2012 Yamaha F40 HP outboard service repair manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

2009

OUTBOARD

SERVICE MANUAL

Model : F40JEA, F40JEA-(6BG1),

F40JEA-(6BG2), F40JEHA,

F40JEHA-(6BG1), F40JEHA-(6BG2), F40LA,

F40LA-(6BG1), F40LA-(6BG2), F40LEHA,

F40LEHA-(6BG1), F40LEHA-(6BG2)

6BG281972L11 *6BG281972L11*

Preface

This manual has been prepared by Yamaha primarily for use by Yamaha dealers and their trained

mechanics when performing maintenance procedures and repairs to Yamaha equipment. It has

been written to suit the needs of persons who have the Bronze Technical Certificate of YTA (Yamaha

Technical Academy) marine or the equivalent basic understanding of the mechanical and electrical

concepts and procedures inherent in the work, for without such knowledge attempted repairs or ser-

vice to the equipment could render it unsafe or unfit for use.

Because Yamaha has a policy of continuously improving its products, models may differ in detail

from the descriptions and illustrations given in this publication. Use only the latest edition of this

manual. Authorized Yamaha dealers are notified periodically of modifications and significant

changes in specifications and procedures, and these are incorporated in successive editions of this

manual. Also, up-to-date parts information is available on YPEC-web. Additional information and up-

to-date information on Yamaha products and services are available on Yamaha Service Portal.

Important information

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

A WARNING indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

A NOTICE indicates special precautions that must be taken to avoid damages to the out-

board motor or other property.

TIP:

A TIP provides key information to make procedures easier or clearer.

F40H

SERVICE MANUAL

©2010 by Yamaha Motor Co., Ltd.

2

nd

Edition, December 2010

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Co., Ltd.

is expressly prohibited.

Printed in Canada

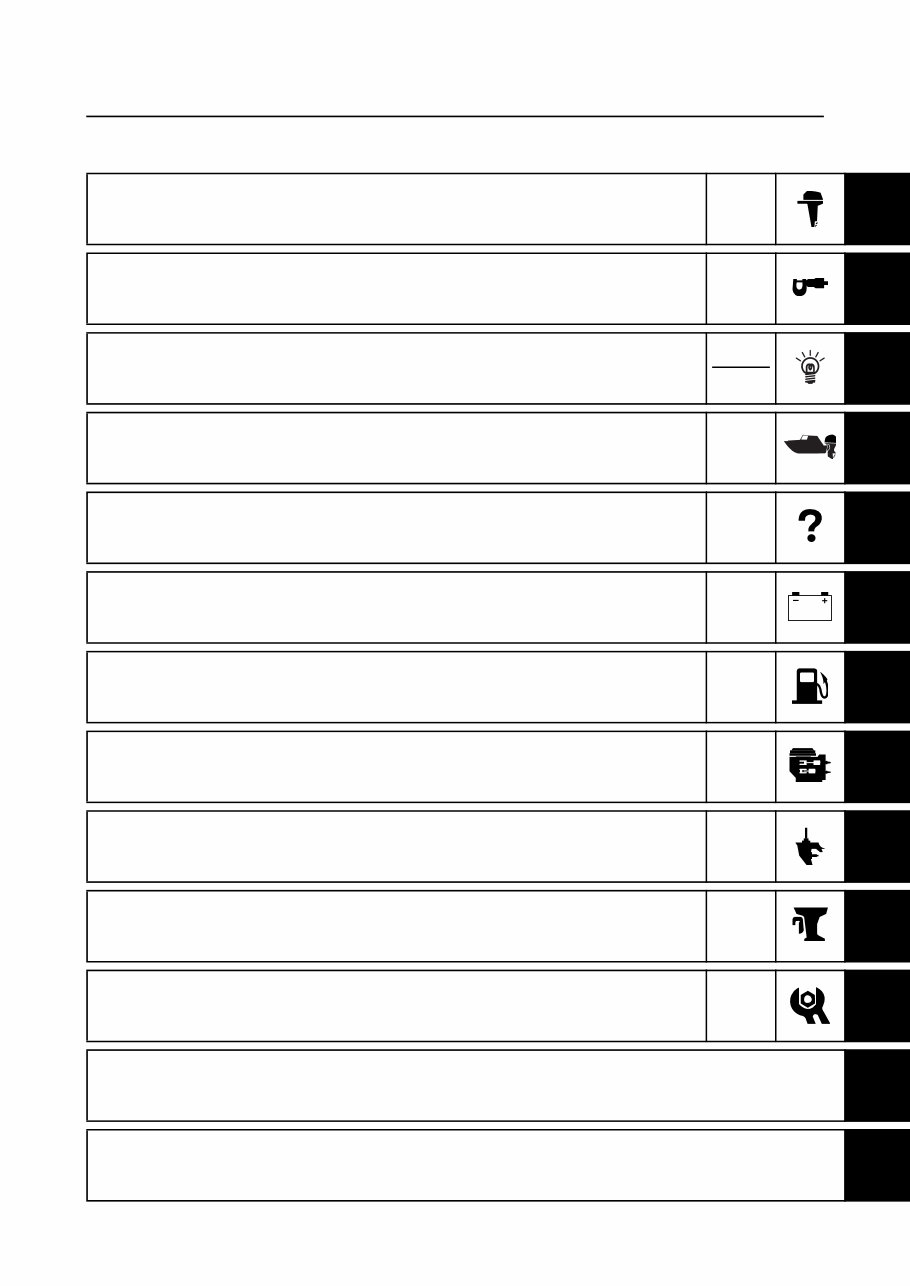

Contents

General information

0

Specification

1

Technical features and description

2

Rigging information

3

Troubleshooting

4

Electrical system

5

Fuel system

6

Power unit

7

Lower unit

8

Bracket unit

9

Maintenance

10

Index

Appendix

A

GEN

INFO

SPEC

TECH

FEA

RIG

GING

TRBL

SHTG

ELEC

FUEL

POWR

LOWR

BRKT

MNT

GEN

INFO

0

1

2

3

4

5

6

7

8

9

10

A

General information 0

Safety while working ........................................................... 0-1

Rotating part .............................................................................. 0-1

Hot part ...................................................................................... 0-1

Electric shock ............................................................................ 0-1

Propeller .................................................................................... 0-1

Handling of gasoline .................................................................. 0-1

Ventilation .................................................................................. 0-1

Self-protection ........................................................................... 0-2

Working with crane .................................................................... 0-2

Handling of burner ..................................................................... 0-2

Part, lubricant, and sealant ........................................................ 0-2

Handling of sealant .................................................................... 0-2

Special service tool ................................................................... 0-3

Tightening torque ...................................................................... 0-3

Non-reusable part ...................................................................... 0-3

Disassembly and assembly ....................................................... 0-3

How to use this manual ........................................................... 0-4

Manual format ........................................................................... 0-4

Abbreviation .............................................................................. 0-5

Sealant and locking agent ...................................................... 0-6

Symbol ...................................................................................... 0-6

Special service tool .................................................................. 0-7

0-1

GEN

INFO

General information

Safety while working

To prevent an accident or injury and to

ensure quality service, follow the safety pro-

cedures provided below.

Rotating part

• Hands, feet, hair, jewelry, clothing, Personal

flotation device straps, and so on can

become entangled with internal rotating

parts of the engine, resulting in serious

injury or death.

• Keep the top cowling in place whenever

possible. Do not remove or replace the

cowling with the engine running.

• Only operate the engine with the cowling

removed according to the specific instruc-

tions in the manual. Keep hands, feet, hair,

jewelry, clothing, Personal flotation device

straps, and so on away from any exposed

moving parts.

Hot part

During and after operation, engine parts are

hot enough to cause burns. Avoid touching

any parts under the top cowling until the

engine has cooled.

Electric shock

Do not touch any electrical parts while start-

ing or operating the engine. They can cause

shock or electrocution.

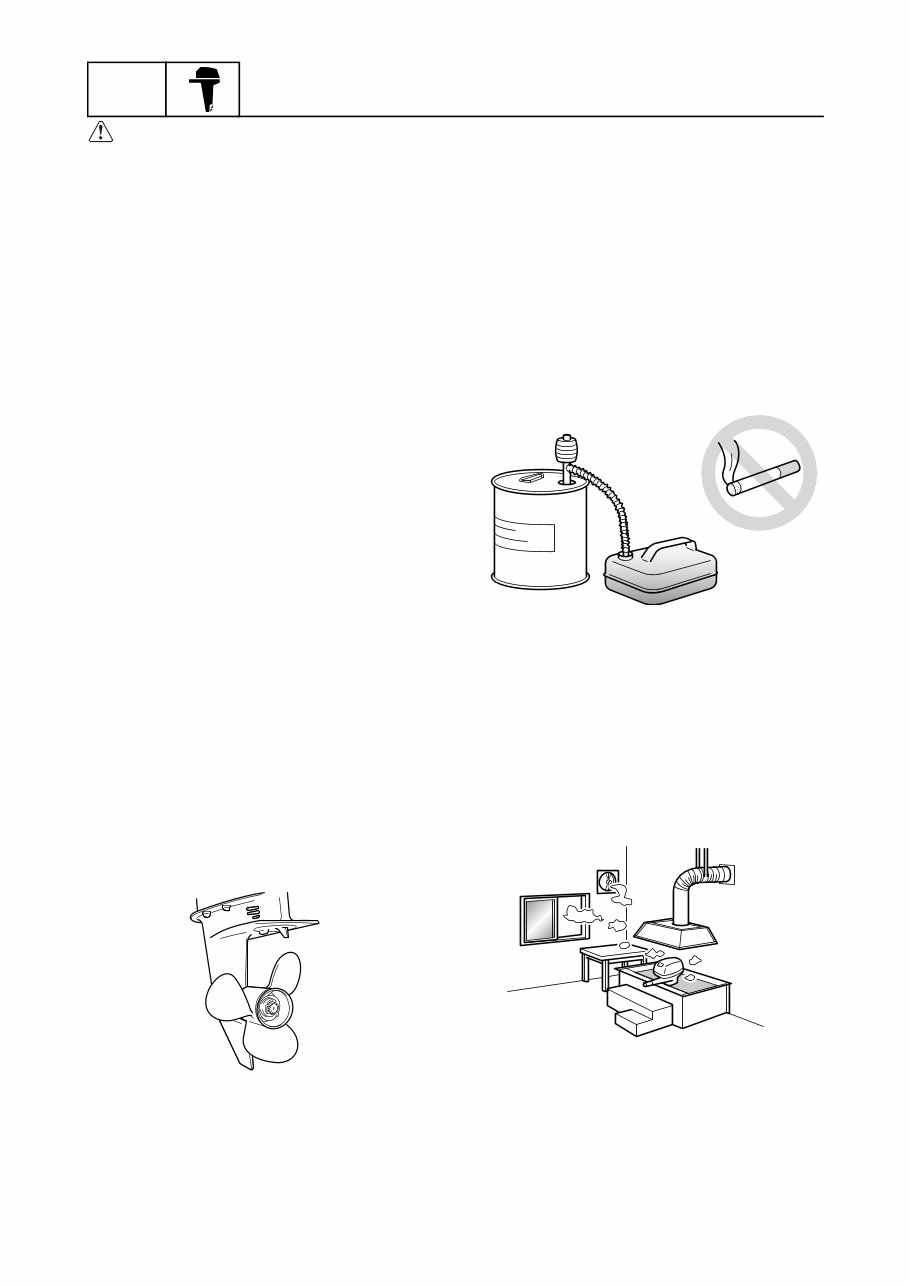

Propeller

Do not hold the propeller with your hands

when loosening or tightening it.

Handling of gasoline

• Gasoline is highly flammable. Keep gaso-

line and all flammable products away from

heat, sparks, and open flames.

• Gasoline is poisonous and can cause injury

or death. Handle gasoline with care. Never

siphon gasoline by mouth. If you happen to

swallow some gasoline or inhale a lot of

gasoline vapor, or get some gasoline in

your eyes, see your doctor immediately. If

gasoline spills on your skin, wash with soap

and water. If gasoline spills on your cloth-

ing, change your clothes.

Ventilation

• Gasoline vapor and exhaust gas are

heavier than air and extremely poisonous. If

inhaled in large quantities they may cause

loss of consciousness and death within a

short time.

• When test running an engine indoors

(example: in a water tank), make sure to do

so where adequate ventilation can be main-

tained.

0-2

Safety while working

0

1

2

3

4

5

6

7

8

9

10

A

Self-protection

• Protect your eyes by wearing safety

glasses or safety goggles during all opera-

tions involving drilling and grinding, or when

using an air compressor.

• Protect your hands and feet by wearing pro-

tective gloves and safety shoes when nec-

essary.

Working with crane

• Outboard motors weighing 18.0 kg (39.7 lb)

and over must be carried by a crane.

• Use a wire rope of adequate strength, and

lift up the outboard motor with the three

point suspension.

• If the outboard motor does not have three

or more points to be suspended, support it

with additional ropes or the like so that the

outboard motor can be lifted and carried in

a stable manner.

Handling of burner

• Incorrect handling of burner may result in

burns. Refer to the operation manual

issued by the manufacturer to assure the

correct handling.

• When using a burner, keep it away from the

gasoline and oil, to prevent a fire.

• Components become hot enough to cause

burns. Do not touch them directly.

Part, lubricant, and sealant

Use only genuine Yamaha parts, lubricants,

and sealants or those recommended by

Yamaha, when servicing or repairing the out-

board motor.

Handling of sealant

• Wear protective gloves to protect your skin,

when using the sealants.

• Refer to the material data sheet issued by

the manufacturer. Some of the sealants

may be harmful for human health.

0-3

GEN

INFO

General information

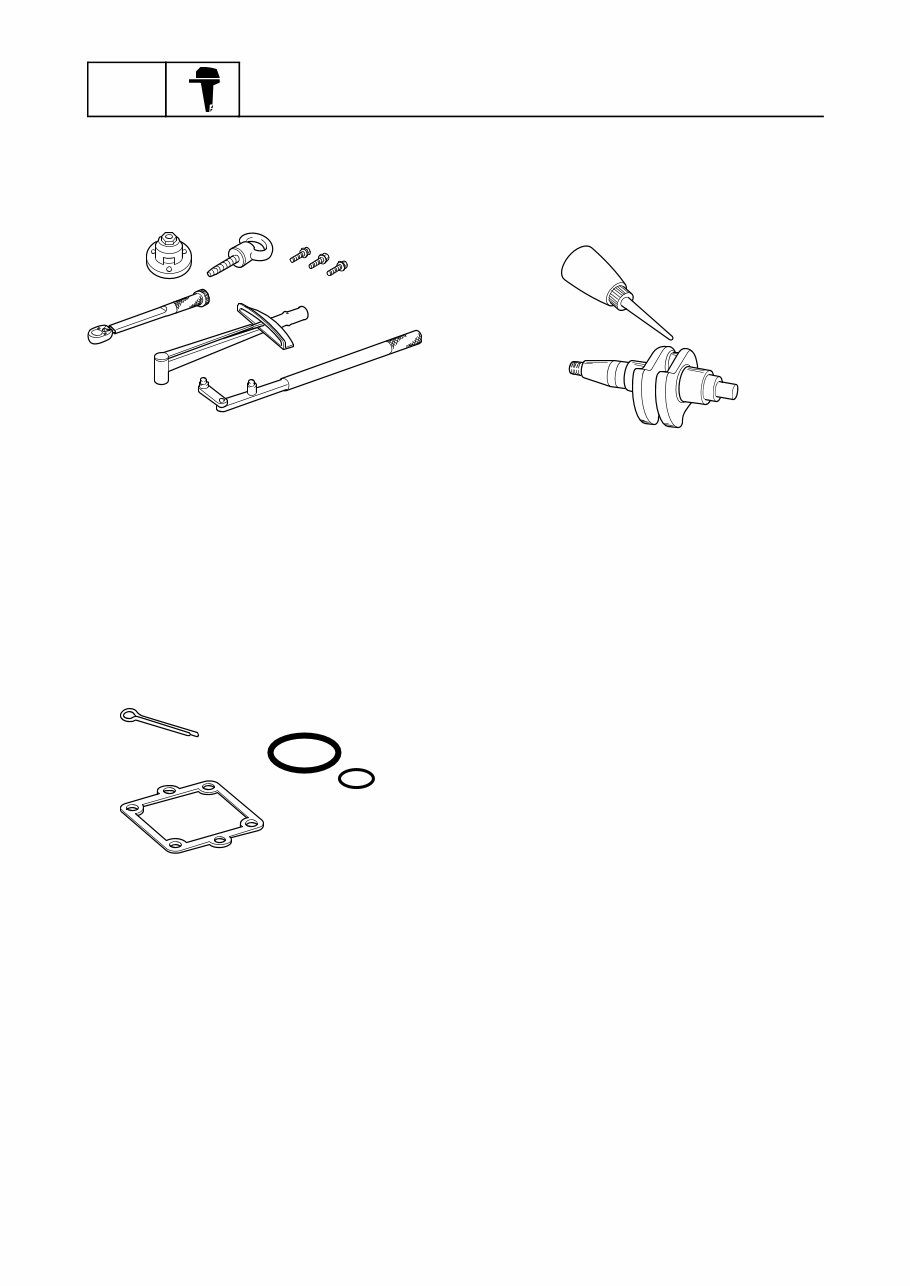

Special service tool

Use the recommended special service tools

to work safety, and to protect parts from dam-

age.

Tightening torque

Follow the tightening torque specifications

provided throughout the manual. When tight-

ening nuts, bolts, and screws, tighten the

large sizes first, and tighten fasteners starting

in the center and moving outward.

Non-reusable part

Always use new gaskets, seals, O-rings, cot-

ter pins, and so on, when installing or assem-

bling parts.

Disassembly and assembly

• Use compressed air to remove dust and dirt

during disassembly.

• Apply engine oil to the contact surfaces of

moving parts before assembly.

• Install bearings with the manufacture identi-

fication mark in the direction indicated in

the installation procedure. In addition, be

sure to lubricate the bearings liberally.

• Apply a thin coat of water-resistant grease

to the lip and periphery of an oil seal before

installation.

• Check that moving parts operate normally

after assembly.

0-4

0

1

2

3

4

5

6

7

8

9

10

A

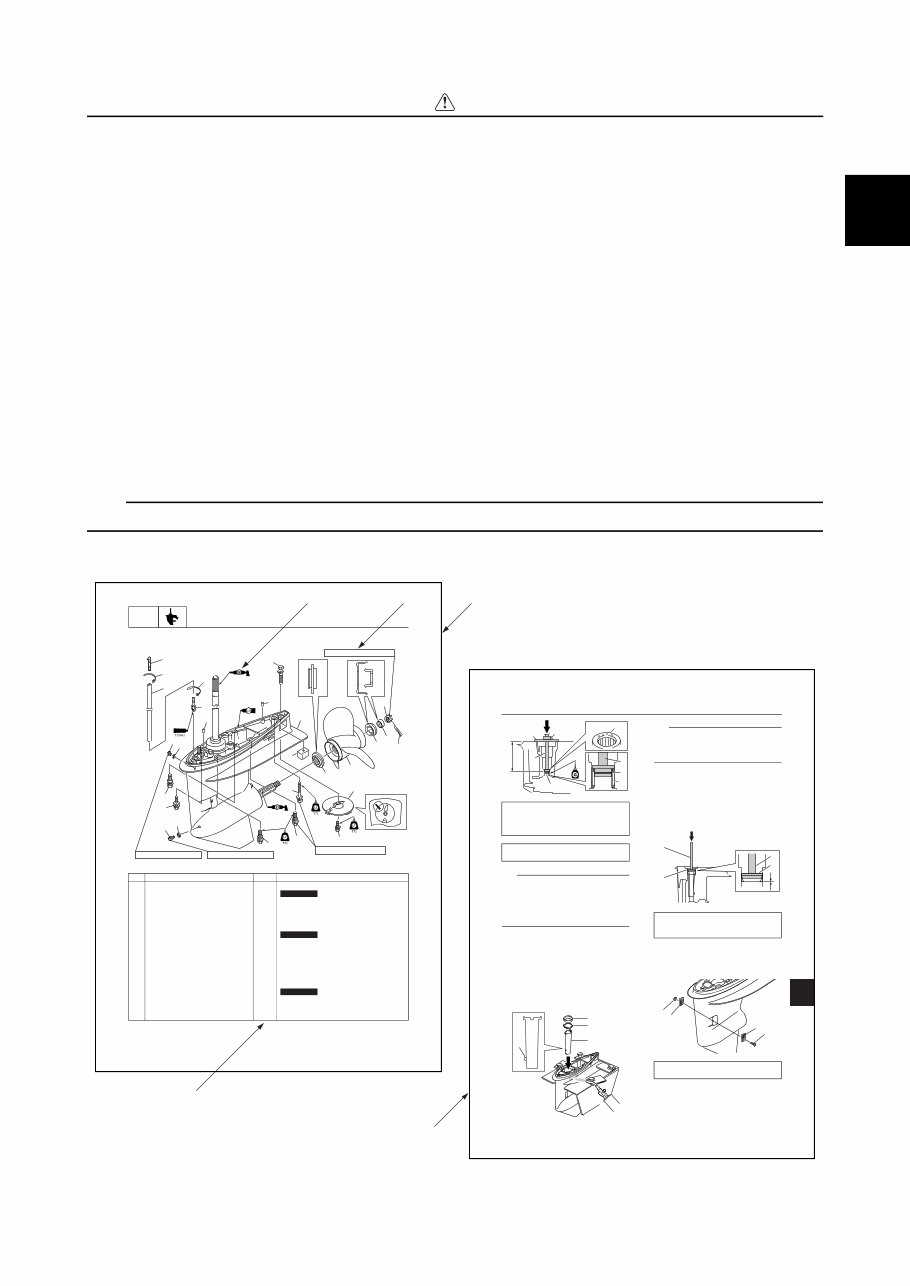

How to use this manual

Manual format

The format of this manual has been designed to make service procedures clear and easy to under-

stand. Use the information below as a guide for effective and quality service.

• Parts are shown and detailed in an exploded diagram and are listed in the component list (see a

in the figure below for an example page).

• The component list consists of part names and quantities, as well as bolt and screw dimensions

(see b in the figure below).

• Symbols are used to indicate important aspects of a procedure, such as the grade of lubricant and

lubrication point (see c in the figure below).

• Tightening torque specifications are provided in the exploded diagrams (see d in the figure below

for an example), and in the related detailed instructions. Some torque specifications are listed in

stages as torque figures or angles in degrees.

• Separate procedures and illustrations are used to explain the details of removal, checking, and

installation where necessary (see e in the figure below for an example page).

TIP:

For troubleshooting procedures, see Chapter 4, “Troubleshooting.”

8-1

LOWR

Lower unit

Lower unit

No. Part name Q’ty Remarks

1 Drain screw 1

2 Gasket 2

Not reusable

3 Bolt 4 M10 x 40 mm

4 Check screw 1

5 Dowel 2

6 Hose nipple 1

7 Plastic tie 2

Not reusable

8 Hose 1

9 Nipple 1

10 Bolt 1 M8 x 35 mm

11 Lower unit 1

12 Anode 1

13 Propeller nut 1

14 Cotter pin 1

Not reusable

15 Washer 1

16 Washer 1

17 Propeller 1

12

18

19

20

21

3

3

11

1

3

3

4

6

5

2

7

8

9

7

5

10

2

17

16

15

14

13

9 N·m (0.9 kgf·m, 6.6 ft·lb)

40 N·m (4.0 kgf·m, 29.5 ft·lb)

35 N·m (3.5 kgf·m, 25.8 ft·lb)

9 N·m (0.9 kgf·m, 6.6 ft·lb)

8-16

Drive shaft and lower case

0

1

2

3

4

5

6

7

8

9

10

A

TIP:

• Install a new needle bearing with the identi-

fication mark b facing toward the water

pump side.

When using the driver rod, do not strike the

special service tool in a manner that will

force the stopper c out of place.

5. Heat the installation area of the taper

roller bearing outer race in the lower case

with a gas torch, and then install the drive

shaft sleeve i, original shim(s) (T3) j

and a new taper roller bearing outer race

k. NOTICE: When heating the lower

case, heat the entire installation area

evenly. Otherwise, the paint on the

lower case could be burned.

TIP:

Install the drive shaft sleeve with the protru-

sion d facing forward.

Do not reuse a shim if deformed or

scratched.

6. While holding the special service tool c,

strike the tool to check that the taper

roller bearing outer race is installed

properly. If a high-pitched metallic sound

is produced when the special service tool

is struck, the outer race is installed

properly.

7. Install the water inlet covers m, n, the

nut o and the water inlet cover screw p,

and then tighten the water inlet cover

screw p to the specified torque.

Assembling the forward gear

1. Install a new taper roller bearing a.

Driver rod SL f: 90890-06602

Needle bearing attachment g:

90890-06614

Bearing depth plate h: 90890-06603

Installation depth a:

182.5–183.0 mm (7.19–7.20 in)

a

b

c

f

f

g

h

g

e

i

j

k

d

Driver rod LL c: 90890-06605

Bearing outer race attachment l:

90890-06627

Water inlet cover screw p:

1 N·m (0.1 kgf·m, 0.7 ft·lb)

c

l

c

l

m

n

o

p

e

b

c d

a

Safety while working / How to use this manual

0-5

GEN

INFO

General information

Abbreviation

The following abbreviations are used in this service manual.

Abbreviation Description

ABYC American Boat and Yacht Council

API American Petroleum Institute

ATDC After Top Dead Center

BTDC Before Top Dead Center

CARB California Air Resources Board

CCA Cold Cranking Ampere

C/E Check Engine

ECM Electronic Control Module

EPA Environmental Protection Agency

EX Exhaust

F Forward

IC Integrated Circuit

IN Intake

ISC Idle Speed Control

MCA Marine Cranking Ampere

N Neutral

P.O.N. Pump Octane Number = (RON+Motor Octane Number) / 2

PORT Port side

PTT Power Trim and Tilt

R Reverse

RC Reserve Capacity

SAE Society of Automotive Engineers

SOHC Single Overhead Camshaft

STBD Starboard side

TDC Top Dead Center

TPS Throttle Position Sensor

W/F Water in Fuel

http://ReadManuals.com

0-6

0

1

2

3

4

5

6

7

8

9

10

A

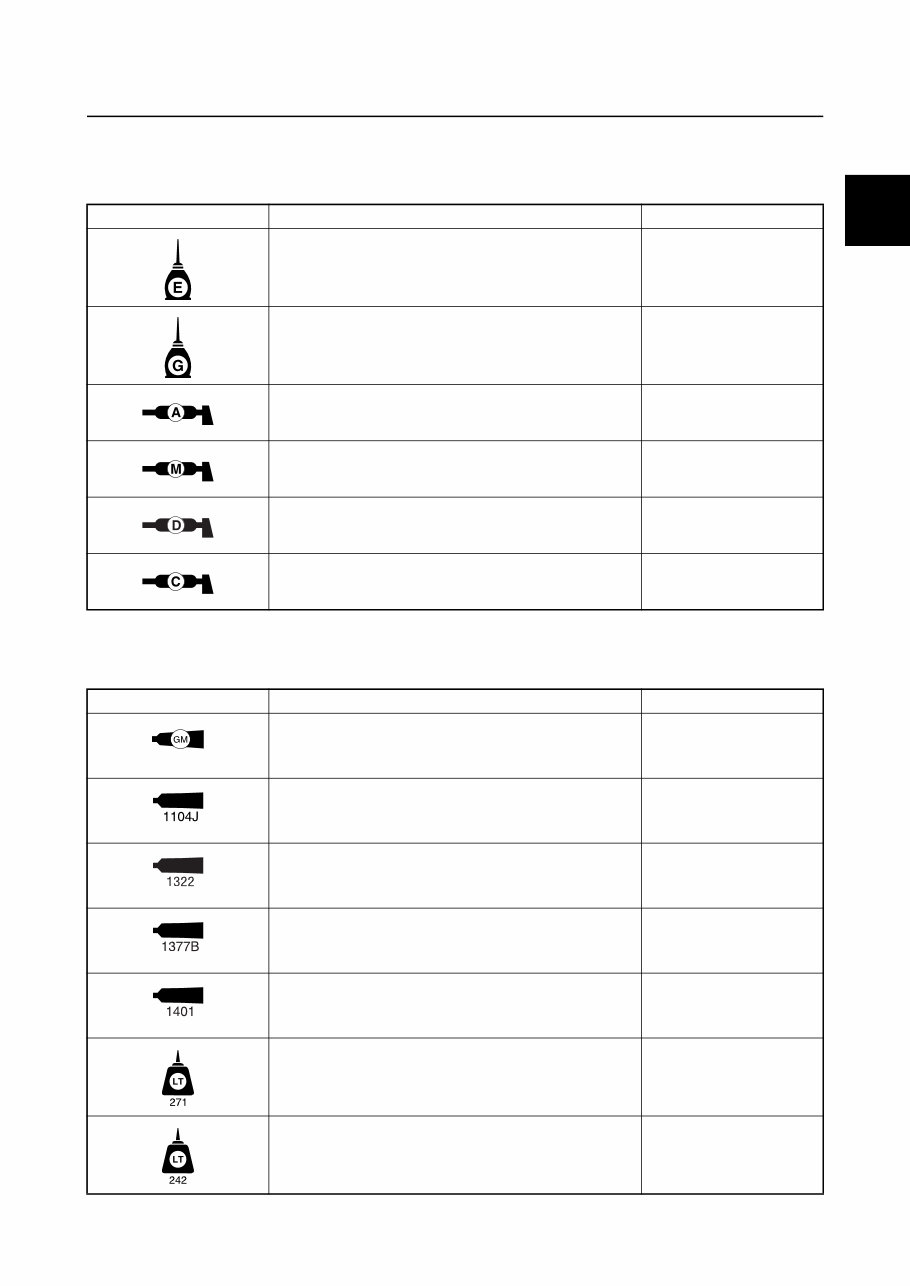

Sealant and locking agent

Symbol

Symbols in an exploded diagram or illustration indicate the grade of lubricant and the lubrication points.

Symbols in an exploded diagram or illustration indicate the type of sealant or thread locking agent

and the application points.

Symbol Name Application

Yamaha 4-stroke motor oil Lubricant

Gear oil Lubricant

Water resistant grease

(Yamaha grease A)

Lubricant

Molybdenum disulfide grease Lubricant

Corrosion resistant grease

(Yamaha grease D)

Lubricant

Low temperature resistant grease

(Yamaha grease C)

Lubricant

Symbol Name Application

Gasket Maker Sealant

ThreeBond 1104J Sealant

ThreeBond 1322 Sealant

ThreeBond 1377B Thread locking agent

ThreeBond 1401 Thread locking agent

LOCTITE 271 (red) Thread locking agent

LOCTITE 242 (blue) Thread locking agent

How to use this manual / Sealant and locking agent

http://ReadManuals.com

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 17 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

This manual is a comprehensive guide for the 2012 Yamaha F40 HP outboards. It is designed to provide mechanics with a convenient and easy-to-read reference for all disassembly, repair, assembly, and inspection operations. Each chapter includes exploded diagrams before the disassembly section to facilitate the identification of correct procedures. The manual is fully bookmarked and searchable, making it an invaluable resource for both professional mechanics and DIY enthusiasts. It encompasses all aspects of the motor, ensuring thorough coverage of essential information.