Suzuki 2-15HP outboard motors Service Repair Workshop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SERVICE MANUAL

TUNE-UP

SUZUKI

SUZUKI AMERICA CORPORATION

3251 E. Imperial Way

P.O. Box 1100

Brea, California 92621

SUZUKI DT2

1b determine model and year of manufacture of Suzuki outboard motors, refer

to numbers located on motor clamp bracket. The first six characters indicate the

model and second six characters are motor serial number. The first character of

serial number indicates year of manufacture. The years 1977, 1978 and 1979 are

identified by the letters "C," "D" and "F" respectively. Starting with 1980, the

first number in serial number corresponds with model year. For example, if first

number in serial number is 1, model year is 1981.

CONDENSED SERVICE DATA

NOTE: Metric fasteners are used throughout outboard motor.

Hp/rpm ......................... , ... . ..... . 2/4500

SIZES-CLEARANCES CONT.

Crankshaft Runout at Main

Suzuki OT2

Bore ....................... . ........... .41.0 mm Bearing Journal (Max.) ........ _ .......... 0.03 mm·

(1.614 in.)

Stroke ......... . ......................... 37.8 mm

(1.488 in.)

Displacement ......... . ...................... 50 cc

(3.05 cu. in.)

Spark Plug:

NGK .................................... BR5HS

Electrode gap ...... . .................. 0.5-0.6 mm

(0.020-0.023 in.)

Magneto:

Breaker point gap ................ , .... 0.3-0.4 mm

(0.012-0.016 in.)

Carburetor:

Make .................................... Mikuni

Model ............ ... ...... . .... . ...... VM-11-10

Fuel:Oil Ratio ................. . ..... . _ .... See Text

SIZES-CLEARANCES

Piston Ring End Gap ....... . .......... 0.10-0.25 mm

(0.004-0.010 in.)

Piston to Cylinder

Clearance .............. . ......... 0.053-0.060 mm

(0.0021-0.0024 in.)

Piston Pin Diameter ............... 11.996-12.000 mm

(0.4723-0.4724 in.)

(0.0012 in.)

Connecting Rod Small End

Side Shake (Max.) ........... . ...... , ..... 3.0 mm

(0.118 in.)

TIGHTENING TORQUES

Cylinder Head ............................ 8-12 N'm

(6-9 ft.-Ibs.)

Crankcase ....... . ............. . ... , ..... 8-12 N'm

(6-9 ft.-Ibs.)

Reed Plate ............................ 0.5-0.75 N'm

(4.5-6_6 in.-Ibs.)

Flywheel Nut ............... . .......... .40-~0 N'm

(30-37 ft.-lbs.)

Standard Screws:

5 mm ............. . ...... . ............. 2-4 N'm

(18-36 in.-Ibs.)

6 mm ....... . .... . .................... · . .4-7 N'm

(36-62 in.-Ibs.)

8 mm ....... _. ........................ 10-16 N'm

(89-141 in.-Ibs.)

10 mm ....... .. .... . .................. 22-35 N'm

(195-310 in.-Ibs.)

Suzuki DT2

WBRICATION

The power head is lubricated by oil

mixed with the fueL Fuel:oil ratio

should be 30:1 during brea k-in of a new

or rebuilt engine. Fuel:oil ratio for nor -

mal service is 50: I on models prior to

1987 and 100:1 on 1987 and later

models. Recommended oil is Suzuki Out-

board Motor Oil or a good quality NMMA

certified TC-W oiL When using any oth-

er type of two-stroke engine oil, fuel:oil

ratios should be 20: I during break -in

and 30:1 for normal service. Manufac-

turer recommends regular or unleaded

automotive ga';oline having an 85-95 oc-

tane rating. Gasoline and oil should be

thoroughly mixed.

The lower unit gears and bearings are

lubricated with SAE 90 hypoid outboard

gear oil. Lower unit capacity on models

priorto 1987 is approximately 40 mL (1.3

oz.). Oil capacity on later models is ap-

proximately 70 mL (2.4 oz.) on short

drive shaft models and 120 mL (4 .1 oz. )

on long drive shaft. models. On early

models (prior to 1987). lay motor on side

to fill with oil. Later models are

equipped with a vent /oil level check

plug on side of gearcase. Reinstall plug

securely using a new gasket if necessary

to ensure a water tight seal.

FUEL SYSTEM

CARBURETOR. A Mikuni sliding

valve float type carburetor is used . Re-

fer to Fig. S21-1 for exploded view. Idle

speed should be adjusted after motor

has reached normal operating temper-

ature. Move speed control to slow speed

stop and adjust idle speed screw (14) to

obtain idle speed of 800-900 rpm. Note

that on 1987 and later models, carbure -

tor is equipped with a pilot air screw

(Fig. SZI-2) for low speed mixture ad-

jus tment. Carburetor with pilot air

screw can be identified by the presence

of a float bowl drain plug. Initial setting

of pilot air scre w is two turns out from

a lightly seated position. Final adjust-

ment should be made with engine at

ope rating temperature and running in

forward gear . Adjust pilot air screw so

engine idles smoothly and accelerates

without hesitation.

Main fuel metering is controlled by

main jet (20-Fig. SZI-I). Standard main

jet size is 1195 for models through 1986

and 1190 for 1987 and later models. Nor-

mal position for clip (9) onjet needle (10)

is third notch from top of needle. If

midrange mixture is too lean or too lich,

minor fuel mixture adjustment can be

accomplished by repositioning clip on

jet needle. Moving clip down on needle

richens fuel mixture while moving clip

up on needle leans fuel mixture. Fuel

filter (17) should be cleaned after eve-

ry 50 hours of operation.

Th check float level, remove float bowl

and invert carburetor. With float in-

stalled on float ann (23), float surface

nearest main jet should be 19-21 mm

(0.748-0.826 in.) away from carburetor

gasket surface. Make certain float is lev-

el with gasket surface when measuring.

Adjust float level by bending float arm

tang.

When installing carburetor, renew

"0" ring (13) as required.

IGNITION SYSTEM

Breaker point gap should be set to 0.3-

0.4 mm (0.012-0.016 in.) at maximum

opening. Adjustment may be accom-

plished through holes in flywheel. Fly-

wheel must be removed to renew break-

er l)oint.~. Tighten flywheel nut to 40-50

N'm (30-37 fUbs .).

Fig. SZI-I-Exploded view of c."'urelo, used on

models p,'o, 10 1987. On 1987 snd I. Ie' models,

CB"'urero, Is equipped wlrh • pI/or .,, screw (Fig.

SZ1-2) fo, 'ow speed mixture sd/usrmen/.

1. Sp~t..·d co ntrol a.:;::;y. 13 "0" rtn~

2. CIlP nut 14. Idle speed scrc .....

3. Spring tG . Spring

1 . Tube: 16. Chok ~ a..-.., .. y.

5. Clip 17. FUf'J (iller

fl . SprlnR !lC!l( 18 . l-'uI.'1 illiN \.' ;] \ve

1. ~at pin 1~. :\11Iin nO:t:llc

8. Throttle rod 20. :\1.'110 j et

f) Clip 2 1. Float

10 . .TN n .. 'OOle 22. Float bowl

11. Throttle valve 23. FIOfll ann

12 . Dody 2-1 . Pi\'ot pin

OUTBOARD MOTOR

After adjusting breaker points, check

ignition timing using a dial indicator and

an o hmmeter or continuit.y tester . Re -

move the spark plug and insert the dial

indicator. Set piston position at TOC,

then zero the dial indicator . Disconnect

the black lead to stop button and con-

ne ct the ohmmet.er or continuity tester

between lead from magneto and

ground. Rotate the flywheel clockwise

until meter or continuity tester indi-

cates that points have just opened. Dial

indicator should read 0.804 mm (0.032

in .). If ignition timing adjustment is re-

quired, remove the flywheel and loos-

en magneto base plate (7-Fig. SZI-3) re-

taining screws. Rotating base plate

clockwise retard s ignition timing while

rotating counterclockwise advances ig-

nition t.iming.

COOLING SYSTEM

WATER PUMP. A rubb er impeller

type water pump is used to cool the

Pilot Ai r Screw

....... --_Plug

Fig. SZI-2-lnltl.' setting of pilot .,, screw on

models so equipped Is /WO lums our from sllghr-

Iy seared position.

--- 1

---2

~:.--=:::::-- 3

Fig. SZI-3-Exploded vleMf of magnero.

t. ~ur

2 . Lo('KW3!ihN

3. K(')"

4. FIY""h~1

;). Ignition coil

6. I~nilion bh'ilk(!r poinL"

lJ.a .. ">(! pl;lle

B. Stop ~witch

SERVICE MANUAL

power h ead and lower unit. Pump is lo-

ca ted in the gearcase and driven by the

propeller s haft.

Wat er inlet should be insp ecte d for

plugging or partial r estriction if cooling

system malfunction is not ed. Refer to

Fig. SZI-9 for exploded view of wat er

pump. To remove the impeller, remove

propeller, propeller thrust pin and gear-

case end ca p (I), then withdraw the im -

peller (2). Inspect impe ll er for cr.l.cks or

excessive wear or scoring. Power h ead

should be separated from drive shaft

housing and wat er passages thorough-

ly cleaned if large accum ulations of for-

eign material are evide nt. Turn propel-

ler shaft in a clockwise direction when

inserting impe ll er in pump cavity.

POWER HEAD

REMOVE AND REINSTALL. To re-

move power h ead, remove power h ead

cover, fuel tank. control panel assembly

and ca rbureto r. Remove reco il starter

assembly, flywh ee l and magne to ba~e

plate assembly. Unscrew the six ca p

screws securing power head to drive

s haft housing and sepa rate power head

from drive s haft housing.

Before reinsta lling power h ead, in-

spect water inl et and outlet passages in

drive shaft housing and remove any for-

eign material. Apply a coat of s ili co ne

sealer to mating surfaces of power h ead

and drive shaft housing and install a

new gasket. Assemble power h ead on

drive shaft housing a nd tight en r eta in-

ing cap screws to 6-10 N'm (5:3-88 in .-

Ibs.). Co mpl ete installation by reversing

removal proce dure.

DISASSEMBLY. Disassembly and in-

spect.ion may be accomplished in the fol-

lowing mann er: Remove cy linder h ead

and clean ca rb on from co mbusti on

chamber and any foreign mat erial ac-

cumulated in wate r passages. Detach

c rank case half (I- Fig. SZI-4) fr om cyl-

inder block afte r removing six crankcase

cap screws. Cra nksh a ft and piston as-

sembly may now be removed from cyl-

inder block.

REASSEl\ffiLY. Refer to specific serv-

ice sections when assembling c nmk -

shaft, co nne cting rod, piston and r ee d

valves. Make sure all joint and gasket

surfaces are clean and free of nicks a nd

burrs. Make sure all carbon. salt, dirt.

and sand are cleaned from the combu s-

tion c hamb e r, ex haust port a nd water

passages.

On early models place thrust rings

(ll-Fig. SZI-5) in cylinder block (2-Fig.

SZI-4), then install crankshaft a'>Se mbly.

On lat er mode ls , thrust rings are full-

circle design and must be a'>Sembled on

c ranksh aft prior to installing c rank -

s haft. Press c ranksh aft seals flush

against thrust rings. Install "0" ring (8)

in cylinder block, then apply a suitable

wat er r es istant-grease to "0" ring and

splined ar ea of crankshaft. Apply a

suitable sealer to cylinder block and

cra nkcase half mating surfaces and po-

siti on c rank case half on cylinder block.

USing a crossing patte~ , tighten six

c rank case screws to 8-12 N'm (6-9

ft ..-lbs.).

Do not use sealer when installing cyl-

inder head gasket. Align wat er passage

holes in cylinder block with holes in

he ad gasket and install cylinder h ead.

Tighten cy linder head bolts in a cross-

ing pattern to 8-12 N'm (6-9 ft.-lbs.).

Fig. SZI · 4-Exploded view of crankcase and cyl-

1. Cr:mk (':I "'<.' h~(lr

~. Cylind C' r bluck

l)ow l, l

"".'1d ~n. ... k (· t

Inder assembly.

.J . C-yhndc:-r 1)(':\Ij

Ij ik('(l ~raJ

7. RN' d stop

:'l "0·· rinp:

Fig. SZI-5-Explod6d .'61M of crankshan, plsron

and related components. On 1988 snd later

mod61., Ihrusl rings (II) ar6 full·clrcl6 design .

I. Pbton rim; 7. lJe;lJ"inlt

2 . PC!lon 8. Ctankpln

:1. ReuJm'r rin/ol !I Crankshaf t

·1. Piston pin 10. Ball tM..ol'lrtn!t-~

u. Durln.Q. II . Thrust rin gs

fi . C()nn('ctln~ rod 12 . Crank!ihafl !\ellis

Suzuki OT2

PISTON, PIN, RINGS AND CYLIN-

DER. The piston is fitted with two pis-

ton rings. Piston ring e nd gap should be

0.10-0.25 mm (0.004-0.010 in .) with a

maximum allowable ring end gap of 0.60

mm (0.024 in.). Piston rings are retained

in position by loca ting pins. Piston-to-

cylinder clearance should be 0.053-0.060

mm (0.0021-0.0024 in .). Pistons and

rings are available in standard size as

we ll .as 0.25 mm (0.010) and 0.50 mm

(0.020 in.) oversize. Cylinder should be

bored to an oversize if cylinder is o ut of

ro und or taper exceeds 0.10 mm (0.004

in.). Install piston on co nn ecting rod so

arrow on pist.on crown will point toward

exhau st. port ..

CONNECTING ROD, BEARINGS

AND CRANKSHAFT. Co nnecti ng r od ,

bearings and c rankshaft are a press to-

gether unit. Crankshaft should be dis-

assembled ONLY by experienced se rv-

ice personnel using appropriate service

equipment.

Caged roller bearings are used at both

large and small e nds of th e conn ect ing

rod. Determine rod bearing wea r fr om

side-to-side a~ shown in Fig_ SZI-6. Nor-

mal side-to-side moveme nt is 3.0 mm

(0.118 in.) or less. Maximum limit of

cra nkshaft nmo ut is 0.03 mm (0_0012

in.) me as ured at bearing surfaces with

cra nkshaft ends s upported.

Apply a suitable high temperature

grease to lip area of crankshaft seals and

install seals on crankshaft with ope n

side toward bearings.

REED VALVE. The r eed va lve is lo-

cated on the inside of crankcase (I-Fig.

SZI-4). Power head must be removed

a nd cra nkc ase separated from cylinder

block as outlined in the POWER IIEAO

sec tion to se rvice reed valve assembly.

Renew reed (6) if petals are broken,

c ra cked, warped or ru sted. Tip of r eed

petal must not stand ope'n in excess of

0.2 nnn (0.008 in.) fr om contac t s urface.

Reed stop ope ning shou ld be 4.0 mm

(0. 160 in .). Reed pet al should be in-

Ag. SZ1a6-Move connecting rod small fHfd side-

to-side as shown to detennlne rod, bearing snd

crsnkpln wear. Refer '0 text.

Suzuki DT2

stalled in crankcase with beveled cor-

ner(C-Fig. SZI-7) away from flywheel

end of crankcase.

MANUAL STARTER

Refer to Fig. SZI-S for exploded view

of manual stalter assembly. Starter may

be removed as a complete unit by

removing three cap screws securing

start.er assembly to power head. 1b dis-

assemble starter , proceed as follows: If

rewind spring (3) remains under ten-

sion, pull starter rope and hold rope pul-

ley (4) with notch in pulley ad,jacent to

rope outlet. Pull rope back through out-

let so rope engages notch in pulley and

allow pulley to slowly unwind. Remove

cap screw (8) and disassemble unit. Be

careful when removing rewind spring

(:3) to prevent personal if\iury.

Rewind spring is wound in counter-

clockwise direction in starter housing.

Rope is wound on rope pulley in coun-

terclockwise direction as viewed with

pulley in housing. Reassemble starter by

reversing disassembly procedure mak-

ing certain pin on starter pawl (5) is en-

gaged between ends of spring clip (6).

To place tension on rewind spring, pass

rope through rope outlet in housing and

install rope handle. Pull rope out and

hold rope pulley so notch on pulley is

adjacent to rope outlet. Pull rope back

through outlet between notch in pulley

and housing. Turn rope pulley counter-

clockwise six complete revolutions to

place tension on spring. Do not place

more tension on rewind spring than is

necessary to draw rope handle snug

against housing.

LOWER UNIT

PROPELLER AND SHEAR PIN. Pro-

peller for normal use has three blades

and is equipped with a shear pin to pre-

vent damage. Standard propeller is ISS

Fig. SZI·7-Reed petal (6) should be Insralled wllh

belleled comer (C) toward drive end 01 crankcBS6

8S shown.

mm (7.4 in.) in diameter and has 115 mm

(4.5 in.) pitch. Optional propellers are

available from the manufacturer and

should be selected to provide full throt-

tle operation within the recommended

limits of 4200-4S00 rpm.

R&R AND OVERHAUL. To remove

gearcase, unscrew drain plug and drain

Fig. SZI-B-Exploded view of manual srarter as·

sembly.

1. IloWling

2. Ra rx:

:I. R~oil !lprlnA:

4. RoIK' pulky

,j, Sf.3.rt(' f pawl

Fig. SZI-9-Exploded view of

gearc8se and water pump 8S~

56mbly. Nore rhar drive sha"

spacer (21) Is redesigned on

18te models and must be In-

sralled wlrh "up" mar/( facing

fop of gearcase.

1. Cap

2. imp('lIcr

: 1. Pi.n

,1. rump hf)u~jnR

d. "U" rin,ii:

6. ~~I

7. Bearin.w:

8. Spacer

~. Propeller ~h:lrt

"

Spring clip

7. Plate

8. Cap S(:rew

9 Driv'J pla.t('

W. Magneto insulator

(

10. Solms 23

11. BeMi ns:

12. "E " rin,ll 22 ---.e_

1 :1 . Pinlon J(~:lr

lot . Shimll

15. Shim

Ifl. Gt! :\r<::aSe

17 Drain plug

18 . Cover .

Ig . Shim

20. lJea.rin~

21. Sp.t.ccr

22. Snap ring

2:1. Sc.-al

24 . B~hing

2]) . Tube

2t" Drive ~hart

27. BU$hing

28. Water 1ub(1

29. Grommet

OUTBOARD MOTOR

gear lubricant. Remove propeller and

shear pin. Remove cover (IS-Fig. SZI·

9) and unscrew two retaining nuts, then

separate gearcase (16) from drive shaft

housing. Remove gearcase end cap (I),

withdraw impeller (2), impeller drive

pin (3) and pump housing (4). Pull drive

shaft seal tube (25) from gearcase. De-

tach"E" ring (12) and withdraw drive

shaft (2()) while simultaneously remov-

ing pinion gear (]:3) and shims (14 and

15). Remove propeller shaft (9) and

shims (10). If necessary, use a suitable

puller to remove bearing (II).

Inspect all components for excessive

wear or other damage. Apply a water

resistant grease to lip area of all seals.

If removed, install bearing (20) and

check clearance between upper bearing

and retaining ring (22). Clearance

should not exceed 0.1 mm (0.004 in .) and

can be ad,justed by varying thickness of

shims (19). Shims are available in 0.1

mm, 0.2 mm and 0.5 mm sizes. Install

propeller shaft (9) with original shims

(10). Reassemble pinion gear (13) with

original shims (14 and 15) and drive

shaft (26) in gearcase, then check mesh

pattern of pinion gear and forward gear.

Mesh pattern is ad,justed by varying

thickness of shims (14). Install water

pump assembly, then check propeller

shaft end play. Propeller shaft end play

should be 0.05-0.50 mm (0.002-0.020 in.)

and is ad,justed using shims (10). Com-

plete reassembly by reversing disassem-

bly procedure. Fill gearcase with SAE 90

hypoid outboard gear oil.

,1

I

I

I

26

(\

~/' / /) ;: ~ i~\:)

15 ~ 'I , t

~

. 6

8 1

9

10

SERVICE MANUAL

Suzuki 013.5

SUZU KI DT3.5

CONDENSED SERVICE DATA

NOTE: Metric fasteners are used throughout outboard motor.

TUNE·UP SIZES-CLEARANCES CONT.

Hp/rpm . ........... . ............ .. .... 3.5/4800-5300

Piston Pin Diameter ... . ............. 11.996-12 .000 mm

Bore .. ...... ...... .. .. . ........ ..... .... .... 46 mm

(1.81 in .)

(0.4 723-0.4 724 in.)

Max. Crankshaft Runout at Main

Stroke ............. • ...... .. ......... ... .... 42 mm

(1.65 in .)

Bearing Journal ................. .. ........ 0.03 mm

Displacement ..... ....... .. ...... . ...... .. .. .. 69.8 cc

(4.3 cu . in .)

Spark Plug:

(0 .0012 in.)

Max . Connecting Rod Small End

Side Shake .. .. ... . ............ ....... ..... . 3.0 mm

NGK .. ........ ....... ..... ... ...... .. .... BP6HS

(0.12 in.)

El ec trod e Gap .... . .. ... . .. .. ... . ..... ... 0.6-0 .7 mm

(0 .024-0.028 in.)

TIGHTENING TORQUES

Ignition Type . ........ .. .. . .... .. ... .... Breaker Point

Power Head Mounting Screws and Nuts ... .. .. 15-20 N· m

(11-14 ft.-Ibs.)

Breaker Point Gap ........... .. .. .. .... .... 0.3-0.4 mm

Crankcase ............ ... . ..... .. .. .. .. .... 8-12N·m

(0.012-0.016 in .)

(6-8 ft.-Ibs.)

Ignition Timing@ 5000 rpm .. . ... . ...... .. . 23.5° BTDC

Carburetor:

Flywheel Nut .......... ....... .... ...... .. 40-50 N· m

Make .. .. ..... ........ .. ...... ... .... .. . ... Mikuni

(29-36 ft.-Ibs.)

Standard Screws:

Mod el ................................... BV-18-15

5 mm ..... . .. .. .... ...... . .. ............. 2-4 N'm

Idle Speed (in gear) ........... . ......... . 900-1000 rpm

(1-3 ft.-Ibs.)

Fuel:Oil Ratio .. ...... ..... .. . ... . .. .. .. ........ 50: 1

6mm ............... .... ................. 4-7N·m

(3-5 ft.-Ibs .)

SIZES-CLEARANCES

8 mm . .... ..... ...... ............ ... ... 10-16 N'm

Piston Ring End Ga p ......... .. .. .... .... 0. 15-0.35 mm

(7-11 ft .-Ibs.)

(0.006-0.014 in .)

10 mm ..... ... .......... .... .. .... ... .. 22-35 N'm

Piston to Cylinder Clearance ... . ........ 0. 052-0.067 mm

LUBRICATION

The power head is lubricated by oil

mixed with the fu el. Fuel:oil ratios

should be 30:1 during break-in of a new

or rebuilt engine and 50: 1 for normal

service when using a BIA certified TC- W

engine oil or Suzuki "CCI" oil. Wh en us-

ing any other type of two-stroke engine

oil . fuel :o il ratios should be 20 :1 during

break-in and 30:1 for normal service.

Manufacturer recommends regular or

no-lead automotive gasoline having an

85-95 octane rating. Gasoline and oil

should be thoroughly mixed.

The lower unit gears and bearings are

lubricated by approximately 85 mL (2.9

ozs.) of SAE 90 hypoid outboard gear

oil. Reinstall vent and fill plugs securely

using a new gasket, if necessary. to en-

sure a water tight seal.

(0 .00 20-0.0026 in .)

FUEL SYSTEM

CARBURETOR. A Mikuni BV-18-15

carburetor is used. Refer to Fig. SZ2-1

for exploded view. Initial setting of pilot

air screw (15) from a lightly seated posi-

tion should be 3/.-1

1

/. turns. Final car-

buretor adjustment should be made with

engine at normal operating temperature

and running in forward gear. Adjust

throttle stop screw (12) so engine idles

at approximately 900-1000 rpm. Adjust

pil ot air screw so engine idl es smooth

and will accelerate c1eanlv without

hesitation. If necessary. readjust throt-

tle stop screw to obtain 900-1000 rpm

idl e speed.

Main fuel metering is controlled by

main jet (2). Standard main jet size for

normal operation is #90. Standard pilot

jet (14) size is #15.

(16-25 ft.-Ibs.)

To check float level. remove float bowl

(7) and invert carburetor body (1). Base

of float (6) should be 12-14 rnm (0.47-

0.55 in.) away from sealing ring surface

of carburetor body with sealing ring (3)

removed. Adjust float level by bending

float tang.

FUEL PUMP. A diaphragm fuel

pump (Fig. SZ2-2) is mounted on the

side of power head cylinder blOCk and is

actuated by pressure and vacuum pulsa-

tions from the engine crankcase.

When servicing pump. defective or

questionable parts should be renewed.

Diaphragm should be renewed if air

leaks or cracks are found. or if

deterioration is evident.

REED VALVE. The reed valve is

located in a reed plate that is located

•

Suzuki DT3.5

12

\

I~

13 .

behind the intake manifold. The intake

manifold must be removed in order to

remove reed plate and service reed

valve.

Renew reed valve (2 - Fig. SZ2·3) if

petals are broken, cracked, warped,

rusted or bent. Tip of reed petal must

not stand open more than 0.2 mm (0.008

in.) from contact surface. Reed stop

opening should be 4.8-5.2 mm (0.19-0.20

in.).

SPEED CONTROL LINKAGE.

Engine speed is regulated by position of

twist grip. As twist grip is rotated, the

carburetor's throttle valve is operated

via throttle cable. An engine kill switch

is used to stop engine operation.

3

Fig. SZ2·!-E.plod.d ., ... 01 Mlkunl BV·"·!5

carburetor.

L Body

2. ~nj('t

3. SmIing ring

4. N~le\'al\'e

5. Float pin

6. Float

7. Float bowl

8. Ga."ket

9. PIUjI;

To Carry-On

Tank

10. Cllhle lever

11 Throttle lever

12. Throttle stop SCrtW

13 . Cable adjU5ter

14. Pilot jet

15 . Pilot air sere""

16. Sprin~

Fig. SZ2·3 - VI ... sho .. /ng reed pl.,. (!~ re.d

•• 1 •• (2) .nd reed .,op (3~

17. Choke lever

To Motor

Haunted Tank

11 IT

Ie

Fig. SZ2·2-E.p/oded ., ...

of dl.phr.gm Iyp. fu.'

pump.

1. Ourq housing

2. Gasket

3. Diaphr .....

4. Valve body assy.

5. Gaskets

6. DiapIu'Kgm

7. Inner housing

8. Sealing ring

9. Adapter pl ...

10. Gasket

11 . Fuel AAllt-off valve

12. Gasket

13. Strainer

1.4. CllP

15. Disposable filter

OUTBOARD MOTOR

IGNITION SYSTEM

Breaker point gap should be set to

0.3-0.4 mm (0.012-0.016 in.) at max-

imum opening. Adjustment may be ac-

co mplished through hol es in flywheel.

Flywheel must be removed to renew

breaker points. Tighten flywheel nut to

40-50 N· m (29-36 ft.-lbs.).

After adjusting breaker points, check

ignition timing using a dial indicator

and an ohmmeter or continuitv tester.

Remove the spark plug and i~sert the

dial indicator. Set piston position at

TOC, then z ero the dial indicator.

Unplug wire at connector leading from

magneto base plate (11- F ig. SZ2-4) to

kill engine switch. Co nnect red tester

lead of ohmmeter or continuity tester to

wire co ming from magneto base plate

(11). Connect the black tester lead to an

engine ground. Rotate the flywheel

clockwise until meter or continuity

tester indicates that points have jus't

opened. Dial indicator should read 2.52

mm (0.099 in.). If ignition timing adjust-

ment is required. remove the flywheel

and loosen magneto base plate (11) re-

taining screws. Rotating base plate

clockwise retards ignition timing while

rotating counterclockwise advances ig-

nition timing.

COOLING SYSTEM

WATER PUMP, A rubber impeller

type water pump is mounted between

Fig. SZ2-4 - E.p/od.d .1 ... of m.gn.'o com·

ponents and starte, cup.

1. Nut

2. to::kwa..-.her

3. Key

4. Starter cup

S. Insulator

6. Pia ..

7. Flyw .... 1

8. Ignition coil

9. Breaker point.s

10. Condenser

11. Base pl ...

SERVICE MANUAL

Fig. SZ2·S - Explod.d .i... o( .. ,I., pump

assembly.

i: ~P housing

3. Impeil(! r dri\'e key

4. fmptl.!er-

5. Back pbt~

6. G:u;kd

7. Watxr tu b(. r.u i dt.,

R Gromm .. 'l

9. Grommet

10. Wil ler tube

the drive shaft housing and gearcase. A

key in the drive shaft is used to turn the

pump impeller. If cooling system prob·

lems are encountered, check water in·

takes for plugging or partial stoppage.

If water intakes are clear. remove gear·

case as outlined under LOWER UNIT

and check condition of the water pump,

water passages and sealing surfaces.

When water pump is disassembled,

check cond ition of impeller (4 - Fig.

SZ2·5) and plate (5) for excessive wear.

Turn drive shaft clockwise (viewed from

top) while placing pump housing ovel

impeller. A void turning drive shaft in

opposite direction when water pump is

assembled.

POWER HEAD

REMOVE AND REINSTALL. To re-

move the power head, first remove ell-

gine's top cover and shut-off fuel. Dis-

connect throttle cable, carburetor fuel

inlet line and wires which will interfere

v.ith power head removal. Remove fuel

tank and selector valve, carburetor ,

fuel pump, secondary ignition coil, re-

wind starter, starter cup , flywheel and

key and magneto components. Remove

four screws and two nuts which secure

Before installing power head, make

certain drive shaft splines are clean then

coat them with a light coating of water

resistant grease. Apply a coat of silicone

sealer to mating surfaces of power head

and drive shaft housing and install a new

gasket. Install power head on drive

shaft housing and tighten retaining cap

screws and nuts to 15·20 N'm (11-14

ft.-lbs.). The remainder of installation is

the reverse of removal procedure.

DISASSEMBLY. Disassemblv and

inspection may be accomplished "in the

following manner. Remove cylinder

head. Remove intake manifold and reed

valve assembly from crankcase. Remove

four crankcase cap screws, then sep-

arate crankcase from cylinder block.

Lift crankshaft assembly with piston

and connecting rod assembly from

cylinder block.

Engine components are now accessi-

ble for overhaul as outlined in the ap-

propriate following paragraphs. Clean

carbon from cylinder head and combus-

tion chamber 'and remove any foreign

material accumulation in water pas-

sages. Inspect components for damage

and renew if needed. Referto the follow-

ing section for assembly procedure.

ASSEMBL Y. Refer to specific serv-

ice sections when assembling the crank-

shaft, connecting rod, piston and reed

valve. Make sure all joint and gasket

surfaces are clean and free from nicks

and burrs. Make sure all carbon, salt,

dirt and sand are cleaned from the com-

bustion chamber, exhaust port and

water passages.

Lubricate c rankpin bearing and

cylinder wall of cy linder block with

Suzuki "CCI" oil or a suitable BIA cer-

tified two-stroke engine oil. Install

crankshaft assembly in crankcase. Make

sure thrust ring (1- Fig. SZ2-7) fits

properly in crankcase groove. Spread a

coat of Suzuki Bond No.4 or a suitable

power head assembly to drive shaft Fig. SZZ-$- Vlo ... ho .. /ngl/ghr,n/ng .oqulnco

housing and lift off power head. o( (au' c,onkc .. o sc, .....

Suzuki DT3.5

Fig. SZ2·7 - Erplod.d .10" o( pis ron Ind

crankshaft assembly.

1. Thrust rin£

2. Ball bearing

3. Crank half'

4. CraN< pin

5, Roller bearing

6. O:mneeti,,~ rod

1. Crank half

8. Ball bearin~

9. ScaI

10. Seal

11. Rctamt'r

12. Piston pin

13. Piston rings

14. ?Uton

15. Roller karing

16. Seal

equivalent on the mating surfaces of the

crankcase and the cylinder block. Posi-

tion crankcase half on cylinder block and

tigh ten the four crankcase screws to

8-12 N'm (6-8 ft.-Ibs.) in the sequence

shown in Fig. SZ2 - 6.

PISTON, PIN. RINGS AND CYLIN·

DER. The piston is fitted with two

piston rings. Piston ring end gap should

be 0.15-0.35 mm (0.006-0.014 in.) with a

maximum allowable ring end gap of 0. 70

mm (0.028 in.). Piston rings are retained

in position by locating pins. I nstall mark-

ed side of piston ring toward top of

piston. Piston to cylinder wall clear-

ance should be 0.052-0.067 mm (0 .002(}'

0.0026 in.). Piston and rings are avail-

able in standard size as well as 0.25

mm (0.010 in.) and 0.50 mm (0.020 in.)

oversizes. Cylinder should be bored to

an oversize if cylinder is out-of-round or

taper exceeds 0.10 mm (0 .004 in.). In-

stall piston on connecting rod- so arrow

Fig. SZZ.f- Mo •• conn.cr/ng nod sml/l.nd s/do

ro side and me. sur. with I' dill Indlc.tor IS

shown to det.rmlne connecting rod, be. ring and

crank pin we.r. A.f., to t.a,.

Suzuki DT3.5

on piston crown points toward drive

shaft end of crankshaft.

CONNECTING ROD, BEARINGS

AND CRANKSHAFT. Connecting rod,

bearings and crankshaft are a press

together unit. Crankshaft should be

disassembled ONLY by experienced

service personnel and with suitable servo

ice equipment.

Cage roller bearings are used at both

large and small ends of connecting rod.

De termine rod bearing wear from side

to side as shown in Fig. SZ2·8. Normal

side to side movement is 3.0 mm (0 . 12

in.) or less. Maximum limit of crankshaft

runou t is 0.03 mm (0.0012 in.) measured

at bearing surfaces with crankshaft ends

supported.

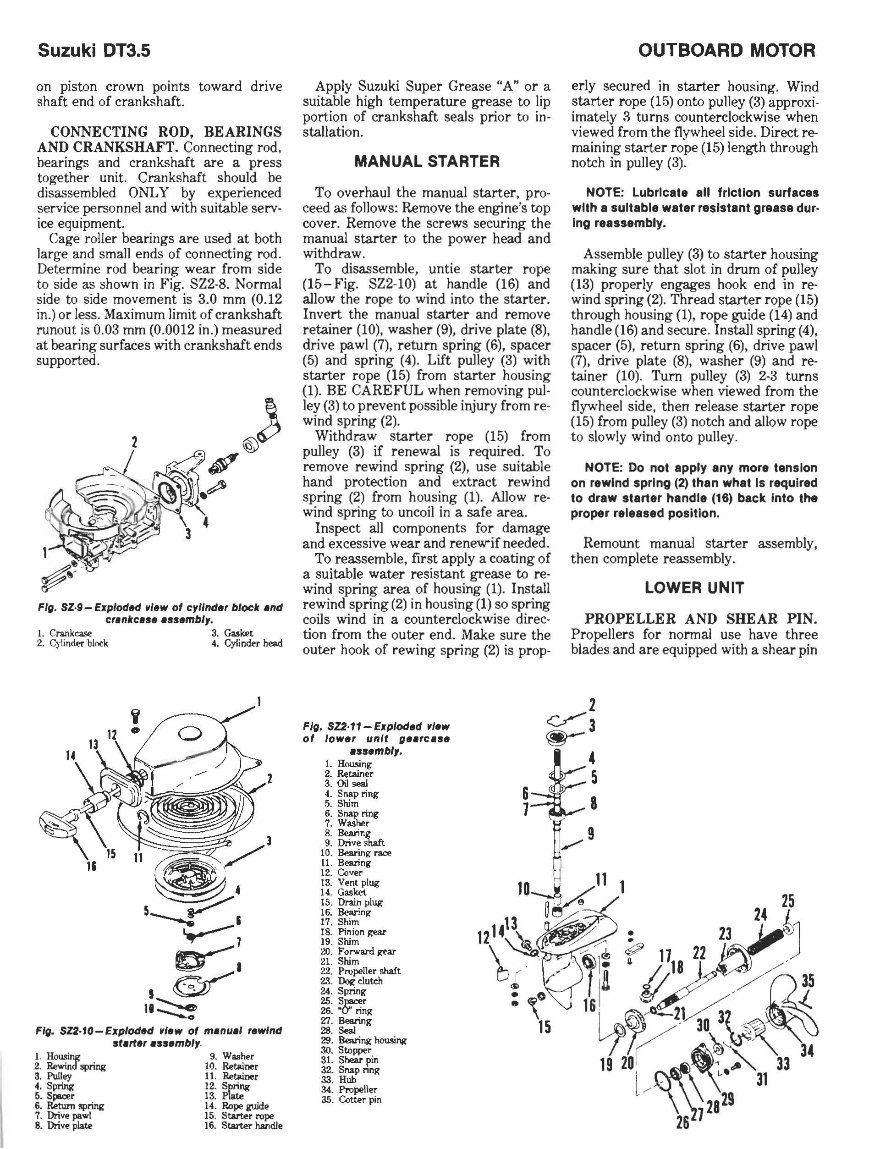

Fig. sz·g - Exploded .Iew of cylinder block end

cr.nlrc.se .s58mbl,.

I. Crankca..c:.e 3. Gasket

2. Cylinder block 4. Cylinder head

Fig. SZ2·10-Exploded .Iew of menuel rewind

st."e, .ss8mbl,_

1. HOIl.<Mg

2. Rewind spring

3. Pulley

~. Spring

6. Spo<:<r

6. Return "Pring

7. Drive pawl

8. Drive plate

9. Washer

10. Retainer

11 . Retainer

12. Spring

13. PIa ..

14. Rope guide

15. Starter rope

16. Stalter handle

Apply Suzuki Super Grease "A" or a

suitable high temperature grease to lip

portion of crankshaft seals prior to in·

stallation.

MANUAL STARTER

To overhaul the manual starter, pro·

ceed as follows: Remove the engine's top

cover. Remove the screws securing the

manual starter to the power head and

withdraw.

To disassemble, untie starter r ope

(15-Fig. SZ2·10) at handle (16) and

allow the rope to wind into the starter.

Invert the manual starter and remove

retainer (10), washer (9), drive plate (8) ,

drive pawl (7) , return spring (6), spacer

(5) and spring (4). Lift pulley (3) with

starter rope (15) from starter housing

(1). BE CAREFUL when removing pul ·

ley (3) to prevent possible injury from reo

wind spring (2).

Withdraw starter rope (15) from

pulley (3) if renewal is required. To

remove rewind spring (2), use suitable

hand protection and extract rewind

spring (2) from housing (1). Allow reo

wind spring to uncoil in a safe area.

Inspect all components for damage

and excessive wear and renew-if needed.

To reassemble, fIrst apply a coating of

a suitable water resistant grease to reo

wind spring area of housing (1). Install

rewind spring (2) in housing (1) so spring

coils wind in a counterclockwise direc-

tion from the outer end. Make sure the

outer hook of rewing spring (2) is prop-

Fig. SZ2·11- Exploded .Iew

of lower unit g •• re.a •

• ss8mbl,.

L HOW!.ing

2. IWtainer

3. Oil seal

4. Snap ring

5. Shim

6. Snap ring

7. Washer

8. IleJuing

9. Drive shaft

10. Bearing race

11. Bearing

12. O:lver

13. Vent plug

14. Gasket

15. Drain plug

16. Bearing

17. Shim

18. Pinion gear

19. Shim

20. Forward gear

21. Shim

22. Propeller shaft

23. Dot< clutch

24. Spring

25. Spacer

26. "0" ring

'1:1. Bearing

28. Seal

29. Bearing hou.~ng

30. Stopper

31. Shear pin

32. Snap nng

33. Huh

34. Propeller

35. Cotter pin

OUTBOARD MOTOR

erly secured in starter housing. Wind

starter rope (15) onto pulley (3) approxi-

imately 3 turns counterclockwise when

viewed from the flywheel side. Direct re-

maining starter rope (15) length through

notch in pulley (3).

NOTE: Lubricate all friction surfaces

with a suitable water resistant grease duro

Ing reassembly.

Assemble pulley (3) to starter housing

making sure that slot in drum of pulley

(13) properly engages hook end in re-

wind spring (2). Thread starter rope (15)

through housing (1), rope guide (14) and

handle (16) and secure. Install spring (4),

spacer (5) , return spring (6) , drive pawl

(7), drive plate (8) , washer (9) and re-

tainer (10). Turn pulley (3) 2-3 turns

counterclockwise when viewed from the

flywheel side, then release starter rope

(15) from pulley (3) notch and allow rope

to slowly wind onto pulley.

NOTE: Do not apply any more tension

on rewind spring (2) than what Is required

to draw starter handle (16) back into the

proper released position.

Remount manual starter assembly,

then complete reassembly.

LOWER UNIT

PROPELLER AND SHEAR PIN.

Propellers for normal use have three

blades and are equipped with a shear pin

SERVICE MANUAL

to prevent damage. Standard propeller

has a 190 mm (7

'

;' in .) diameter and a

150 mm (5

7

/0 in.) pitch. Optional pro-

pellers are available from the manufac-

turer and should be selected to provide

full throttle operation within the recom-

mended limits of 4800-5300 rpm.

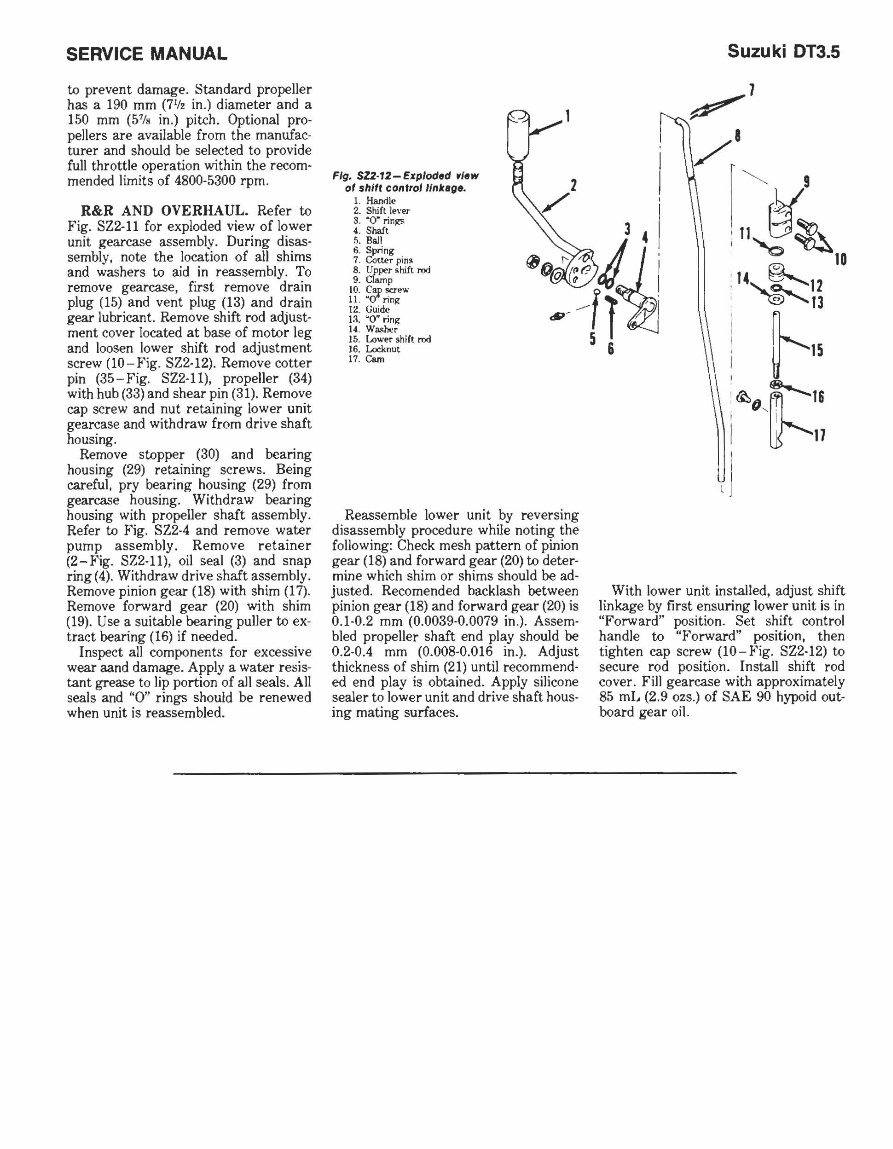

R&R AND OVERHAUL_ Refer to

Fig. 822-11 for exploded view of lower

unit gearcase assembly. During disas-

sembly, note the location of all shims

and ';ashers to aid in reassembly. To

remove gearcase, first remove drain

plug (15) and vent plug (13) and drain

gear lubricant. Remove shift rod adjust-

ment cover located at base of motor leg

and loosen lower shift rod adjustment

screw (10 - Fig. 822-12). Remove cotter

pin (35 - Fig. 822-11), propeller (34)

with hub (33) and shear pin (31). Remove

cap screw and nut retaining lower unit

gearcase and withdraw from drive shaft

housing.

Remove stopper (30) and bearing

hou sing (29) retaining screws. Being

careful, pry bearing housing (29) from

gearcase housing. Withdraw bearing

housing with propeller shaft assembly .

Refer to Fig. 822-4 and remove water

pump assembly. Remove retainer

(2-Fig. 822-11), oil seal (3) and snap

ring (4). Withdraw drive shaft assembly.

Remove pinion gear (18) with shim (17).

Remove forward gear (20) with shim

(19). Use a suitable bearing puller to ex-

tract bearing (16) if needed.

Inspect all components for excessive

wear aand damage. Apply a water resis-

tant grease to lip portion of all seals. All

seals and "0" rings should be renewed

when unit is reassembled.

Fig. SZ2·12-Exp/odod r/ow

01 shift conlrolllnkapo.

1. H.a.Mle

2. Shift lever

3. ·0" ri n g!'>

4. Shaft

5. Ball

6. Spring

7. Cotter pin~

8. Upper li hift rod

9. Clamp

10. C5' ~e"'"

11. "0 nn~

12. Guide

13. "0" rin~

14 . WMhcr

15. Lo ..... er shift rod

16. Loclmut

17. Com

Reassemble lower unit by reversing

disassembly procedure while noting the

following: Check mesh pattern of pinion

gear (18) and forward gear (20) to deter-

mine which shim or shims should be ad-

justed. Recomended backlash between

pinion gear (18) and forward gear (20) is

0.1-0.2 mm (0.0039-0.0079 in.). Assem-

bled propeller shaft end play should be

0.2-0.4 mm (0.008-0.016 in.). Adjust

thickness of shim (21) until recommend-

ed end play is obtained. Apply silicone

sealer to lower unit and drive shaft hous-

ing mating surfaces.

Suzuki DT3.5

With lower unit installed, adjust shift

linkage by first ensuring lower unit is in

"Forward" position. 8et shift control

handle to "Forward" position, then

tighten cap screw (lO-Fig. 822-12) to

secure rod position. Install shift rod

cover. Fill gearcase with approximately

85 mL (2 .9 ozs.) of 8AE 90 hypoid out-

board gear oil.

Suzuki DT4 OUTBOARD MOTOR

SUZUKI DT4

CONDENSED SERVICE DATA

NOTE: Metric fasteners are used throughout outboard motor.

TUNE-UP

Hplrpm ...................... . ............... 4/5000

Bore .......... .. ............................ 50mm

(1.97 in.)

Stroke . . .................. . ................. 46 mm

(1.81 in.)

Displacement .......... .. .. . .. ........ .. . .... .. 90 cc

(5.5 cu. in.)

Spark Plug:

NGK ...... .. ...... .. ..... .... . ........... BP6HS

Electrode Gap .... . ......... ... .......... 0.6-0 .7 mm

(0.024-0.028 in.)

Ignition Type .. .. .. ... ......... .. ......... .. .. .. CD!

Carburetor:

Make .................. .. ..... . ... ......... Mikuni

Model ................................... BV-18-15

Idle Speed (in gear) ... .. _. . _. . . .... ..... . . 850-900 rpm

Fuel:Oil Ratio ..... .. . . See Text

SIZES-CLEARANCES

Piston Ring End Gap .. . ........... . ...... 0.15-0.35 mm

(0.006-0_014 in.)

Piston to Cylinder Clearance ............ 0_052-0_067 mm

(0.0020-0.0026 in_)

Piston Pin Diameter ..... __ .. _. _ ..... 11.995-12.000 mm

(0.4 722-0.4 724 in.)

SIZES-CLEARANCES CONT.

Max. Crankshaft Runout at Main

Bearing Journal .................. . _____ ... 0_05 mm

(0.002 in.)

Max . Connecting Rod Small End

Side Shake ...... .... . .......... .. .. ...... __ 4.0 mm

(0.16 in.)

TIGHTENING TORQUES

Power Head Mounting Screws ... .. . .. ....... 15-20 N· m

(11-14 ft.-Ibs_)

Crankcase ... .. .. .. . . _. __ ... __ .. ...... . __ .. 8-12 N • m

(6-8 ft.-Ibs_)

Flywheel Nut . .. . .... .. .. ... _. _ ........ . .. .. . 45 N'm

(32 ft.-lbs.)

Standard Screws:

5 mm ............ .. . . . , .. . .... ........... 2-4 N' m

(1-3 ft.-Ibs .)

6mm .............................. , ..... 4-7N·m

(3-5 ft.-Ibs.)

8mm .................................. 1O-16N·m

(7-11 ft .-I bs.)

10mm ........... ... . ... ..... . ......... 22-35N·m

(16-25 ft.-Ibs.)

LUBRICATION

The power head is lubricated by oil

mixed with the fuel. Fuel:oil ratios

should be 30: 1 during break-in of a new

or rebuilt engine. For normal service,

fuel:oil ratio should be 50: 1 on models

prior to 1986 and 100: 1 on 1986 and

later models when using Suzuki Out-

board Motor Oil or a good quality NMMA

certified TC- W engine oil. When using

any other two-stroke oil, fuel:oil ratio

should be 20: 1 during break-in and 30: 1

for normal service. Manufacturer

recommends regular or unleaded au-

tomotive gasoline having an 85 mini-

mum octane rating. Gasoline and oil

should be thoroughly mixed.

turns out from a lightly seated position.

Final atljustment should be made with

engine at normal operating temperature

and running in forward gear. Atljust

throttle stop screw (9) so engine idles at

approximately 850-900 rpm. Atljust pi-

lot air screw so engine idles smoothly

and will accelerate cleanly without hesi-

tation. If necessary, readjust throttle

stop screw to obtain 850-900 rpm idle

·s peed.

Main fuel metering is controlled by

main jet (2). Standard main jet size for

normal operation is #97.5. Standard pi-

lot jet (10) size is #45.

To check float leve l. remove float

bowl (12) and invert carburetor body

(1) . Base of float (3) should be 12-14 mm

(0.47 -0.55 in.) away from gasket surface

of carburetor body with float bowl gas-

ket removed. Atljust fl oat level by bend-

ing float tang.

The lower unit gears and bearings are

lubricated by approximately 190 mL

(6.4 ozs.) of SAE 90 hypoid outboard

gear oil. Reinstall vent and fill plugs se-

curely using a new gasket, if necessary,

to ensure a water tight seal.

FUEL SYSTEM

CARBURETOR. A Mikuni BV-18-15

carburetor is used. Refer to Fig. SZ3-1

for exploded view. Initial setting of pi-

lot air screw (6) should be 1 to 1-112

10

B 7 6 9 I 11

~~~

1 _

'--8-<

5--:'0"

Fig. SZ3·1- Exploded vi ... 01 ""tunl 8'1-18-15

c.rbur.fOr.

1. Bods

2. Main jet

3. Float

4. Screw

.5. Plug

6. Pilot air screw

7. Choke le ... ("t

8. Choke k.nob

9. Idle ~xre\lll

10. Pl/ot)et

11. <4skl't

12. Float bowl

FUEL PUMP. A diaphragm fuel

pump (Fig_ SZ3-2) is mounted on the

side of power head cylinder block and is

actuated by pressure and vacuum pulsa-

tions from the engine crankcase.

When servicing pump, defective or

questionable parts should be renewed.

Diaphragm should be renewed if air

leaks or cracks are found, or if

deterioration is evident.

SPEED CONTROL LINKAGE.

Engine speed is controlled by position of

throttle linkage. Ignition advance is

electronically controlled. A twist grip at

the steering handle is used to control

throttle settings.

•

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 45 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

The Suzuki 2-15HP outboard motors Service Repair Manual is a comprehensive informational book designed to assist both professional mechanics and DIY enthusiasts. It contains easy-to-read text sections accompanied by high-quality diagrams and instructions, making it an invaluable resource for anyone undertaking repair or maintenance tasks.

Models Covered:

- Suzuki DT2

- Suzuki DT3.5

- Suzuki DT4

- Suzuki DT5, DT6 and DT8

- Suzuki DT9.9 and DT15 (1983 1984 1985 1986 1987) and DT15C (1988)

Service Repair Manual Covers:

- Lubrication

- Fuel System

- Ignition System

- Cooling System

- Power Head

- Manual Starter

- Lower Unit

The manual is available in PDF format, compatible with all versions of Windows and Mac. It is presented in English and requires Adobe Reader for access. This manual is an essential investment for anyone looking to save time and money by performing repairs and maintenance on their Suzuki 2-15HP outboard motors with confidence and precision.