Mercury Mariner Outboard 2.2 2.5 3 3.3 HP 2-stroke Factory Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

MODELS

2.5 3.3 2.2 3.0

90-44477--1 1192 Printed in U.S.A.

1992, Brunswick Corporation

!

90-44477--1 1192

Notice

Throughout this publication, “Dangers”, “Warnings” and

“Cautions” (accompanied by the International HAZARD

Symbol ) are used to alert the mechanic to special in-

structions concerning a particular service or operation that

may be hazardous if performed incorrectly or carelessly.

OBSERVE THEM CAREFULLY!

These “Safety Alerts” alone cannot eliminate the hazards

that they signal. Strict compliance to these special instruc-

tions when performing the service, plus “Common Sense”

operation, are major accident prevention measures.

! DANGER

DANGER - Immediate hazards which WILL result in se-

vere personal injury or death.

! WARNING

WARNING - Hazards or unsafe practices which COULD

result in severe personal injury or death.

! CAUTION

Hazards or unsafe practices which could result in mi-

nor personal injury or product or property damage.

Notice to Users of This

Manual

This service manual has been written and published by the

service department of Mercury Marine to aid our dealers’

mechanics and company service personnel when servic-

ing the products described herein.

It is assumed that these personnel are familiar with the

servicing procedures of these products, or like or similar

products manufactured and marketed by Mercury Marine,

that they have been trained ing the recommended servic-

ing procedures of these products which includes the use of

mechanics’ common hand tools and the special Mercury

Marine or recommended tools from other suppliers.

We could not possibly know of and advise the service trade

of all conceivable procedures by which a service might be

performed and of the possible hazards and/or results of

each method. We have not undertaken any such wide eval-

uation. Therefore, anyone who uses a service procedure

and/or tool, which is not recommended by the manufactur-

er, first must completely satisfy himself that neither his nor

the products safety will be endangered by the service pro-

cedure selected.

All information, illustrations and specifications contained in

this manual are based on the latest product information

available at the time of publication. As required, revisions

to this manual will be sent to all dealers contracted by us

to sell and/or service these products.

It should be kept in mind, while working on the product, that

the electrical system and ignition system is capable of vio-

lent and damaging short circuits or severe electrical

shocks. When performing any work where electrical termi-

nals could possibly be grounded or touched by the me-

chanic, the battery cables should be disconnected at the

battery.

Any time the intake or exhaust openings are exposed dur-

ing service they should be covered to protect against acci-

dental entrance of foreign material which could enter the

cylinders and cause extensive internal damage when the

engine is started.

It is important to note, during any maintenance procedure

replacement fasteners must have the same measure-

ments and strength as those removed. Numbers on the

heads of the metric bolts and on the surfaces of metric nuts

indicate their strength. Customary bolts use radial lines for

this purpose, while most customary nuts do not have

strength markings. Mismatched or incorrect fasteners can

result in damage or malfunction, or possibly personal inju-

ry. Therefore, fasteners removed should be saved for re-

use in the same locations whenever possible. Where the

fasteners are not satisfactory for re-use, care should be

taken to select a replacement that matches the original.

90-44477--1 1192

Cleanliness and Care of

Outboard Motor

A marine power product is a combination of many ma-

chined, honed, polished and lapped surfaces with toler-

ances that are measured in the ten thousands of an inch.

When any product component is serviced, care and clean-

liness are important. Throughout this manual, it should be

understood that proper cleaning, and protection of ma-

chined surfaces and friction areas is a part of the repair pro-

cedure. This is considered standard shop practice even if

not specifically stated.

Whenever components are removed for service, they

should be retained in order. At the time of installation, they

should be installed in the same locations and with the same

mating surfaces as when removed.

Before raising or removing and outboard engine from a

boat, the following precautions should be adhered to:

(1) Check that flywheel is secured to end of crankshaft with

a locknut and lifting eye is threaded into flywheel a mini-

mum of 5 turns.

(2) Connect a hoist of suitable strength to the lifting eye.

In addition, personnel should not work on or under an out-

board which is suspended. Outboards should be attached

to work stands, or lowered to ground as soon as possible.

We reserve the right to make changes to this manual with-

out prior notification.

Refer to dealer service bulletins for other pertinent informa-

tion concerning the products described in this manual.

Service Manual Outline

Section 1 - General Information & Specifications

Section 2 - Electrical & Ignition

Section 3 - Fuel System & Carburetion

Section 4 - Powerhead

Section 5 - Mid-Section

Section 5A - Gear Housing (Non-Shifting)

Section 5B - Gear Housing (Shiftable-F/N)

Section 6 - Rewind Starter Assembly

1

50966

GENERAL INFORMATION

AND SPECIFICATIONS

90-44477--1 1192

Table of Contents

Page

Motors Parts Identification 1-1 . . . . . . . . . . . . . . . . . . . . . . .

General Specifications 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . .

Dimensions 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powerhead 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel System 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition System 1-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Housing 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mid-Section 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Specifications 1-3 . . . . . . . . . . . . . . . . . . . . . . . .

Powerhead 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Bolts and Nuts 1-3 . . . . . . . . . . . . . . . . . . .

Outboard Installation 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transom Height 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mounting Outboard on Transom 1-4 . . . . . . . . . . . . . . .

Fuel Recommendations 1-4 . . . . . . . . . . . . . . . . . . . . . . . . .

Gasoline Recommendations 1-4 . . . . . . . . . . . . . . . . . .

Oil Recommendations 1-4 . . . . . . . . . . . . . . . . . . . . . . .

Fuel Mixture 1-4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Correct Fuel Mixing Procedure 1-4 . . . . . . . . . . . . . . .

Tilt Angle Adjustment 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments and Maintenance 1-5 . . . . . . . . . . . . . . . . . . .

Cowl Removal and Installation 1-5 . . . . . . . . . . . . . . . .

Model 2.2 1-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Models 2.5/3.0 (1990) 1-6 . . . . . . . . . . . . . . . . . . . . .

Models 2.5/3.0/3.3 (1991 and later) 1-6 . . . . . . . . .

Throttle Lever Friction Adjustment 1-6 . . . . . . . . . . . . .

Idle Speed Adjustment 1-6 . . . . . . . . . . . . . . . . . . . . . . .

Servicing Spark Plug 1-7 . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Housing Lubrication 1-7 . . . . . . . . . . . . . . . . . . . .

Propeller and Drive Pin 1-8 . . . . . . . . . . . . . . . . . . . . . . .

Removal 1-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 1-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Points of Lubrication - All Models 1-8 . . . . . . . . . . . . . .

Periodic Inspection 1-9 . . . . . . . . . . . . . . . . . . . . . . . . . .

Flushing Outboard 1-9 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zinc Anode 1-9 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Following Complete Submersion 1-10 . . . . . . . . . . . . .

Salt Water Submersion

(Special Instructions) 1-10 . . . . . . . . . . . . . . . . .

Submerged While Running

(Special Instructions) 1-10 . . . . . . . . . . . . . . . . .

Fresh Water Submersion

(Special Instructions) 1-10 . . . . . . . . . . . . . . . . .

Out-of-Season Outboard Storage 1-10 . . . . . . . . . . . . . . .

How Weather Affects Engine Performance 1-11 . . . . . . .

Conditions Affecting Operation 1-11 . . . . . . . . . . . . . . . . . .

Detonation: Causes and Prevention 1-12 . . . . . . . . . . . . .

Compression Check 1-12 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller Chart 1-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Serial Number Location 1-13 . . . . . . . . . . . . . . . . . . . . . . . .

50649

1 - Air Vent Knob

2 - Fuel Tank Cap

3 - Cowl

4 - Cowl Latch (Model 2.5/3.0/3.3)

5 - Fuel Cock Knob

6 - Spark Plug Access Door

7 - “Tell-Tale” Outlet

8 - Driveshaft Housing

9 - Exhaust Relief Outlet

10- Anti-Ventilation Plate

11- Exhaust Outlet

12- Anodic Plate

13- Cotter Pin

14- Propeller

15- Skeg

16- Starter Handle

17- Control Panel

18- Tiller Handle

19- Lift Handle

20- Tilt Lock Pin

21- Clamp Screw (2)

22- Clamp Bracket (2)

23- Tilt Angle Adjustment Pin

24- OIL LEVEL Plug

25- Cooling Water Intake

26- Gear Housing

27- OIL FILL Plug

GENERAL INFORMATION and SPECIFICATIONS - 1-1 90-44477--1 1192

Motors Parts Identification

1-2 - GENERAL INFORMATION and SPECIFICATIONS 90-44477--1 1192

General Specifications

NOTE: Other specifications (torque, etc) are listed in the

respective sections.

Dimensions

Overall Length w/Tiller Handle 23-1/4 in.(591mm) . . . . .

Overall Width 8-1/2 in.(215mm) . . . . . . . . . . . . . . . . . . . . .

Overall Height (Short Shaft) 38 in. (965mm) . . . . . . . . . .

Recommended Boat Transom Height 15 in. (381mm) . .

Weight (Short Shaft) 27.5 lb. (12.5kgs) . . . . . . . . . . . . . .

Powerhead

Horsepower (Model 2.2) 2.2 @ 5000 RPM . . . . . . . . . . .

Kilowatts* 1.6 @ 5000 RPM . . . . . . . . . . . . . . . . . . . .

Horsepower (Model 2.5) 2.5 @ 5000 RPM . . . . . . . . . . .

Kilowatts* 1.9 @ 5000 RPM . . . . . . . . . . . . . . . . . . . .

Horsepower (Model 3.0) 3.0 @ 5000 RPM . . . . . . . . . . .

Kilowatts* 2.2 @ 5000 RPM . . . . . . . . . . . . . . . . . . . .

Horsepower (Model 3.3) 3.3 @ 5000 RPM . . . . . . . . . . .

Kilowatts* 2.5 @ 5000 RPM . . . . . . . . . . . . . . . . . . . .

RPM Range at Full Throttle

Model 2.2 4200 - 5200 . . . . . . . . . . . . . . . . . . . . . . . . .

Model 2.5 4000 - 5000 . . . . . . . . . . . . . . . . . . . . . . . . .

Model 3.0 4500 - 5500 . . . . . . . . . . . . . . . . . . . . . . . . .

Model 3.3 4500 - 5500 . . . . . . . . . . . . . . . . . . . . . . . . .

Type Two-Stroke Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Number of Cylinders 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Displacement 4.6 cu. in. (74.6cc) . . . . . . . . . . . . . . . . . . . .

Bore 1.85 in. (47mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dia. 0.5mm Oversized 1.869 in. (47.5mm) . . . . . . . .

Out of Round (Max.) 0.002 in. (0.05mm) . . . . . . . . .

Taper (Max.) 0.002 in. (0.05mm) . . . . . . . . . . . . . . . .

Crankshaft

Runout (Max.) 0.001 in. (0.05mm) . . . . . . . . . . . . . . .

Connecting Rod Deflection 0.022 in. to 0.056 in. . . .

(0.6mm to 1.5mm)

Stroke 1.69 in. (43mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intake System Reed Valve . . . . . . . . . . . . . . . . . . . . . . . . .

Reed Block

Reed Stop Opening 0.236 in. to 0.244 in. . . . . . . . . .

(6mm to 6.2mm)

Scavenging System Loop Charge . . . . . . . . . . . . . . . . . .

Exhaust System T . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

hru-Prop

Lubrication System Pre-Mixed Gasoline and Oil . . . . . .

Cooling System Water-Cooled . . . . . . . . . . . . . . . . . . . . . .

Starting System Manual Start . . . . . . . . . . . . . . . . . . . . . .

*Measured at the propeller shaft in accordance with ICOMIA 28

Fuel System

Carburetor Center Bowl Gravity Feed . . . . . . . . . . . . . . .

Float Level (All Models) 0.090 in. (from gasket) . . . . . . .

(2.0mm) Ref. Section 3

Main Jet (Model 2.2) #96 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Jet (Model 2.5) #92 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Jet (Model 3.0) #92 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Jet (Model 3.3) #94 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Idle RPM 900 - 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pre-Mixed Gasoline and Oil . . . . . . . . . . . . . . . . . . . .

Recommended Gasoline Automotive Leaded or . . . . . . .

Lead-Free Gasoline

Recommended Oil Quicksilver 2-Cycle . . . . . . . . . . . . . .

Outboard Oil

Gasoline/Oil Ratio 50:1 (Including Break-In) . . . . . . . . . . .

Integral Fuel Tank Capacity

U.S. Gallons 0.375 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Imperial Gallons 0.3 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Liters 1.4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition System

Ignition Type (Models 2.0/2.5/3.0) Flywheel Magneto . .

Spark Plug (All Models) NGK BPR6HS-10 . . . . . . . . . . .

or Champion RL87YC

Spark Plug Gap 0.040 in. (1.0mm) . . . . . . . . . . . . . . . . . .

Breaker Point Gap 0.012 - 0.016 in. . . . . . . . . . . . . . . . . . . .

(0.3mm - 0.4mm)

Primary Ignition Coil Test 1.5 Ohms . . . . . . . . . . . . . . . . . .

Condenser Capacity 0.22mF - 0.28mF . . . . . . . . . . . . . . .

Secondary Ignition Coil Test

Primary Winding Resistance 0.81 - 1.09 Ohms . . . .

Secondary Winding Resistance 4250 - 5750 Ohms . .

Ignition Type [1993 Models (2.5/3.3)] Capacitor . . . . . . .

Discharge

Test Specifications Refer to DVA Chart . . . . . . . . . . . . . . .

GENERAL INFORMATION and SPECIFICATIONS - 1-3 90-44477--1 1192

Gear Housing

Gear Ratio (Model 2.2) 1.85:1 . . . . . . . . . . . . . . . . . . . . . .

Gear Ratio (Models 2.5/3.0/ 3.3) 2.18:1 . . . . . . . . . . . . .

Gear Type Spiral Bevel . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Type Sliding Dog . . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller Drive System Drive (Shear) Pin . . . . . . . . . . . . .

Lubricant

Type Quicksilver Gear Lube . . . . . . . . . . . . . . . . . . .

Capacity 3 oz. (90ml) . . . . . . . . . . . . . . . . . . . . . . . . . .

Mid-Section

Steering Angle 360° . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tilt Pin Positions 4 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Full Tilt-Up Angle 75° . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Allowable Transom Thickness 1.18 in. - 2.165 in. . . . . .

(30mm - 55mm)

Torque Specifications

1. All torque values are for clean, dry, corrosion free

threads, except where locking compounds are speci-

fied. Refer to appropriate section of this manual.

2. Cover and housing screws MUST BE torqued by tight-

ening in 3 progressive steps (following specified

torque sequence) until specified torque is reached.

Refer to appropriate section of this manual.

3. When retightening powerhead and gear housing

mounting bolts, first back them out one turn, and then

retorque to specification.

4. To retighten spark plug, start engine and warm-up to

operating temperature. Stop engine and allow to cool,

then retorque plug to specification.

5. Propeller MUST BE secured with cotter pin.

Powerhead

Flywheel Nut 30 lb. ft. (4.1 N·m) . . . . . . . . . . . . . . . . . . . . .

Crankcase Cover to

Cylinder Block Bolts 50 lb. in. (5.6 N·m) . . . . . . . . . . . .

Cylinder Head Bolts 85 lb. in. (9.6 N·m) . . . . . . . . . . . . . . .

Spark Plug 20 lb. ft. (27.1 N·m) . . . . . . . . . . . . . . . . . . . . . .

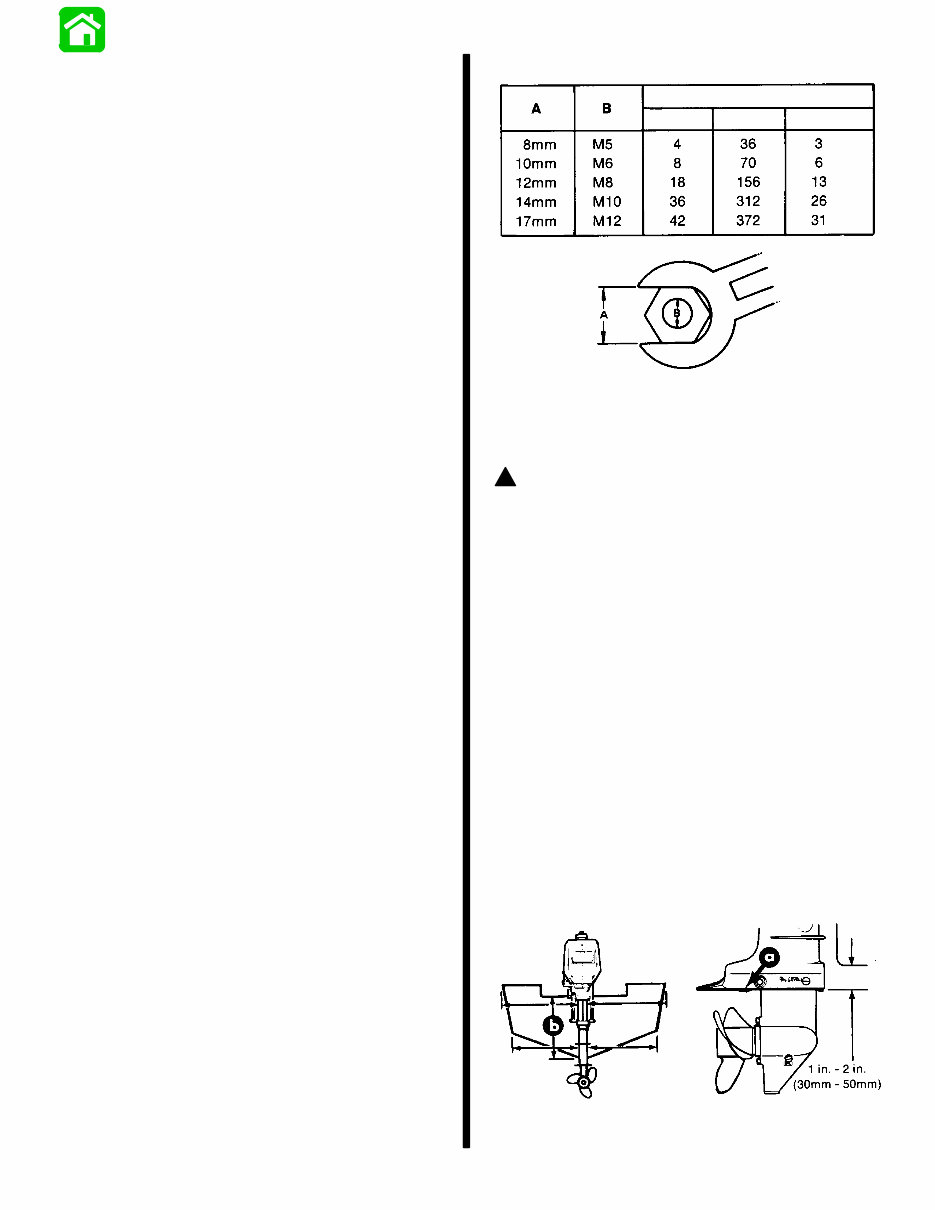

STANDARD BOLTS AND NUTS

TORQUE SPECIFICATION

N·M LB. FT. LB. IN.

Outboard Installation

! WARNING

DO NOT OVERPOWER - Most boats are rated and certi-

fied for the maximum horsepower capabilities of the

boat. Refer to the boat “Certification Plate” for the

maximum horsepower limit. If in doubt, contact your

dealer.

Transom Height

1. This outboard is designed to provide optimum per-

formance when mounted at the recommended tran-

som height. If the transom is too high, the propeller

may operate too close to the water surface introducing

air over the propeller blades, causing a lost of thrust

(particularly when attempting to plane off or during a

turn). If the transom is too low, a performance loss is

created by excessive lower unit drag and water spray

(additionally, under clearance may also present a

problem).

2. Conventional installations generally locate the gear

housing anti-ventilation plate parallel to and approxi-

mately 1 in. - 2 in. (30mm - 50mm) below the boat bot-

tom.

50649

a - Anti-Ventilation Plate

b - Recommended Boat Transom Height - 15 in. (381mm)

1-4 - GENERAL INFORMATION and SPECIFICATIONS 90-44477--1 1192

Mounting Outboard on Transom

! WARNING

Before operating the outboard, it MUST BE PROPERLY

SECURED to the boat transom. Failure to adhere to the

outboard mounting instructions, following, may result

in loss of the outboard, damage to boat and/or out-

board and injury to occupants of the boat.

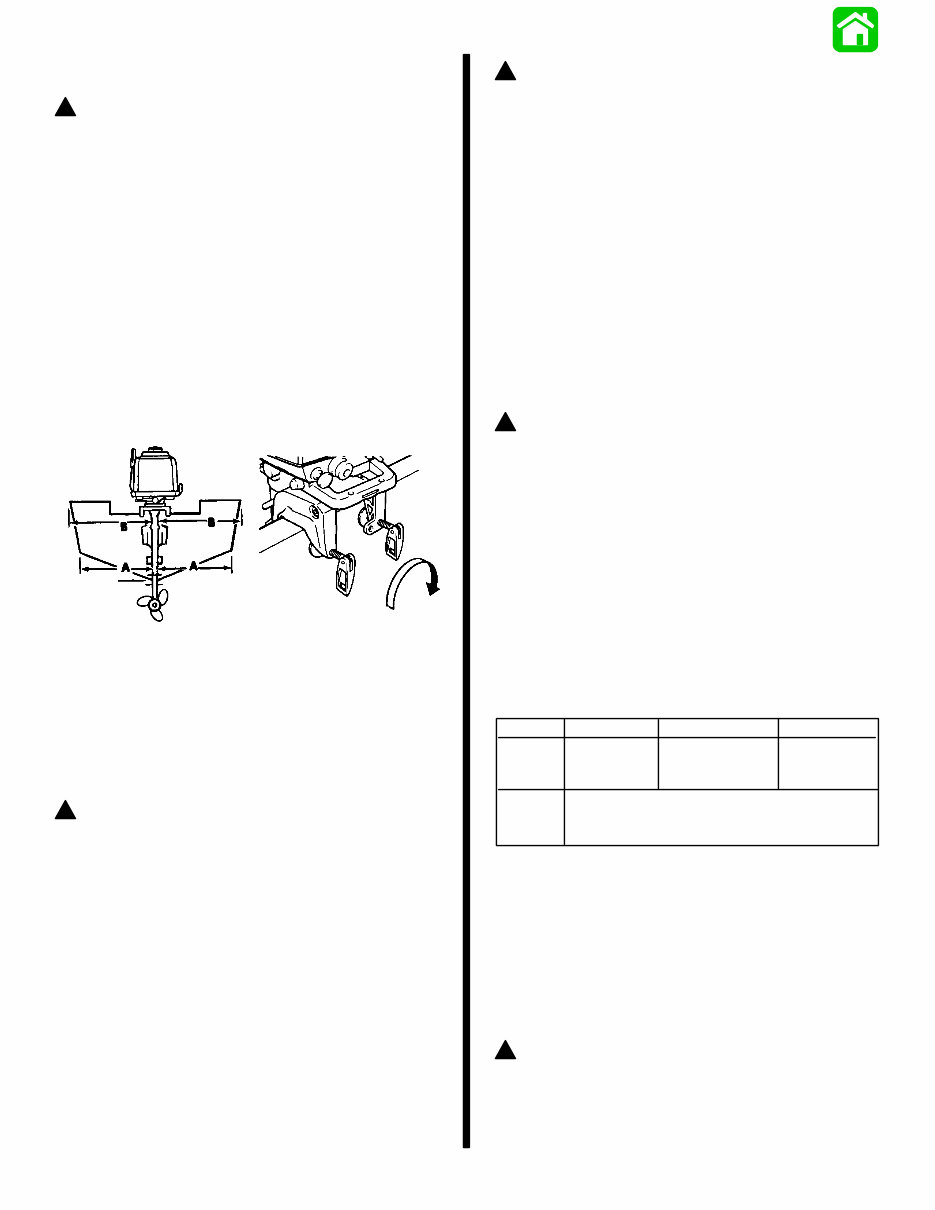

1. Center outboard on boat transom at recommended

transom height (see “Transom Height,” preceding)

and secure outboard to transom with clamp screws. To

avoid damage to transom and to prevent clamp screws

from working loose during operation, make certain that

clamp screws are tightened securely and equally.

Clamp screws should be checked for tightness periodi-

cally.

IMPORTANT: During use, a periodic check of the clamp

screws is recommended to ensure that the outboard

remains secure on the transom.

Fuel Recommendations

Gasoline Recommendations

! WARNING

Use CARE when transporting fuel container, whether

in a boat or car. DO NOT fill fuel container to maximum

capacity. Gasoline will expand considerably as it

warms up and can build up pressure in the fuel con-

tainer. This can cause fuel leakage and a potential fire

hazzard.

Any gasoline that will satisfactorily operate an automobile

engine is suitable for your outboard motor.

IMPORTANT: While the use of REGULAR LEADED gas-

oline is entirely satisfactory, LEAD FREE or LOW

LEAD regular gasolines are PREFERRED as they gen-

erally provide an “extra margin” of spark plug life.

Some fuel distributors pre-mix gasoline and oil for 2-cycle

engines. Such fuels, if known to be of of recommended

quality, are acceptable. If in doubt, check with your local

dealer.

! CAUTION

DO NOT USE white gasolines or fuels intended for

stoves and lanterns. Use of improper gasolines and/or

oils can cause serious damage to your outboard mo-

tor.

Oil Recommendations

Mix recommended gasoline with Quicksilver 2-Cycle Out-

board Oil in ratio shown in the following chart. If Quicksilver

2-Cycle Oil is not available, substitute a high quality 2-cycle

oil intended for outboard use and meets NMMA rating TC-

WII, as shown on oil container. NMMA rating TC-WII is

the Boating Industry Association’s designation for ap-

proved, 2-cycle water-cooled outboard oils. Use at oil man-

ufacturer’s recommended gasoline-oil mixture as shown

on the label. (NOT TO EXCEED 50:1 RATIO.)

! CAUTION

The use of other than recommended gasoline and

Quicksilver 2-Cycle Outboard Oil or an acceptable oil

may cause piston scoring, bearing failure or both. DO

NOT, under any circumstances, use multi-grade or oth-

er highly detergent automobile oils or oils which con-

tain metallic additives.

IMPORTANT: When checking fuel level and/or filling

the motor fuel tank ALWAYS check the fuel tank cap to

verify that the seal is properly seated inside the cap.

Tighten fuel tank cap securely.

FUEL MIXTURE

Use a 50:1 gasoline-oil ratio for “break-in” and all normal

operation of your outboard motor. (See chart, following.)

U.S. Measure Imperial Measure Metric Measure

Quicksilver

2-Cycle

Oil

16 U.S. oz. to

each 6 gallons

of gasoline

15 Imp. oz. to

each 5 Imp.

gallons gasoline

400cc to each

20 liters of

gasoline

Other

Acceptable

Oils

Use at manufacturer’s recommended gasoline/oil

ratio, not to exceed 50:1

IMPORTANT: Using less than the recommended pro-

portion of oil may result in very serious damage from

lack of sufficient lubrication. Using more than the rec-

ommendations will cause spark plug fouling, erratic

carburetion, excessive smoking and faster-than-nor-

mal carbon accumulation.

Correct Fuel Mixing Procedure

! WARNING

Observe fire prevention rules, particularly the matter

of smoking. Mix fuel outdoors or in a well-ventilated lo-

cation.

GENERAL INFORMATION and SPECIFICATIONS - 1-5 90-44477--1 1192

Mix fuel in a separate container . Measure accurately the

required amounts of oil and gasoline. Pour a small amount

of gasoline into container and add a small amount of oil

(about the same amount as gasoline). Mix thoroughly by

shaking or stirring vigorously; then add balance of oil and

gasoline, mix again and pour into fuel tank. Cleanliness is

important in mixing fuel. Be consistent; prepare each batch

of fuel exactly the same as previous amounts (to avoid

readjustment of carburetor low speed mixture screw).

IMPORTANT: Always use fresh gasoline. Gasoline

forms gum and varnish deposits and when kept in a

tank for a length of time, may cause trouble.

! WARNING

Use care to prevent spilling fuel when filling the motor

fuel tank. DO NOT OVERFILL. If tank is overfilled, fuel

may spill into the cowling and if gasoline vapors are

present, an errant spark could cause an explosion or

fire.

If fuel is spilled, remove cowling and clean up as much

of the spill as possible. Allow a minimum of 5 minutes

for ventilation/evaporation of fuel and/or vapors BE-

FORE ATTEMPTING TO START ENGINE.

Tilt Angle Adjustment

The angle of the motor can be adjusted by changing the po-

sition of the tilt angle adjustment pin in the holes provided

in the clamp brackets.

50652

a - Tilt Angle Adjustment Pin

Adjusting Tilt Angle of the Motor - 2.5/3.0

Model 2.2/3.3 - Reposition tilt screw/nut as in (a) above.

The angle of the motor is important for obtaining the best

performance of the motor. The tilt angle should be adjusted

so that the motor anti-ventilation plate is parallel to the wa-

ter surface when at full speed.

Wrong!

Bow Up

Wrong!

Bow Down

Right!

Plane or

Even Keel

Outboard Motor Angle Positions

Adjustments and

Maintenance

! WARNING

DO NOT attempt to remove or install cowl while engine

is running.

Cowl Removal and Installation

MODEL 2.2

Remove spark plug access cover. Remove 10 screws to

remove cowling. Replace 10 screws and access cover to

reinstall cowl.

MODELS 2.5/3.0 (1990)

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 17 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

The Mercury Mariner Outboard 2.2 2.5 3 3.3 HP 2-stroke Factory Service Repair Manual covers all the essential repair procedures required for maintaining your outboard motor. Whether you are a professional mechanic or a DIY enthusiast, this manual provides comprehensive guidance.

Models covered in this manual: 2.2, 2.5, 3, 3.3 HP

The service manual includes:

- General information & specifications

- Electrical & ignition

- Fuel system & carburetion

- Powerhead

- Mid-section

- Gear housing (non-shifting)

- Gear housing (shiftable F/N)

- Rewind starter assembly

This manual is available in .PDF format. To access the manual, you will need a .PDF reader. If you encounter any issues opening the manual, please feel free to reach out to us for assistance.

Obtain immediate access to the comprehensive manual by clicking the instant download button now!