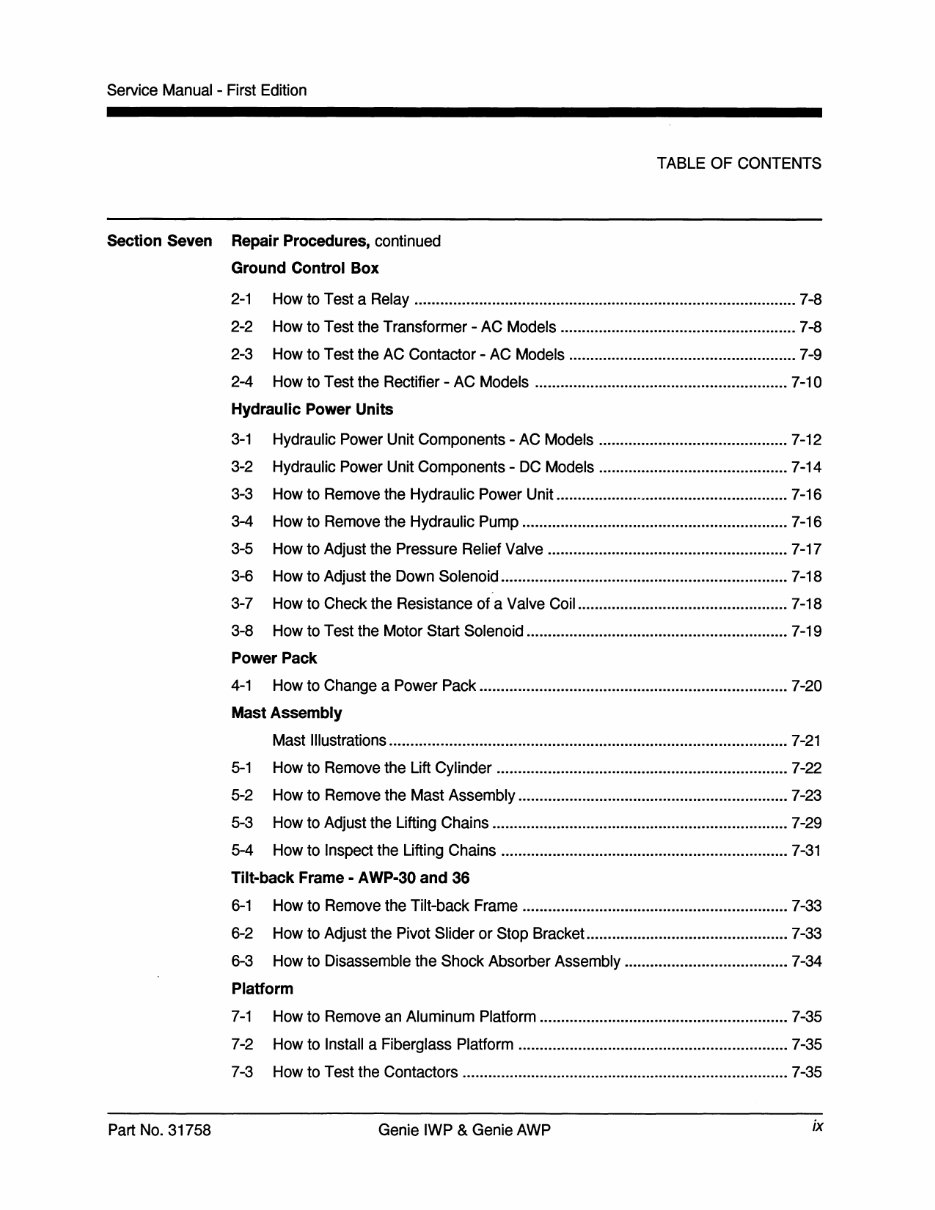

Section Seven Repair Procedures, continued

Ground Control Box

Part No. 31758

2-1 How to Test a Relay ........... ….................................. …......... …...........................7-8

2-2 How to Test the Transformer - AC Models ……................. …...... ……....... …....... 7-8

2-3 How to Test the AC Contactor - AC Models ...... ............ …………......... …...........7-9

2-4 How to Test the Rectifier - AC Models ...... …........ …......... …....... …………........ 7-10

Hydraulic Power Uni恒

3-1 Hydraulic Power Unit Components - AC Models ...……....... ….........................7-12

3-2 Hydraulic Power Unit Components - DC Models ........................ ….................7-14

3-3 How to Remove the Hydraulic Power Unit ................. …................... …......... …. 7-16

3-4 How to Remove the Hydraulic Pump …….............. …....... …............................. 7-16

3-5 How to Adjust the Pressure Relief Valve …............... …………..........................7-17

3-6 How to Adjust the Down Solenoid ......................... …........ ……………................ 7-18

3-7 How to Check the Resistance of a Valve Coil........ …........................ …...........7-18

3-8 How to Test the Motor Start Solenoid …..................................... ….................. 7-19

Power Pack

4-1 How to Change a Power Pack ...... ... ... ... ......... ......... ................. ...... ……..........7-20

Mast Assembly

Mast IlI ustrations ....................... …·….................. …......... …........................... … 7-21

5-1 How to Remove the Li ft Cylinder ...... .............. ... ................... ... ........ …............7-22

5-2 How to Remove the Mast Assembly .......... …..……....... …......... …....................7-23

5-3 How to Adjust the Li fting Chains ............ …................. …·…...... ……..................7-29

5-4 How to Inspect the Li fting Chains ........ …·…........... ……·…"…·……........ …·…….7-31

Tilt-back Frame - AWP-30 and 36

6-1 How to Remove the Tilt-back Frame ................................…...... ...…...............7-33

6-2 How to Adjust the Pivot Slider or Stop Bracket............................................... 7-33

6-3 How to Disassemble the Shock Absorber Assembly …....... …....... …...............7-34

Platform

7-1 How to Remove an Aluminum Platform ......................................... …..............7-35

7-2 How to Install a Fiberglass Platform ..........................…..................................7-35

7-3 How to Test the Contactors ................. …......... …............................................7-35

Genie IWP & Genie AWP

IX

Service Manual - First Edition

TABLE OF CONTENTS

This page intentionally left blank.

X

Genie IWP & Genie AWP Part No. 31758

Service Manual - First Edition Section 2 - Specifications

Specifications

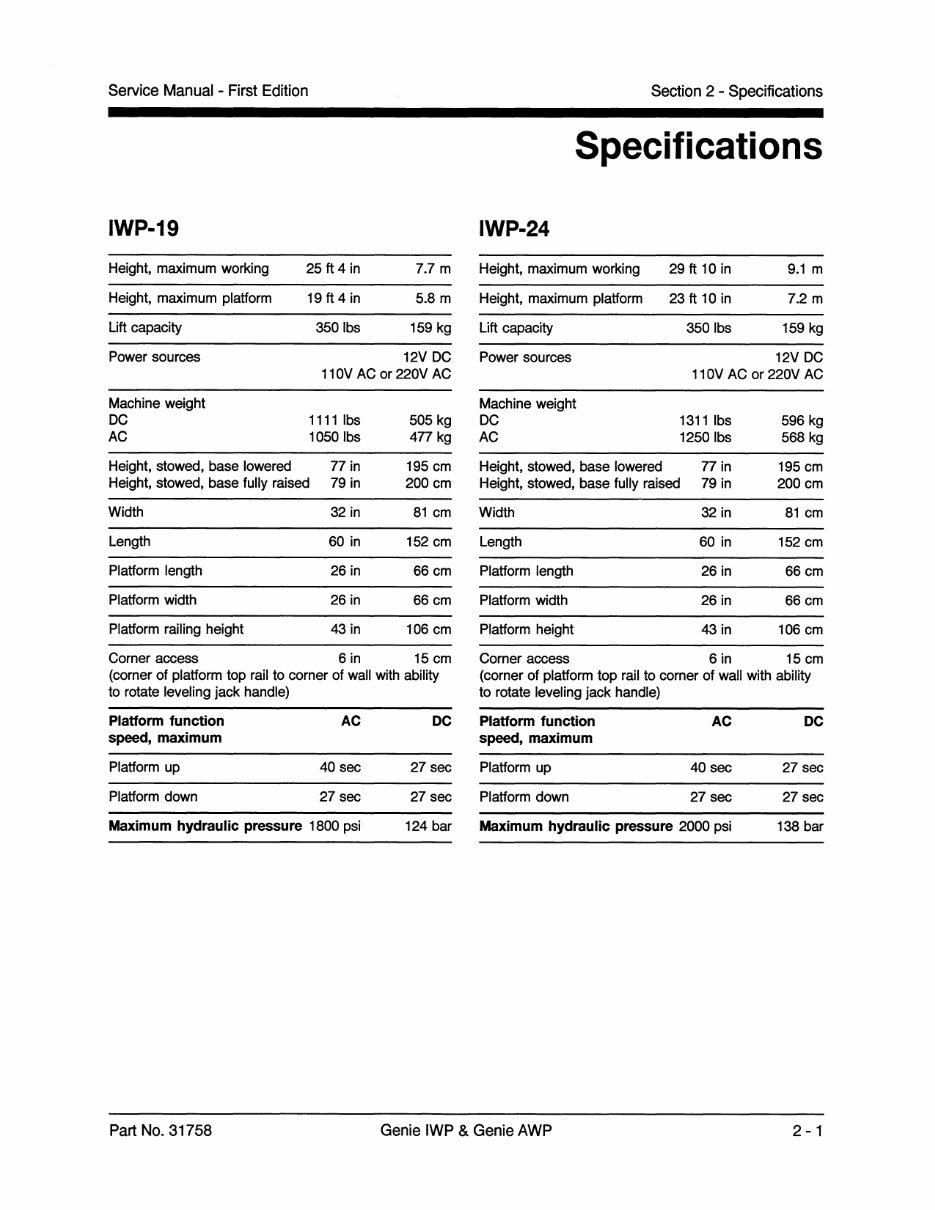

IWP-19 IWP-24

Height, maximum working 25 ft 4 in 7.7 m Height, maximum working 29 仕 10 in 9.1 m

Height, maximum platform 19 仕 4in 5.8 m Height, maximum pla甘orm 23 仕 10 in 7.2 m

Lift capacity 350lbs 159 kg Li仕 capacity 350lbs 159 kg

Power sources 12V DC Power sources 12V DC

110V AC or 220V AC 110V AC or 220V AC

Machine weight Machine weight

DC 1111 Ibs 505 kg DC 1311 Ibs 596 kg

AC 1050lbs 477 kg AC 1250lbs 568 kg

Height, stowed , base lowered 77in 195 cm Height, stowed , base lowered 77in 195 cm

Height, stowed, base fully raised 79in 200 cm Height, stowed, base fully raised 79 in 200 cm

Width 32 in 81 cm Width 32 in 81 cm

Length 60 in 152 cm Length 60 in 152 cm

Platform length 26in 66cm Platform length 26in 66cm

Platform width 26in 66 c町1 Platform width 26in 66cm

Platform railing height 43in 106 cm Platform height 43in 106 cm

Corner access 6in 15 cm Corner access 6in 15 cm

(corner of pla甘orm top rail to corner of wall with ability (corner of pla甘Orm top rail to corner of wall with ability

to rotate leveling jack handle) to rotate leveling jack handle)

Platform function AC DC Platform function AC DC

speed, maximum sp锦d, maximum

Platform up 40 sec 27 sec Platform up 40 sec 27 sec

Platform down 27 sec 27 sec Platform down 27 sec 27 sec

Maximum hydraulic pressure 1800 psi 124 bar Maximum hydraulic pressure 2000 psi 138 bar

Part No. 31758 Genie IWP & Genie AWP 2 -1

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

$40.99

Viewed 27 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

$40.99

The Genie AWP IWP Work Platform Service Repair Manual is a vital guide for the upkeep and repair of Genie work platforms. This professional-grade manual offers comprehensive, step-by-step instructions and detailed diagrams, making it ideal for both DIY enthusiasts and professional technicians.

It covers models including 27476 AWP-19, 27477 AWP-24, 27478 AWP-30, 27479 AWP-36, 29814 IWP-19, and 29815 IWP-24. The manual features sections on Introduction, Safety Rules, Specifications, Scheduled Maintenance Inspections, Scheduled Maintenance Procedures, Troubleshooting Flow Charts, Schematics, and Repair Procedures. It is a trusted resource to ensure your equipment functions efficiently and safely.

No physical product shipped.