1996+ Mercury 60HP BigFoot Outboard OEM Service & Repair Manual

1996+ Mercury 60HP BigFoot Outboard OEM Service & Repair Manual

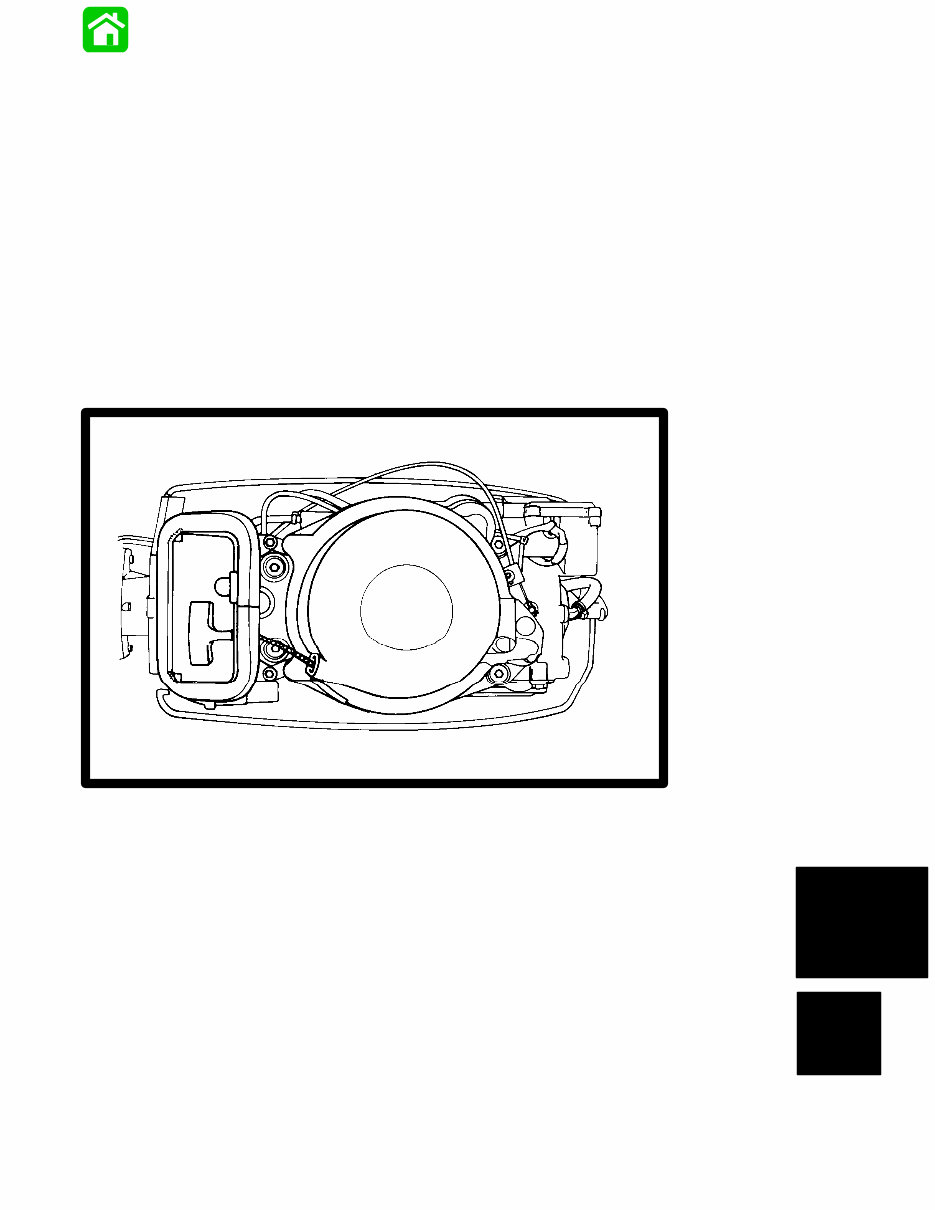

The 1996+ Mercury 60HP BigFoot Outboard OEM Service & Repair Manual provides the factory-authorized procedures, specifications, and troubleshooting guidance needed to properly service and maintain the 60HP BigFoot series engines. This is the same reference used by Mercury-certified marine technicians, structured to support both seasoned mechanics and DIY boat owners who prefer handling their own repairs with accurate, step-by-step direction.

The manual covers all major systems on the engine and drive assembly, including routine inspection, mechanical adjustments, powerhead servicing, mid-section repairs, and lower unit overhaul procedures. Each section is written clearly and practically, keeping the process grounded and approachable even if you’re not a full-time tech.

What’s Inside the Mercury 60HP BigFoot Service & Repair Manual

General Information & Specifications

Model identification, standard torque values, operating principles, lubrication points, and recommended service intervals. Ensures all repair work is completed to proper factory-spec standards.

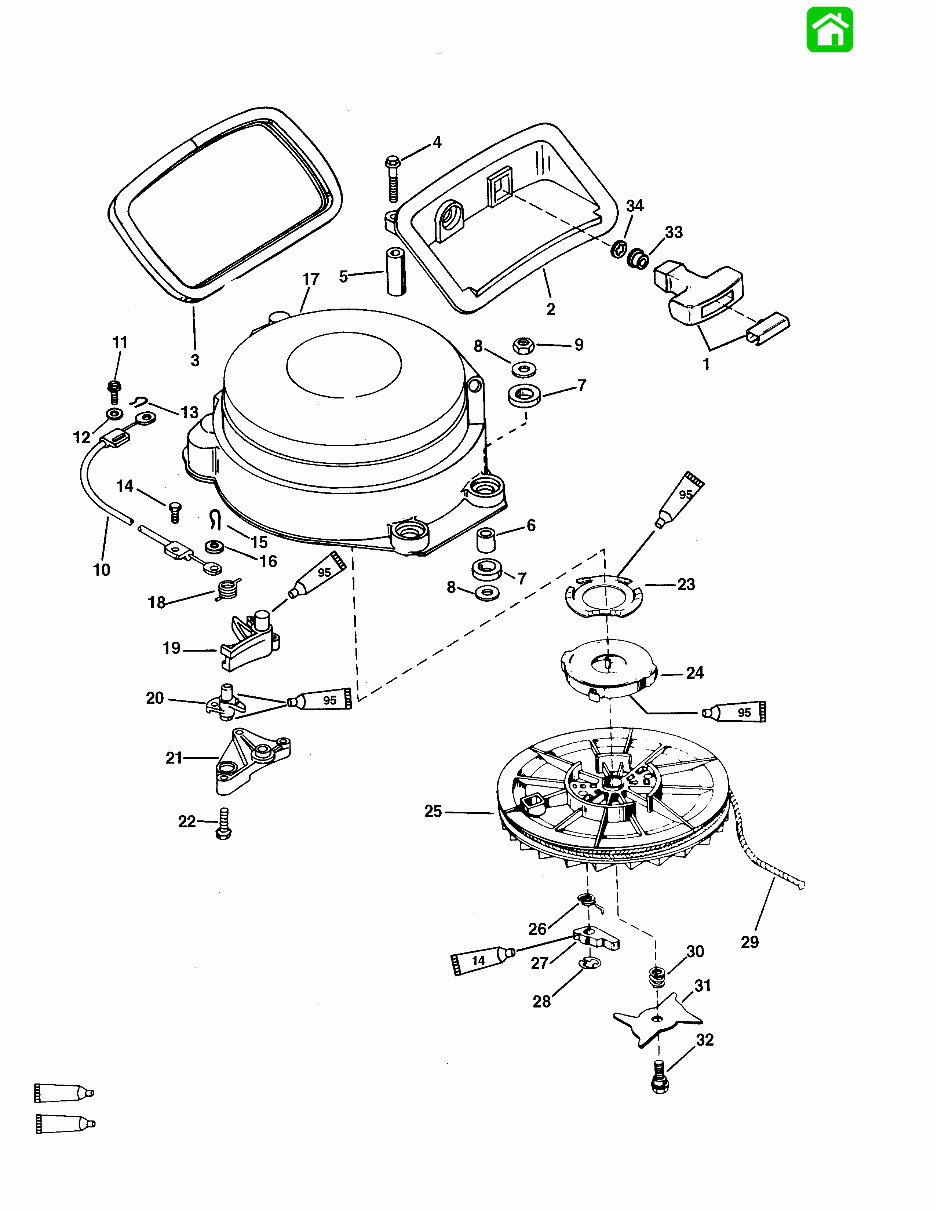

Electrical & Ignition System

Testing and servicing ignition modules, coils, spark plugs, starter motor operation, charging system output, and battery/alternator checks. Includes troubleshooting for no-start, weak spark, and charging faults.

Engine Timing & Synchronization

Procedures for setting idle and throttle control linkages, synchronization of carburetor timing, and verifying proper ignition advance across operating RPM ranges.

Fuel Delivery & Carburetion

Fuel pump service, carburetor disassembly and cleaning, choke/enrichment system checks, oil injection system servicing, and leak testing for safe, reliable engine performance.

Powerhead Service & Overhaul

Disassembly, inspection, and reassembly procedures for pistons, crankshaft, cylinder block, reed valves, seals, and rotating assemblies. Includes wear limits and service measurements.

Mid-Section & Power Trim/Tilt

Servicing clamp brackets, exhaust housing, swivel mechanisms, steering pivot points, and trim/tilt hydraulic components. Covers pressure checks and cylinder maintenance.

Lower Unit & Gearcase Assembly

Gear housing teardown and assembly, impeller and water pump servicing, bearing replacement, shift shaft adjustments, and BigFoot-specific gear ratio identification. Also includes notes for SeaPro, Marathon, and Jet Drive variants.

Controls & Installation

Guidance on installing tiller handles, Ride-Guide steering, throttle and shift linkages, co-pilot control setups, and correct alignment for proper steering and throttle response.

How This Mercury Manual Is Useful

It’s clear and methodical, providing actual OEM service procedures instead of generic advice. Great for routine service, seasonal prep, diagnosing mechanical issues, and full rebuild work — whether you're maintaining a fishing boat, work skiff, or tender.

Format & Compatibility

Provided as a fully searchable digital PDF for easy navigation and printing. Suitable for desktop, laptop, or mobile device use in the shop or on the dock.

Download the 1996+ Mercury 60HP BigFoot Service Manual

Keep maintenance consistent and reliable with factory-correct service instructions designed specifically for the Mercury 60HP BigFoot platform.

Language: English

Compatibility: Windows, macOS, Linux, iOS, Android

Requirements: PDF Reader (e.g., Adobe Reader)