1998-2005 Mercury Mariner 75HP 2-Stroke Outboard OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Quick Reference Data

VEHICLE HISTORY DATA

MODEL: YEAR:

VIN NUMBER:

ENGINE SERIAL NUMBER:

CARBURETOR SERIAL NUMBER OR I.D. MARK:

Record the numbers here for your reference.

MAINTENANCE SCHEDULE

Maintenance interval Maintenance required

Before each use Check the lanyard switch operation*

Inspect the propeller for damage

Check the propeller nut tightness

Inspect the fuel system for leakage

Check the outboard mounting bolt tighteness

Check the steering for binding or looseness

Check the shift and throttle control

After each use Flush the cooling system

Wash debris from the gearcase

After the first 10 days of operation Check the gearcase lubricant level

Every 30 day or 50 hours of usage Check the gearcase lubricant level

IX

(continued)

MAINTENANCE SCHEDULE (continued)

Maintenance interval Maintenance required

Once a season or 100 hours of usage Lubricate the steering system

Lubricate tiller control pivots*

Lubricate the tilt and swivel shaft

Lubricate the shift and throttle linkages/cables

Check the tightness of all accessible fasteners

Clean and inspect the spark plugs

Remove carbon from the combustion chambers

Inspect fuel filters for contamination

Check control cable adjustments

Adjust the carburetors*

Test and inspect the battery

Check ignition timing

Check trim/tilt fluid level (Chapter Eleven)

Clean and inspect sacrificial anodes

Lubricate the drive shaft splines

Lubricate the propeller shaft splines

Change the gearcase lubricant

Lubricate the starter motor pinion

Clean remote fuel tank filter*

Change the water separating filter (EFI)*

Inspect or replace the water pump impeller

Replace the compressor air filter (Optimax)*

Clean the compressor cooling water strainer*

Before long term storage Drain and refill the gearcase lubricant

*This maintenance item does not apply to all models.

LUBRICANT CAPACITIES

Model Oil capacity Gearcase capacity

65 jet, 75 hp and 90 hp 1 gal. (3.8 liter)* 22.5 oz. (665 ml)*

80 jet and 100-125 hp

(except 115 Optimax) 1.4 gal (5.3 liter)* 22.5 oz. (665 ml)*

105 jet and 140 jet 12.9 qt. (12.2 liter) –

135-200 hp (except Optimax) 12.9 qt. (12.2 liter)* 22.5 oz. (665 ml)*

115-175 hp Optimax models 13.5 qt. (12.8 liter)* 22.5 oz. (665 ml)*

200/225 hp Optimax, 225 hp and 250 hp 13.5 qt. (12.8 liter) 28.0 oz. (828 ml)*

*Approximate capacity. Always add lubricant until it reaches the full level.

SPARK PLUG RECOMMENDATIONS

Model Recommended plug Spark plug gap

65 jet, 75 hp and 90 hp NGK BUHW-2 Surface gap plug

Alternate plug (resistor type) NGK BUZHW-2 Surface gap plug

80 jet, 100 hp, 115 hp and 125 hp NGK BP8H-N-10 0.040 in. (1.0 mm)

Alternate plug (resistor type) NGK-BPZ8H-N-10 0.040 in. (1.0 mm)

105 jet and 140 jet

1998 and 1999 NGK BU8H Surface gap plug

2000-on NGK BPZ8HS-10 0.040 in. (1.0 mm)

135-200 hp (except Optimax)

1998 and 1999 NGK BU8H surface gap plug

2000-on NGK BPZ8HS-10 0.040 in. (1.0 mm)

X

(continued)

SPARK PLUG RECOMMENDATIONS (continued)

Model Recommended plug Spark plug gap

115-150 hp (Optimax models) NGK PZFR5F-11 0.040 in. (1.0 mm)

Alternate plug NGK ZFR5F-11 0.040 in. (1.0 mm)

Alternate plug Champion RC12MC4 0.040 in. (1.0 mm)

200 and 225 hp (Optimax models)

1998 and 1999 NGK PZFR5F-11 0.040 in. (1.0 mm)

Alternate plug NGK ZFR5F-11 0.040 in. (1.0 mm)

2000 Champion QC12GMC 0.040 in. (1.0 mm)

2001-on NGK PZFR5F-11 0.040 in. (1.0 mm)

225 and 250 hp (except Optimax) Champion QL77CC 0.035 in. (0.9 mm)

BATTERY CAPACITY

Provides continuous Approximate

Accessory draw power for: recharge time

80 amp-hour battery

5 amps 13.5 hours 16 hours

15 amps 3.5 hours 13 hours

25 amps 1.6 hours 12 hours

105 amp-hour battery

5 amps 15.8 hours 16 hours

15 amps 4.2 hours 13 hours

25 amps 2.4 hours 12 hours

STANDARD TORQUE SPECIFICATIONS

Screw or nut size in.-lb. ft.-lb. N•m

U.S. Standard

6-32 9 – 1.0

8-32 20 – 2.3

10-24 30 – 3.4

10-32 35 – 4.0

12-24 45 – 5.1

1/4-20 70 – 7.9

1/4-28 84 – 9.5

5/16-18 160 13 18.1

5/16-24 168 14 19.0

3/8-16 – 23 31.1

3/8-24 – 25 33.8

7/16-14 – 36 48.8

7/16-20 – 40 54.2

1/2-13 – 50 67.8

1/2-20 – 60 81.3

Metric

M5 36 – 4.1

M6 70 – 8.1

M8 156 13 17.6

M10 – 26 35.3

M12 – 35 47.5

M14 – 60 81.3

XI

Chapter One

General Information

This detailed, comprehensive manual contains com-

plete information on maintenance and overhaul. Hun-

dreds of photos and drawings guide the reader through

every step-by-step procedure.

Troubleshooting, tune-up, maintenance and repair pro-

cedures are not difficult with the necessary tools and equip-

ment, and the ability to use them. Anyone with some

mechanical ability can perform most of the procedures in

this manual. See Chapter Two for more information on

tools and techniques.

A shop manual is a reference. Clymer books are de-

signed for finding information quickly. All chapters are

thumb tabbed and important topics are indexed at the end

of the manual. All procedures, tables, photos and instruc-

tions in this manual assume the reader may be working on

the machine or using the manual for the first time.

Store the manual with other tools in the workshop or

boat. It will help in gaining a better understanding of how

the boat runs, and help to lower repair and maintenance

costs.

MANUAL ORGANIZATION

Chapter One provides general information useful to

boat owners and mechanics.

Chapter Two discusses the tools and techniques for pre-

ventative maintenance, troubleshooting and repair.

Chapter Three provides troubleshooting procedures for

all engine systems and individual components.

Chapter Four provides maintenance, lubrication and

tune-up instructions.

Additional chapters cover storage, adjustment and spe-

cific repair instructions. All disassembly, inspection and

assembly instructions are in step-by-step form. Specifica-

tions are included at the end of the appropriate chapters.

WARNINGS, CAUTIONS AND NOTES

The terms, WARNING, CAUTION and NOTE have

specific meanings in this manual.

1

A WARNING emphasizes areas where injury or even

death could result from negligence. Mechanical damage

may also occur. WARNINGS are to be taken seriously .

A CAUTION emphasizes areas where equipment dam-

age could occur. Disregarding a CAUTION could cause

permanent mechanical damage, though injury is unlikely.

A NOTE provides additional information to make a step

or procedure easier or clearer. Disregarding a NOTE

could cause inconvenience, but would not cause equip-

ment damage or personal injury.

TORQUE SPECIFICATIONS

Torque specifications throughout this manual are given

in foot-pounds (ft.-lb.), inch-pounds (in.-lb.) and newton

meters (N•m). Torque wrenches calibrated in me-

ter-kilograms can be used by performing a simple conver-

sion: move the decimal point one place to the right. For

example, 4.7 mkg = 47 N•m. This conversion is accurate

enough for mechanical repairs even though the exact

mathematical conversion is 3.5 mkg = 34.3 N•m.

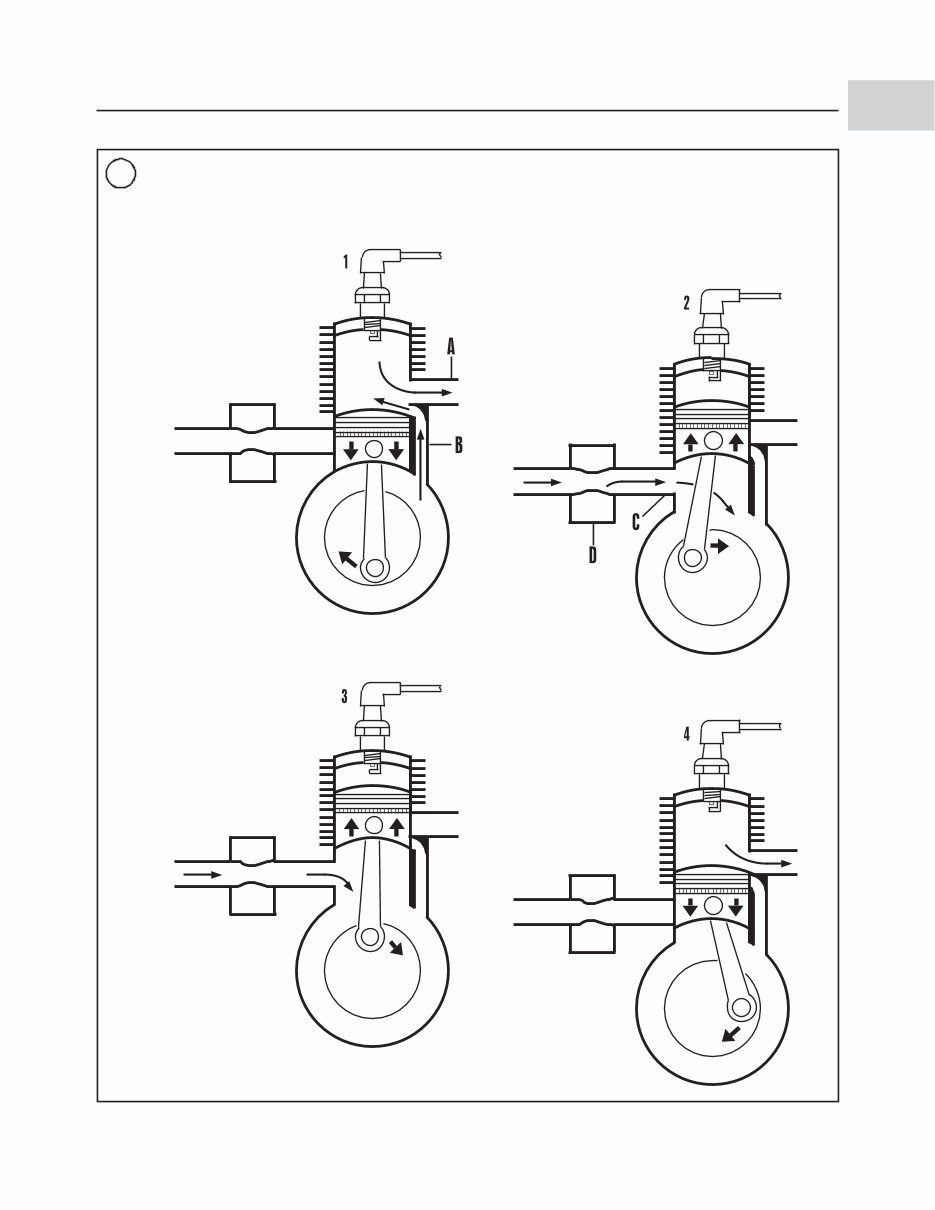

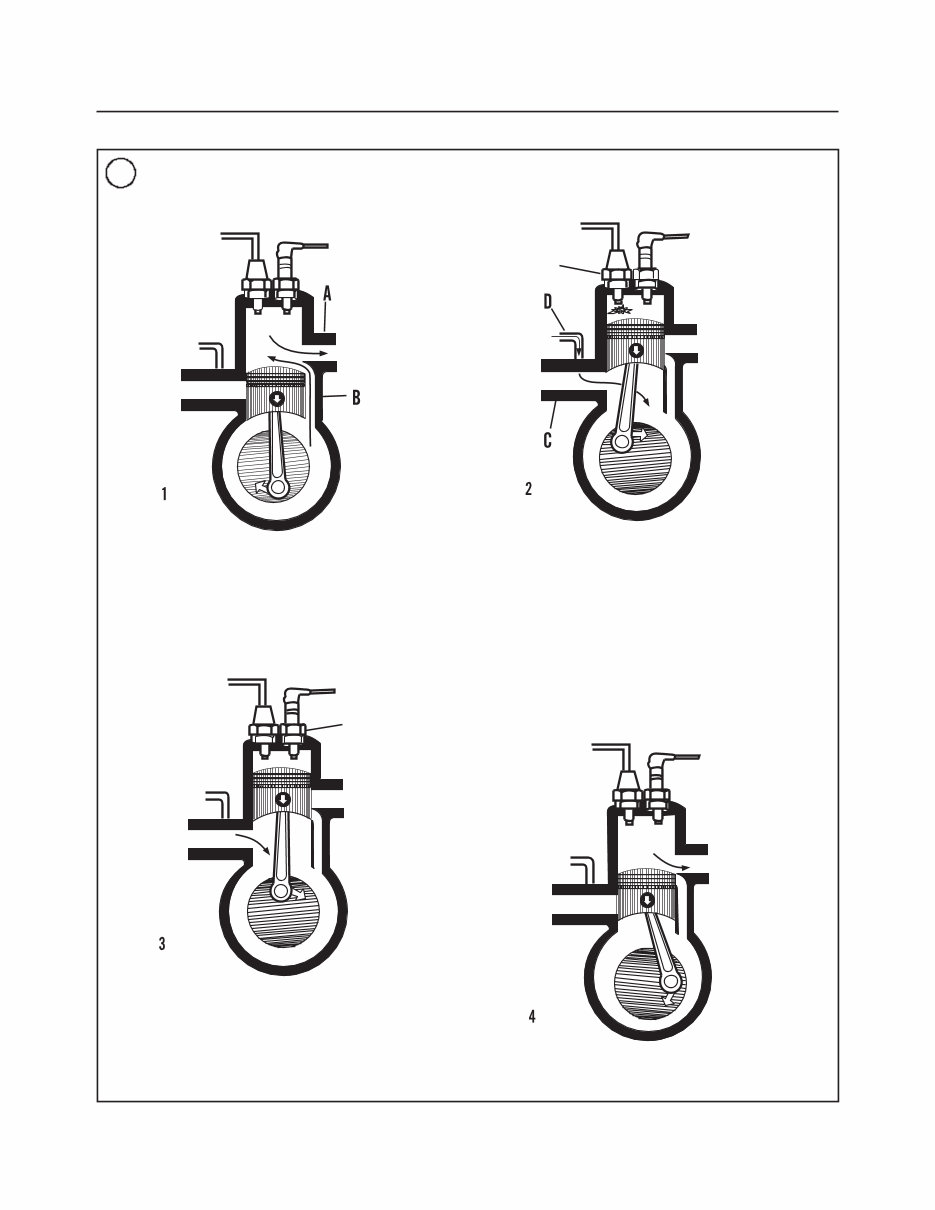

ENGINE OPERATION

All marine engines, whether two- or four-stroke, gaso-

line or diesel, operate on the Otto cycle of intake, compres-

sion, power and exhaust phases. A two-stroke engine

requires one crankshaft revolution (two strokes of the pis-

ton) to complete the Otto cycle. All Mercury and Mariner

engines covered in this manual are of the two-stroke de-

sign. Figure 1 shows typical gasoline two-stroke engine

operation.

Optimax models use a direct fuel injection system. On

these models, fuel is injected directly into the combustion

chamber after the exhaust port is covered; preventing un-

burned fuel from exiting along with the exhaust gases.

Compared to typical two-stroke engines, direct fuel in-

jected engines run smoother, emit far less unburned fuel,

use less oil and provide improved fuel economy. Figure 2

shows direct injection two-stroke engine operation.

FASTENERS

The material and design of the various fasteners used on

marine equipment are specifically chosen for perfor-

mance and safety. Fastener design determines the type of

tool required to work with the fastener. Fastener material

is carefully selected to decrease the possibility of physical

failure or corrosion. See Galvanic Corrosion in this chap-

ter for information on marine materials.

Threaded Fasteners

Nuts, bolts and screws are manufactured in a wide

range of thread patterns. To join a nut and bolt, the diame-

ter of the bolt and the diameter of the hole in the nut must

be the same. The threads must also be compatible.

Determine if the threads on the fasteners are compatible

by turning the nut on the bolt (or bolt into its respective

opening) with fingers only. Make sure both pieces are

clean. If much force is required, check the thread condi-

tion on each fastener. If the thread condition is good but

the fasteners jam, the threads are not compatible.

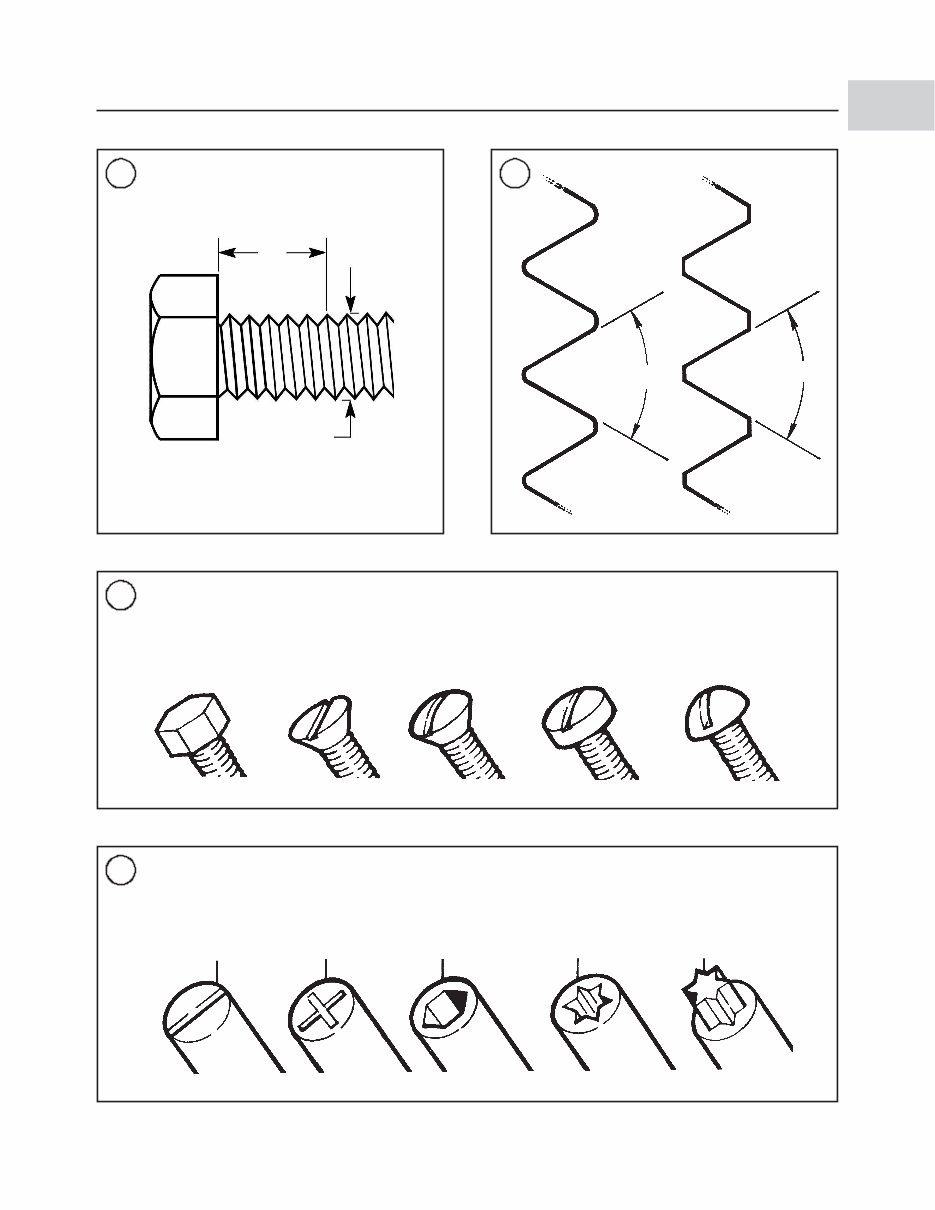

Four important specifications describe the thread:

1. Diameter.

2. Threads per inch.

3. Thread pattern.

4. Thread direction.

Figure 3 shows the first two specifications. Thread pat-

tern is more subtle. Italian and British standards exist, but

the most commonly used by marine equipment manufac-

turers are American and metric. The root and top of the

thread are cut differently as shown in Figure 4.

Most threads are cut so the fastener must be turned

clockwise to tighten it. These are called right-hand

threads. Some fasteners have left-hand threads; they must

be turned counterclockwise for tightening. Left-hand

threads are used in locations where normal rotation of the

equipment would loosen a right-hand threaded fastener.

Fasteners with left-hand threads are identified in the in-

structions.

Machine Screws

There are many different types of machine screws (Fig-

ure 5). Most are designed to protrude above the secured

surface (rounded head) or be slightly recessed below the

surface (flat head). In some applications, the screw head is

recessed well below the fastened surface. Figure 6 shows

a number of screw heads requiring different types of turn-

ing tools. See Chapter Two for detailed information.

Bolts

Commonly called bolts, the technical name for these

fasteners is cap screw. They are normally described by di-

ameter, threads per inch and length. For example, 1/4-20 ×

1 indicates a bolt that is 1/4 in. in diameter with 20 threads

per inch, and is 1 in. long. The measurement across two

flats on the head of the bolt indicates the proper wrench

size to use.

2 CHAPTER ONE

GENERAL INFORMATION 3

1

1

As the piston travels

downward, it uncovers the

exhaust port (A) allowing the

exhaust gases to leave the

cylinder. A fresh air-fuel

charge, which has been

compressed slightly in the

crankcase, enters the cylinder

through the transfer port (B).

Since this charge enters under

pressure, it also helps to push

out the exhaust gases.

As the piston travels down,

the exhaust gases leave the

cylinder and the complete

cycle starts all over again.

As the piston almost reaches

the top of the travel, the spark

plug fires, igniting the

compressed air-fuel mixture.

The piston continues to top

dead center (TDC) and is

pushed downward by the

expanding gases.

While the crankshaft

continues to rotate, the piston

moves upward, covering the

transfer (B) and exhaust (A)

ports. The piston compresses

the new air-fuel mixture and

creates a low-pressure area in

the crankcase at the same

time. As the piston continues

to travel, it uncovers the

intake port (C). A fresh air-fuel

charge from the carburetor (D)

is drawn into the crankcase

Spark

plug

TWO-STROKE OPERATING PRINCIPLES

(EXCEPT OPTIMAX MODELS)

4 CHAPTER ONE

2

TWO-STROKE OPERATING PRINCIPLES

OPTIMAX MODELS (DIRECT INJECTION)

As the piston travels downward, it uncovers the exhaust

port (A) allowing the exhaust gases to leave the cylinder.

A fresh air-oil charge, which has been compressed

slightly in the crankcase, enters the cylinder through the

transfer port (B). Since this charge enters under

pressure, it also helps to push out the exhaust gases.

As the piston travels down, the exhaust gases leave the

cylinder and the complete cycle starts all over again.

As the piston almost reaches the top of its travel, the

spark plug fires, igniting the compressed air-fuel

mixture. The piston continues to top dead center (TDC)

and is pushed downward by the expanding gases.

While the crankshaft continues to rotate, the piston

moves upward, covering the transfer (B) and exhaust

ports (A). The piston compresses the fresh air charge

and creates a low-pressure area in the crankcase. A

computer controlled electronic pump delivers a precise

amount of oil into the crankcase through a dedicated

passage (D). The fresh air-oil charge is drawn into the

crankcase through the intake opening (C). Further

upward movement of the piston closes the transfer port

(B) and exhaust port (A). After both ports close, the

computer controlled direct injector sprays the required

amount of fuel into the combustion chamber.

Spark plug

Direct injector

GENERAL INFORMATION 5

1

3 4

1.in.

(TPI)

Diameter

American Metric

60°

60°

5

MACHINE SCREWS

Flat Hex Oval Filister Round

6

OPENINGS FOR TURNING TOOLS

Slotted Phillips Allen Internal torx External torx

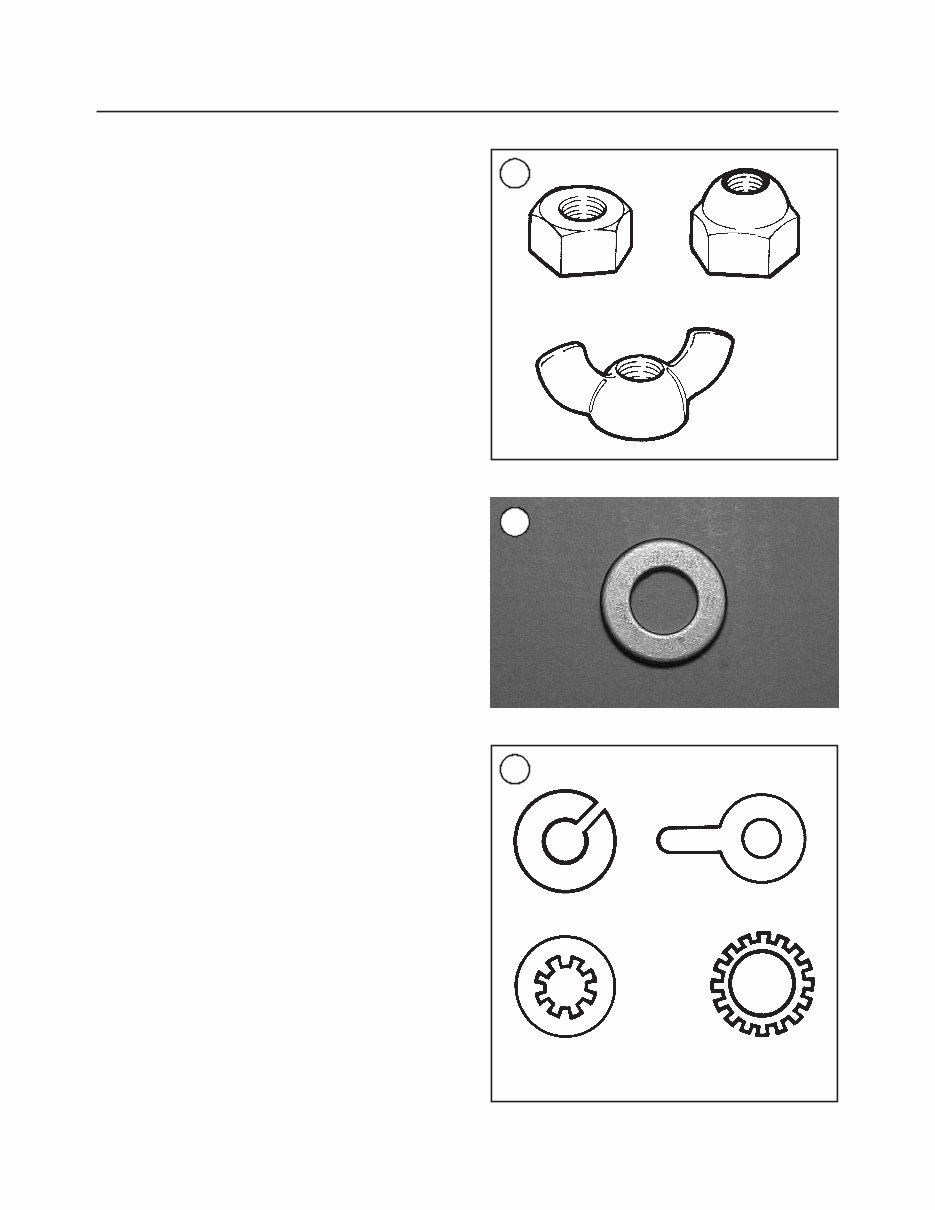

Nuts

Nuts are manufactured in a variety of types and sizes.

Most are hexagonal (six-sided) and fit on bolts, screws

and studs with the same diameter and threads per inch.

Figure 7 shows several types of nuts. The common nut

is usually used with some type of lockwasher.

Self-locking nuts have a nylon insert that helps prevent

the nut from loosening; no lockwasher is required. Wing

nuts are designed for fast removal by hand. Wing nuts are

used for convenience in non-critical locations.

To indicate the size of a nut, manufacturers specify the

diameter of the opening and the threads per inch. This is

similar to a bolt specification, but without the length di-

mension. The measurement across two flats on the nut in-

dicates the wrench size to use.

Washers

There are two basic types of washers: flat washers and

lockwashers. Flat washers (Figure 8) are simple discs

with a hole that fits the screw or bolt. Lockwashers are de-

signed to prevent a fastener from working loose due to vi-

bration, expansion and contraction. Figure 9 shows

several types of lockwashers. Flat washers are often used

between a lockwasher and a fastener to provide a smooth

bearing surface. This allows the fastener to be turned eas-

ily with a tool.

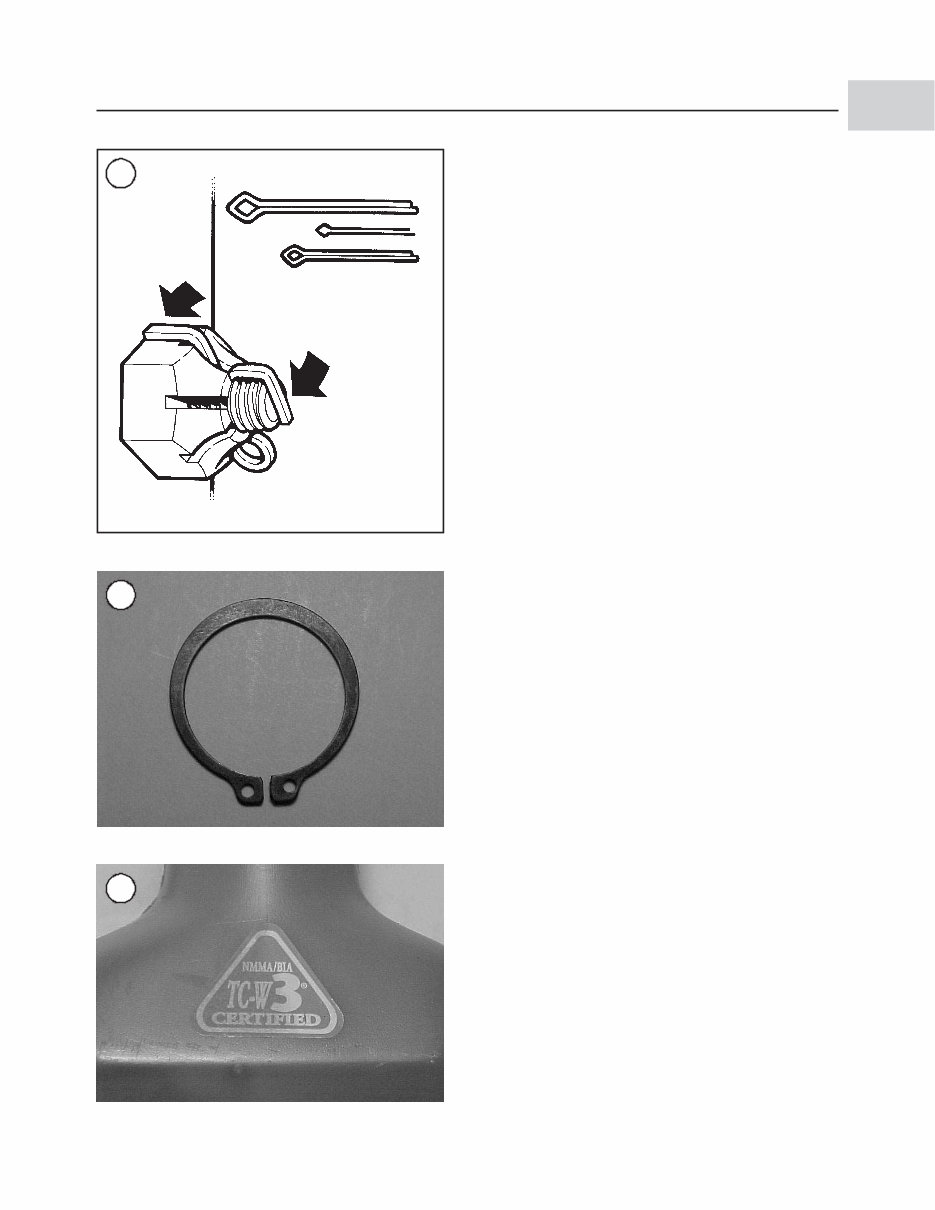

Cotter Pins

Cotter pins (Figure 10) are used to secure special kinds

of fasteners. The threaded stud, bolt or shaft has a hole for

the cotter pin; the nut or nut lock piece has projections for

the cotter pin. This type of nut is called a castellated nut.

Always replace the cotter pin if it is removed.

Snap Rings

Snap rings (Figure 11) can be an internal or external de-

sign. They are used to retain components on shafts (exter-

nal type) or within openings (internal type). Snap rings

can be reused if they are not distorted during removal. In

some applications, snap rings of varying thickness can be

selected to position or control end play of parts assem-

blies.

LUBRICANTS

Periodic lubrication ensures long service life for any

type of equipment. It is especially important with marine

6 CHAPTER ONE

7

Common nut

Self-locking nut

Wing nut

8

9

Internal tooth

Plain

Folding

External tooth

equipment because of exposure to salt, brackish or pol-

luted water and other harsh environments. The type of lu-

bricant used is just as important as the lubrication service

itself; although, in an emergency, the wrong type of lubri-

cant is better than none at all. The following sections de-

scribe the types of lubricants most often used on marine

equipment. Follow the equipment manufacturer’s recom-

mendations for the lubricant types.

Generally, all liquid lubricants are called oil. They may

be mineral-based (including petroleum bases), natu-

ral-based (vegetable and animal bases), synthetic-based

or emulsions (mixtures). Grease is an oil thickened with

additives, and maybe enhanced with anticorrosion, anti-

oxidant and extreme pressure (EP) additives. Grease is of-

ten classified by the type of thickener added; lithium and

calcium soap are the most commonly used.

Two-stroke Engine Oil

Lubrication for a two-stroke engine is provided by oil

mixed into the incoming air or air-fuel mixture. Some of

the oil mist settles in the crankcase, lubricating the crank-

shaft, bearings and lower end of the connecting rod. The

rest of the oil enters the combustion chamber to lubricate

the piston, rings and the cylinder wall. This oil is then

burned with the air-fuel mixture during the combustion

process.

Engine oil must have several special qualities to work

well in a two-stroke engine. It must mix easily and stay in

suspension with gasoline. When burned, it cannot leave

behind excessive deposits. It must also withstand the high

operating temperatures associated with two-stroke en-

gines.

The National Marine Manufacturer’s Association

(NMMA) has set standards for oil used in two-stroke, wa-

ter-cooled engines (TC-W). This is the NMMA TC-W

grade (Figure 12). It indicates the oil’s performance in the

following areas:

1. Lubrication (prevention of wear and scuffing).

2. Spark plug fouling.

3. Piston ring sticking.

4. Preignition.

5. Piston varnish.

6. General engine condition (including deposits).

7. Exhaust port blockage.

8. Rust prevention.

9. Mixing ability with gasoline.

In addition to oil grade, manufacturers specify the ratio

of gasoline to oil required during break-in and normal en-

gine operation.

GENERAL INFORMATION 7

1

10

Correct installation

of cotter pin

11

12

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 91 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

- The 1998-2005 Mercury Mariner 75HP 2-Stroke Outboard Service & Repair Manual is a comprehensive resource for fixing outboard problems, providing troubleshooting and replacement procedures recommended by the manufacturer.

- It includes step-by-step instructions, clear images, and exploded-view illustrations, making it useful for both professional mechanics and DIY enthusiasts.

- Regular maintenance is essential for outboard longevity, and this manual offers the manufacturer's recommended troubleshooting charts and replacement procedures to ensure proper maintenance.

- Having this manual on hand can help save on repairs, increase outboard reliability, and prevent issues, making it a valuable resource for outboard owners.

- This is not a generic repair manual but the OEM manual used by professional technicians, ensuring accuracy and reliability.

- It eliminates the hassle of searching through numerous pages and offers the convenience of digital access, allowing easy searching, bookmarking, and even printing if desired.

- It is printable and available in English, compatible with various electronic devices including PC, Mac, Android, and Apple devices, requiring only Adobe Reader (free) for access.