2012-2013 Suzuki DF15A/DF20A 4-Stroke Outboards Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

00

0

1

2

3

4

5

6

7

8

9

10

11

12

Precautions............................................................... 00-i

Precautions ............................................................ 00-1

General Information ................................................... 0-i

General Information ............................................... 0A-1

Maintenance and Tune-Up..................................... 0B-1

Power Head................................................................. 1-i

Precautions .............................................................. 1-1

Engine Control ....................................................... 1A-1

Engine Electrical Devices....................................... 1C-1

Power Unit Mechanical .......................................... 1D-1

Power Unit Lubrication ........................................... 1E-1

Power Unit Cooling System ................................... 1F-1

Fuel System ...........................................................1G-1

Ignition System....................................................... 1H-1

Starting System....................................................... 1I-1

Manual Starting System ..........................................1J-1

Charging System.................................................... 1K-1

Mid Unit ....................................................................... 2-i

Precautions .............................................................. 2-1

Housing and Bracket .............................................. 2A-1

Lower Unit ................................................................... 3-i

Precautions .............................................................. 3-1

Right Hand Rotation Unit ....................................... 3A-1

Wire / Hose Routing ................................................... 4-i

Precautions .............................................................. 4-1

Wire Routing .......................................................... 4A-1

Fuel / Water Hose Routing ..................................... 4B-1

TABLE OF CONTENTS

Table of Contents 00- i

00

Section 00

CONTENTS

Precautions

Precautions ............................................... 00-1

Precautions........................................................... 00-1

General Precautions ........................................... 00-1

00-1 Precautions:

Precautions

Precautions

Precautions

General Precautions

CENDK1110000001

The WARNING, CAUTION and NOTICE messages below describe some general precautions that you should observe

when servicing the outboard motor. These general precautions apply to many of the service procedures, but they will

not necessarily be repeated for every procedure to which they apply.

WARNING !

Failure to take proper precautions when servicing the outboard motor can cause severe personal

injury.

• To avoid eye injury, always wear protective glasses when filing metals, working on a grinder, or

doing other work, which could cause debris.

• When two or more persons work together, pay attention to the safety of each other.

• When it is necessary to run the outboard motor indoors, make sure that exhaust gas is vented

outdoors.

• When testing an outboard motor in the water, ensure that the necessary safety equipment is on

board.

Such equipment includes: flotation aids for each person, fire extinguisher, distress signals, anchor,

paddles, bilge pump, first aid kit, emergency starter rope, etc.

• Whenever handling toxic or flammable materials, wear safety glasses to protect your eyes. Any

toxic or flammable materials getting into your eye may cause inflammation. Also wear moisture-

proof gloves to protect your skin.

• Do not swallow any toxic or flammable materials. Swallowing them could cause diarrhea, nausea or

other health problems. Be especially careful not to allow children and pets to swallow these

materials.

• Keep all toxic or flammable materials out of reach of children and pets.

• When working with toxic or flammable materials, make sure that the area you work in is well

ventilated and that you follow all of the material manufacturer’s instructions.

• Never use gasoline as a cleaning solvent.

• To avoid getting burned, do not touch the engine, engine oil or exhaust system during or shortly

after engine operation.

• Avoid contact with new and used oil. Prolonged contact with used oil has been shown to cause skin

cancer in laboratory animals. Brief contact with used oil may irritate the skin. Keep new and used oil

away from children and pets. To minimize your exposure to oil, wear a long sleeve shirt and

moisture - proof gloves (such as latex gloves) when changing oil. If oil contacts your skin, wash

thoroughly with soap and water. Launder any clothing or rags if wet with oil. Recycle or properly

dispose of used oil.

• Never disconnect any of the fuel lines between the fuel pump and injectors without first releasing

the fuel pressure, or fuel can be sprayed out under pressure.

• After servicing the fuel, lubrication, cooling and/or the exhaust system, check all lines and fittings

related to the system for leaks.

• Carefully adhere to the battery handling instructions laid out by the battery supplier.

Precautions: 00-2

NOTICE

Failure to take proper precautions when servicing the outboard motor can cause damage to the parts

or the outboard motor.

To prevent the parts or the outboard motor from damage, be sure to take the following precautions:

• When removing parts that are to be reused, keep them arranged in an orderly manner so that they

may be reinstalled in the proper order and orientation.

• Be sure to use special tools where instructed.

• Make sure that all parts used in assembly are clean and also lubricated when specified.

• When use of a certain type of lubricant, bond, or sealant is specified, be sure to use the specified

type.

• When removing the battery, disconnect the negative cable first and then the positive cable. When

reconnecting the battery, connect the positive cable first and then the negative cable.

• When performing service to electrical parts, if the service procedures do not require using battery

power, disconnect the negative cable at the battery.

• Do not expose connectors and electrical parts to water, which will cause electrical systems

problems.

• Always be careful not to drop electrical components (ECM, relays, etc.) or handle them in a rough

manner.

• Whenever you remove oil seals, gaskets, packing, O-rings, locking washers, locking nuts, cotter

pins, circlips, and certain other parts as specified, always replace them with new ones. Also, before

installing these new parts, be sure to remove any left over material from the mating surfaces.

• Never reuse a circlip. When installing a new circlip, take care not to expand the end gap larger than

required to slip the circlip over the shaft. After installing a circlip, always ensure that it is completely

seated in its groove and securely fitted.

• Use a torque wrench to tighten fasteners to the torque values when specified.

• Remove grease or oil from screw / bolt threads unless a lubricant is specified.

• After assembly, check parts for tightness and proper operation.

NOTE

• To protect the environment, do not unlawfully dispose of used motor oil, other fluids or batteries.

• To protect the Earth's natural resources, properly dispose of used motor parts.

Replacement Parts

NOTICE

Use of replacement parts which are not equivalent in quality to genuine SUZUKI parts can lead to

performance problems and damage.

Use only genuine SUZUKI replacement parts or their equivalent. Genuine SUZUKI parts are high

quality parts which are designed and built specially for SUZUKI outboard motors.

If parts replacement is necessary, Suzuki strongly recommends that you use genuine Suzuki parts or their equivalent.

They are precision-made to ensure high quality and correct fit.

00-3 Precautions:

Table of Contents 0- i

0

Section 0

CONTENTS

General Information

General Information ................................ 0A-1

General Description ............................................. 0A-1

Symbols .............................................................. 0A-1

Abbreviations ...................................................... 0A-1

Wire Color Symbols ............................................ 0A-2

Warning, Caution and Information Label

Locations........................................................... 0A-2

Outboard Motor Identification Number

Location ............................................................ 0A-4

Fuel and Oil Recommendations .......................... 0A-4

Break-In Procedures ........................................... 0A-5

Propeller Selection Guide ................................... 0A-5

Battery Requirement ........................................... 0A-6

Specifications ....................................................... 0A-7

Specifications ...................................................... 0A-7

Service Data ....................................................... 0A-9

Tightening Torque Specifications ...................... 0A-16

Special Tools and Equipment ........................... 0A-17

Recommended Service Material ....................... 0A-17

Special Tool ...................................................... 0A-18

Maintenance and Tune-Up ...................... 0B-1

Precautions........................................................... 0B-1

Precautions for Maintenance .............................. 0B-1

General Description ............................................. 0B-1

Recommended Oil and Lubricants ...................... 0B-1

Scheduled Maintenance ...................................... 0B-1

Periodic Maintenance Schedule Chart ................ 0B-1

Lubrication Point ................................................. 0B-2

Service Instructions ............................................. 0B-3

Engine Oil Level Check ....................................... 0B-3

Engine Oil Change and Engine Oil Filter

Replacement ..................................................... 0B-3

Gear Oil Change ................................................. 0B-6

Spark Plug Removal and Installation .................. 0B-7

Spark Plug Inspection and Cleaning ................... 0B-7

Valve Clearance Inspection and Adjustment ...... 0B-8

Timing Belt Inspection ....................................... 0B-10

Timing Belt Replacement .................................. 0B-10

Idle Speed and Idle Air Control (IAC) Duty

Inspection ........................................................ 0B-14

Ignition Timing Inspection ................................. 0B-16

Breather Line and Fuel Line Inspection ............ 0B-17

Low Pressure Fuel Filter Inspection .................. 0B-17

Water Pump and Water Pump Impeller

Inspection ........................................................ 0B-18

Propeller / Propeller Nut and Cotter Pin

Inspection ........................................................ 0B-18

Anodes Inspection............................................. 0B-19

Battery Inspection ............................................. 0B-20

Bolts and Nuts Inspection ................................. 0B-21

Oil Pressure Check ........................................... 0B-21

Cylinder Compression Pressure Check ............ 0B-22

0A-1 General Information:

General Information

General Information

General Description

Symbols

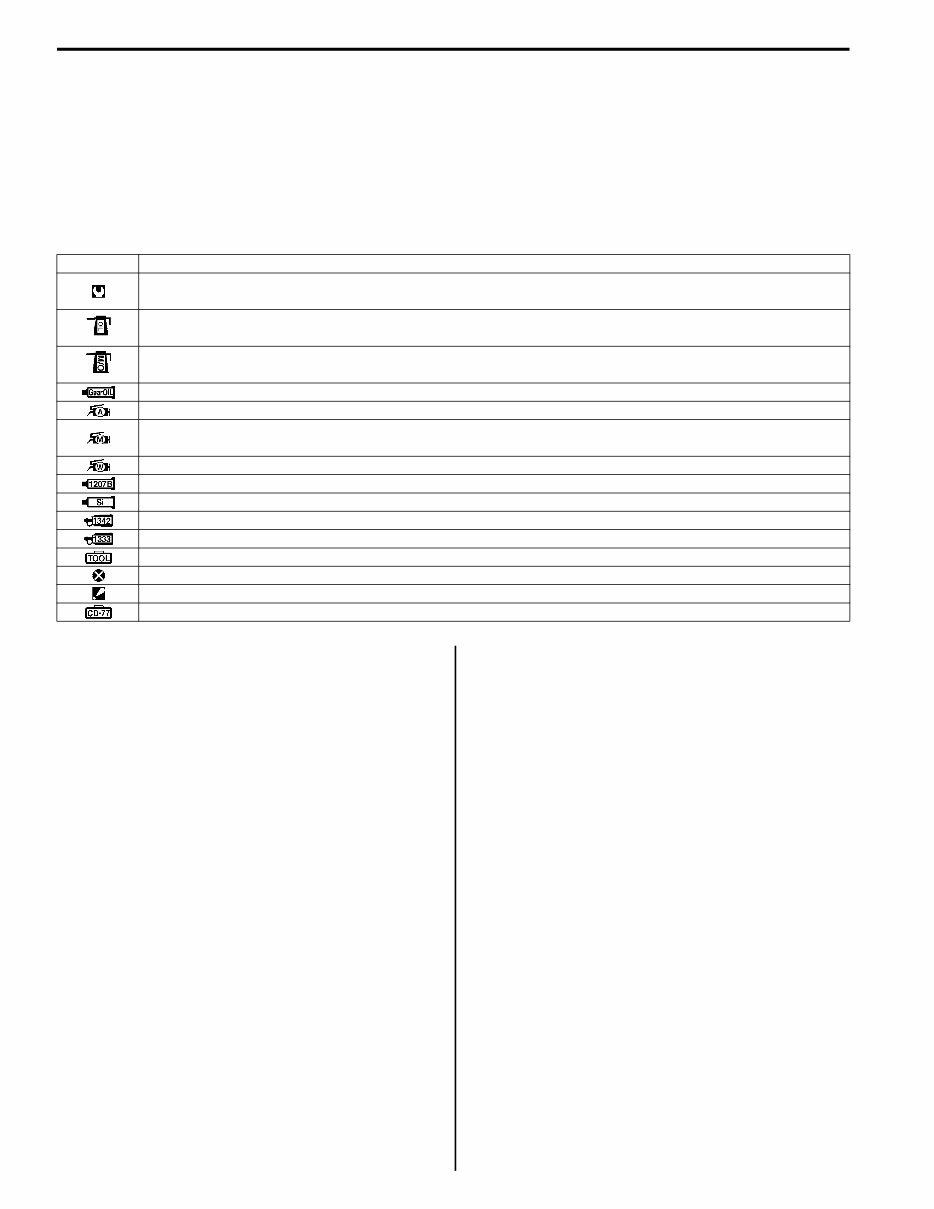

CENDK1110101001

Listed in the table below are the symbols indicating instructions and other important information necessary for proper

servicing.

Please note the definition for each symbol. You will find these symbols used throughout this manual.

Refer back to this table if you are not sure of any symbol (s) meanings.

Abbreviations

CENDK1110101002

Abbreviations used in this service manual are as follows:

A:

ATDC: After Top Dead Center

AC: Alternating Current

B:

BTDC: Before Top Dead Center

C:

CKP Sensor: Crankshaft Position sensor

CMP Sensor: Camshaft Position sensor

CTP: Close Throttle Position

D:

DC: Direct Current

DOHC: Double Over Head Camshaft

E:

ECM: Engine Control Module

EX (Ex.): Exhaust

F:

FP: Fuel Pump

G:

GND: Ground

I:

IAC: Idle Air Control

IAT: Intake Air Temperature

IG: Ignition

Ign.: Ignition

IN (In.): Intake

L:

LPS: Lever Position Sensor

M:

MAP: Manifold Absolute Pressure

P:

PCV: Positive Crankcase Ventilation

PORT: Port

PTT: Power Trim and Tilt

S:

SPS: Shift Position Sensor

STBD: Starboard

SIGP: Start-In-Gear Protection

T:

TPS: Throttle Position Sensor

Symbol Definition

Torque control required.

Data beside it indicates specified torque.

Apply oil.

Use engine oil unless otherwise specified.

Apply molybdenum oil solution.

(Mixture of engine oil and SUZUKl MOLY PASTE in a ratio of 1 : 1)

Apply SUZUKI Outboard Motor Gear Oil.

Apply SUZUKI Super Grease A.

Apply SUZUKI Moly Paste.

99000-25140

Apply SUZUKI Water Resistant Grease.

Apply SUZUKI Bond 1207B.

Apply SUZUKI Silicone Seal.

Apply SUZUKI Thread Lock 1342.

Apply SUZUKI Thread Lock Super 1333B.

Use special tool.

Do not reuse.

Note on reassembly.

Use peak voltmeter Stevens CD-77.

General Information: 0A-2

Wire Color Symbols

CENDK1110101003

There are two kinds of colored wire used in this product.

One is single colored wire and the other is dual colored (striped) wire.

The single colored wire uses only one color symbol. example: B (Black).

The dual colored wire uses two color symbols. example: Bl/B.

The first symbol represents the base color of the wire and the second symbol represents the color of the stripe.

Example: Bl/B (Blue with Black stripe).

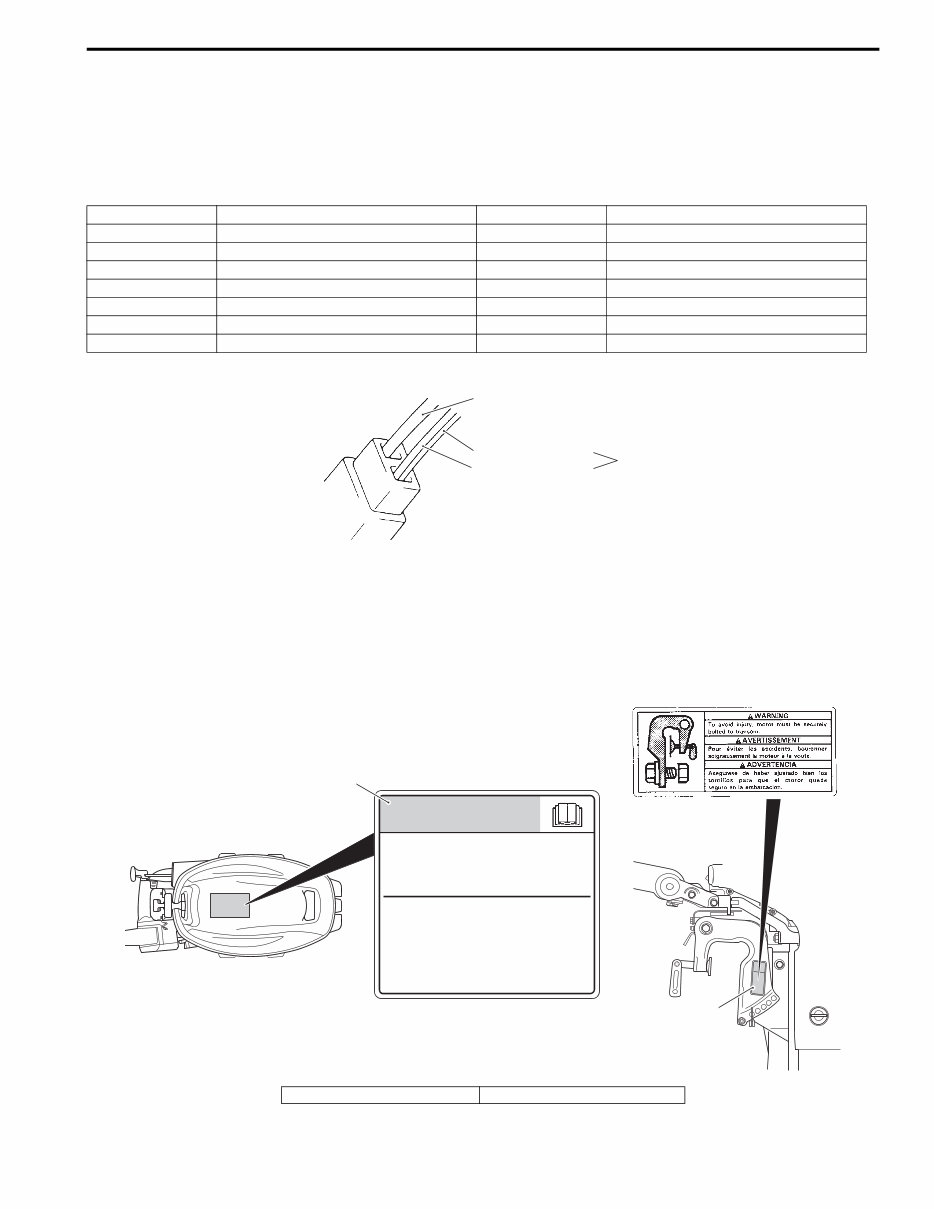

Warning, Caution and Information Label Locations

CENDK1110101004

The figure shows main labels among others that are attached to outboard motor.

When servicing outboard motor, refer to WARNING / CAUTION instructions printed on labels.

If any WARNING / CAUTION label is found stained or damage, clean or replace it as necessary.

Do not reuse a label after it has been removed. Always use new label.

Symbol Wire color Symbol Wire color

B Black Lg Light green

Bl Blue O Orange

Br Brown P Pink

Dg Dark green R Red

G Green V Violet

Gr Gray W White

Lbl Light blue Y Yellow

B (Base Color)

Bl (Blue Color)

Bl/B

Black (Stripe Color)

IAJ311010009-01

2

WARNING

AVERTISSEMENT

• Fuel can leak creating a fire hazard if

you lay motor on its side. Drain fuel

completely from vapor separator or

carburetor before laying motor on its side.

• See owner’s manual for details.

• Le carburant risque de fuir et de

présenter un danger d’incendie si le

moteur est placé sur le côté.

Vidanger entièrement le carburant du

séparateur de vapeurs ou du

carburateur avant de procéder.

• Pour plus de détail, voir le manuel

du propriétaire.

1

IDK111010005-01

1. Label, engine cover 2. Label, clamp bracket

0A-3 General Information:

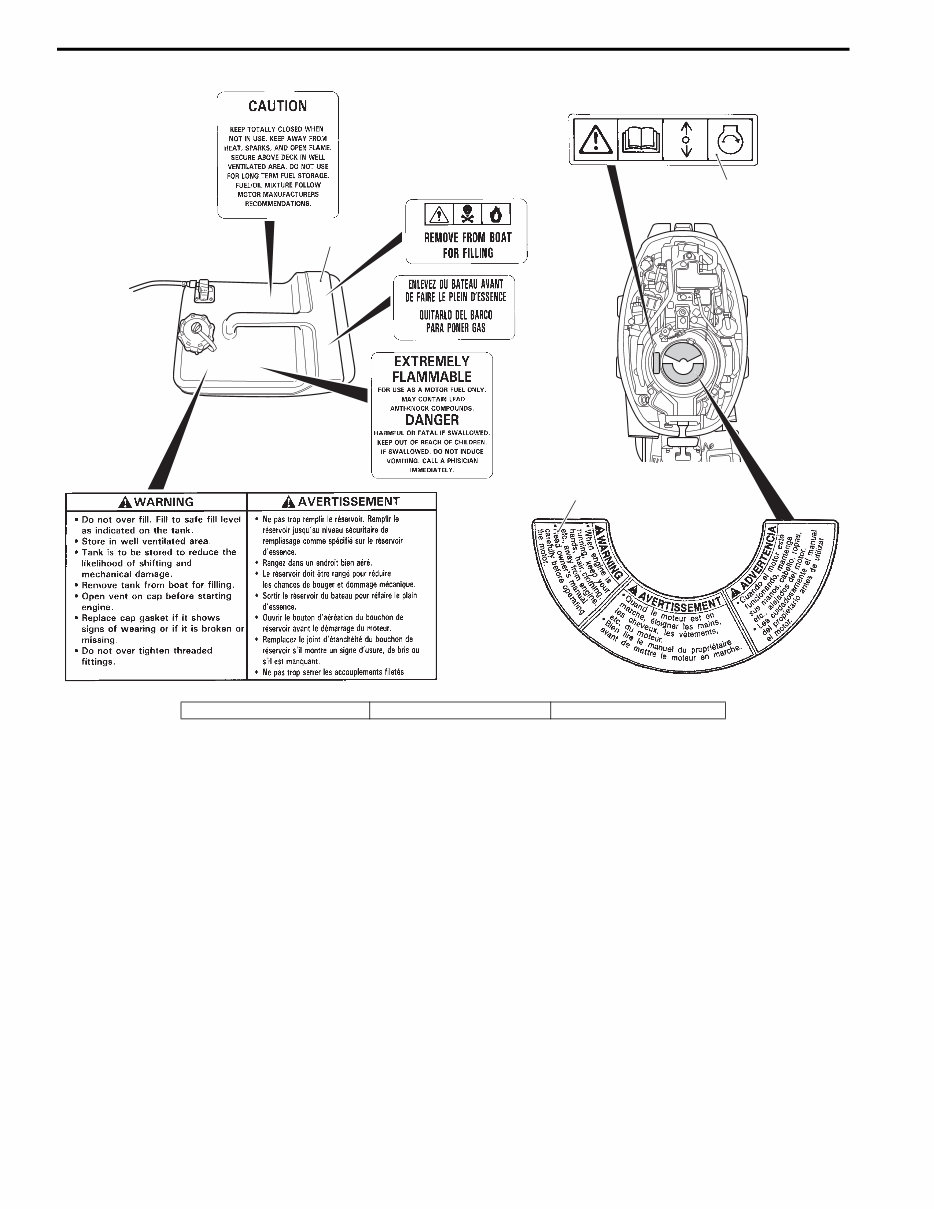

4

5

3

IDK111010006-01

3. Label, mag cover 4. Label, S.I.G.P 5. Fuel tank

General Information: 0A-4

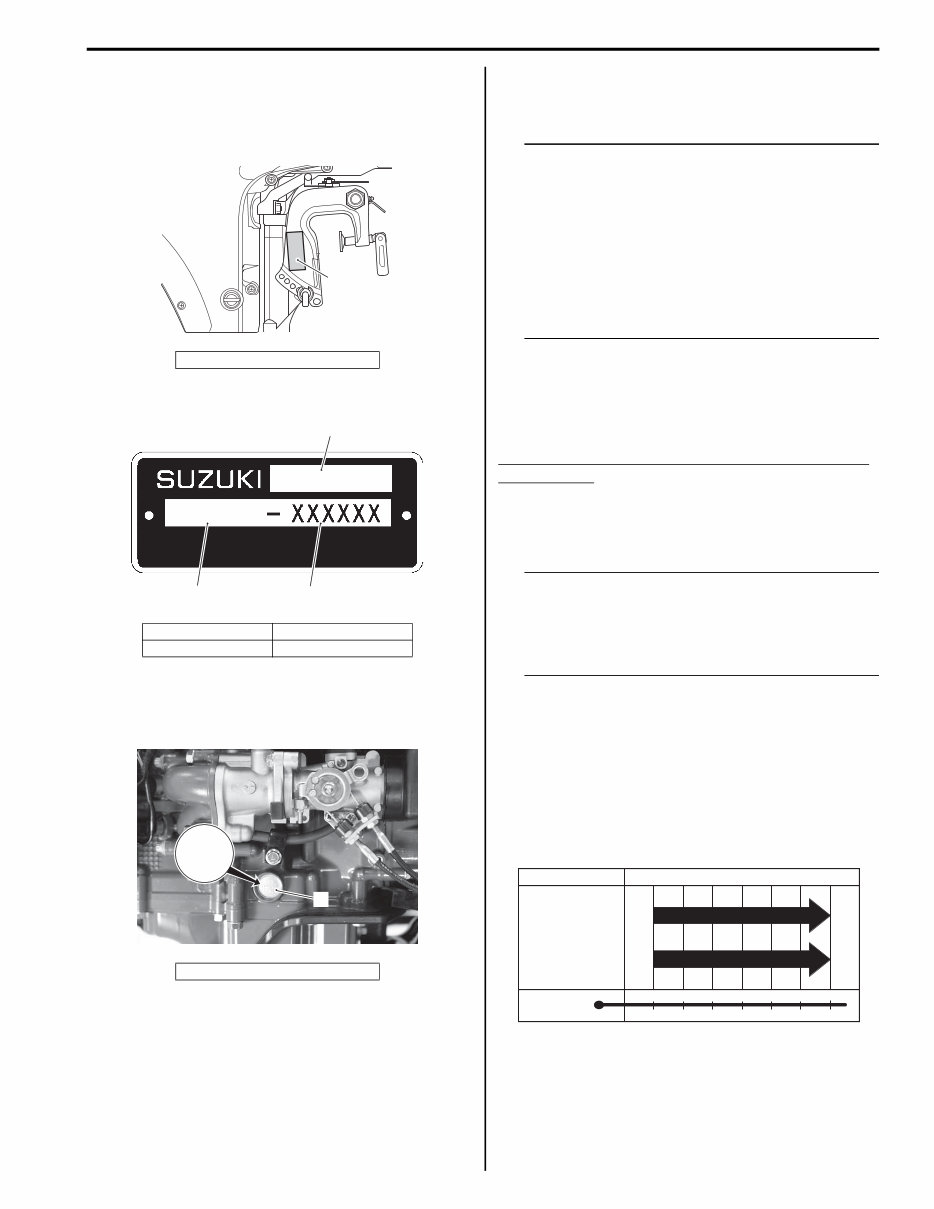

Outboard Motor Identification Number Location

CENDK1110101006

Model, Pre-fix, Serial Number

The Model, Pre-fix and Serial number of motor are

stamped on a plate attached to the clamp bracket.

Example

Engine Serial Number Location

A second engine serial number plate is pressed into a

boss on the cylinder block.

Fuel and Oil Recommendations

CENDK1110101007

Gasoline

NOTICE

Use of leaded gasoline can cause engine

damage.

Use of improper or poor quality fuel can

affect performance and may damage the

motor and fuel system.

Use only unleaded gasoline. Do not use fuel

having lower than the recommended octane,

or fuel that may be stale or contaminated by

dirt/water etc.

Suzuki highly recommends that you use alcohol-free

unleaded gasoline with a minimum pump octane rating

of 87 (R/2+M/2 method) or 91 (Research method).

However, blends of unleaded gasoline and alcohol with

equivalent octane content may be used.

Allowable maximum blend of a single additive (not

combination)

5% Methanol, 10% Ethanol, 15% MTBE

Engine Oil

NOTICE

Use of a poor quality engine oil can adversely

affect engine performance and life.

Suzuki recommends that you use Suzuki

Marine 4-Cycle Engine Oil or its equivalent.

Oil quality is a major contributor to your engine’s

performance and life. Always select good quality engine

oil.

Suzuki recommends the use of SAE 10W-40 SUZUKI

MARINE 4-CYCLE ENGINE OIL.

If SUZUKI MARINE 4-CYCLE ENGINE OIL is not

available, select a NMMA certified FC-W oil or good

quality 4-cycle motor oil from the following chart

according to the average temperatures in your area.

Gear Oil

Suzuki recommends the use of SUZUKI Outboard Motor

Gear Oil. If it is not available, use SAE 90 hypoid gear oil

which is rated GL-5 under the API classification system.

1. Identification number plate

1. Model 3. Serial number

2. Pre-fix

1. Serial number plate

1

IDK111010007-01

THAI SUZUKI MOTOR CO.,LTD.

MADE IN THAILAND FABRIQUE AU THAILANDE

DF 20A

02002F

1

2 3

IDK111010001-01

1

XXXXXX

IDK111010004-01

–20 –10 0 10 20 30

–4 14 32 50 68 86

40

104

TEMP.

API Classification SAE Viscosity Grade

SG

SH

SL

SJ

SM

10W–40

10W–30

F

C

I9J011010003-02

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 60 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

The 2012-2013 Suzuki DF15A/DF20A 4-Stroke Outboards Service & Repair Manual is a complete factory service repair workshop manual designed specifically for these models. It provides comprehensive service and repair guidance for all aspects of the Suzuki DF15A/DF20A outboards.

- Complete Factory Service Repair Workshop Manual for 2012-2013 Suzuki DF15A/DF20A 4-Stroke Outboards

- Available for instant access on your computer, tablet, or smartphone

- Covers all repairs, servicing, and troubleshooting procedures specific to these models

- Contains detailed photos and diagrams to assist in repair tasks

- Used by professional mechanics and technicians for accurate diagnostics and repairs

- Includes step-by-step instructions with highly detailed exploded diagrams and pictures

- Can be printed out for easy reference during maintenance and repair work

- Can be used on multiple computers without location limitations

- Full manual without any limitations or trial periods

- No expiration or renewal fees, ensuring lasting access

- Fully compatible with Windows and MAC computers