© 2006 PDF Manual Master

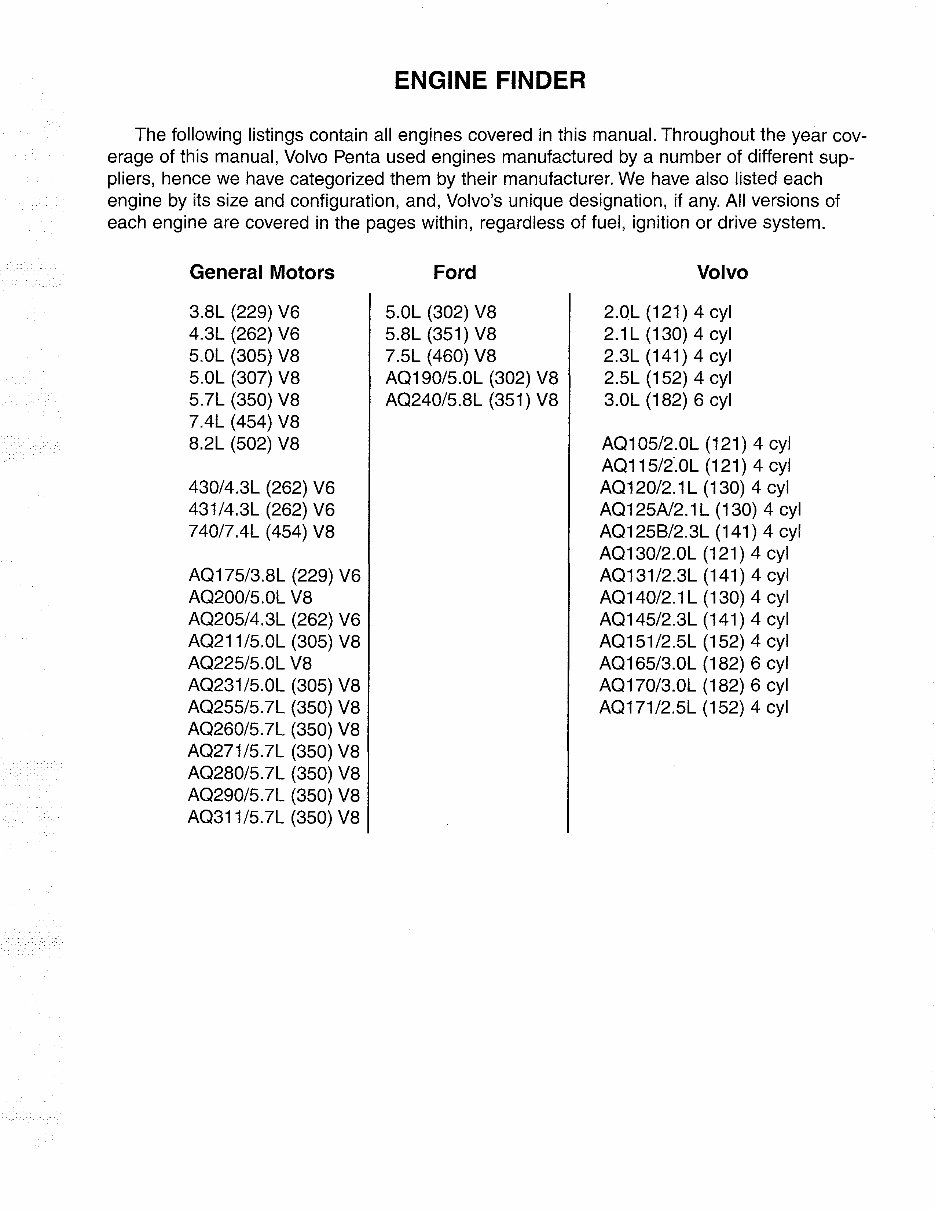

ENGINE FINDER

The following listings contain all engines covered in this manual. Throughout the year cov-

erage of this manual, Volvo Penta used engines manufactured by a number of different sup-

pliers, hence we have categorized them by their manufacturer. We have also listed each

engine by its size and configuration, and, Volvo's unique designation, if any. All versions of

each engine are covered in the pages within, regardless of fuel, ignition or drive system.

General Motors

3.SL (229) V6

4.3L (262) V6

5.0L (305) VS

5.0L (307) VS

5.7L (350) VS

7.4L (454) VS

S.2L (502) VS

430/4.3L (262) V6

431/4.3L (262) V6

740/7.4L (454) VS

AQ175/3.SL (229) V6

AQ200/5.0L VS

AQ205/4.3L (262) V6

AQ211/5.0L (305) VS

AQ225/5.0L VS

AQ231/5.0L (305) VS

AQ255/5.7L (350) VS

AQ260/5.7L (350) VS

AQ271/5.7L (350) VS

AQ2S0/5.7L (350) VS

AQ290/5.7L (350) VS

AQ311/5.7L (350) VS

Ford

5.0L (302) VS

5.SL (351) VS

7.5L (460) VS

AQ190/5.0L (302) VS

AQ240/5.SL (351) VS

Volvo

2.0L (121) 4 cyl

2.1 L (130) 4 cyl

2.3L (141) 4 cyl

2.5L (152) 4 cyl

3.0L (1S2) 6 cyl

AQ105/2.0L (121) 4 cyl

AQ115/2.0L (121) 4 cyl

AQ120/2.1L (130) 4 cyl

AQ125A12.1 L (130) 4 cyl

AQ1258/2.3L (141) 4 cyl

AQ130/2.0L (121) 4 cyl

AQ131/2.3L (141) 4 cyl

AQ140/2.1 L (130) 4 cyl

AQ145/2.3L (141) 4 cyl

AQ151/2.5L (152) 4 cyl

AQ165/3.0L (1S2) 6 cyl

AQ170/3.0L (1S2) 6 cyl

AQ171/2.5L (152) 4 cyl

© 2006 PDF Manual Master

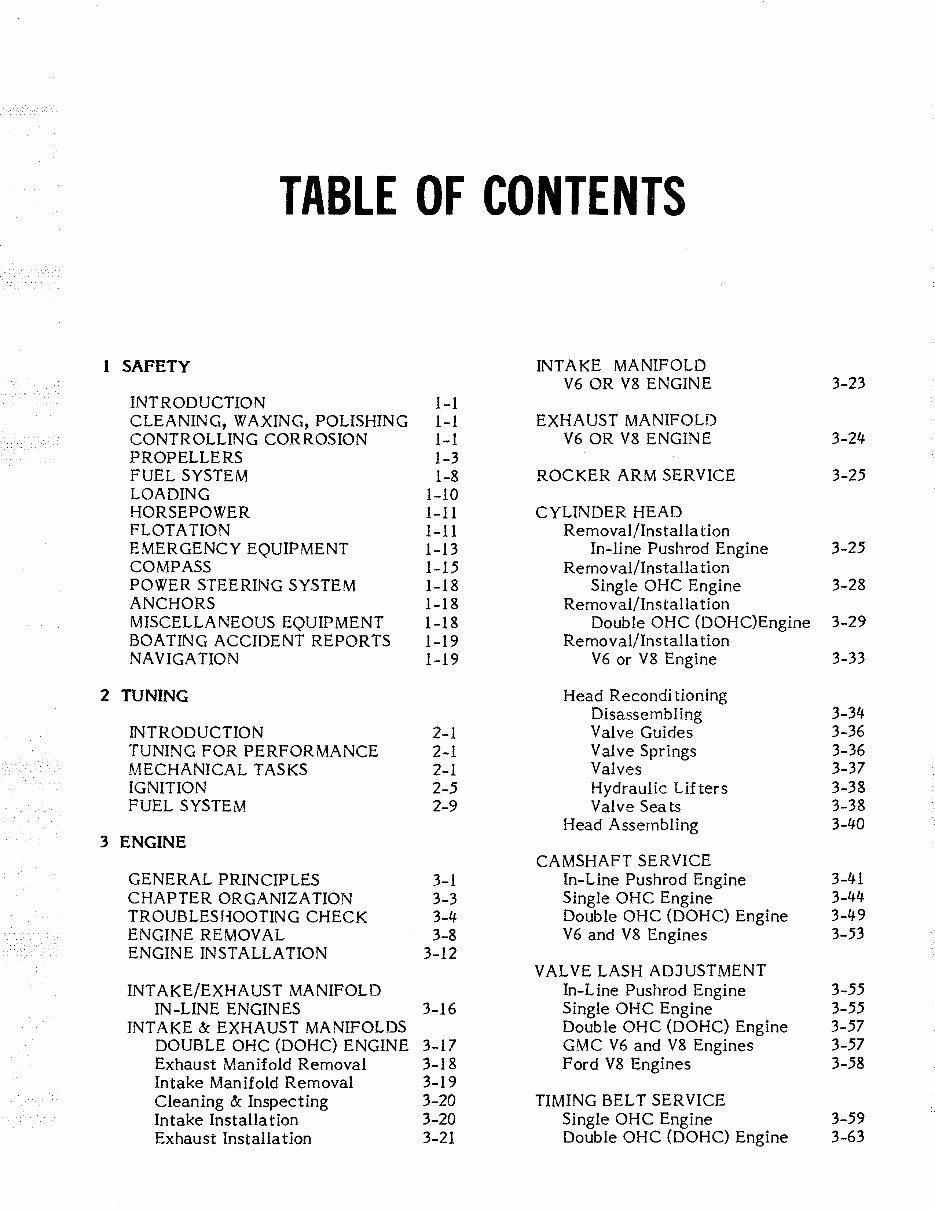

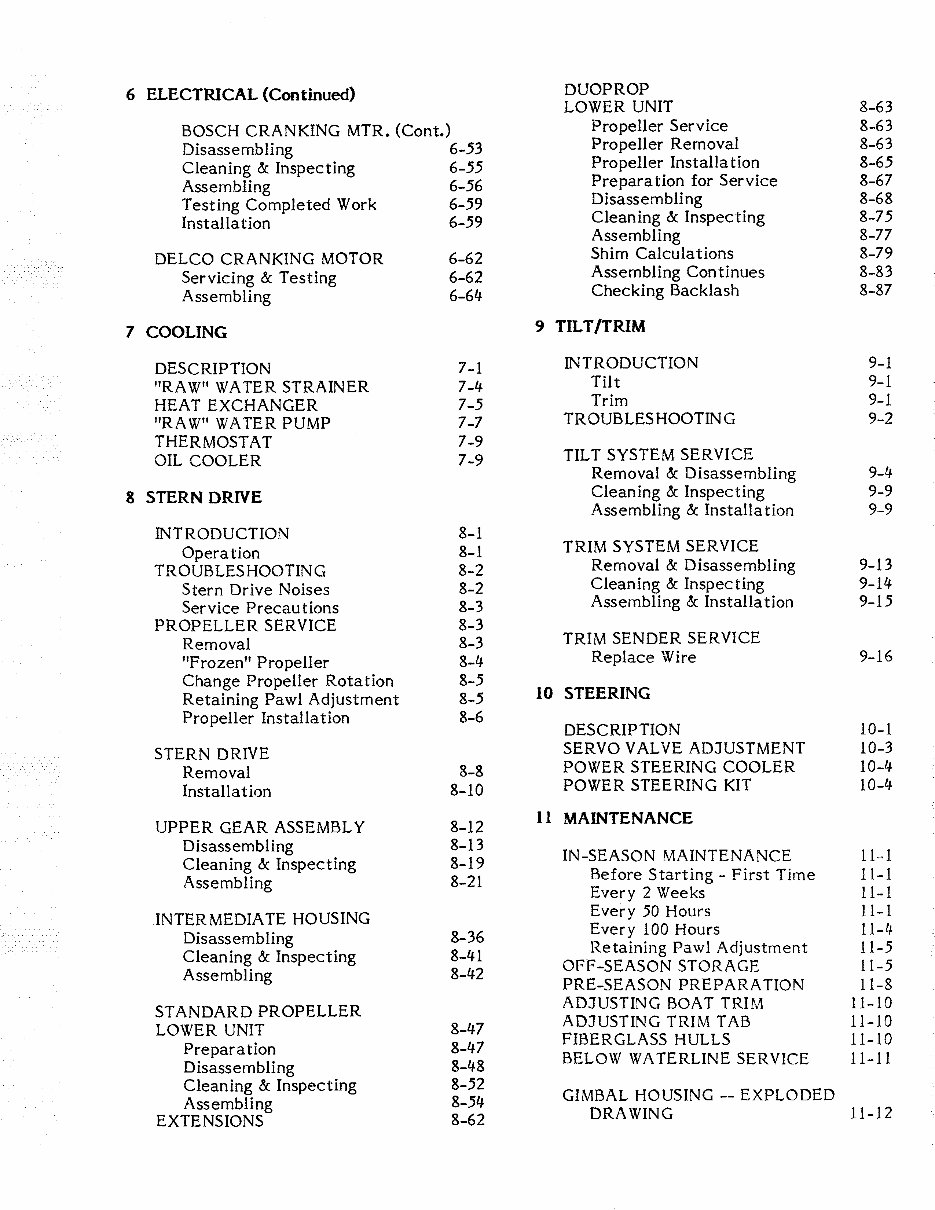

TABLE OF CONTENTS

1 SAFETY INTAKE MANIFOLD

V6 OR V8 ENGINE 3-23

INTRODUCTION 1-1

CLEANING, WAXING, POLISHING 1-1 EXHAUST MANIFOLD

CONTROLLING CORROSION 1-1 V6 OR V8 ENGINE 3-24

PROPELLERS 1-3

FUEL SYSTEM 1-8 ROCKER ARM SERVICE 3-25

LOADING 1-10

HORSEPOWER 1-11 CYLINDER HEAD

FLOTATION 1-11 Removal/Installa tion

EMERGENCY EQUIPMENT 1-13 In-line Pushrod Engine 3-25

COMPASS 1-15 Removal/Installation

POWER STEERING SYSTEM 1-18 Single OHC Engine 3-28

ANCHORS 1-18 Re mo v al/Installa ti on

MISCELLANEOUS EQUIPMENT 1-18 Double OHC (DOHC)Engine 3-29

BOATING ACCIDENT REPORTS 1-19 Removal/Installa tion

NAVIGATION 1-19 V6 or V8 Engine 3-33

2 TUNING Head Recondi tioning

Disassembling 3-34

INTRODUCTION 2-1 Valve Guides 3-36

TUNING FOR PERFORMANCE 2-1 Valve Springs 3-36

MECHANICAL TASKS 2-1 Valves 3-37

IGNITION 2-5 Hydraulic Lifters 3-38

FUEL SYSTEM 2-9 Valve Seats 3-38

Head Assembling 3-40

3 ENGINE

CAMSHAFT SERVICE

GENERAL PRINCIPLES 3-1 In-Line Pushrod Engine 3-41

CHAPTER ORGANIZATION 3-3 Single OHC Engine 3-44

TROUBLESHOOTING CHECK 3-4 Double OHC (DOHC) Engine 3-49

ENGINE REMOVAL 3-8 V6 and V8 Engines 3-53

ENGINE INSTALLATION 3-12

VALVE LASH ADJUSTMENT

INT AKE/EXHAUST MANIFOLD In-Line Pushrod Engine 3-55

IN-LINE ENGINES 3-16 Single OHC Engine 3-55

INTAKE &: EXHAUST MANIFOLDS Double OHC (DOHC) Engine 3-57

DOUBLE OHC (DOHC) ENGINE 3-17 GMC V6 and V8 Engines 3-57

Exhaust Manifold Removal 3-18 Ford V8 Engines 3-58

Intake Manifold Removal 3-19

Cleaning &: Inspecting 3-20 TIMING BELT SERVICE

Intake Installation 3-20 Single OHC Engine 3-59

Exhaust Installation 3-21 Double OHC (DOHC) Engine 3-63

© 2006 PDF Manual Master

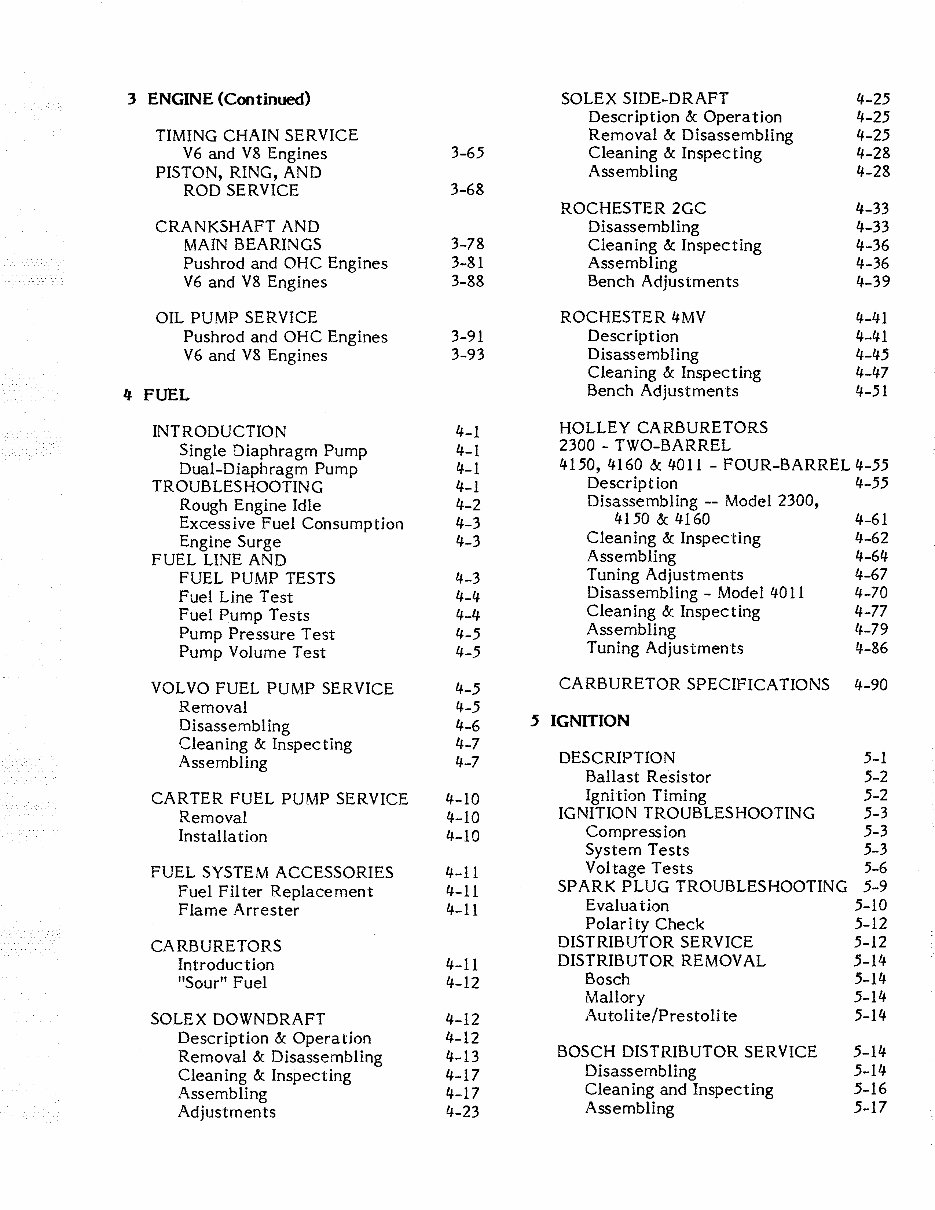

3 ENGINE (Continued) SOLEX SIDE-DRAFT 4-25

Description & Operation 4-25

TIMING CHAIN SERVICE Removal & Disassembling 4-25

V6 and V8 Engines 3-65 Cleaning & Inspecting 4-28

PISTON, RING, AND Assembling 4-28

ROD SERVICE 3-68

ROCHESTER 2GC 4-33

CRANKSHAFT AND Disassembling 4-33

MAIN BEARINGS 3-78 Cleaning & Inspecting 4-36

Pushrod and OHC Engines 3-81 Assembling 4-36

V6 and V8 Engines 3-88 Bench Adjustments 4-39

OIL PUMP SERVICE ROCHESTER 4MV 4-41

Pushrod and OHC Engines 3-91 Description 4-41

V 6 and V8 Engines 3-93 Disassembling 4-45

Cleaning & Inspecting 4-47

4 FUEL

Bench Adjustments 4-51

INTRODUCTION 4-1

HOLLEY CARBURETORS

Single Diaphragm Pump 4-1

2300 - TWO-BARREL

Dual-Diaphragm Pump 4-1

4150, 4160 & 4011 - FOUR-BARREL 4-55

TROUBLESHOOTING 4-1

Description 4-55

Rough Engine Idle 4-2

Disassembling -- Model 2300,

Excessive Fuel Consumption 4-3

4150 & 4160 4-61

Engine Surge 4-3

Cleaning & Inspecting 4-62

FUEL LINE AND

Assembling 4-64

FUEL PUMP TESTS 4-3

Tuning Adjustments 4-67

Fuel Line Test 4-4

Disassembling - Model 4011 4-70

Fuel Pump Tests 4-4

Cleaning & Inspecting 4-77

Pump Pressure Test 4-5

Assembling 4-79

Pump Volume Test 4-5

Tuning Adjustmen ts 4-86

VOLVO FUEL PUMP SERVICE 4-5

CARBURETOR SPECIFICATIONS 4-90

Removal 4-5

Disassembling 4-6

5 IGNmON

Cleaning & Inspecting 4-7

Assembling 4-7

DESCRIPTION 5-1

Ballast Resistor 5-2

CARTER FUEL PUMP SERVICE 4-10

Igni tion Timing 5-2

Removal 4-10

IGNITION TROUBLESHOOTING 5-3

Installa tion 4-10

Compression 5-3

System Tests 5-3

FUEL SYSTEM ACCESSORIES 4-11

Voltage Tests 5-6

Fuel Filter Replacement 4-11

SPARK PLUG TROUBLESHOOTING 5-9

Flame Arrester 4-11

Evaluation 5-10

Polar i ty Check 5-12

CARBURETORS

DISTRIBUTOR SERVICE 5-12

Introduction 4-11

DISTRIBUTOR REMOVAL 5-14

"Sour" Fuel 4-12

Bosch 5-14

Mallory 5-14

SOLEX DOWNDRAFT 4-12

Autoli te/Prestolite 5-14

Description & Operation 4-12

Removal & Disassembling 4-13

BOSCH DISTRIBUTOR SERVICE 5-14

Cleaning & Inspecting 4-17

Disassembling 5-14

Assembling 4-17

Cleaning and Inspecting 5-16

Adjustments 4-23

Assembling 5-17

© 2006 PDF Manual Master

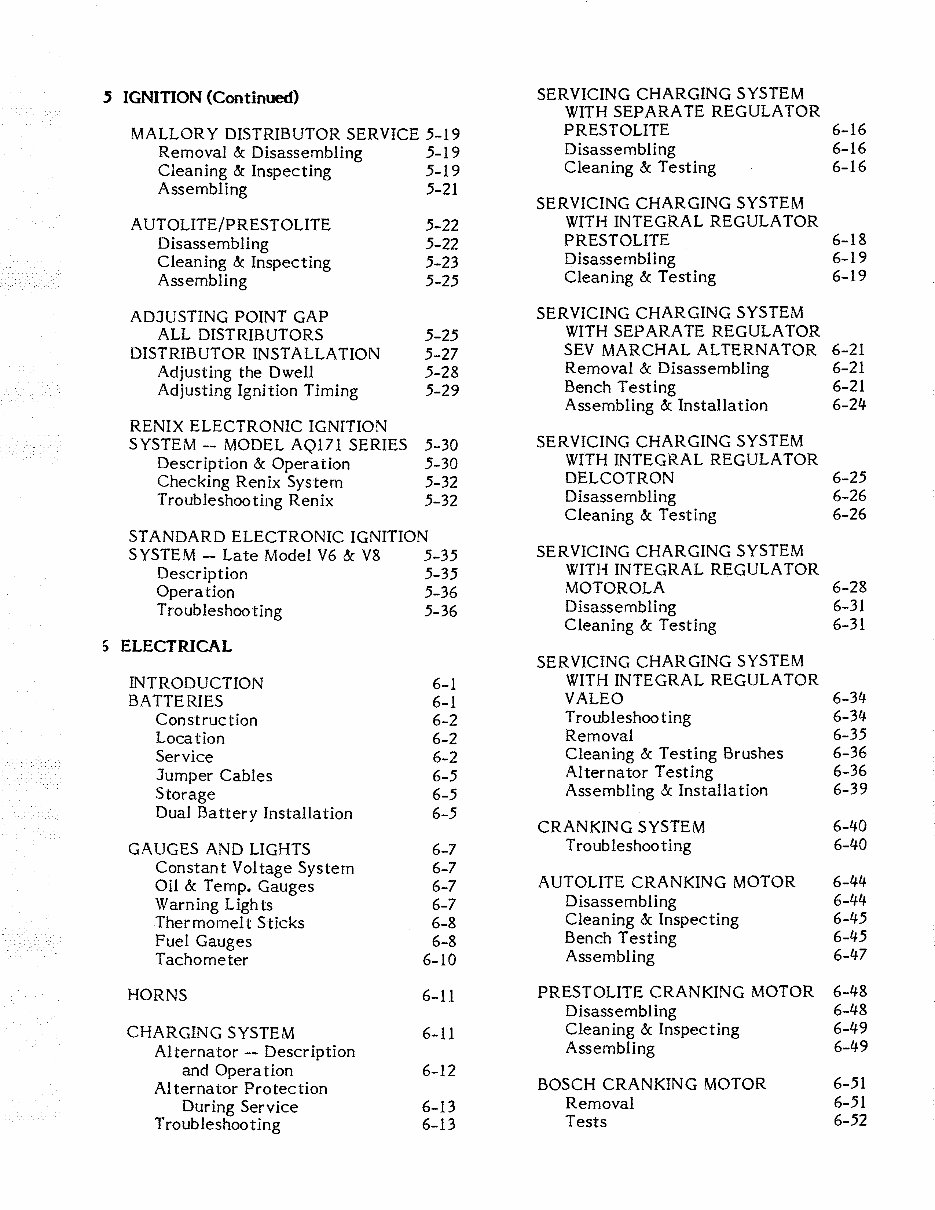

5 IGNITION (Continued)

SERVICING CHARGING SYSTEM

WITH SEPARATE REGULATOR

MALLORY DISTRIBUTOR SERVICE 5-19

PRESTOLITE 6-16

Removal & Disassembling 5-19

Disassembling 6-16

Cleaning & Inspecting 5-19

Cleaning & Testing 6-16

Assembling 5-21

SERVICING CHARGING SYSTEM

AUTOLITE/PRESTOLITE 5-22

WITH INTEGRAL REGULA TOR

Disassembling 5-22

PRESTOLITE 6-18

Cleaning & Inspecting 5-23

Disassembling 6-19

Assembling 5-25

Cleaning & Testing 6-19

ADJUSTING POINT GAP

SERVICING CHARGING SYSTEM

ALL DISTRIBUTORS 5-25

WITH SEPARATE REGULA TOR

DISTRIBUTOR INSTALLATION 5-27

SEV MARCHAL AL TERNA TOR 6-21

Adjusting the Dwell 5-28

Removal & Disassembling 6-21

Adjusting Ignition Timing 5-29

Bench Testing 6-21

Assembling & Installation 6-24

RENIX ELECTRONIC IGNITION

SYSTEM -- MODEL AQ171 SERIES 5-30

SERVICING CHARGING SYSTEM

Description & Operation 5-30

WITH INTEGRAL REGULA TOR

Checking Renix System 5-32

DEL COT RON 6-25

Troubleshooting Renix 5-32

Disassembling 6-26

Cleaning & Testing 6-26

ST ANDARD ELECTRONIC IGNITION

SYSTEM -- Late Model V6 & V8 5-35

SERVICING CHARGING SYSTEM

Description 5-35

WITH INTEGRAL REGULA TOR

Operation 5-36

MOTOROLA 6-28

Troubleshooting 5-36

Disassembling 6-31

Cleaning & Testing 6-31

,.

ELECTRICAL :>

SERVICING CHARGING SYSTEM

INTRODUCTION 6-1

WITH INTEGRAL REGULA TOR

BATTERIES 6-1

VALEO 6-34

Construction 6-2

Troubleshooting 6-34

Location 6-2

Removal 6-35

Service 6-2

Cleaning & Testing Brushes 6-36

Jumper Cables 6-5

Alternator Testing 6-36

Storage 6-5

Assembling & Installation 6-39

Dual Ba ttery Installation 6-5

CRANKING SYSTEM 6-40

GAUGES AND LIGHTS 6-7

Troubleshooting 6-40

Constant Voltage System 6-7

Oil & Temp. Gauges 6-7

AUTOLITE CRANKING MOTOR 6-44

Warn ing Ugh ts 6-7

Disassembling 6-44

Thermomelt Sticks 6-8

Cleaning & Inspecting 6-45

Fuel Gauges 6-8

Bench Testing 6-45

Tachometer 6-10

Assembling

6-47

HORNS 6-11

PRESTOLITE CRANKING MOTOR 6-48

Disassembling 6-48

CHARGING SYSTEM 6-11

Cleaning & Inspecting 6-49

Alternator -- Description

Assembling 6-49

and Operation 6-12

Alternator Protection

BOSCH CRANKING MOTOR 6-51

During Service 6-13

Removal 6-51

Troubleshooting 6-13

Tests 6-52

© 2006 PDF Manual Master

6 ELECTRICAL (Continued)

DUOPROP

LOWER UNIT 8-63

BOSCH CRANKING MTR. (Cont.)

Propeller Service 8-63

Disassembling 6-53

Propeller Removal 8-63

Cleaning & Inspecting 6-55

Propeller Installa tion 8-65

Assembling 6-56

Pre para tion for Service 8-67

Testing Completed Work 6-59

Disassembling 8-68

Installa tion 6-59

Cleaning & Inspecting 8-75

Assembling 8-77

DELCO CRANKING MOTOR 6-62

Shim Calculations 8-79

Servicing & Testing 6-62

Assembling Continues 8-83

Assembling 6-64

Checking Backlash 8-87

7 COOLING

9 TILT/TRIM

DESCRIPTION 7-1

INTRODUCTION 9-1

"RAW" WATER STRAINER 7-4

Tilt 9-1

HEAT EXCHANGER 7-5

Trim 9-1

"RAW" WATER PUMP 7-7

TROUBLESHOOTING 9-2

THERMOSTAT 7-9

OIL COOLER 7-9

TILT SYSTEM SERVICE

Removal & Disassembling 9-4

8 STERN DRIVE

Cleaning & Inspec ling 9-9

Assembling & Installation 9-9

INTRODUCTION 8-1

Operation 8-1

TRIM SYSTEM SERVICE

TROUBLESHOOTING 8-2

Removal & Disassembling 9-13

Stern Drive Noises 8-2

Cleaning & Inspec ting 9-14

Service Precau tions 8-3

Assembling & Installation 9-15

PROPELLER SERVICE 8-3

Removal 8-3

TRIM SENDER SERVICE

"Frozen" Propeller 8-4

Replace Wire 9-16

Change Propeller Rotation 8-5

Retaining Pawl Adjustment 8-5

10 STEERING

Propeller Installation 8-6

DESCRIPTION 10-1

STERN DRIVE

SERVO VALVE ADJUSTMENT 10-3

Removal 8-8

POWER STEERING COOLER 10-4

Installation 8-10

POWER STEERING KIT 10-4

UPPER GEAR ASSEMBLY 8-12

11 MAINTENANCE

Disassembling 8-13

Cleaning & Inspecting 8-19

IN-SEASON MAINTENANCE 11···1

Assembling 8-21

Before Starting - First Time 11-1

Every 2 Weeks 11-1

INTERMEDIATE HOUSING

Every 50 Hours 11-1

Disassembling 8-36

Every 100 Hours 11-4

Cleaning & Inspecting 8-41

Retaining Pawl Adjustment 11-5

Assembling 8-42

OFF-SEASON STORAGE 11-5

PRE-SEASON PREPARATION 11-8

STANDARD PROPELLER

ADJUSTING BOAT TRIM 11-10

LOWER UNIT 8-47

ADJUSTING TRIM TAB 11-10

Preparation 8-47

FIBERGLASS HULLS 11-10

Disassembling 8-48

BELOW WATERLINE SERVICE 11-11

Cleaning & Inspecting 8-52

Assembling

8-54

GIMBAL HOUSING -- EXPLODED

EXTENSIONS 8-62

DRAWING 11-12

© 2006 PDF Manual Master

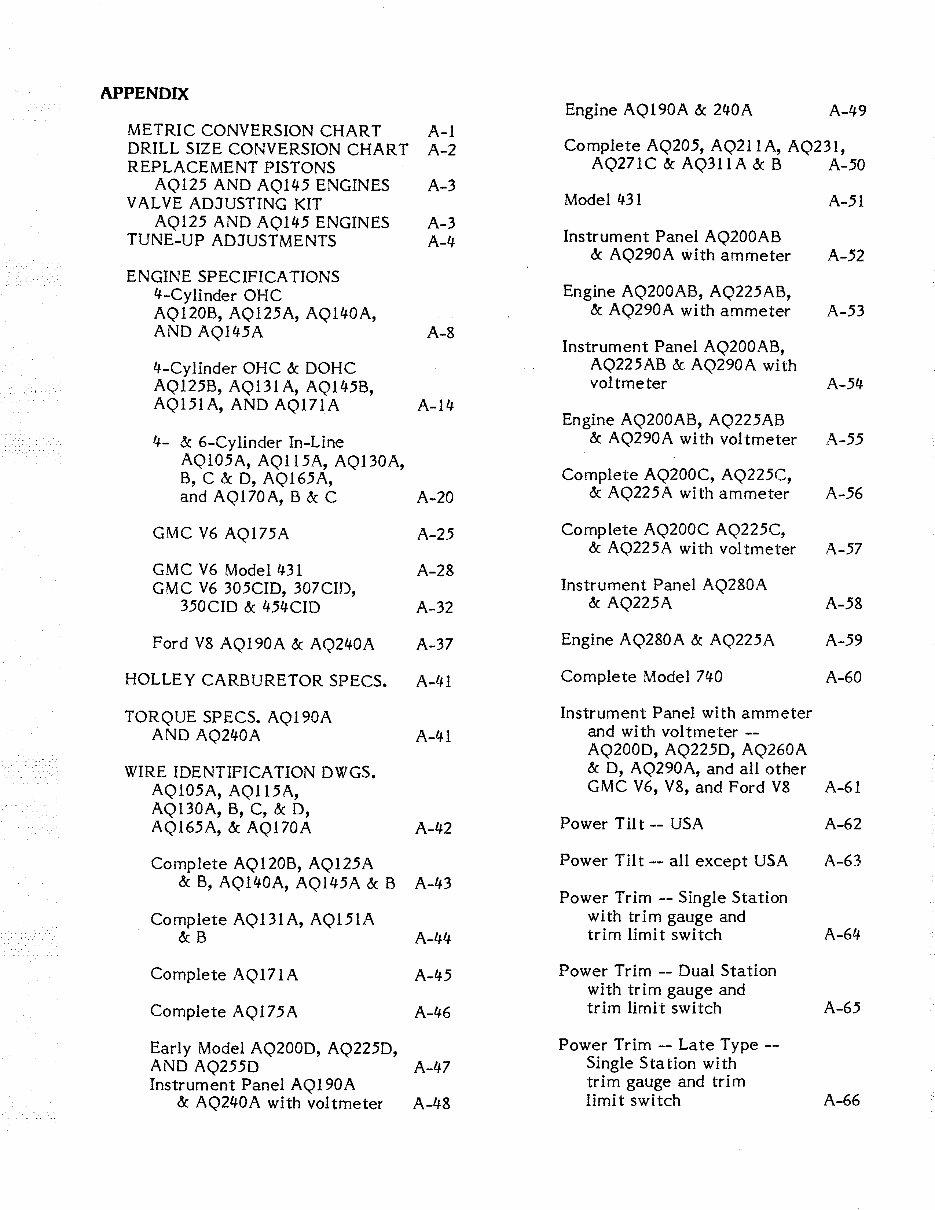

APPENDIX

Engine AQ190A & 240A A-49

METRIC CONVERSION CHART A-I

DRILL SIZE CONVERSION CHART A-2

Complete AQ205, AQ21IA, AQ231,

REPLACEMENTP5TONS

AQ271C & AQ31lA & B A-50

AQ125 AND AQ145 ENGINES A-3

V ALVE ADJUSTING KIT

Model 431 A-51

AQ125 AND AQ145 ENGINES A-3

TUNE-UP ADJUSTMENTS A-4

Instrument Panel AQ200AB

& AQ290A with ammeter A-52

ENGINE SPECIFICATIONS

4-Cylinder OHC

Engine AQ200AB, AQ225 AB,

AQI20B, AQI25A, AQI40A,

& AQ290A with ammeter A-53

AND AQ145A A-8

Instrument Panel AQ200AB,

4-Cylinder OHC & DOHC

AQ225AB &. AQ290A with

AQI25B, AQ131 A, AQI45B,

voltmeter A-54

AQI5IA, AND AQ171A A-14

Engine AQ200AB, AQ225AB

4- & 6-Cylinder In-Line

& AQ290A with voltmeter A-55

AQ105A, AQ1l5A, AQ130A,

Complete AQ200C, AQ225C,

B, C & D, AQ165A,

and AQI70A, B &. C A-20

& AQ225A with ammeter A-56

GMC V6 AQ175A A-25

Complete AQ200C AQ225C,

& AQ225A with voltmeter A-57

GMC V6 Model 431 A-28

GMC V6 305CID, 307CID,

Instrument Panel AQ280A

350CID & 454CID A-32

& AQ225A A-58

Ford V8 AQ190A & AQ240A A-37

Engine AQ280A & AQ225A A-59

HOLLEY CARBURETOR SPECS. A-41

Complete Model 740 A-60

TORQUE SPECS. AQl90A

Instrument Panel with ammeter

AND AQ240A A-41

and with voltmeter --

AQ200D, AQ225D, AQ260A

WIRE IDENTIFICATION DWGS.

& D, AQ290A, and all other

AQ105A, AQ115A,

GMC V6, V8, and Ford V8 A-61

AQ130A, B, C, & D,

AQ165A, & AQl70A A-42

Power Tilt -- USA A-62

Complete AQI20B, AQ125A

Power Til t -- all except USA A-63

& B, AQ140A, AQ145A & B A-43

Power Trim -- Single Station

Complete AQ131A, AQ151A

with trim gauge and

&B A-44

trim limit switch A-64

Complete AQ171A A-45

Power Trim -- Dual Station

with trim gauge and

Complete AQ175A A-46

trim limit switch A-65

Early Model AQ200D, AQ225D,

Power Trim -- Late Type --

AND AQ255D A-47

Single Station with

Instrument Panel AQ190A

trim gauge and trim

& AQ240A with voltmeter A-48

limit switch A-66

© 2006 PDF Manual Master

1

SAFETY

1-1 INTRODUCTION

Your boat probably represents a sizeable

investm ent f or you. In order to protect this

investment and to receive the maximum

amount of enjoyment from your boat it must

be cared for properly while being used and

when it is out of the water. Always store

your boat with the bow higher than the stern

and be sure to remove the transom drain

plug and the inner hull drain plugs. If you

use any type of cover to protect your boat,

plastic, canvas, whatever, be sure to allow

for some movement of air through the hull.

Proper ventilation will assure evaporation of

any condensation that may form due to

changes in temperature and humidity.

1-2 CLEANING, WAXING, AND POLISHING

Any boat should be washed with clear

water after each use to remove surface dirt

and any salt deposits from use in salt water.

Regular rinsing will extend the time be-

tween waxing and polishing. It will also give

you "pride of ownership", by having a sharp

looking piece of equipment. Elbow grease, a

mild detergent, and a brush will be required

to remove stubborn dirt, oil, and other un-

sightly deposits.

Stay away from harsh abrasives or strong

chemical cleaners. A white buffing com-

pound can be used to restore the original

gloss to a scratched, dull, or faded area.

The finish of your boat should be thoroughly

cleaned, buffed, and polished at least once

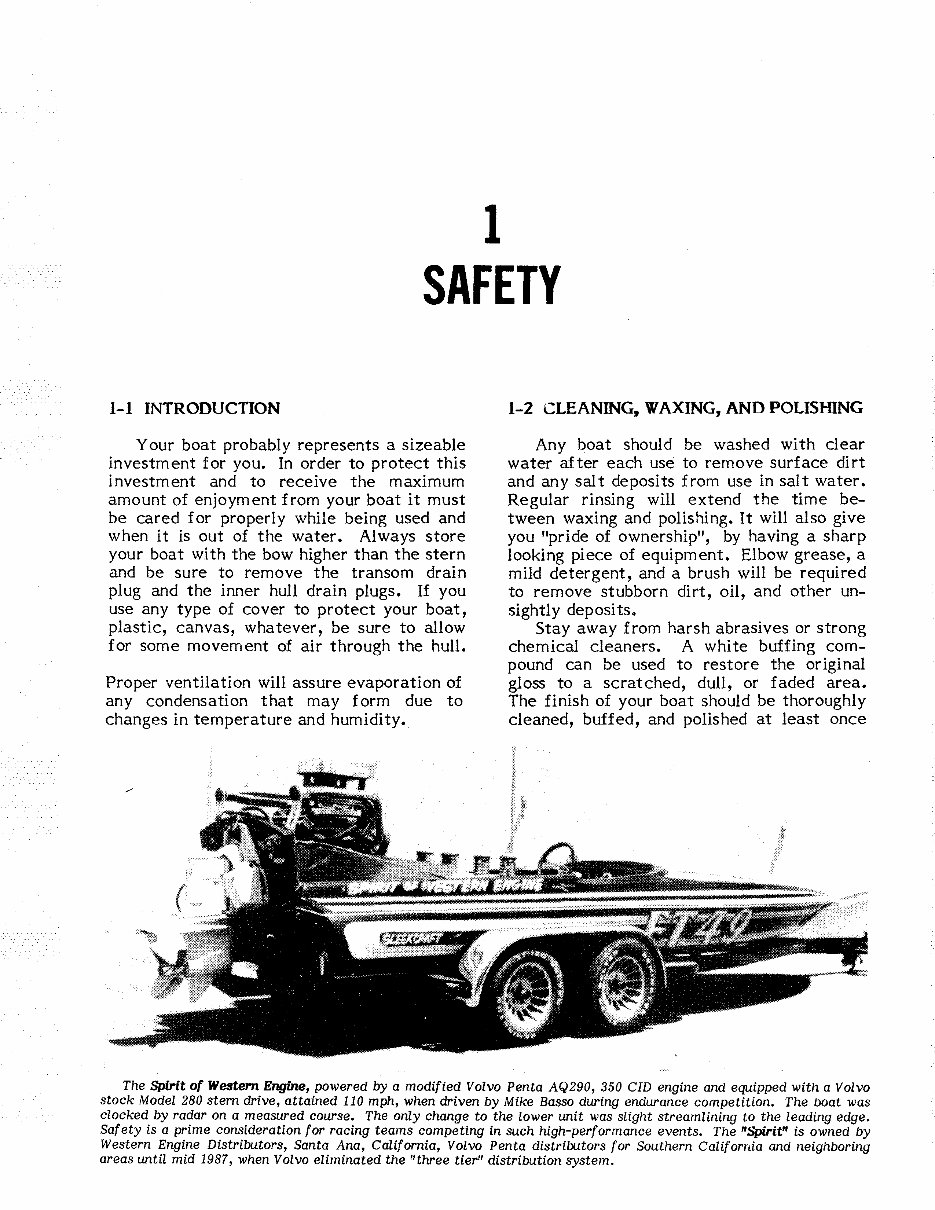

The Spirit of Western Engine, powered by a modified Volvo Penta AQ290, 350 CID engine and equipped with a Volvo

stock Model 280 stern drive, attained 110 mph, when driven by Mike Basso during endurance competition. The boat was

clocked by radar on a measured course. The only change to the lower unit was slight streamlining to the leading edge.

Safety is a prime consideration for racing teams competing in such high-performance events. The "Spirit" is owned by

Western Engine Distributors, Santa Ana, California, Volvo Penta distributors for Southern Califomia and neighboring

areas until mid 1987, when Volvo eliminated the "three tier" distribution system.

© 2006 PDF Manual Master

1-2 SAFETY

Pride of Ownership This well-maintained boat, en-

gine, stem drive, and trailer, reflect the owners pride

in his/her equipment. The rewards are efficiency,

economy, enjoyment, and safe boating.

each season. Take care when buffing or

polishing with a marine cleaner not to over-

heat the surface you are working, because

you will burn it.

1-3 CONTROLLING CORROSION

Since man first started out on the water,

corrosion on his craft has been his enemy.

The first form was merely rot in the wood

and then it was rust, followed by other

forms of destructive corrosion in the more

modern materials. One defense against cor-

rosion is to use similar metals throughout

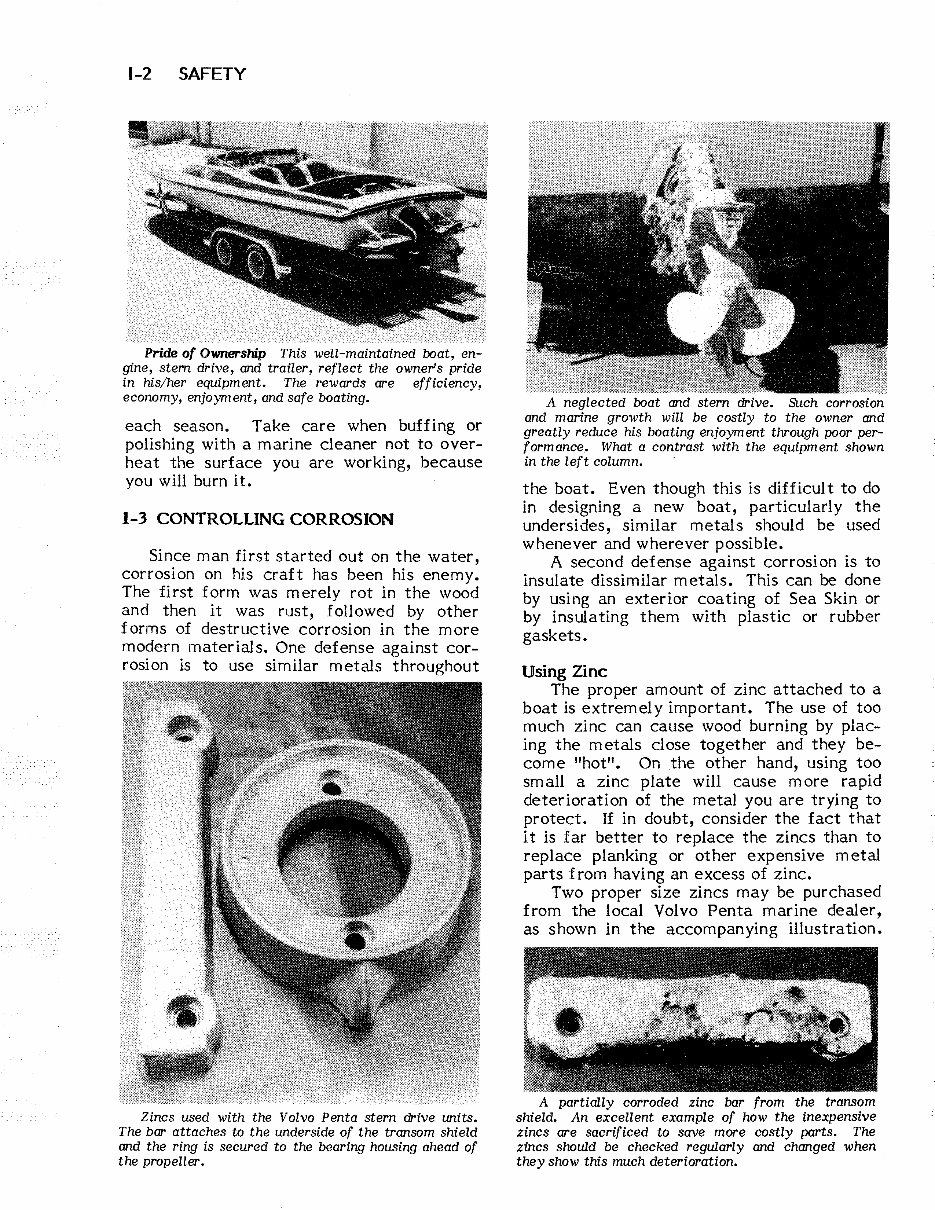

Zincs used with the Volvo Penta stern drive units.

The bar attaches to the underside of the transom shield

and the ring is secured to the bearing housing ahead of

the propeller.

A neglected boat and stern drive. Such corrosion

and marine growth will be costly to the owner and

greatly reduce his boating enjoyment through poor per-

formance. What a contrast with the equipment shown

in the left column.

the boat. Even though this is difficult to do

in designing a new boat, particularly the

undersides, similar metals should be used

whenever and wherever possible.

A second defense against corrosion is to

insulate dissimilar metals. This can be done

by using an exterior coating of Sea Skin or

by insulating them with plastic or rubber

gaskets.

Using Zinc

The proper amount of zinc attached to a

boat is extremely important. The use of too

much zinc can cause wood burning by plac-

ing the metals close together and they be-

come "hot". On the other hand, using too

small a zinc plate will cause more rapid

deterioration of the metal you are trying to

protect. If in doubt, consider the fact that

it is far better to replace the zincs than to

replace planking or other expensive metal

parts f rom having an excess of zinc.

Two proper size zincs may be purchased

from the local Volvo Penta marine dealer,

as shown in the accompanying lllustration.

A partially corroded zinc bar from the transom

shield. An excellent example of how the inexpensive

zincs are sacrificed to save more costly parts. The

zincs should be checked regularly and changed when

they show this much deterioration.

© 2006 PDF Manual Master

A Volvo Penta spare parts kit includes a raw water

pump impeller, set of spark plugs, condenser, V-belt for

the alternator, and a fuse. Such a kit, sold at modest

cost, could prove most valuable in an emergency situa-

tion. A zinc bar and ring (lower right), and a spare oil

filter (Zeft), might be added to the kit by the prudent

boat owner.

The bar attaches to the underside of the

transom shield and the ring is secured to the

double bearing housing ahead of the propel-

ler.

The other illustration on the previous

page is an excellent example of how the

inexpensive zincs are sacrificed to save

more costly parts. The zincs should be

checked regularly and changed when they

show signs of deteriorating.

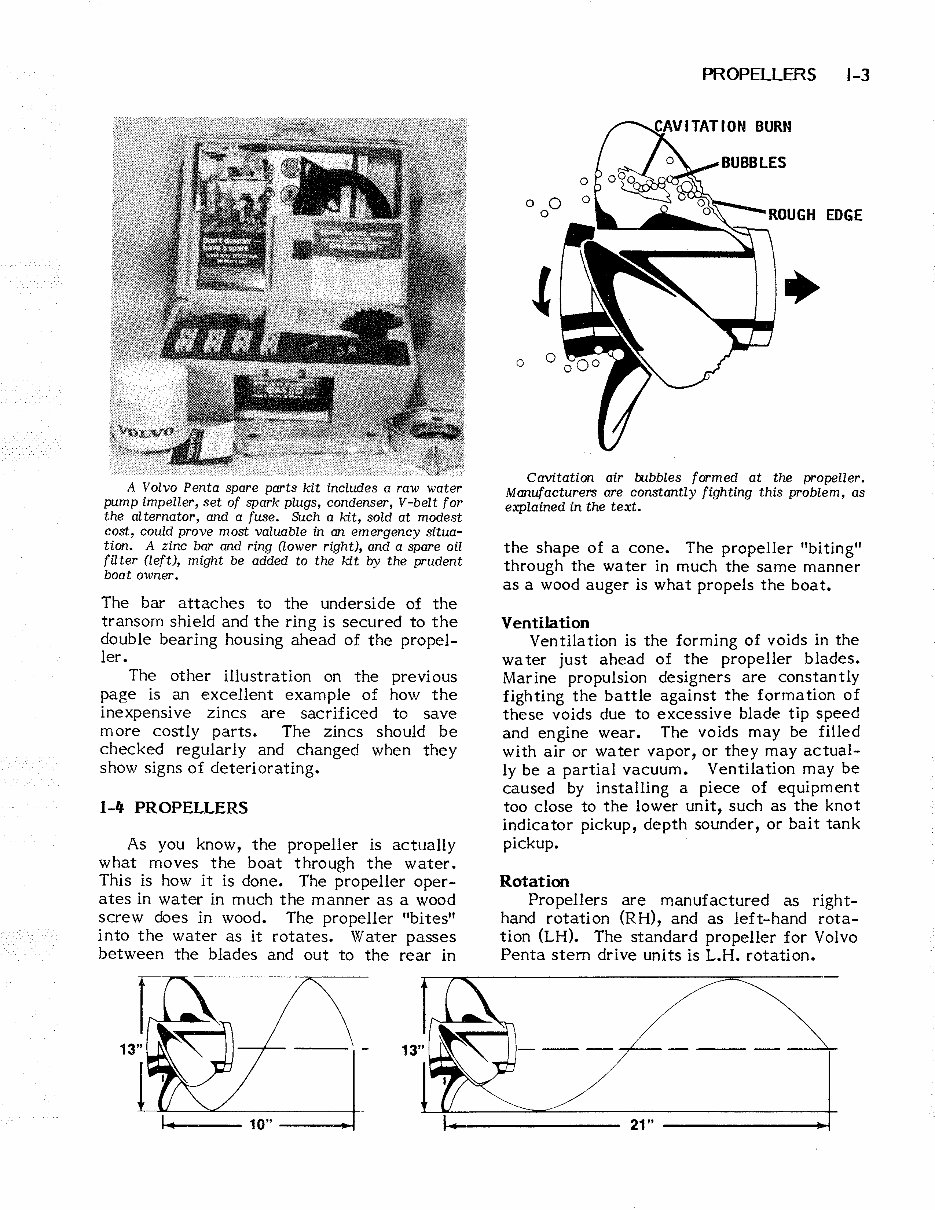

1-4 PROPELLERS

As you know, the propeller is actually

what moves the boat through the water.

This is how it is done. The propeller oper-

ates in water in much the manner as a wood

screw does in wood. The propeller "bites"

into the water as it rotates. Water passes

between the blades and out to the rear in

"""I .. _--- 10"

o

o 0

o

PROPELLERS 1-3

ITATION BURN

Cavitation air bubbles formed at the propeller.

Manufacturers are constantly fighting this problem, as

explained in the text.

the shape of a cone. The propeller "biting"

through the water in much the same manner

as a wood auger is what propels the boat.

Ventilation

Ventilation is the forming of voids in the

wa ter just ahead of the propeller blades.

Marine propUlsion designers are constantly

fighting the battle against the formation of

these voids due to excessive blade tip speed

and engine wear. The voids may be filled

with air or water vapor, or they may actual-

ly be a partial vacuum. Ventilation may be

caused by installing a piece of equipment

too close to the lower unit, such as the knot

indicator pickup, depth sounder, or bait tank

pickup.

Rotation

Propellers are manufactured as right-

hand rotation (RH), and as left-hand rota-

tion (LH). The standard propeller for Volvo

Penta stem drive units is L.H. rotation.

21"

You're Reading a Preview

What's Included?

Lifetime Access

Access Contents & Bookmarks

Print one or all pages of your manual