2002-2004 Mercury 150/175/200 HP 2-Stroke EFI Outboards Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

6

A

RIGHT HAND NON-RATCHETING

90-883728 JULY 2001 Page 6A-1

LOWER UNIT

Section 6A – Right Hand Non-Ratcheting

Table of Contents

Gear Housing Specifications (Standard Rotation) 6A-1 .

Special Tools 6A-2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes: 6A-5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Housing (Drive Shaft)(Standard Rotation) 6A-6 . .

Gear Housing (Prop Shaft)(Standard Rotation) 6A-8 . . .

General Service Recommendations 6A-10 . . . . . . . . . . .

Removal, Disassembly, Cleaning and Inspection

– Standard Rotation 6A-11 . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A-11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Draining and Inspecting Gear Housing

Lubricant 6A-12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water Pump 6A-13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bearing Carrier and Propeller Shaft Removal 6A-16

Shift Shaft 6A-18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Propeller Shaft 6A-20 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clutch Actuator Rod 6A-22 . . . . . . . . . . . . . . . . . . . . . .

Pinion Gear and Driveshaft 6A-22 . . . . . . . . . . . . . . . .

Forward Gear 6A-25 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Housing 6A-26 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reassembly and Installation Standard Rotation 6A-26 .

Driveshaft Needle Bearing 6A-26 . . . . . . . . . . . . . . . . .

Bearing Carrier 6A-27 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Forward Gear 6A-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Forward Gear Bearing Race 6A-31 . . . . . . . . . . . . . . .

Driveshaft and Pinion Gear 6A-32 . . . . . . . . . . . . . . . .

Pinion Gear Depth/Forward Gear

Backlash/Reverse Gear Backlash 6A-34 . . . . . . . . . .

Clutch Actuator Rod 6A-38 . . . . . . . . . . . . . . . . . . . . . .

Shift Shaft Bushing 6A-38 . . . . . . . . . . . . . . . . . . . . . . .

Propeller Shaft 6A-39 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Water Pump 6A-42 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gear Lubricant Filling Instructions 6A-45 . . . . . . . . . .

Installing Gear Housing to Driveshaft Housing 6A-45

Propeller Installation 6A-47 . . . . . . . . . . . . . . . . . . . . . .

Speedometer Tube Installation 6A-48 . . . . . . . . . . . . .

Gear Housing Specifications (Standard Rotation)

Ratio Pinion Depth

Forward Gear

Backlash

Reverse Gear

Backlash

1.87:1

0.025 in. (0.635 mm) With Tool

91-12349A2 using Disc #2 and

Flat #7

0.018 in. to 0.027 in. (0.460 mm

to 0.686 mm) Pointer on line

mark #1

0.030 in. to 0.050 in.

(0.762 mm to 1.27 mm)

2.00:1

0.025 in. (0.635 mm)With Tool

91-12349A2 using Disc #2 and

Flat #7

0.015 in. to 0.022 in. (0.38 mm to

0.56 mm) Pointer on line mark #2

0.030 in. to 0.050 in.

(0.762 mm to 1.27 mm)

Gearcase Lubricant Capacity

All Ratios 22.5 fl. oz. (665.4 ml)

Gear Ratio Teeth on Pinion Gear Teeth on Forward and Reverse

Gear

1.87:1 15 28

2.00:1 12 24

RIGHT HAND NON-RATCHETING

Page 6A-2 90-883728 JULY 2001

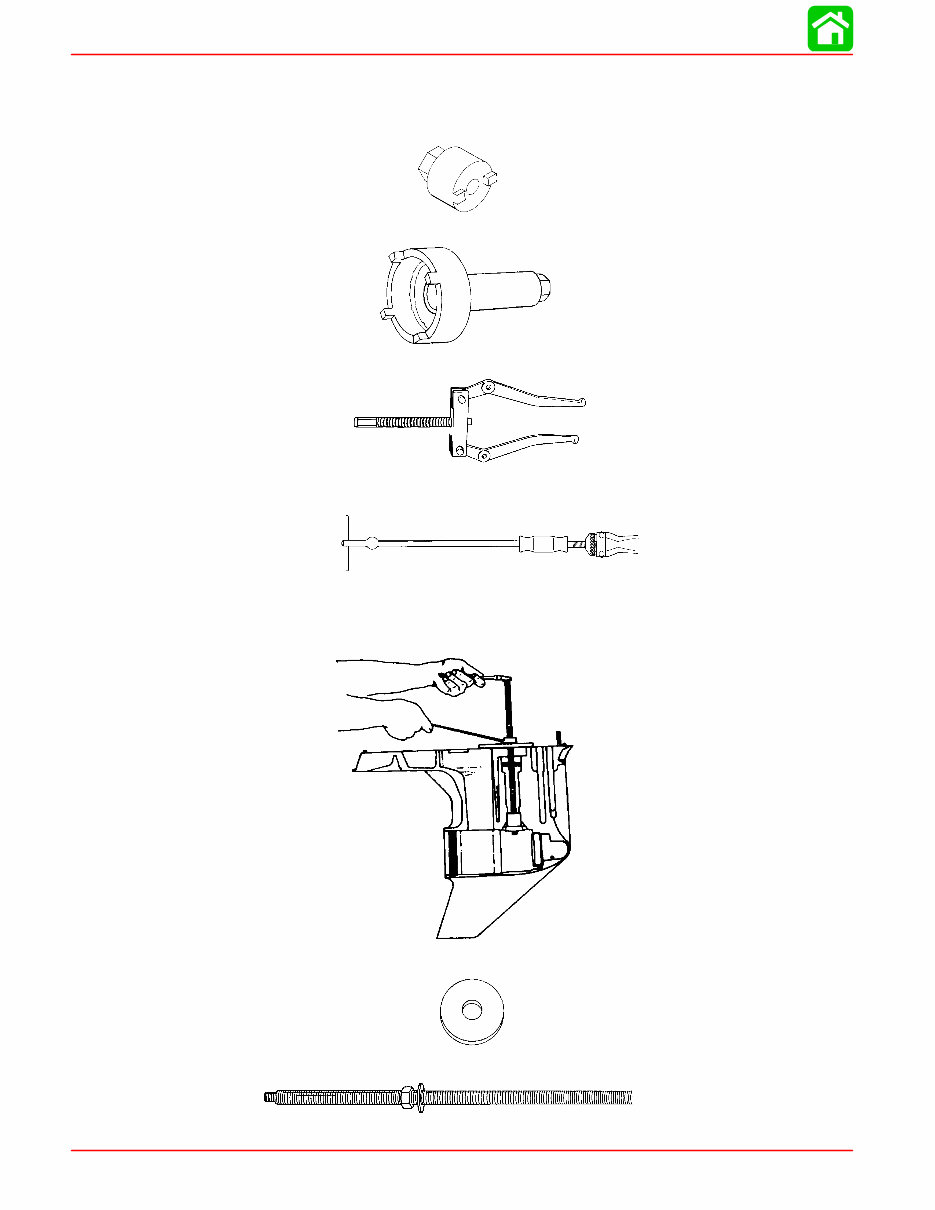

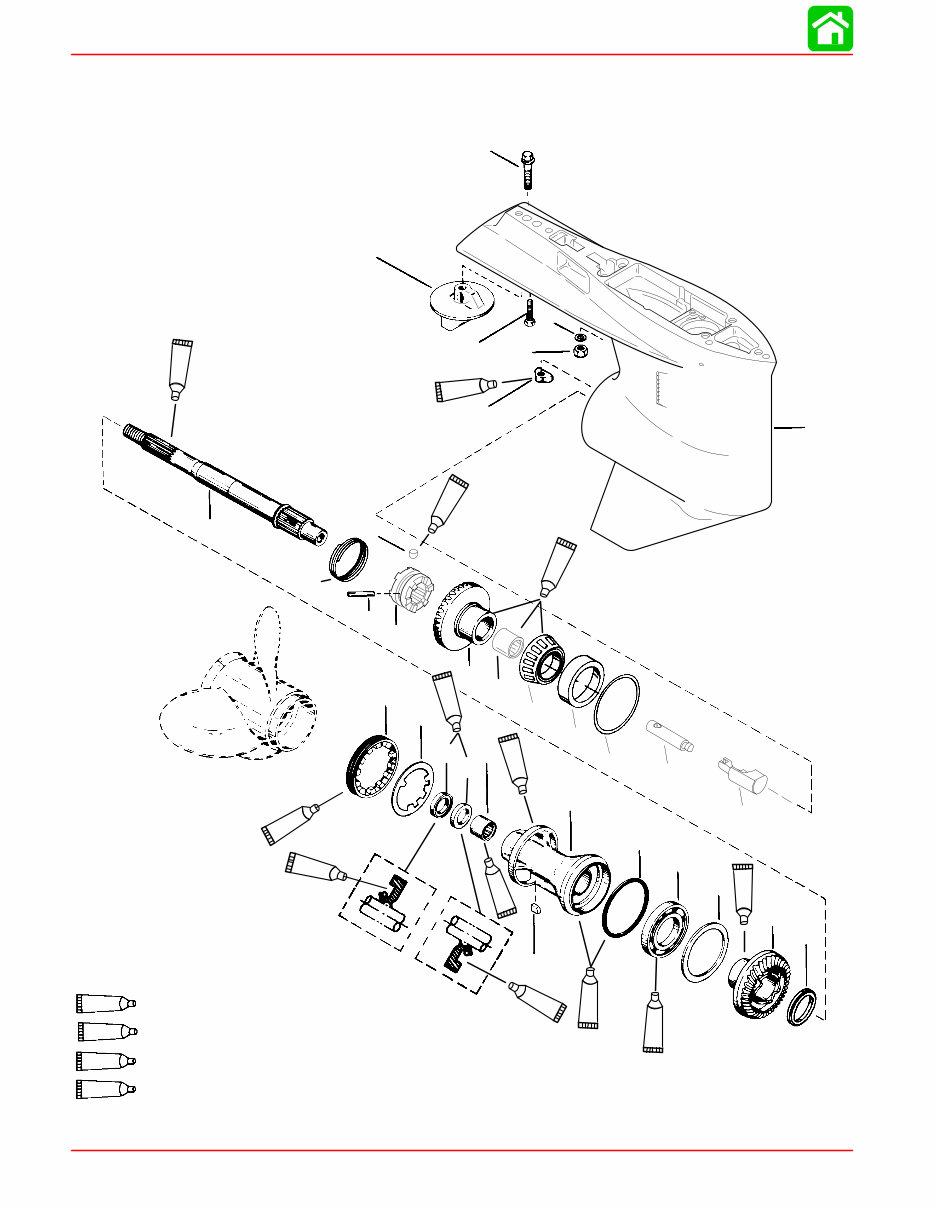

Special Tools

1. Shift Shaft Bushing Tool 91-31107T

2. Gear Housing Cover Nut Tool 91-61069T

3. Bearing Carrier Removal Tool 91-46086A1 and Puller Bolt 91-85716

4. Slide Hammer Puller 91-34569A1

5. Bearing Removal and Installation Kit 91-31229A7. This kit contains the following

tools: Pilot 91-36571T; Puller Rod 91-31229; Nut 11-24156; Puller Plate 91-29310;

Mandrel 91-38628T; and Driver Rod 91-37323.

6. Pilot 91-36571T

7. Puller Rod 91-31229 and Nut 91-24156

RIGHT HAND NON-RATCHETING

90-883728 JULY 2001 Page 6A-3

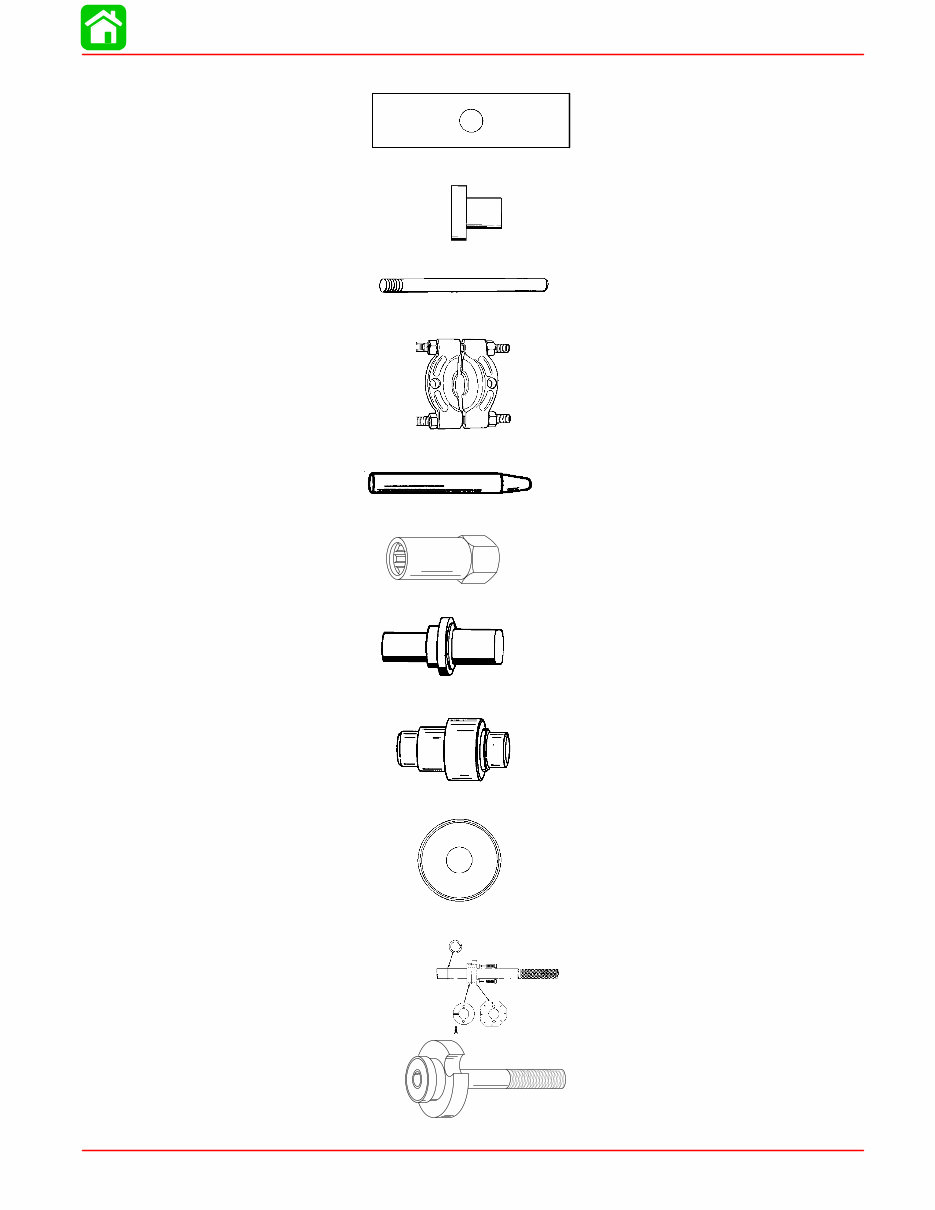

8. Puller Plate 91-29310

9. Mandrel 91-38628T

10. Driver Rod 91-37323

11. Universal Puller Plate 91-37241

12. Cross Pin Tool 91-86642

13. Driveshaft Holding Tool 91-90094

14. Oil Seal Driver 91-31108T

15. Forward Gear Bearing Tool 91-86943T

16. Bearing Driver Cup 91-31106

17. Pinion Locating Gear Tool 91-12349A2 or 91-74776T

RIGHT HAND NON-RATCHETING

Page 6A-4 90-883728 JULY 2001

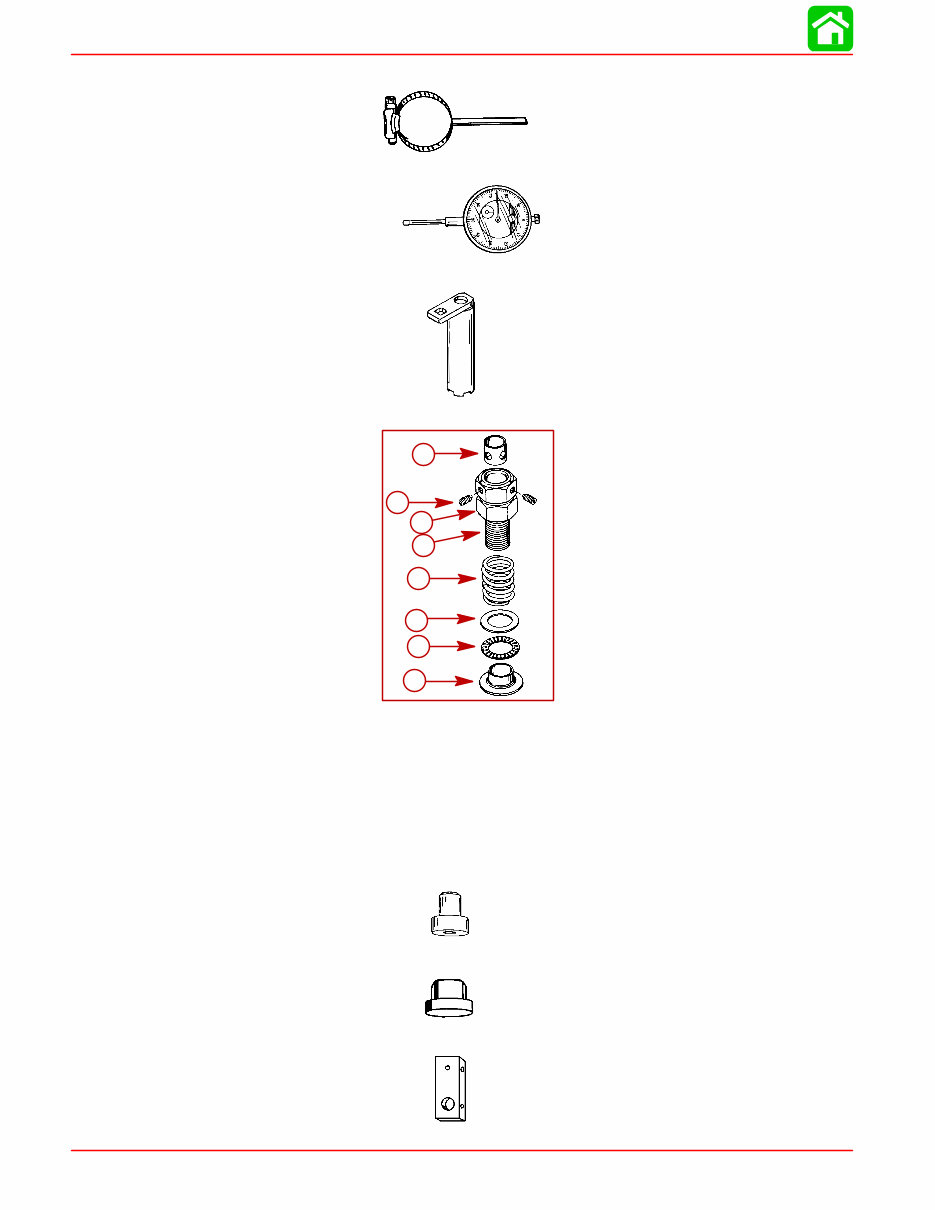

18. Backlash Indicator Rod 91-78473

19. Dial Indicator 91-58222A1

20. Bearing Retainer Tool 91-43506T

21. Bearing Preload Tool 91-14311A2

a

b

c

d

e

f

g

h

1

2

3

4

5

6

7

8

1- Adaptor (N.S.S.)

2- Bearing (N.S.S.)

3- Washer (N.S.S.)

4- Spring (24-14111)

5- Bolt (10-12580)

6- Nut (11-13953)

7- Set Screw (10-12575)

8- Sleeve (23-13946)

22. Mandrel 91-92788

23. Mandrel 91-15755

24. Dial Indicator Holder 91-89897

RIGHT HAND NON-RATCHETING

90-883728 JULY 2001 Page 6A-5

Notes:

RIGHT HAND NON-RATCHETING

Page 6A-6 90-883728 JULY 2001

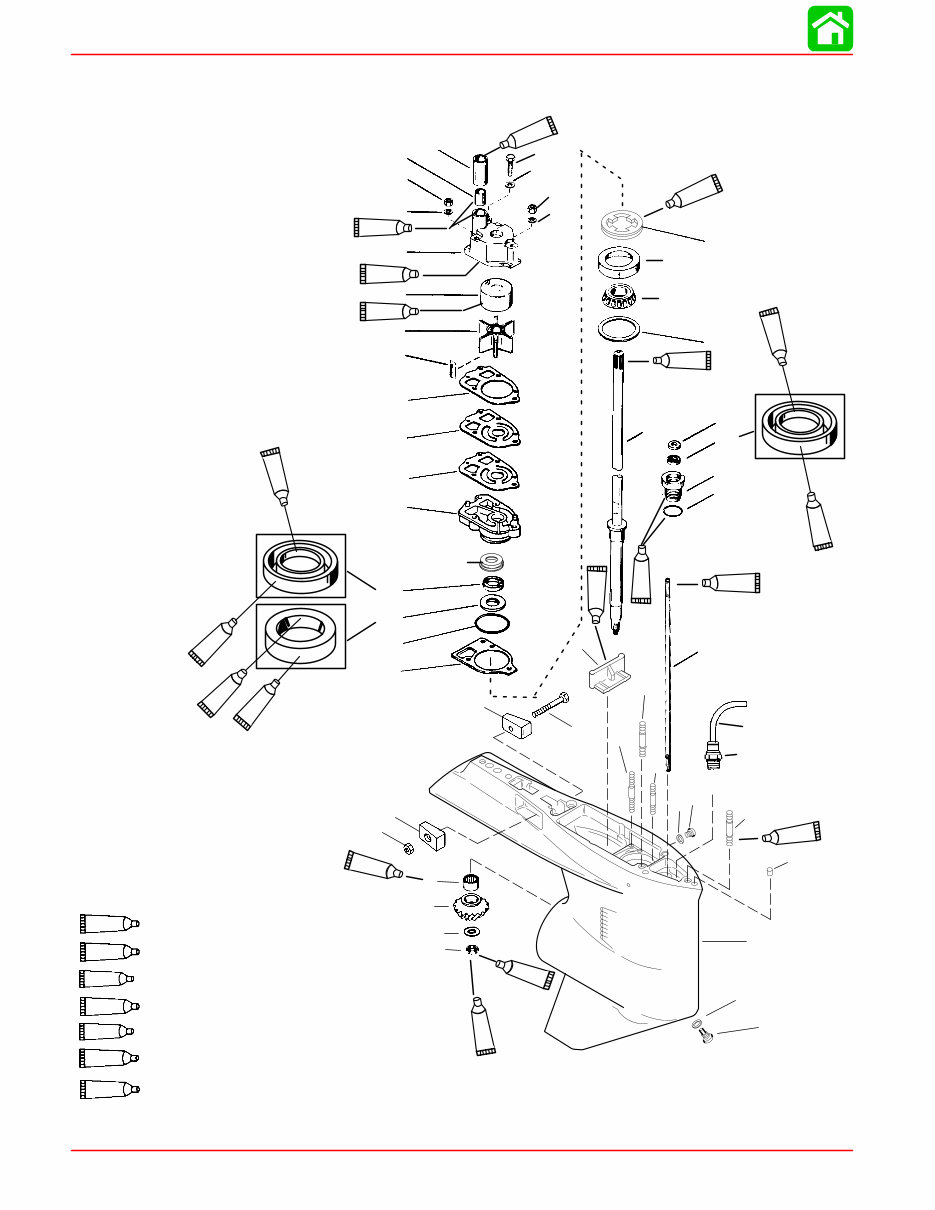

Gear Housing (Drive Shaft)(Standard Rotation)

19

1

12

2

3

4

5

6

7

9

11

14

15

16

17

18

19

20

21

22

23

24

25

26

28

29

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

10

13

9

44

27

30

Liquid Soap (Purchase Locally)

G.E. Sealer RTV #1473

23

95

95

7

95

95

95

33

7

95

95

7

95

19

95

78

23

78

8

95

4.75

IN/120.65MM

TORPEDO DIA.

18

Perfect Seal 19

7 Loctite 271

Loctite 680 33

95

2-4-C with Teflon

92

Loctite 7649 Primer

92

7

RIGHT HAND NON-RATCHETING

90-883728 JULY 2001 Page 6A-7

Gear Housing (Drive Shaft)(Standard Rotation)

REF

TORQUE

REF .

NO.

QTY. DESCRIPTION lb-in lb-ft Nm

1 1 GEAR HOUSING (BLACK)(BASIC)

2 2 DOWEL PIN

3

1 STUD (3-1/8 IN.) (LONG)

3

1 STUD (3-11/16 IN.) (X-LONG)

4 2 STUD (2-1/16 IN.)

5 1 STUD (3-3/8 IN.)

6 2 STUD (3-1/8 IN.)

7 1 FILLER BLOCK

8 1 ROLLER BEARING

9 2 ANODE

10 1 SCREW (M6 x 40)

11 1 NUT 60 7

12

1 HOSE (10 IN. - LONG)

12

1 HOSE (12 IN. - X-LONG)

13 1 FITTING

14

1 PINION GEAR (1.87:1- 15 TEETH)

14

1 PINION GEAR (2:1 - 14 TEETH))

15 1 WASHER

16 1 NUT 75 101

17 AR SHIM (006 thru 048)

18 2 SCREW–drain 60 7

19 2 WASHER

20 1 SHIFT SHAFT

21 1 O-RING

22 1 BUSHING ASSEMBLY 50 68

23 1 OIL SEAL

24 1 WASHER–rubber

25

1 DRIVE SHAFT (LONG)

25

1 DRIVE SHAFT (X-LONG)

26 1 ROLLER BEARING

27 1 CUP

28 1 RETAINER 100 135

29 1 WATER PUMP BASE

30 1 RETAINER

31 1 GASKET

32 1 O-RING

33 1 OIL SEAL

34 1 OIL SEAL

35 1 GASKET–lower

36 1 GASKET–upper

37 1 FACE PLATE

38 1 WATER PUMP BODY ASSEMBLY

39 1 INSERT

40 1 SEAL–rubber

41 1 lMPELLER

42 1 KEY

43 1 SCREW (#14-8 x 2-1/4 IN.) 35 4

44 2 WASHER

45 2 NUT 50 5.5

46 1 WASHER

47 1 NUT 50 5.5

48 1 SLEEVE

RIGHT HAND NON-RATCHETING

Page 6A-8 90-883728 JULY 2001

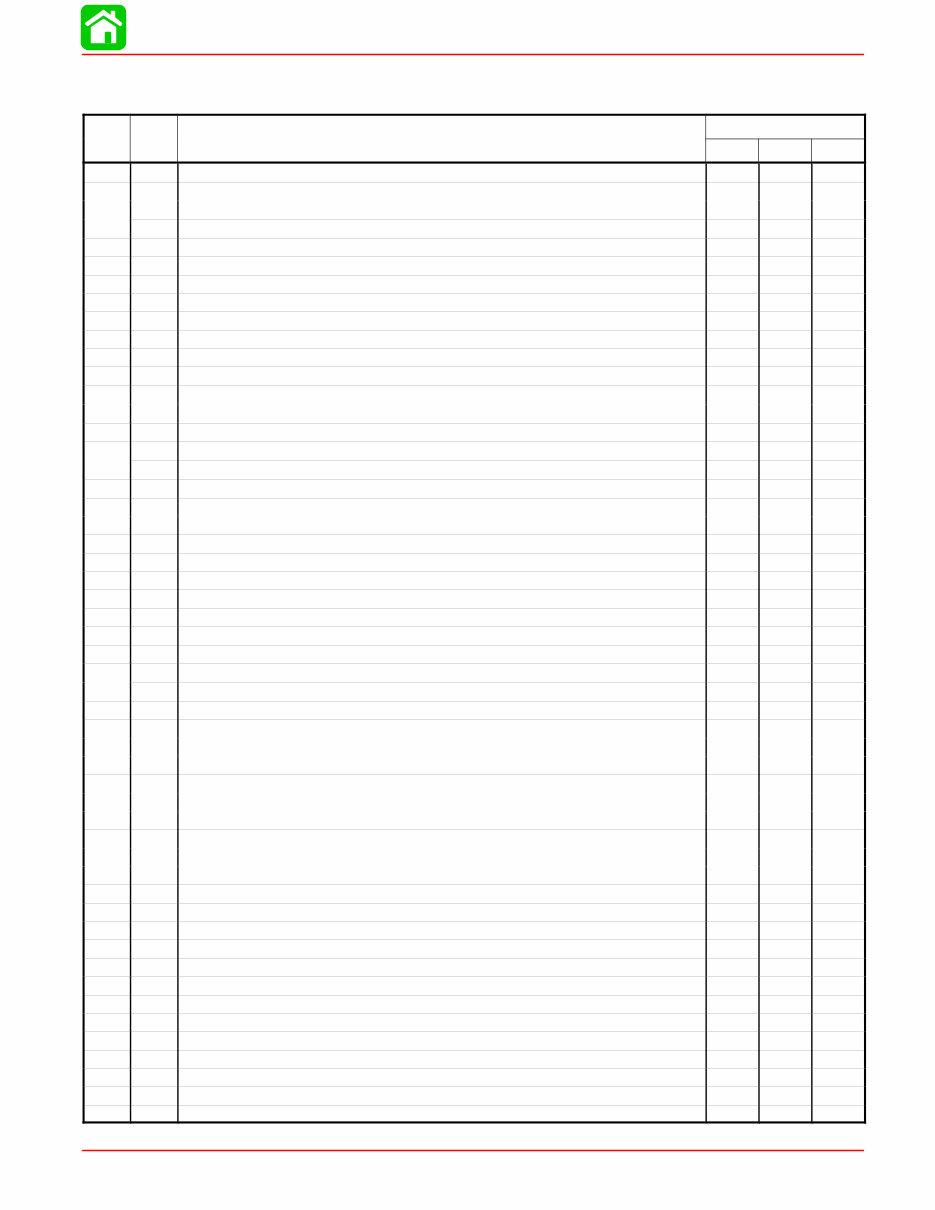

Gear Housing (Prop Shaft)(Standard Rotation)

1

49

50

51

52

53

54

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

55

95

95

87

95

95

87

87

95

95

95

87

7

94

4.75

IN/120.65MM

TORPEDO DIA.

7 Loctite 271

94 Anti-Corrosion Grease

95 2-4-C with Teflon

87 Quicksilver Gear Lubricant

RIGHT HAND NON-RATCHETING

90-883728 JULY 2001 Page 6A-9

Gear Housing (Prop Shaft)(Standard Rotation)

REF

TORQUE

REF .

NO.

QTY. DESCRIPTION lb-in lb-ft Nm

1 1 GEAR HOUSING(BASIC)

49 1 CAM FOLLOWER

50 1 SHIFT CAM

51 1 ROD

52

1 FORWARD GEAR (1.87:1 – 15/28)(150)

52

1 FORWARD GEAR (2:1 – 14/28)(115/135)

53 AR SHIM (.006 thru 050)

54 1 TAPERED ROLLER BEARING

55 1 CUP

56 1 NEEDLE BEARING

57 1 CLUTCH

58 1 CROSS PIN

59 1 DETENT PIN

60 1 SPRING

61 1 PROPELLER SHAFT

62

1 REVERSE GEAR (1.87:1 - 15/28)

62

1 REVERSE GEAR (2:1 – 14/28)

63 1 THRUST SPACER

64 1 THRUST RING

65 1 BALL BEARING

66 1 O-RING

67 1 BEARING CARRIER ASSEMBLY

68 1 ROLLER BEARING

69 1 OIL SEAL (INSIDE)

70 1 OIL SEAL (OUTSIDE)

71 1 KEY

72 1 TAB WASHER

73 1 COVER 210 285

74

1 TRIM TAB

74

1 ANODIC PLATE (TRACKER/150 LONG)

75 1 SCREW (1-3/4 IN.) 25 34

76 1 SCREW (3/8-16 x 1 IN.) 30 41

77 2 WASHER

78 2 NUT 50 68

RIGHT HAND NON-RATCHETING

Page 6A-10 90-883728 JULY 2001

General Service Recommendations

There may be more than one way to “disassemble” or “reassemble” a particular part(s),

therefore, it is recommended that the entire procedure be read prior to repair.

IMPORTANT: Read the following before attempting any repairs.

In many cases, disassembly of a sub-assembly may not be necessary until cleaning and

inspection reveals that disassembly is required for replacement of one or more compo-

nents.

Service procedure order in this section is a normal disassembly-reassembly sequence.

It is suggested that the sequence be followed without deviation to assure proper repairs.

When performing partial repairs, follow the instructions to the point where the desired

component can be replaced, then proceed to “reassembly and installation” of that compo-

nent in the reassembly part of this section. Use the “Table of Contents” (on back of section

divider) to find correct page number.

Threaded parts are right hand (RH), unless otherwise indicated.

When holding, pressing or driving is required, use soft metal vise jaw protectors or wood

for protection of parts. Use a suitable mandrel (one that will contact only the bearing race)

when pressing or driving bearings.

Whenever compressed air is used to dry a part, be sure that no water is present in air line.

BEARINGS

Upon disassembly of gear housing, all bearings must be cleaned and inspected. Clean

bearings with solvent and dry with compressed air. Air should be directed at the bearing

so that it passes thru the bearing. DO NOT spin bearing with compressed air, as this may

cause bearing to score from lack of lubrication. After cleaning, lubricate bearings with

Quicksilver Gear Lubricant. DO NOT lubricate tapered bearing cups until after inspection.

Inspect all bearings for roughness, catches and bearing race side wear. Work inner bear-

ing race in-and-out, while holding outer race, to check for side wear.

When inspecting tapered bearings, determine condition of rollers and inner bearing race

by inspecting bearing cup for pitting, scoring, grooves, uneven wear, imbedded particles

and/or discoloration from overheating. Always replace tapered bearing and race as a set.

Roller bearing condition is determined by inspecting the bearing surface of the shaft that

the roller bearing supports. Check shaft surface for pitting, scoring, grooving, imbedded

particles, uneven wear and/or discoloration from overheating. The shaft and bearing must

be replaced, if the conditions described are found.

SHIMS

Keep a record of all shim amounts and location during disassembly to aid in reassembly.

Be sure to follow shimming instructions during reassembly, as gears must be installed to

correct depth and have the correct amount of backlash to avoid noisy operation and pre-

mature gear failure.

SEALS

As a normal procedure, all O-rings and oil seals SHOULD BE REPLACED without regard

to appearance. To prevent leakage around oil seals, apply Loctite 271 to outer diameter

of all metal case oil seals. When using Loctite on seals or threads, surfaces must be clean

and dry. To ease installation, apply Quicksilver 2-4-C w/Teflon Marine Lubricant on all

O-rings. To prevent wear, apply Quicksilver 2-4-C w/Teflon Marine Lubricant on l.D. of oil

seals.

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 33 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

- Get the complete service and repair manual for the 2002-2004 Mercury 150/175/200 HP 2-Stroke EFI Outboards.

- Perfect for both professional mechanics and DIY enthusiasts.

- Includes troubleshooting charts, step-by-step procedures, clear images, and exploded-view illustrations.

- Ensure your outboard's reliability and save on repairs with the manufacturer's recommended procedures.

- Convenient digital format allows easy access, search, and portability on various electronic devices.

- Printable for those who prefer a physical copy.

- Language: English

- Requirements: Adobe Reader (free)

Keep your outboard in top condition with this comprehensive manual.