1965-1989 Mercury Mariner 45-115HP 3-4 Cyl Outboard OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

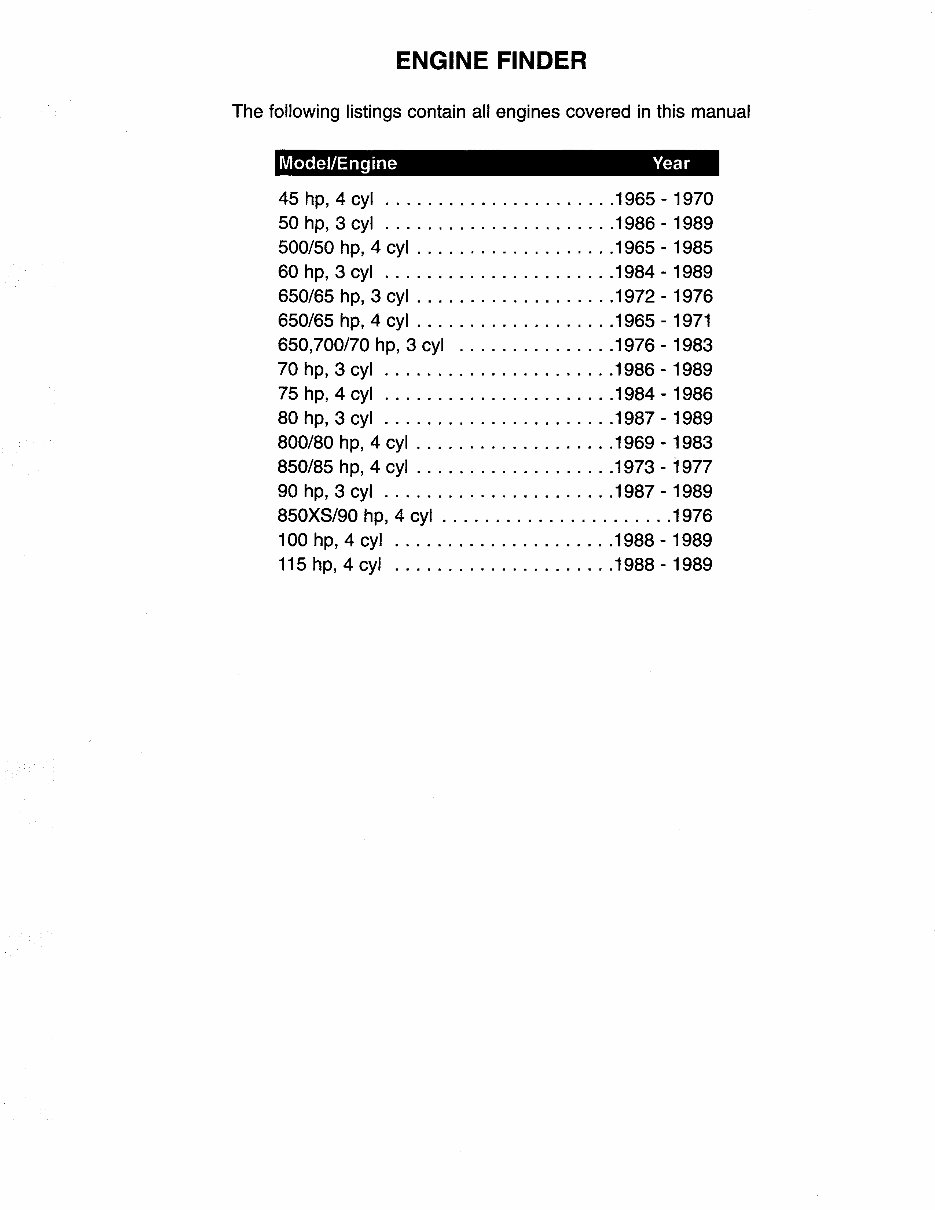

ENGINE FINDER

The following listings contain all engines covered in this manual

IM。del/Engine Year I

45 hp, 4 cyl .................雹.... 1965 - 1970

50 hp, 3 cyl ...................... 1986 - 1989

500/50 hp, 4 cyl .…...… ......... 1965 - 1985

60 hp, 3 cyl ...................... 1984 - 1989

650/65 hp, 3 cyl ................... 1972 - 1976

650/65 hp, 4 cyl ................... 1965 - 1971

650, 700170 hp, 3 cyl ............... 1976 - 1983

70 hp, 3 cyl ...................... 1986 - 1989

75 hp, 4 cyl ..” ................... 1984 - 1986

80 hp, 3 cyl ...................... 1987 - 1989

800/80 hp, 4 cyl ................... 1969 - 1983

850/85 hp, 4 cyl ................... 1973 - 1977

90 hp, 3 cyl ...................... 1987 - 1989

850XS/90 hp, 4 cyl ...................... 1976

100 hp, 4 cyl ..................... 1988 - 1989

115 hp, 4 cyl ..................... 1988 - 1989

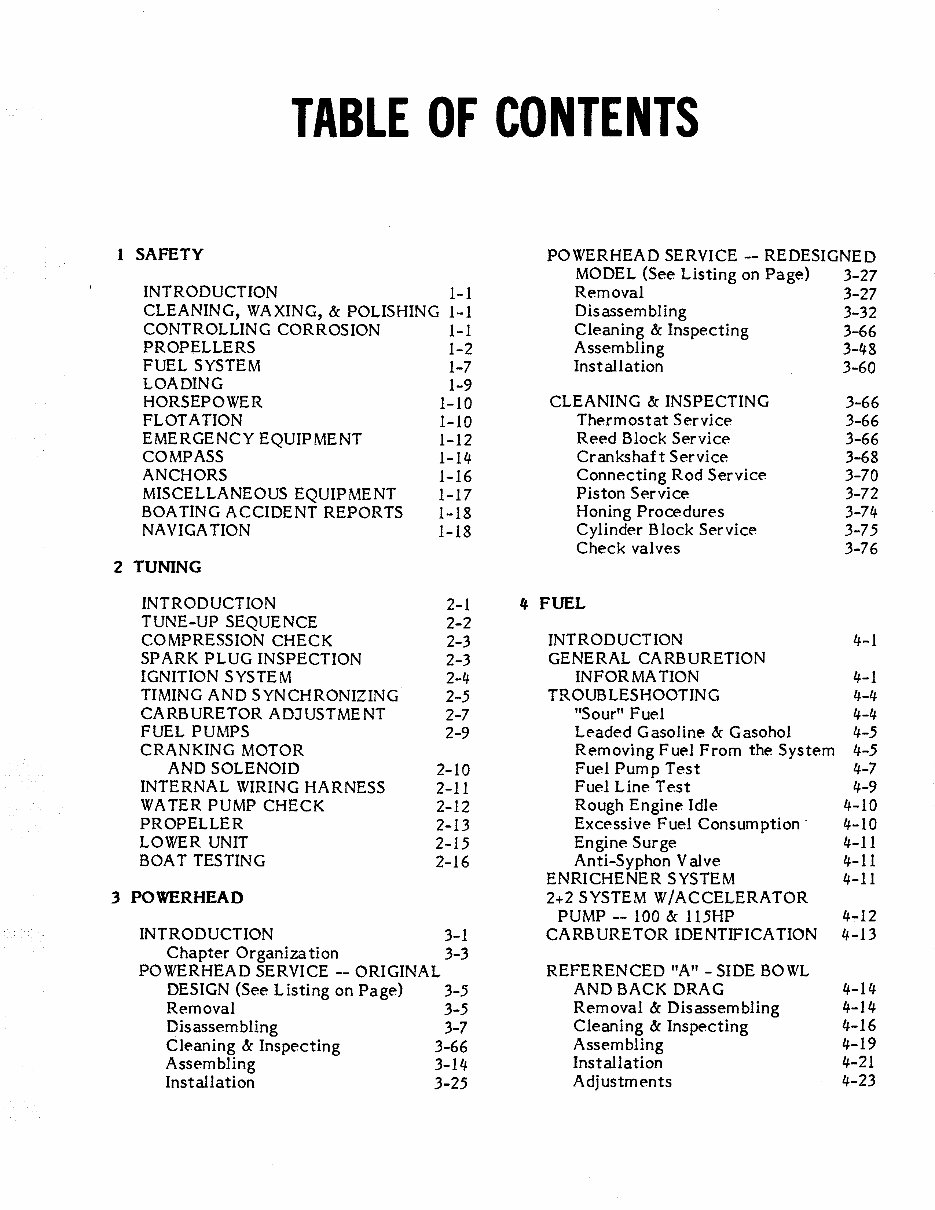

TABLE OF CONTENTS

1 SAFETY

INTRODUCTION 1-1

CLEANING, WAXING, & POLISHING 1-1

CONTROLLING CORROSION 1-1

PROPELLERS 1-2

FUEL SYSTEM 1-7

LOADING 1-9

HORSEPOWER 1-10

FLOTATION 1-10

EMERGENCY EQUIPMENT 1 皿 12

COMPASS 1-14

ANCHORS 1-16

MISCELLANEOUS EQUIPMENT 1-17

BOATING ACCIDENT REPORTS 1-18

NAVIGATION 1-18

2 TUNING

INTRODUCTION 2-1

TUNE-UP SEQUENCE 2-2

COMPRESSION CHECK 2-3

SPARK PLUG INSPECTION 2-3

IGNITION SYSTEM 2,每

TIMING ANDS YNCHRONIZING 2-5

CARBURETOR ADJUSTMENT 2-7

FUEL PUMPS 2-9

CRANKING MOTOR

AND SOLENOID 2-1 O

INTERNAL WIRING HARNESS 2-11

WATER PUMP CHECK 2-12

PROPELLER 2-13

LOWER UNIT 2-15

BOAT TESTING 2-16

3 POWERHEAD

INTRODUCTION 3-1

Chapter Organization 3-3

POWERHEAD SERVICE -- ORIGINAL

DESIGN (See Listing on Page) 3-5

Removal 3-5

Disassembling 3-7

Cleaning & Inspecting 3-66

Assembling 3-14

Installation 3-25

POWERHEAD SERVICE -- REDESIGNED

MODEL (See Listing 。n Page) 3-27

Removal 3-27

Disassembling 3-32

Cleaning & Inspecting 3-66

Assembling 3-48

Installation 3-60

CLEANING & INSPECTING 3-66

Therm 。stat Service 3-66

Reed Block Service 3-66

Crankshaft Service 3-68

c。nnecting R 。d Service 3-70

Piston Service 3-72

Honing Procedures 3-7电

Cylinder Block Service 3-75

Check valves 3-76

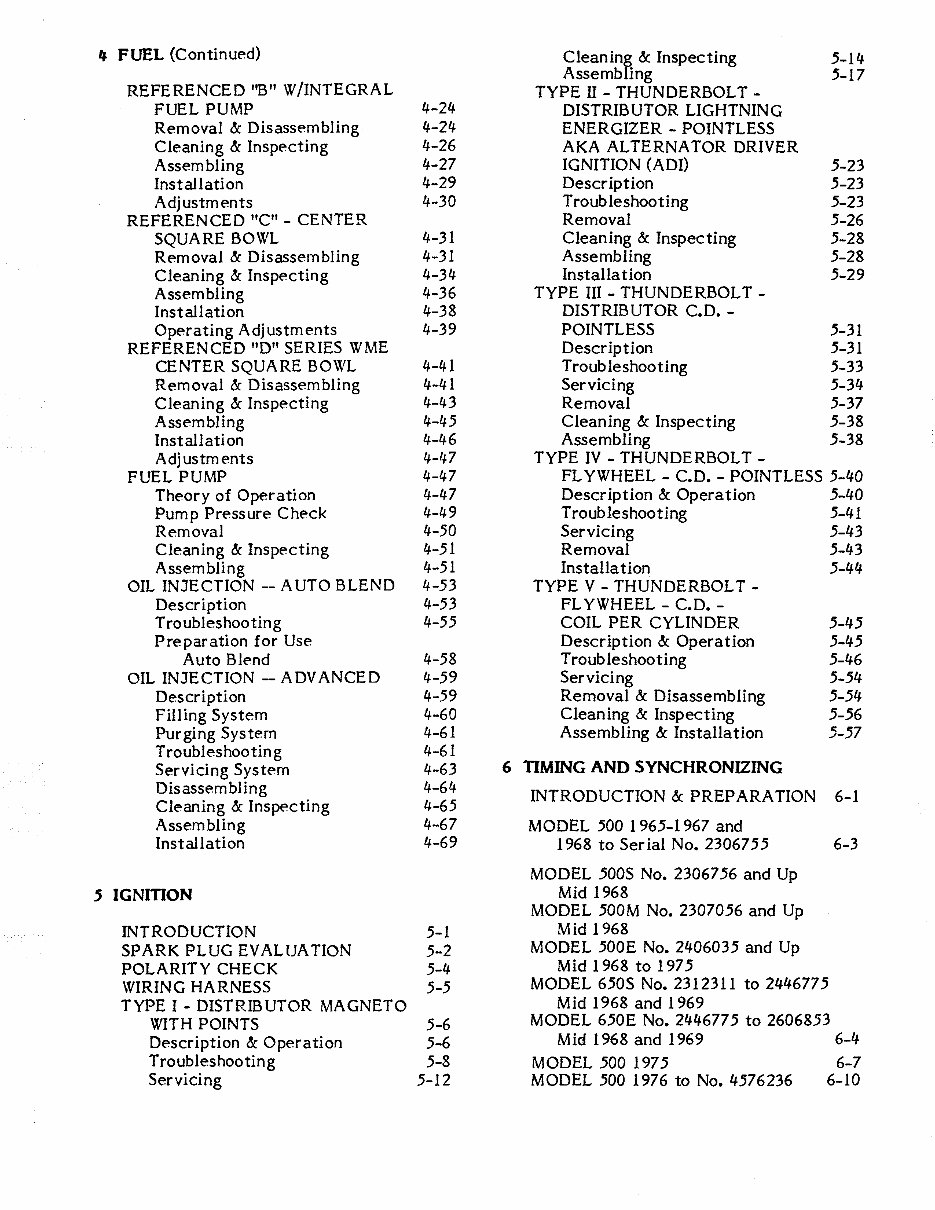

电 FUEL

INTRODUCTION

GENERAL CARBURETION

INFORMATION

TROUBLESHOOTING

”Sour" Fuel

Leaded Gas。line & Gasoh。l

Rem 。ving Fuel From the System

Fuel Pump Test

Fuel Line Test

R。ugh Engine Idle

Excessive Fuel Consumption

Engine Surge

Anti-Syph。n Valve

ENRICHENER SYSTEM

2+2 SYSTEM W/ACCELERATOR

PUMP -- 100 & 115HP

CARBURETOR IDENTIFICATION

REFERENCED "A”- SIDE BOWL

AND BACK DRAG

Removal & Disassembling

Cleanin~ & Inspecting

Assembling

Installation

Adjustments

每- 1

4-1

4-4

每·电

年,5

4-5

4-7

4-9

4-10

4-10

4-11

4-11

4-11

龟, 12

年- 13

每- 1 乌

龟- 1 每

每- 16

件- 19

4-21

龟-23

电 FUEL (Continued)

Clean in俨 Inspecting .5-1 每

Assemb ng .5-17

REFERENCED ” B" W/INTEGRAL

TYPE II - THUNDERBOLT -

FUEL PUMP 电-2龟

DISTRIBUTOR LIGHTNING

Rem 。val & Disassembling 电-2龟

ENERGIZER - POINTLESS

Cleaning & Inspecting 每- 26 AKA ALTERNATOR DRIVER

Assembling

1 斗-27 IGNITION (ADI) .5-23

Installation

年,29 Description .5-23

Adjustments 电-30 Troubleshooting .5-23

REFERENCED "C”- CENTER Removal 5-26

SQUARE BOWL 4-31 Cleaning & Inspecting .5-28

Rem 。val & Disassembling 年-31 Assembling .5-28

Cleaning & Inspecting 龟-3 每 Installation .5-29

Assembling 鸟-36 TYPE III - THUNDERBOLT -

Installation 4-38 DISTRIBUTOR C.D. -

Operating Adjustments 电-39 POINTLESS 5-31

REFERENCED "D" SERIES W ME Description .5-31

CENTER SQUARE BOWL 件-电 1 Trot』b leshooting .5-33

Rem 。val & Disassembling 也-每 1 Servicing .5-3句

Cleaning & Inspecting 电-电3 Removal .5-37

Assembling 电-4.5 Cleaning & Inspecting .5-38

Installation 年-46 Assembling .5-38

Adjustments 1 斗-47 TYPE IV - THUNDERBOLT -

FUEL PUMP 饵-饵 7 FLYWHEEL - C.D. - POINTLESS .5-句。

Theory 。f Operation 民-47 Description & Operation .5-斗。

Pump Pressure Check 4-49 Tr。ublesho。ting .5-每 i

Removal 每-50 Servicing .5-句3

Cleaning & Inspecting 4-51 Removal .5-电3

Assembling 4-51 Installation .5-句句

OIL INJECTION -- AUTO BLEND

龟 -53 TYPE V - THUNDERBOLT -

Description

件-53 FLYWHEEL - C.D. -

Tr。 ublesh。oting 电-55 COIL PER CYLINDER .5-每5

Preparation for Use Description & Operation .5-与5

Auto Blend 年-58

Troubleshooting .5-句6

OIL INJECTION --ADVANCED 4-59 Servicing 5白5句

Descripti。n 4-59 Removal & Disassembling .5-.5每

Filling System 4-60 Cleaning & Inspecting .5-.56

Purging System 年-61 Assembling & Installation 5-57

Troubleshooting 每-61

Servicing System 4-63

6 TIMING AND SYNCHRONIZING

Disassembling 鸟-6 鸟

INTRODUCTION & PREPARATION 6-1

Cleaning & Inspecting 4-65

Assembling 4-67 MODEL .500 1 965-1 967 and

Installation 4-69

1968 t。 Serial No. 23067.55 6-3

MODEL 500S N。. 23067 56 and Up

5 IGNIηON

Mid 1968

MODEL .500M N。. 23070.56 and Up

INTRODUCTION 5-1

Mid 1968

SPARK PLUG EVALUATION 5-2

MODEL .500E N。. 2句0603.5 and Up

POLARITY CHECK

5-龟

Mid 1968 t。 197.5

WIRING HARNESS 5 ” 5

MODEL 6.50S No. 2312311 to 24每677.5

TYPE I - DISTRIBUTOR MAGNETO

Mid 1968 and 1969

WITH POINTS 5-6

MODEL 650E No. 2每每677.5 to 2606853

Description & Operation 5-6

Mid 1968 and 1969 6-每

Troubleshooting 5-8 MODEL 500 197 5 6-7

Servicing 5-12 MODEL 500 1976 to N。.句576236 6喃 10

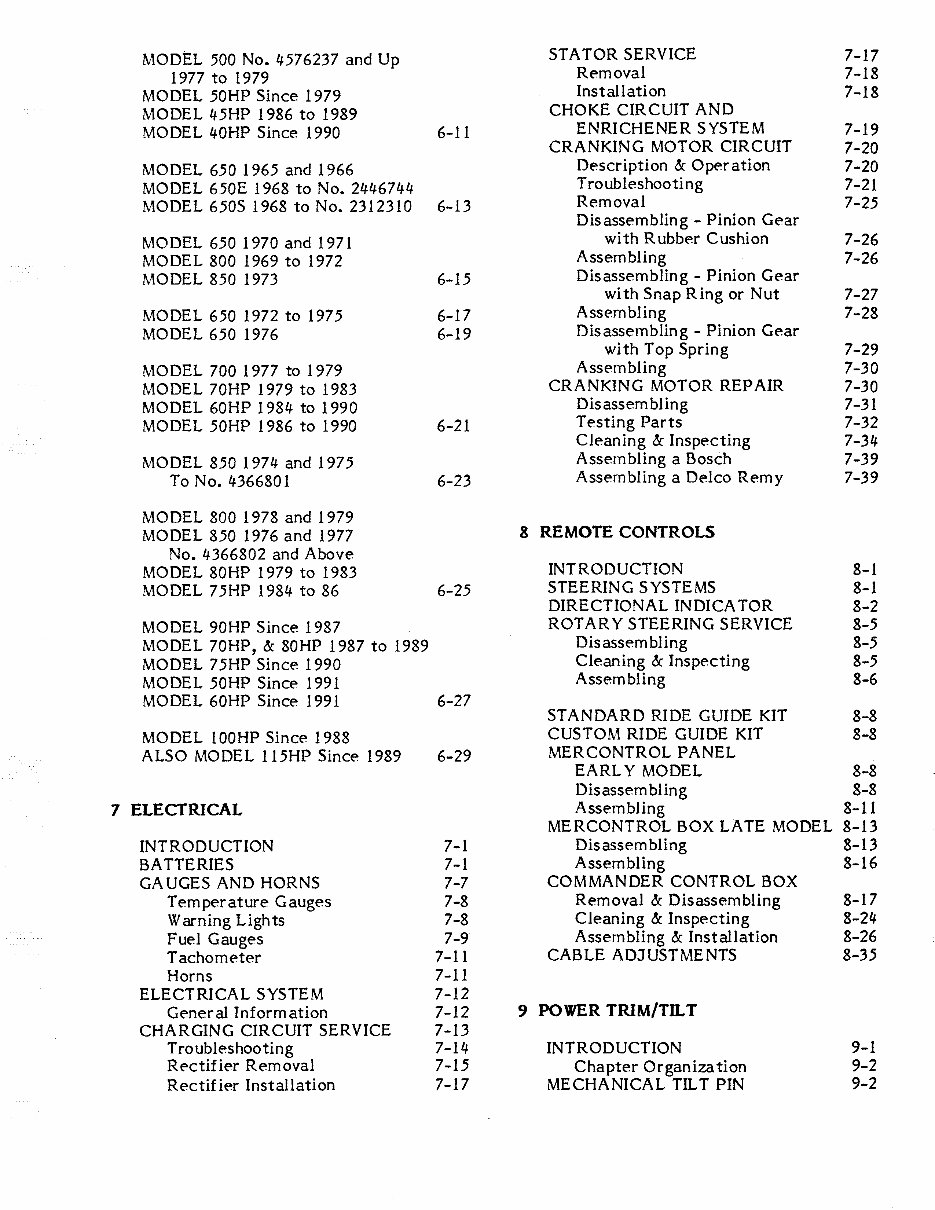

MODEL 500 No. 4576237 and Up

STA TOR SERVICE 7-17

1977 to 1979

Removal 7-18

MODEL 50HP Since 1979

Installation 7-18

MODEL 45HP 1986 to 1989

CHOKE CIRCUIT AND

MODEL 40HP Since 1990 6-11

ENRICHENER SYSTEM 7-19

CRANKING MOTOR CIRCUIT 7-20

MODEL 650 1965 and 1966

Description & Oper ati。n 7-20

MODEL 650E 1968 to No. 2446744

Tr。 ublesho。ting 7-21

MODEL 650S 1968 t。 N。. 2312310 6-13

Removal 7-25

Disassembling - Pinion Gear

MODEL 650 1970 and 1971

with Rubber C ushi 。n 7-26

MODEL 800 1969 to 1972

Assembling 7-26

MODEL 850 1973 6-15

Disassembling - Pinion Gear

with Snap Ring or Nut 7-27

MODEL 650 1972 t。 1975 6-17

Assembling 7-28

MODEL 650 1976 6-19

Disassembling - Pinion Gear

with Top Spring 7-29

MODEL 700 1977 t,。 1979

Assembling 7-30

MODEL 70HP 1979 to 1983

CRANKING MOTOR REPAIR 7-30

MODEL 60HP 198 每 t。 1990

Disassembling 7-31

MODEL 50HP 1986 to 1990 6-21

Testing Parts 7-32

Cleaning & Inspecting 7-34

MODEL 850 197斗 and 1975

Assembling a Bosch 7-39

ToN。.斗366801 6-23

Assembling a Delco Remy 7-39

MODEL 800 1978 and 1979

MODEL 850 1976 and 1977

8 REMOTE CONTROLS

No. 4366802 and Above

MODEL 80HP 1979 t。 1983

INTRODUCTION 8-1

MODEL 75HP 1984 to 86 6-25

STEERING SYSTEMS 8-1

DIRECTIONAL IN DI CA TOR 8-2

MODEL 90HP Since 1987

ROTARY STEERING SERVICE 8-5

MODEL 70HP, & 80HP 1987 to 1989

Disassembling 8-5

MODEL 75HP Since 1990

Cleaning & Inspecting 8-5

MODEL 50HP Since 1991

Assembling 8-6

MODEL 60HP Since 1991 6-27

STANDARD RIDE GUIDE KIT 8-8

MODEL lOOHP Since 1988

CUSTOM RIDE GUIDE KIT 8-8

ALSO MODEL 115HP Since 1989 6-29

MERCONTROL PANEL

EARLY MODEL 8-8

Disassembling 8-8

7 ELECTRICAL

Assembling 8-11

MERCONTROL BOX LATE MODEL 8-13

INTRODUCTION 7-1 Disassembling 8-13

BATTERIES 7-1 Assembling 8-16

GAUGES AND HORNS 7-7 COMMANDER CONTROL BOX

Temperature Gauges 7-8 Rem 。val & Disassembling 8-17

Warning Lights 7-8 Cleaning & Inspecting 8-24

Fuel Gauges 7-9

Assembling & Installation 8-26

Tachometer 7-11 CABLE ADJUSTMENTS 8-35

Horns 7-11

ELECTRICAL SYSTEM 7-12

General Information 7-12

9 POWER TRIM/TILT

CHARGING CIRCUIT SERVICE 7-13

Troubleshooting 7-1 每 INTRODUCTION 9-1

Rectifier Rem 。val 7-15 Chapter Organization 9-2

Rectifier Installation 7-17 MECHANICAL TILT PIN 9-2

9 POWER TRIM/TILT (Continued)

Disassembli~~

Bearing rr ier 10-16

SYSTEM "A”, MODELS WITH TWO Pr。peller Shaft 10-17

TRIM/TILT CYLINDERS 9-3 Drive shaft 10-17

Description&: Operation 9-3

Special Instructions 9-5 Assemblint

Bleeding 9-6

Lower riveshaft Bearing 10-22

Trouble sh。oting 9-8 Shift Shaft 10-22

Trim Switch Service 9-8 Bearing Carrier 10-23

Service System ” A" 9-12 Forward Gear&: Bearing 10-2句

Hydraulic Pump Service 9-1 句 F。rward Bearing Race 10-25

Electric Motor Service 9-17 Driveshaft 10-26

Shimming &: Backlash

SYSTEM "B”- MODELS WITH TWO Pinion Gear Depth 10-28

TRIM CYLINDERS Forward Gear Backlash 10-29

AND ONE TILT CYLINDER 9-21 Assembling &: Installation

Description &: Operation 9-21 Bearing Carrier 10-32

Bleeding 9-22 Reverse Gear Backlash ·I0-33

Flushing 9-23

Tr。ublesho。ting 9-2每 SERVICING CAM由SHIFT TYPE II

Removal &: Disassembling 9-31 UNITS MATCHED WITH LA TE

Manual Release Valve 9-3每 3- and 句-CYLINDER POWERHEADS

Oil Reserv。ir c。ver 9-35 SINCE ABOUT 1980 10-3句

Trim Cylinders 9-35 Removal and Disassembling

Tilt Cylinder 9-36 Bearing Carrier 10-35

Motor &: Pump 9-36 Propeller Shaft 10-36

Cleaning &: Inspecting 9-37

Shift Shaft 10-37

Assembling &: Installation 9-38

Pinion Gear 10-38

Pump &: Motor 9-42 Driveshaft 10-38

Tilt Cylinder 9-每5

F。rward Gear 10-39

Trim Cylinders 9-句 8 Pinion Gear Bearing Race 10-40

Reservoir Cover 9由每9 Forward Bearing Race 10 -句。

Manual Release Valve 9-每9 Driveshaft Bearing 10,每O

System Installati。n 9-50 Assembling and Installation

Driveshaf t Bearing 10 -电l

10 LOWER UNIT

Pinion Gear Bearing Race 10 -每每

Forward Gear Bearing Race 10-44

DESCRIPTION 10-1

Shift Shaft 10-45

CHAPTER COVERAGE 10-1

Forward Gear 10-每5

TROUBLESHOOTING 10 -句

Driveshaft 10-句6

REMOVAL -- ALL UNITS 10-5

Pinion Gear 10 -每6

Pr。peller Shaft 10-47

Propeller Removal 10-7 Bearing Carrier 10 -每8

WATER PUMP SERVICE Pinion Gear Depth 10-49

Removal and Disassembling F。rward Gear Backlash 10-50

High Pressure Type Pump 10-8

WATER PUMP ASSEMBLING AND

High Volume Type Pump 10-9 INSTALLATION

High Pressure Type Pump 10-52

SERVICING CAM-SHIFT TYPE I

Shimming (Certain Units) 10-52

UNITS MATCHED WITH EARLY High Volume Type Pump 10-56

3-CYLINDER POWERHEADS

CLEANING AND INSPECTING

TO ABOUT 1979 10-11

ALL UNITS 10-57

Removal

Bearing Carrier and LOWER UNIT INSTALLATION 10-60

Propeller Shaft 10-12 Filling Lower Unit 10-60

Driveshaft &: Bearing 10-13 Exhaust Tube Installation 10-61

For ward Gear &: Bearing 10-15 Propeller Installation 10-64

11 HAND REWIND STARTER

PROPELLER SERVICE

12-13

POWER TRIM/TILT

12-15

INTRODUCTION

INSIDE THE BOAT

12-16

TYPE ”A ”( See Introduction) 11-2

LOWER UNIT 12-16

Rem。val and Disassembling 11-2

WINTER STORAGE 12-18

Cleaning and Inspecting 11 -每

Units With Oil Injection 12-19

Assembling and Installation 11-6

Battery Storage 12-20

Type 吧”(See Introduction)

APPENDIX

Rem。val and Disassembling 11-13

Cleaning and Inspecting 11-16

METRIC CONVERSION CHART A-1

Assembling and Installation 11-17

ENGINE SPECIFICATIONS

AND TUNE-UP ADJ. A-2 thru A-12

12 MAINTENANCE

REED STOP OPENING A-13

INTRODUCTION 12-1

CARBURETOR JET SIZE/

ELEVATION CHART A-1 年

OUTBOARD SERIAL NUMBERS 12-2

LOWER UNIT BACKLASH TABLE A“ 16

LUBRICATION - COMPLETE UNIT 12-2

LOWER UNIT OIL CAPACITY

PRE-SEASON PREPARATION 12-3

AND GEAR CHART A-17

Units With Oil Injection 12 -句

PISTON & CYLINDER

All Units 12-5

SPECIFICATIONS A-18

FIBERGLASS HULLS 12-10

WIRE IDENTIFICATION DWGS.

BELOW WATERLINE SERVICE 12-10

Ignition Systems A-19 thru A-39

SUBMERGED ENGINE SERVICE 12-11

Power Trim/TH t A -斗。

Salt Water Submersion 12-11

Remote c。ntrols A -斗3

Fresh Water Submersion 12-12

Console Wiring A-47

SAFETY

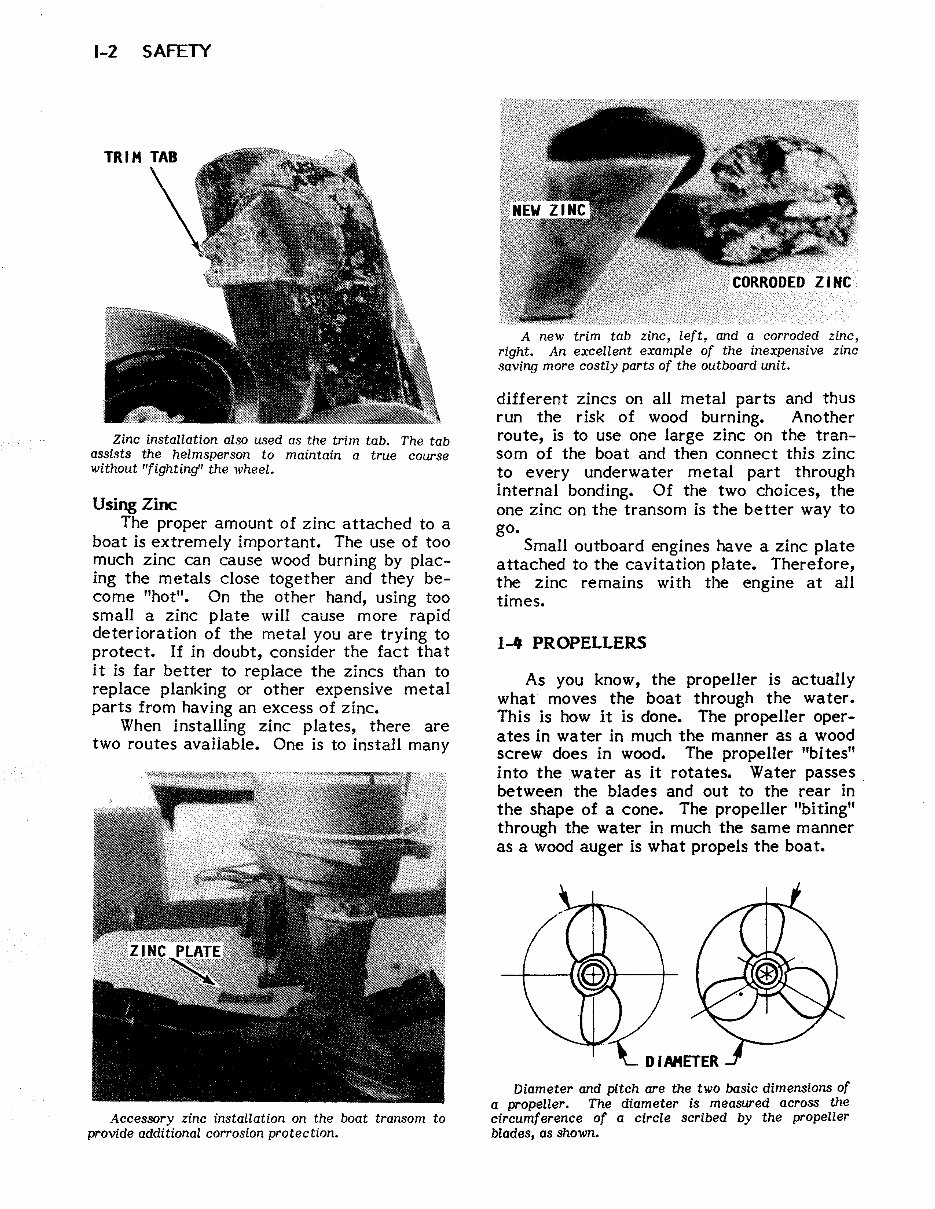

1-1 INTRODUCTION

In order to protect the investment for

the boat and 。utboard, they must be cared

for properly while being used and when out

of the water. Always store the boat with

the bow higher than the stern and be sure to

remove the transom drain plug and the inner

hull drain plugs. If any type of c。ver is used

to protect the boat, be sure to allow for

some m。vement of air through the hull.

Proper ventilation will assure evaporation of

any condensation that may form due to

changes in temperature and humidity.

1-2 CLEAN剧G, WAXING, AND POLISHING

Any boat shot』Id be washed with clear

water after each use to rem。ve surface dirt

and any salt dep。sits fr。m use in salt water.

Regular rinsing will extend the time be-

tween waxing and polishing. It will also give

y。u ”pride of 。wnership”, by having a sharp

looking piece of equipment. Elbow grease, a

mild detergent, and a brush will be required

t。 rem。ve stubb。rn dirt,。 il, and other un-

sightly deposits.

Stay away from harsh abrasives 。r strong

chemical cleaners. A white buffing com-

pound can be used to restore the original

gl。ss to a scratched, dull,。r faded area.

The finish 。f your boat sh。uld be thoroughly

cleaned, buffed, and p。lished at least once

each seas。n. Take care when buffing or

polishing with a marine cleaner not to over-

heat the surface y。u are w。rking, because

you will burn it.

1-3 .~ONTROLLING CORROSION

Since man first started 。ut on the water,

corrosi。n on his craft has been his enemy.

The first form was merely rot in the wood

and then it was rust, followed by other

forms of destructive corrosion in the m。re

modern materials. One defense against c。r-

rosion is to use similar metals throughout

the boat. Even though this is difficult to d。

in designing a new boat, particularly the

undersides, similar metals should be used

whenever and wherever possible.

A second defense against corr。sion is to

insulate dissimilar metals. This can be d。ne

by using an exterior coating of Sea Skin or

by insulating them with plastic or rubber

gaskets.

Mercury outboαrd mounted on α boat in a deαler’s

showroom waiting to give α new owner hours of fun on

the wαter.

1-2 SAFETY

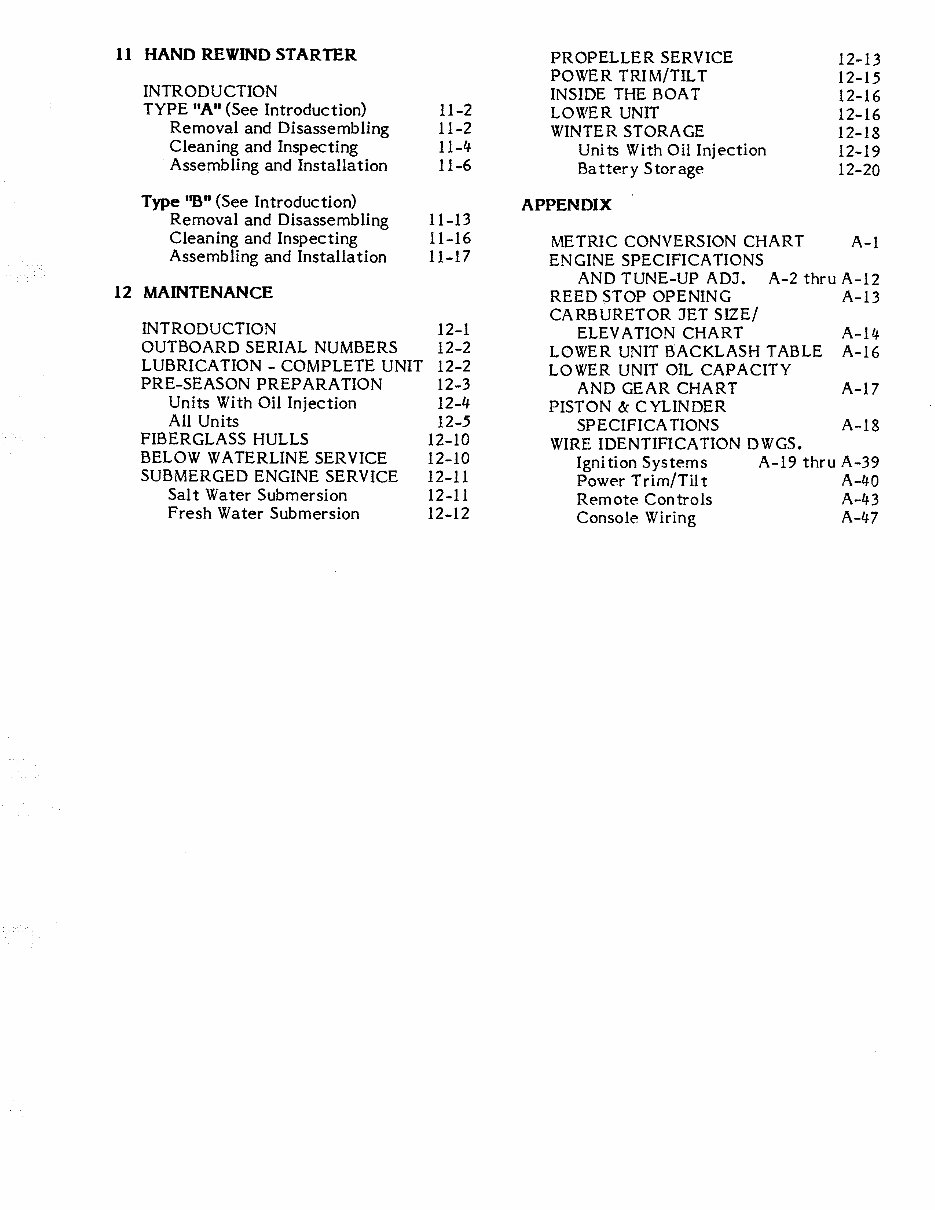

Zinc instαllαti on αlso used αs the trim tab. The tab

αssists the helmsperson to mαintain a true co旷se

without "fighting" the wheel.

Using Zi配

The proper amount of zinc attached to a

boat is extremely important. The use of too

much zinc can cause wood burning by plac-

ing the metals close together and they be-

c。me ”hot”. On the other hand, using too

small a zinc plate will cause more rapid

deterioration of the metal you are trying to

protect. If in doubt, consider the fact that

it is far better to replace the zincs than to

replace planking or other expensive metal

parts from having an excess of zinc.

When installing zinc plates, there are

two routes available. One is to install many

Accessory zinc installation on the boαt trαnsom to

provide αdditionαl corrosion protection.

A new trim tab zinc, left, αnd α corroded zinc,

right. An excellent example of the inexpensive zinc

saving more costly parts of the outboard unit.

different zincs on all metal parts and thus

run the risk of wood burning. Another

route, is to use one large zinc on the tran-

som of the boat and then connect this zinc

t。 every underwater metal part through

internal bonding. Of the two choices, the

one zinc on the transom is the better way to

go.

Small outboard engines have a zinc plate

attached to the cavitation plate. Therefore,

the zinc remains with the engine at all

t1付1es.

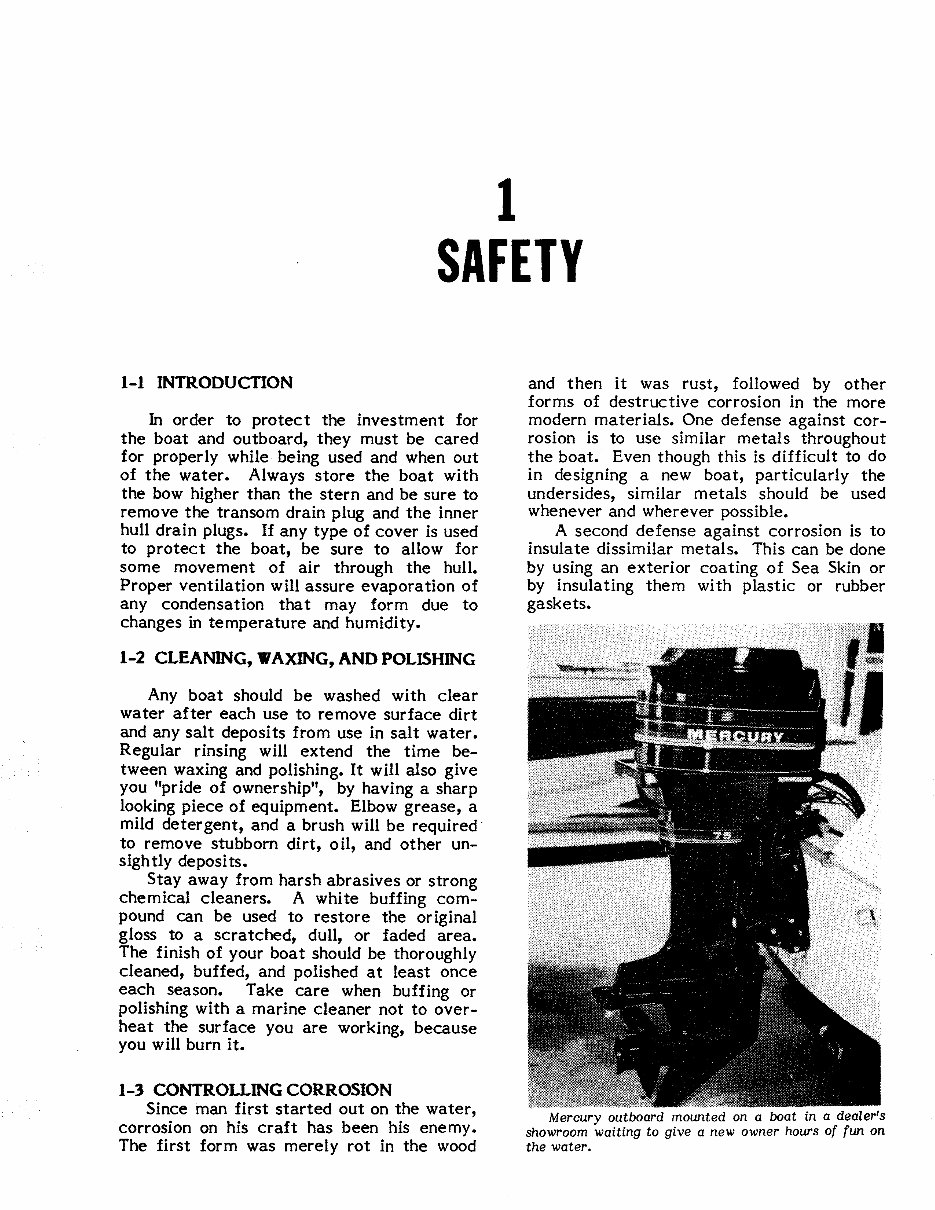

1_. PROPELLERS

As you know, the pr。peller is actually

what moves the b。at through the water.

This is how it is d。ne. The propeller oper-

ates in water in much the manner as a w。。d

screw does in wood. The propeller "bites"

into the water as it rotates. Water passes

between the blades and 。ut to the rear in

the shape of a cone. The propeller ” biting”

through the water in much the same manner

as a w。。d auger is what pr。pels the b。at.

Diameter and pitch αre the two basic dimensions of

α propeller. The diαmeter is meαsured αcross the

circumference of a circle scribed by the propeller

blαdes, αs shown.

Diameter and Pitch

Only two dimensions of the pr。peller are

。f real interest to the boat owner: the

diameter and the pitch. These tw。 dim en-

sions are stamped on the propeller hub and

always appear in the same order: the diam-

eter first and then the pitch. For instance,

the number 15-19 stamped 。n the hub,

w。uld mean the pr。peller had a diameter of

15 inches with a pitch of 19.

The diameter is the measured distance

from the tip d 。ne blade to the tip of the

other as shown in the accompanying illus-

trat1。n.

The pitch of a propeller is the angle at

which the blades are attached to the hub.

This figure is expressed in inches of water

travel f。r each rev。luti。n of the propeller.

In our exam pie of a 15-19 propeller, the

propeller should travel 19 inches thr。ugh the

water each time it revolves. If the pr。pel-

ler action was perfect and there was no

slippage, then the pitch multiplied by the

pr。peller rpms w。uld be the boat speed.

Most outb。ard manufacturers equip their

units with a standard propeller with a di-

ameter and pitch they consider t。 be best

suited to the engine and the boat. Such a

propeller allows the engine to run as near to

the rated rpm and h。rsepower (at full throt-

tle) as possible for the boat design.

The blade area 。f the propeller deter-

mines its load-carrying capacity. A two-

blade pr。peller is used for high-speed run-

ning under very light loads.

A f。ur-blade pr。peller is installed in

boa ts in tended t。 operate at low speeds

under very heavy loads such as tugs, barges,

。r large houseboats. The three-blade pro-

peller is the happy medium covering the

wide range between the high perf。rmance

units and the load carrying workhorses.

阴毛OPELLERS 1-3

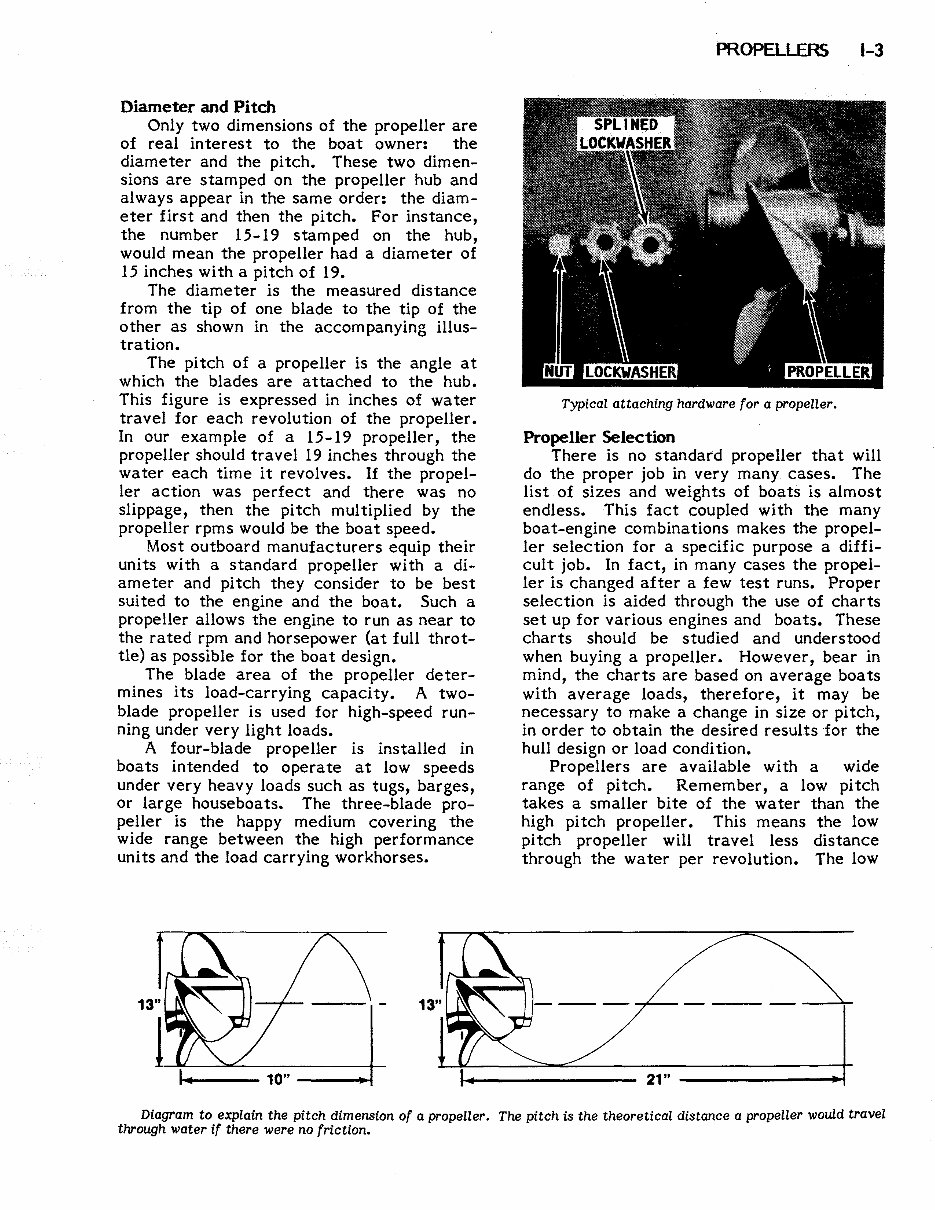

Typicαlαttαching hαrdwαre for αpropeller.

Propeller Selection

There is no standard pr。peller that will

do the pr。per job in very many cases. The

list 。f sizes and weights of boats is almost

endless. This fact coupled with the many

boat-engine combinati。ns makes the pr。pel-

ler selection for a specific purpose a diffi-

cult j。L In fact, in many cases the propel皿

ler is changed after a few test runs. Proper

selection is aided through the use of charts

set up f。r various engines and boats. These

charts should be studied and understood

when buying a propeller. However, bear in

mind, the charts are based on average boats

with average loads, therefore, it may be

necessary to make a change in size 。r pitch,

in order to 。btain the desired results for the

hull design or load con di ti on.

Pr。pellers are available with a wide

range of pitch. Remember, a low pitch

takes a smaller bite 。f the water than the

high pitch pr。peller. This means the low

pitch pr。peller will travel less distance

through the water per rev。lution. The low

21 ”

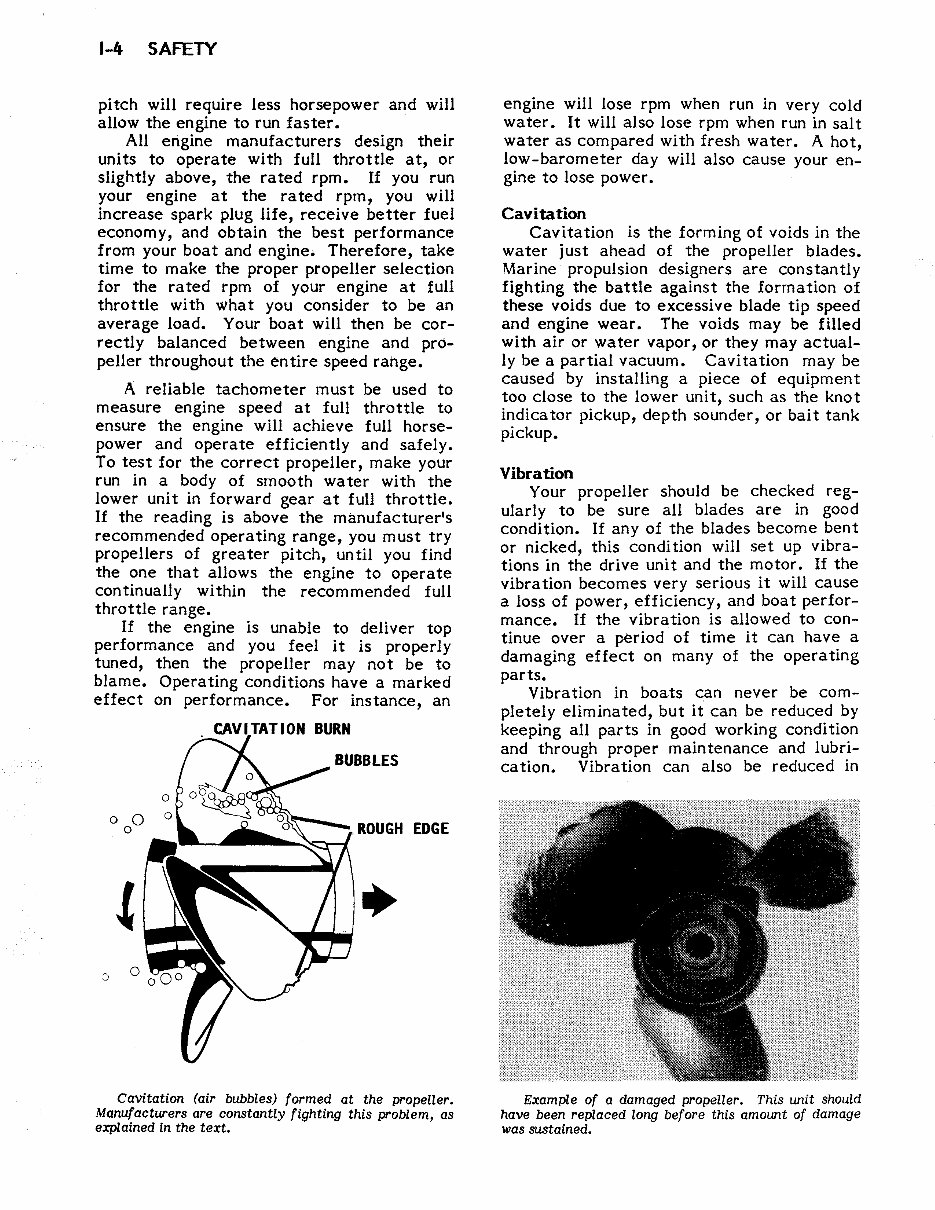

Diαgram to explain the pitch dimension of αpropeller. The pitch is the theoretical distαnce αpropeller would travel

through wαter if there were no friction.

1-4 SAFETY

pitch will require less horsep。wer and will

allow the engine t。 run faster.

All engine manufacturers design their

units to operate with full throttle at, or

slightly above, the rated rpm. If y。u run

y。ur engine at the rated rpm, you will

increase spark plug life, receive better fuel

econ。my, and 。btam the best performance

fr。m y。ur boat and engine. Therefore, take

time to make the proper propeller selection

for the rated rpm of your engine at full

throttle with what y。u consider t。 be an

average load. Your boat will then be c。r-

rectly balanced between engine and pro-

peller throughout the entire speed rahge.

A reliable tach。meter must be used to

measure engine speed at full throttle to

ensure the engine will achieve full horse-

power and 。perate efficiently and safely.

To test for the correct propeller, make your

run in a body 。f smooth water with the

i。wer unit in f。rward gear at full throttle.

If the reading is above the manufacturer’ s

rec。mmended operating range, you must try

propellers of greater pitch, until you find

the 。ne that allows the engine t。。perate

continually within the recommended full

thr。ttle range.

If the engine is unable to deliver top

performance and y。u feel it is properly

tuned, then the propeller may n。t be to

blame. Operating c。nditions have a marked

effect on performance. F。r instance, an

:>

0 0

0

CAVITATION BURN

,ROUGH EDGE

”

Cavitation fαir bubbles) formed αt the propeller.

Manuf,αcturers αre constantly fighting this problem, αs

explαined in the text.

engine will lose rpm when run in very cold

water. It will also lose rpm when run in salt

water as compared with fresh water. A hot,

low-barometer day will als。 cause your en ”

gine t。 lose power.

Ca vi恒tion

Cavitati。n is the f。rming 。f voids in the

water just ahead of the propeller blades.

Marine propulsion designers are constantly

fighting the battle against the formation of

these v。ids due to excessive blade tip speed

and engine wear. The voids may be filled

with air 。r water vap。r,。r they may actual-

ly be a partial vacuum. Cavitation may be

caused by installing a piece of equipment

too close to the l。 wer unit, such as the kn。 t

indicator pickup, depth sounder, or bait tank

pickup.

Vibration

y。ur propeller should be checked reg-

ularly to be sure all blades are in good

condition. If any of the blades become bent

or nicked, this con di ti。n will set up vibra-

tions in the drive unit and the motor. If the

vibration becomes very serious it will cause

a loss of power, efficiency, and boat per for-

mance. If the vibration is allowed to con-

tinue over a period of time it can have a

damaging effect on many of the operating

parts.

Vibration in boats can never be com-

pletely eliminated, but it can be reduced by

keeping all parts in good working condition

and through pr。per maintenance and lubri-

cation. Vibrati。n can also be reduced in

Example of αdαmαged propeller. This unit should

have been replaced long before this amount of dαmage

wαs sustαin ed.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 48 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

- The 1965-1989 Mercury Mariner 45-115HP 3-4 Cyl Outboard Service & Repair Manual is a comprehensive resource for fixing outboard problems, suitable for both professional mechanics and DIY enthusiasts.

- It contains troubleshooting and replacement procedures provided by the manufacturer, including step-by-step instructions, clear images, and exploded-view illustrations.

- Regular maintenance is essential for outboard longevity, and this manual provides manufacturer-recommended troubleshooting charts and replacement procedures to ensure proper maintenance.

- With this manual, users can save on repairs, increase outboard reliability, and effectively address issues, making it a valuable resource for outboard owners.

- Please note: This is not a generic repair manual but the OEM manual used by professional technicians, ensuring access to specific and accurate information for outboard service and maintenance.

- The manual is easily accessible, searchable, and can be carried on electronic devices, making it more convenient than traditional bound manuals.

- It is printable and compatible with various electronic devices, including PC, Mac, Android, and Apple devices, requiring only Adobe Reader (free) for access.