Mercury Mariner 9.9HP, 15HP 4-Stroke Outboards OEM Service & Repair Manual

Mercury Mariner 9.9HP, 15HP 4-Stroke Outboards OEM Service & Repair Manual

Models Covered:

- Mercury Mariner 9.9HP 4-Stroke (323cc)

- Mercury Mariner 15HP 4-Stroke (323cc)

- Mercury Mariner 9.9HP Bigfoot 4-Stroke (323cc)

- Mercury Mariner 15HP Bigfoot 4-Stroke (323cc)

Applicable Serial Numbers: 0G590000 and above (United States)

The Mercury Mariner 9.9HP, 15HP 4-Stroke Outboards OEM Service & Repair Manual provides factory-level service information for standard and Bigfoot 4-stroke models. Covering engines from serial number 0G590000 and up, this manual is essential for professional marine technicians, DIY owners, and anyone looking to maintain or repair these popular mid-range outboards.

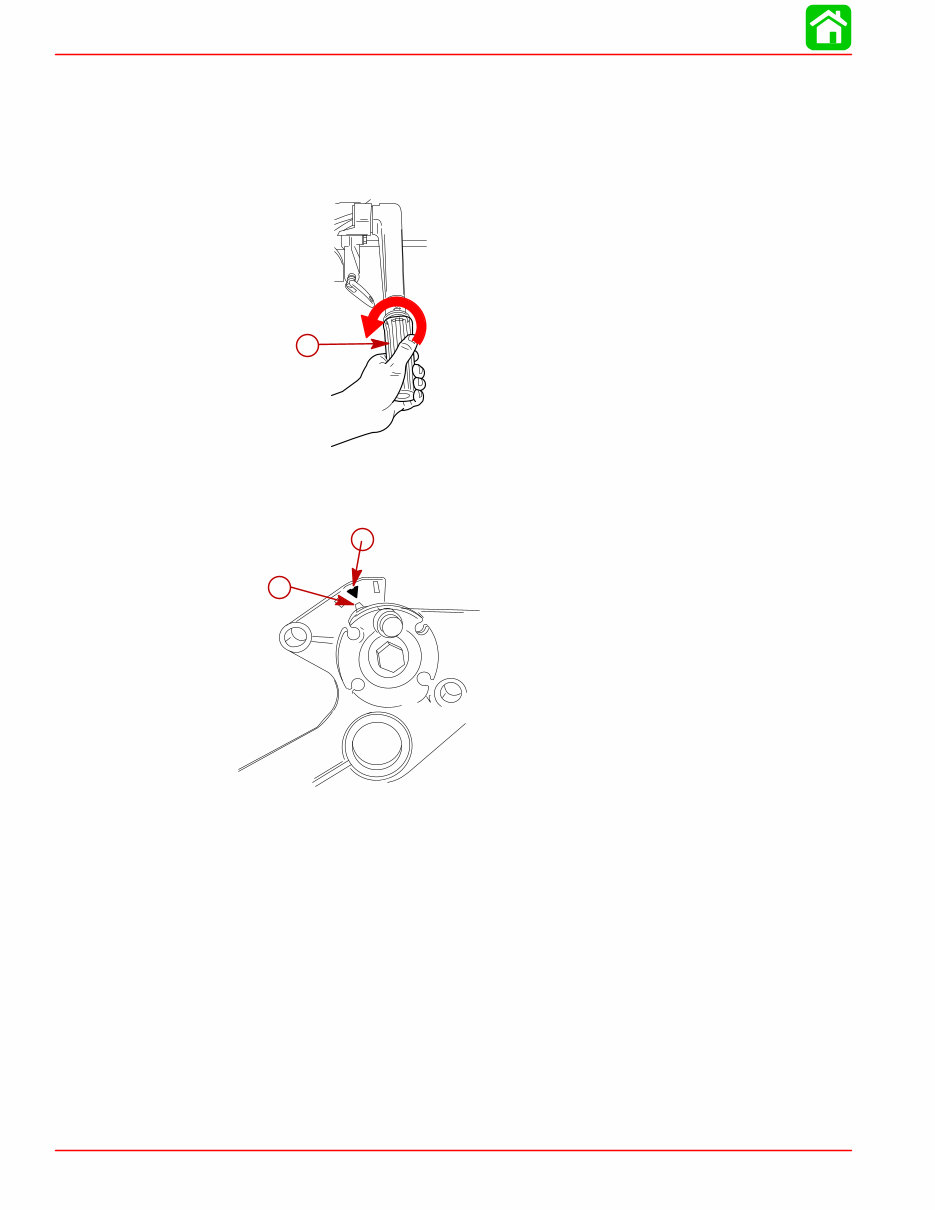

With detailed service procedures, precise torque specifications, and clear illustrations, the manual allows you to perform everything from routine maintenance tasks to complex repairs with confidence. Whether you're servicing the carburetor, repairing the gear housing, or troubleshooting electrical systems, this manual ensures you have the correct information at every step.

Content Overview:

- General Information: Specifications, maintenance intervals, service basics, installation guidelines

- Electrical Systems: Ignition, charging, starting systems, timing adjustments, wiring diagrams

- Fuel System: Fuel pump maintenance, carburetor servicing, emission system components

- Powerhead: Cylinder head and crankcase service, oil pump overhaul

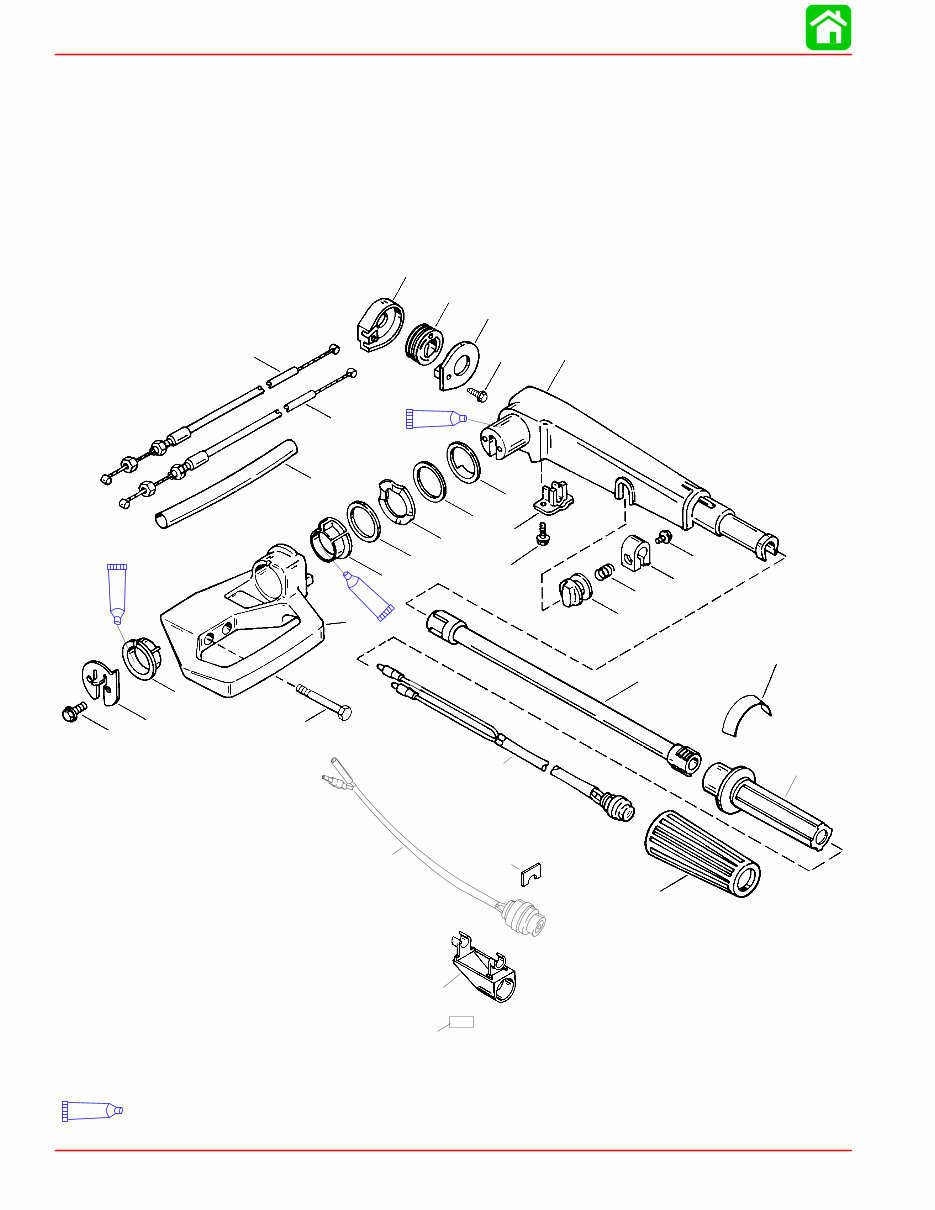

- Mid-Section: Steering components, exhaust passages, trim and tilt systems

- Lower Unit: Gearcase repair for standard and Bigfoot configurations

- Control Linkage & Attachments: Throttle and shift controls, tiller handle maintenance

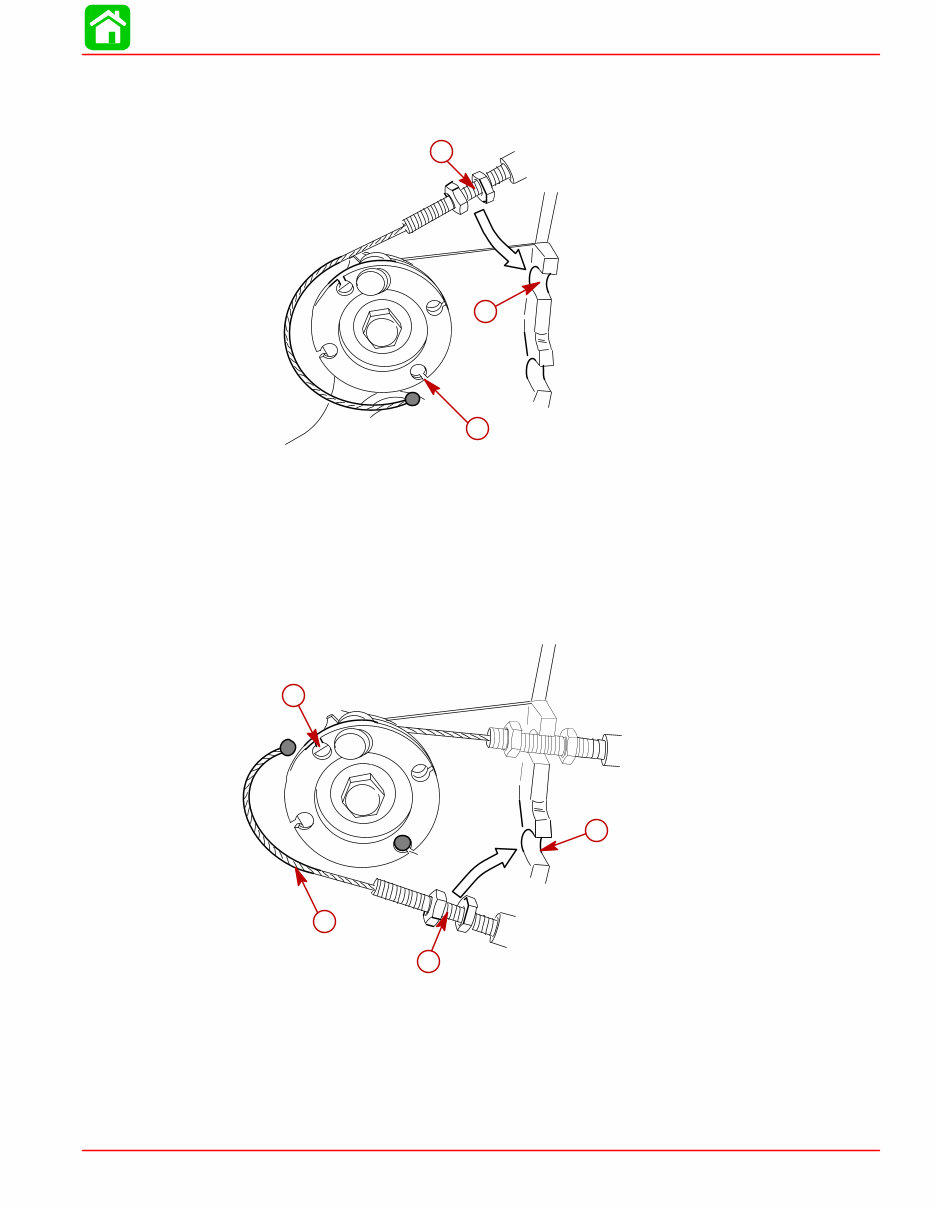

- Manual Starter: Rope starter assembly and troubleshooting

Whether you're preparing for a season of boating or performing a full engine rebuild, this manual offers the trusted information needed to work efficiently and accurately. It’s the same service reference relied on by authorized Mercury dealers, now available for your personal workshop.

Printable: Yes

Language: English

Compatibility: Pretty much any electronic device, including PC & Mac computers, Android and Apple smartphones & tablets

Requirements: Adobe Reader (free)