Sears outboard motor service repair manual 1960 - 1968

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

GLENN'S

MARINE

SERIES

FULLY ILLUSTRATED

HAROLD T. GLENN

A COWLES BOOK

Other Books by Harold T. Glenn

Youth at the Wheel

Safe Living

Automechanics

Glenn's Auto Troubleshooting Guide

Glenn's Triumph Repair and Tune-Up Guide

Exploring Power Mechanics

Glenn's Alfa Romeo Repair and Tune-Up Guide

Glenn's Austin, Austin-Healey Repair and Tune-Up Guide

Automobile Engine Rebuilding and Maintenance

Glenn's Sunbeam-Hillman Repair and Tune-Up Guide

Glenn's MG, Morris, and Magnette Repair and Tune-Up Guide

Glenn's Volkswagen Repair and Tune-Up Guide

Glenn's Volkswagen Repair and Tune-Up Guide (Spanish Edition)

Glenn's Mercedes-Benz Repair and Tune-Up Guide

Glenn's Foreign Carburetors and Electrical Systems Guide

Glenn's Renault Repair and Tune-Up Guide

Glenn's Jaguar Repair and Tune-Up Guide

Automobile Power Accessories

Glenn's Volvo Repair and Tune-Up Guide

Glenn's Peugeot Repair and Tune-Up Guide

Glenn's Auto Repair Manual

Glenn's Foreign Car Repair Manual

Glenn's Fiat Repair and Tune-Up Guide

Automotive Smog Control Manual

Honda Repair and Tune-Up Guide

Copyright 0 1968 by HAROLD T. GLENN

All rights reserved.

This volume may not be reproduced in whole or in part

in any Form without written permission from the publisher.

I

Printed in the United States of America 68A

Library of Congress Catalog Number 68-9719

This is a comprehensive repair and tune-up manual for outboard motors. It is designed

to be used' as a classroom text or mechanic's reference book, or it can be used by a boating

enthusiast who is interested in keeping his engine in tip-top shape. A quick-starting and

dependable engine can contribute to an enjoyable vacation; a balky engine can spoil the fun.

This manual is organized about the conventional units of the outboard motor: the engine

and the lower unit. Chapters are devoted to servicing the fuel and electrical systems. A

separate chapter on engine tuning will enable the enthusiast to get all of the power from the

engine that it was designed to deliver. A chapter on maintenance provides vital nontechnical

information for fuel mixing and lubricating the units properly, to keep the engine operating

dependably.

The first chapter deals with troubleshooting. I t enables a mechanic to isolate trouble

before beginning to disassemble the mechanism. It helps to pinpoint the trouble so that a

mechanic will know what to look for as the unit is being disassembled. This feature can save

valuable time when making repairs.

This book contains comprehensive and accurate specification tables, wiring diagrams,

and exploded views of all mechanical and electrical units.

A special feature of this book is the use of many step-by-step illustrated instructions for

representative types of carburetors, engines, and lower units. The illustrations and text are

so closely correlated that no legends are needed. The illustrations have been especially treated

to drop out the backgrounds.

The author wishes to thank Messrs. Will Rush, Jack Carroll, Don Lideen, Bob Allman,

and Paul Taylor for their kind assistance in helping to take the pictures and for furnishing

technical information that has been used in this Guide.

Especial thanks are due my wife, ANNA GLENN, for her devoted assistance in proof-

reading the text.

Harold T. Glenn

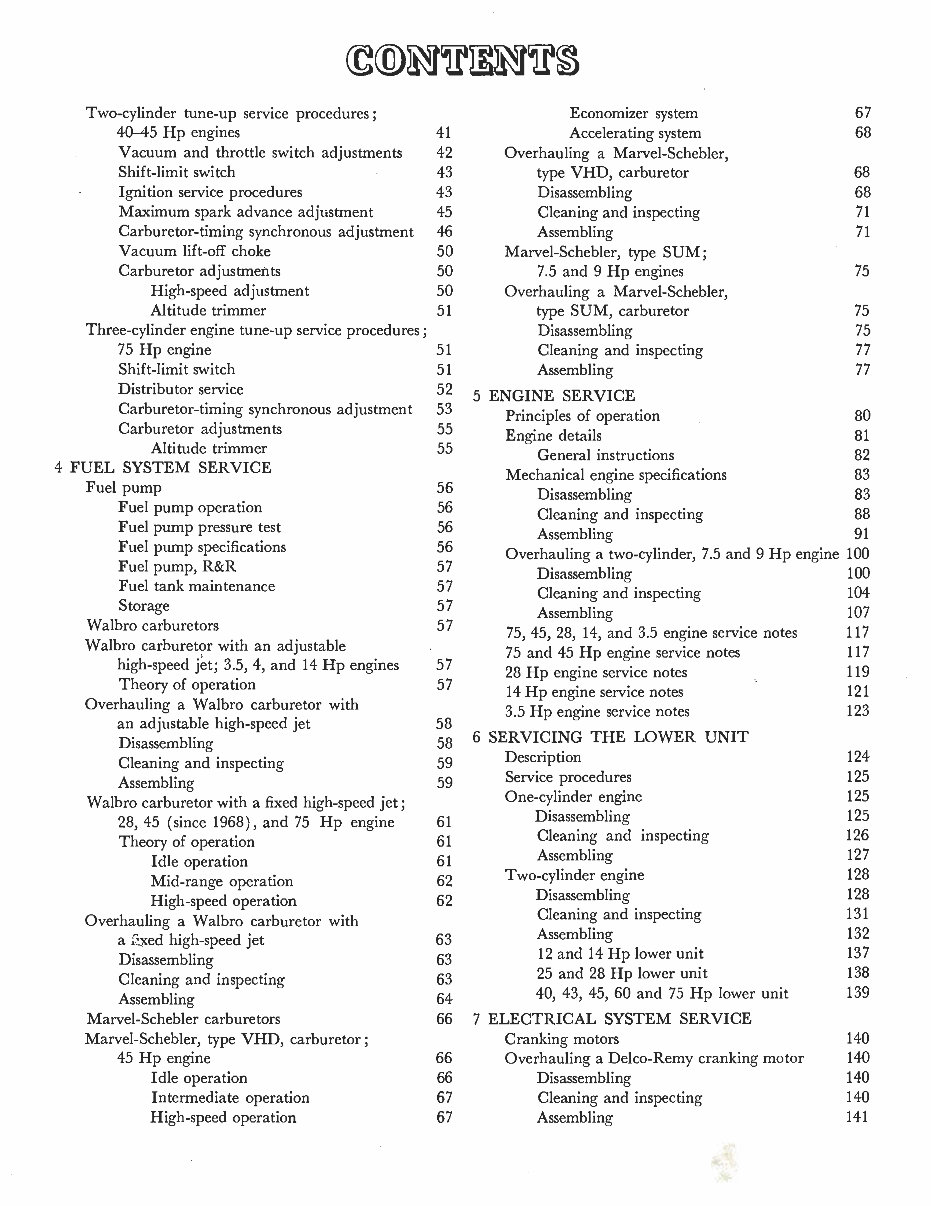

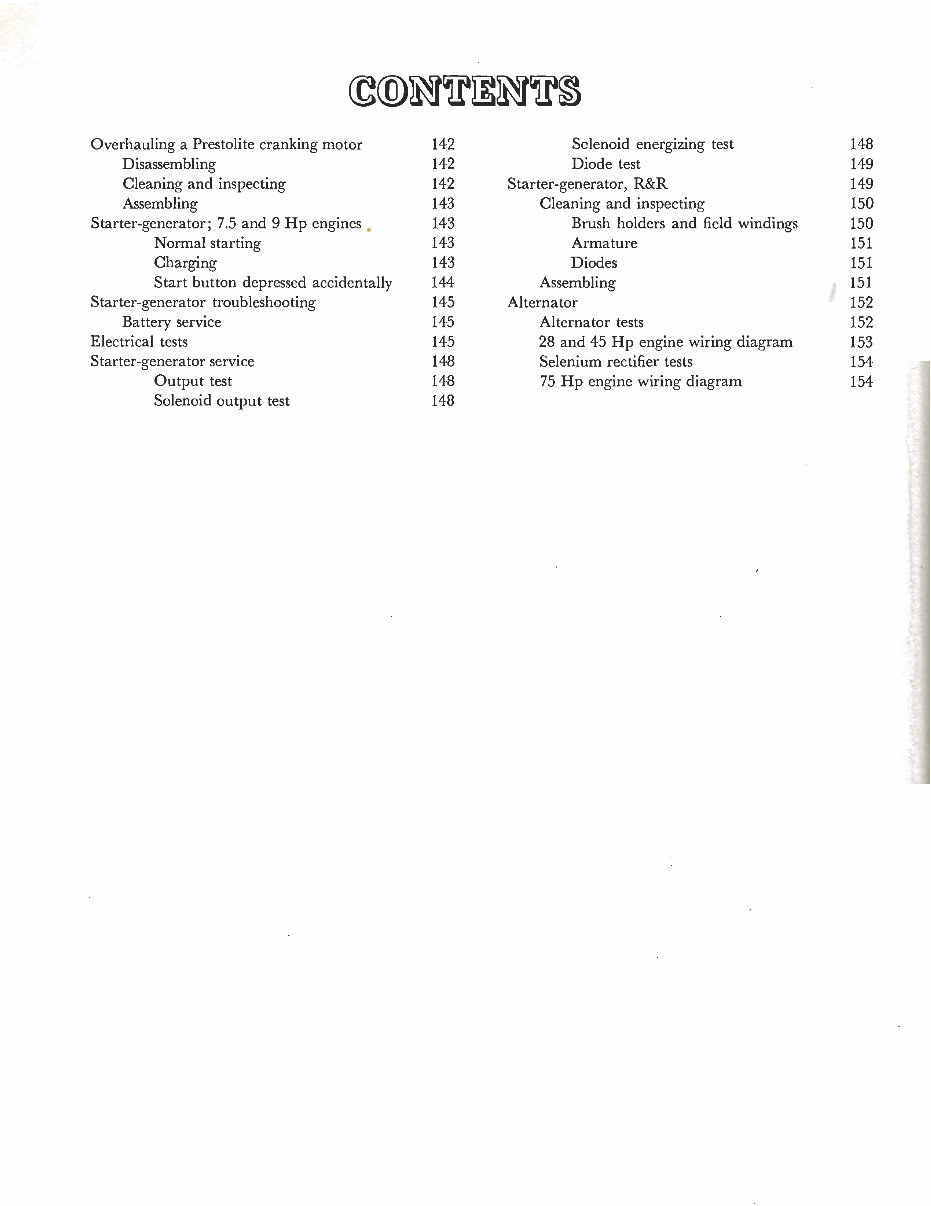

1 TROUBLESHOOTING

Fuel system troubleshooting 1

Troubleshooting chart 2

Fuel system troubleshooting chart 3

Ignition troubleshooting 4

Ignition system troubleshooting chart 4

Compression 5

Compression troubleshooting chart 6

Rough operation 6

Rough operation troubleshooting chart 7

High fuel consumption 8

High fuel consumption troubleshooting chart 8

Noises

Noise troubleshooting chart

Mechanical problems

Mechanical troubleshooting chart

Cooling system troubleshooting chart

Electrical system troubles

Battery troubleshooting chart

Ignition system troubleshooting chart

Starting motor troubleshooting chart

Troubleshooting the cranking motor

Starter-generator troubleshooting chart

Cranking motor troubleshooting chart

2 MAINTENANCE

Boat performance and propeller selection

Boat speed

Center of gravity

Tilt angle

Transom height

Condition of boat bottom

Propeller selection

Fuel consumption

Installing the propeller

Ti1 t pin adjustment

Cavitation

Caution for shallow water operation

Performance factors

Fuel mixing procedure

Fuel mixing chart

Water pump operation

Stopping

Removing the engine from the boat

Maintenance

Lubrication

Fuel filter

Lubrication chart

Operating in salt water or silt

After submersion

Storage

Using a cleaner

Water wisdom

Coast Guard regulations

Rules of the waterways

Signposts

Seamanship for safety

Stepping into the boat

Casting off

Weather signals

8 Rough water

8 Danger zone

9 Overtaking

9 Turns

9 Reverse gear

10 Skiing

10 Stopping

10 Docking

10 3 TUNING FOR PERFORMANCE

11 General ignition service procedures 29

11 Spark plug 29

11 Spark plug troubles 31

Spark plug protectors 33

15 Magneto service procedures 33

15 Removing the flywheel 33

15 Breaker point service 33

15 Breaker point synchronization 34

15 Ignition timing 34

15 Tune-up specifications 35

16 Carburetor throttle pickup adjustment 36

17 One-cylinder tune-up service procedures;

13 3.5 and 4 H P engines 36

17 Breaker point service 36

18 Carburetor adjustments 37

18

Two-cylinder engine tune-up service procedures;

18 7.5, 9, and 12/14 H p engines 37

19 Breaker point service 39

19 Carburetor-timing synchronous adjustment 39

20 Carburetor adjustments 39

20 Two-cyIinder engine tune-up service procedures;

2 1 25/28 Hp engines 40

2 1 Breaker point service 40

2 1 Carburetor-timing synchronous adjustment 41

2 1 Neutral speed limit adjustment 4 1

22 Carburetor adjustments 41

Two-cylinder tune-up service procedures ;

40-45 H p engines 41

Vacuum and throttle switch adjustments 42

Shift-limit switch 43

Ignition service procedures 43

Maximum spark advance adjustment 45

Carburetor-timing synchronous adjustment 46

Vacuum lift-off choke 50

Carburetor adjustmehts 50

High-speed adjustment 50

Altitude trimmer 5 1

Three-cylinder engine tune-up service procedures ;

75 Hp engine

Shift-limit switch

Distributor service

Carburetor-timing synchronous adjustment

Carburetor adjustments

Altitude trimmer

4 FUEL SYSTEM SERVICE

Fuel pump

Fuel pump operation

Fuel pump pressure test

Fuel pump specifications

Fuel pump, R&R

Fuel tank maintenance

Storage

Walbro carburetors

Walbro carburetor with an adjustable

high-speed jkt; 3.5,4, and 14 H p engines

Theory of operation

Overhauling a Walbro carburetor with

an adjustable high-speed jet

Disassembling

Cleaning and inspecting

Assembling

Walbro carburetor with a fixed high-speed jet ;

28, 45 (since l968), and 75 Hp engine

Theory of operation

Idle operation

Mid-range operation

High-speed operation

Overhauling a Walbro carburetor with

a Zxed high-speed jet

Disassembling

Cleaning and inspecting

Assembling

Marvel-Schebler carburetors

Marvel-Schebler, type VHD, carburetor ;

45 H p engine

Idle operation

Intermediate operation

High-speed operation

Economizer system

Accelerating system

Overhauling a Marvel-Schebler,

type VHD, carburetor

Disassembling

Cleaning and inspecting

Assembling

Marvel-Schebler, type SUM;

7.5 and 9 H p engines

Overhauling a Marvel-Schebler,

type SUM, carburetor

Disassembling

-

5 1 Cleaning and inspecting

5 1 Assembling

52 5 ENGINE SERVICE

53 Principles of operation 80

55 Engine details

8 1

55

General instructions 82

Mechanical engine specifications 83

56 Disassembling 83

56 Cleaning and inspecting 88

56 Assembling 9 1

56 Overhauling a two-cylinder, 7.5 and 9 H p engine 100

57 Disassembling 100

57 Cleaning and inspecting 104

57 Assembling 107

57

75, 45, 28, 14, and 3.5 engine service notes 117

75 and 45 H p engine service notes 117

57

28 H p engine service notes 119

57

14 H p engine service notes 121

3.5 Hp engine service notes 123

58

58

6 SERVICING THE LOWER UNIT

59 Description

59 Service procedures

One-cylinder engine

61 Disassembling

61

Cleaning and inspecting

6 1 Assembling

62 Two-cylinder engine

62

Disassembling

Cleaning and inspecting

63 Assembling

63

12 and 14 Hp lower unit

63

25 and 28 Hp lower unit

64

40, 43, 45, 60 and 75 H p lower unit

66 7 ELECTRICAL SYSTEM SERVICE

Cranking motors

66 Overhauling a Delco-Remy cranking motor

66 Disassembling

67 Cleaning and inspecting

67 Assembling

Overhauling a Prestolite cranking motor

Disassembling

Cleaning and inspecting

Assembling

Starter-generator; 7.5 and 9 H p engines ,

Normal starting

Charging

Start button depressed accidentally

Starter-generator troubleshooting

Battery service

Electrical tests

Starter-generator service

Output test

Solenoid output test

Sclenoid energizing test

Diode test

Starter-generator, R&R

Cleaning and inspecting

Brush holders and field windings

Armature

Diodes

Assembling

Alternator

Alternator tests

28 and 45 Hp engine wiring diagram

Selenium rectifier tests

75 H p engine wiring diagram

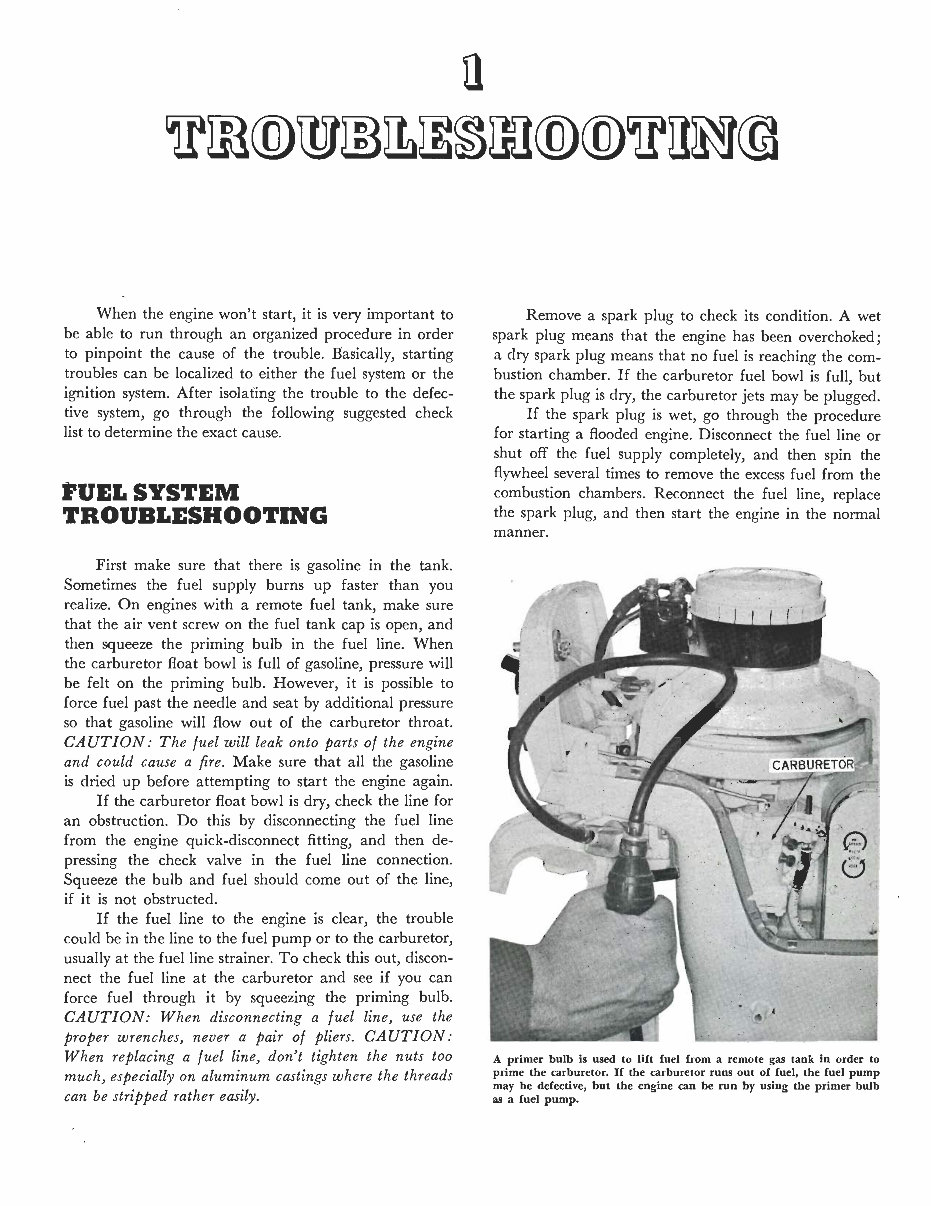

When the engine won't start, it is very important to Remove a spark plug to check its condition. A wet

be able to run through an organized procedure in order spark plug means that the engine has been overchoked;

to pinpoint the cause of the trouble. Bgsically, starting a dry spark plug means that no fuel is reaching the com-

troubles can be localized to either the fuel system or the bustion chamber. If the carburetor fuel bowl is full, but

ignition system. After isolating the trouble to the defec- the spark plug is dry, the carburetor jets may be plugged.

tive system, go through the following suggested check If the spark plug is wet, go through the procedure

list to determine the exact cause. for starting a flooded engine. Disconnect the fuel line or

shut off the fuel supply completely, and then spin the

flywheel several times to remove the excess fuel from the

combustion chambers. Reconnect the fuel line, replace

the spark plug, and then start the engine in the normal

manner.

FUEL SYSTEM

TROUBLESHOOTING

First make sure that there is gasoline in the tank.

Sometimes the fuel supply burns up faster than you

realize. On engines with a remote fuel tank, make sure

that the air vent screw on the fuel tank cap is open, and

then squeeze the priming bulb in the fuel line. When

the carburetor float bowl is full of gasoline, pressure will

be felt on the priming bulb. However, it is possible to

force fuel past the needle and seat by additional pressure

so that gasoline will flow out of the carburetor throat.

CAUTION: The fuel will leak onto parts of the engine

and could cause a fire. Make sure that all the gasoline

is dried up before attempting to start the engine again.

If the carburetor float bowl is dry, check the line for

an obstruction. Do this by disconnecting the fuel line

from the engine quick-disconnect fitting, and then de-

pressing the check valve in the fuel line connection.

Squeeze the bulb and fuel should come out of the line,

if it is not obstructed.

If the fuel line to the engine is clear, the trouble

could be in the line to the fuel pump or to the carburetor,

usually at the fuel line strainer. To check this out, discon-

nect the fuel line at the carburetor and see if you can

force fuel through it by squeezing the priming bulb.

CAUTION: When disconnecting a fuel line, use the

proper wrenches, never a pair of pliers. CAUTION:

When replacing a fuel line, don't tighten the nuts too

much, especially on aluminum castings where the threads

can be stripped rather easily.

\ dl"

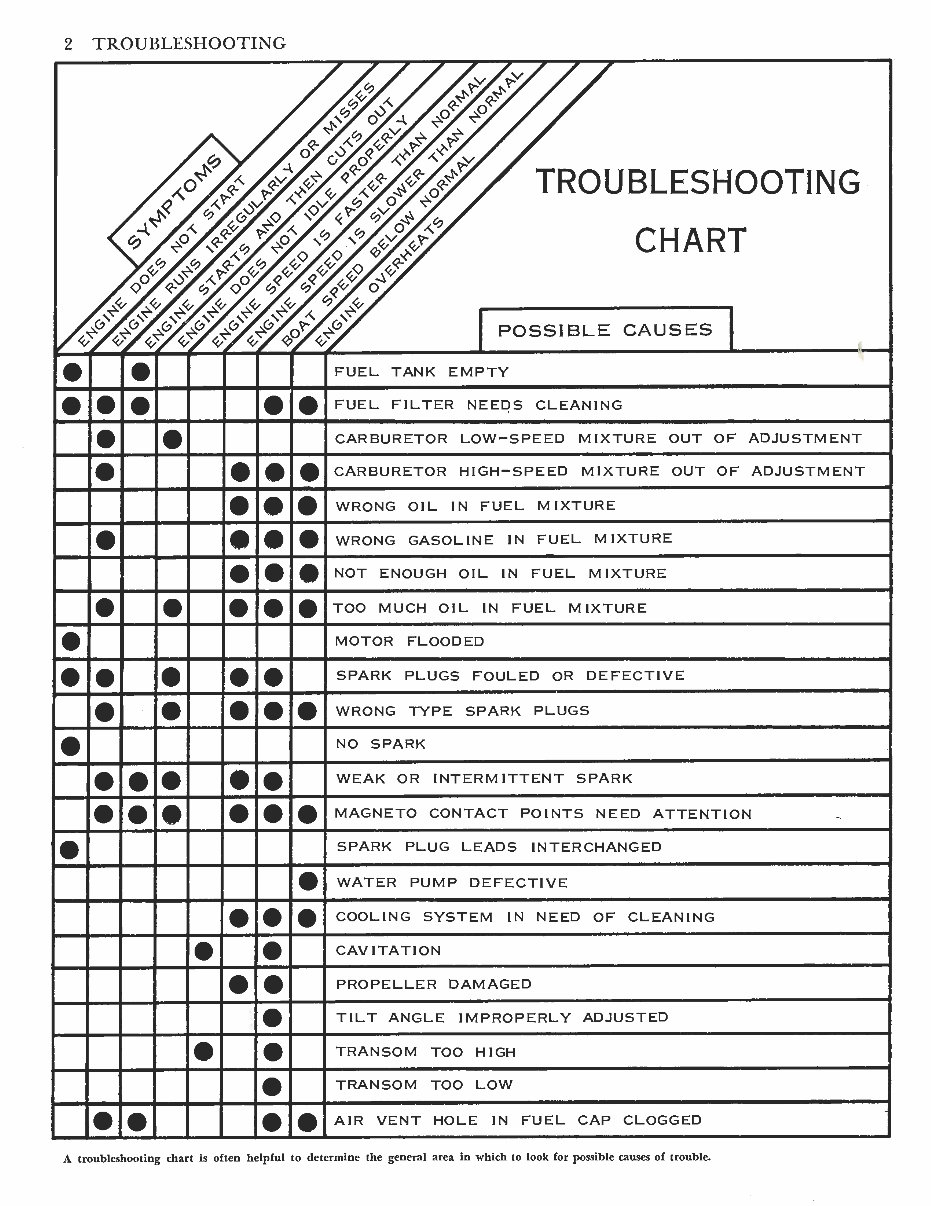

A primer bulb is used to lift fuel from a remote gas tank in order to

prime the carburetor. If the carburetor runs out of fuel, the fuel pump

may be defective, but the engine can be run by using the primer bulb

as a fuel pump.

FUEL SYSTEM 3

Some of the one-cylinder engine carbureton have a drain valve, which

can be depressed to determine whether or not fuel is flowing to the

carburetor. The drain valve should be depressed periodically to drain

water and debris accumulations from the bowl.

Check the fuel in the carburetor to see if water has

gotten into it by catching a little of the gasoline in the

palm of your hand. The water will appear as small beads

or bubbles. If you blow on the mixture, the gasoline will

evaporate, leaving the water behind.

FUEL SYSTEM

TROUBLESHOOTING CHART

1. No fuel in carburetor

la. Empty gas tank

I b. Clogged fuel filter

Ic. Restricted vent in gas tank

Id. Defective fuel pump

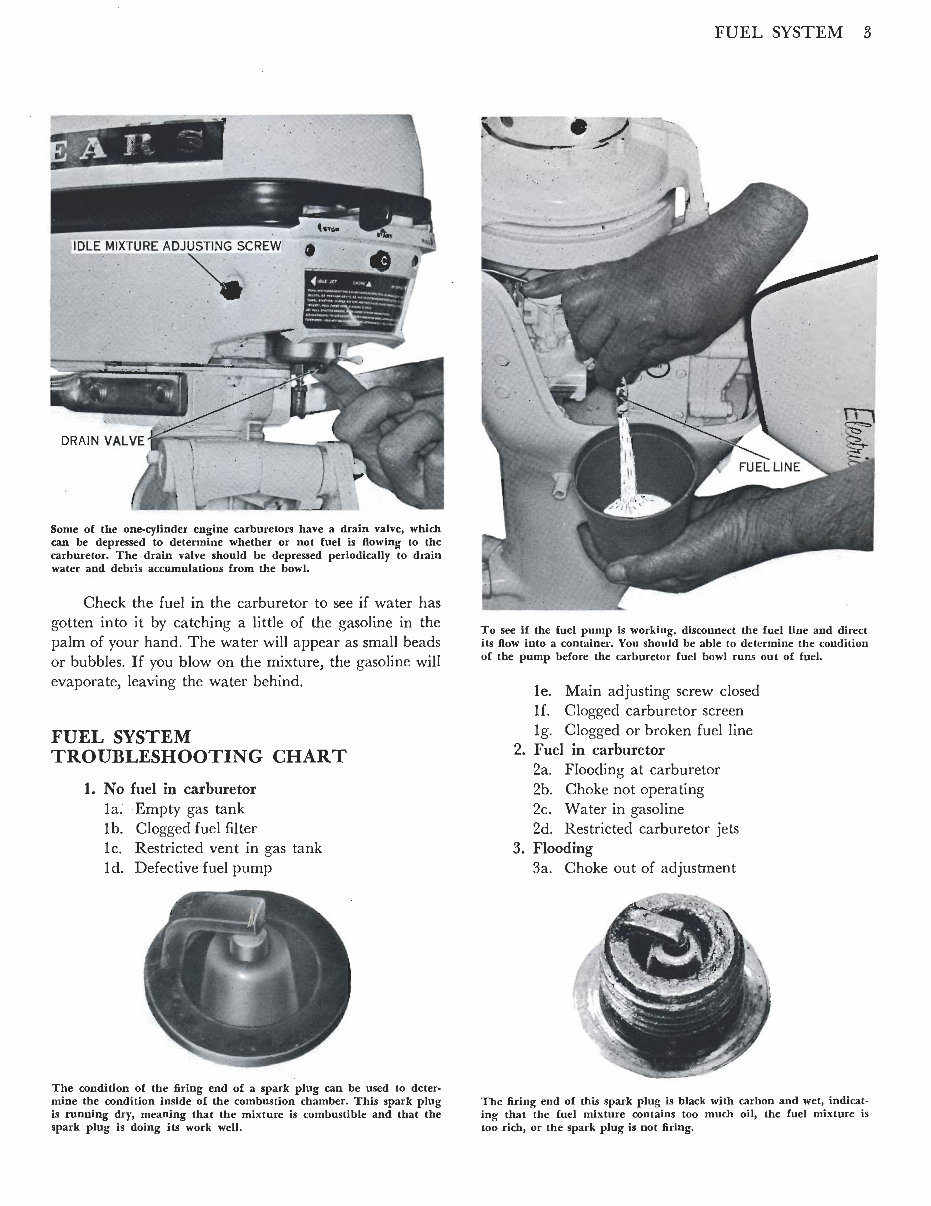

The condition of the firing end of a spark plug can be used to deter-

mine the condition inside of the combustion chamber. This spark plug

is running dry, meaning that the mixture is combustible and that the

spark plug is doing its work well.

To see if the he1 pump is working, disconnect the fuel line and direct

its flow into a container. You should be able to determine the condition

of the pump before the carburetor fuel bowl runs out of fuel.

le. Main adjusting screw closed

If. Clogged carburetor screen

Ig. Clogged or broken fuel line

2. Fuel in carburetor

2a. Flooding at carburetor

2b. Choke not operating

2c. Water in gasoline

2d. Restricted carburetor jets

3. Flooding

3a. Choke out of adjustment

The firing end of this spark plug is black with carbon and wet, indicat-

ing that the fuel mixture contains too much oil, the fuel mixture is

too rich, or the spark plug is not firing.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Viewed 72 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Get your hands on the Sears outboard motor service repair manual covering the years 1960 to 1968. This comprehensive manual is designed for both professional mechanics and DIY enthusiasts, providing detailed information for servicing one, two, and three-cylinder engines.

The manual consists of 160 illustrated pages, offering clear and concise instructions to assist you in maintaining and repairing your outboard motor effectively.