1987-1993 Mercury Mariner 70/75/80/90/100/115 HP Outboards Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

(3 Cylinder)

UNITED STATES S/N 0A996142 thru 0D283221

BELGIUM S/N 09502135 thru 09793576

CANADA S/N 0A722297 and Above

BELGIUM

CANADA

S/N 0B209468 thru 0D283221

S/N 09523034 thru 09793576

S/N 0A731673 and Above

MODELS

70 • 75 • 80 • 90 • 100 • 115

SERVICE

MANUAL

1987–1993 70 • 75 • 75 Marathon •

75XD • 75 Seapro • 80 • 90

1988–1993 100 • 115 (4 Cylinder)

with Serial Numbers

with Serial Numbers

UNITED STATES

Printed in U.S.A.

1995, Brunswick Corporation

90-13645--2 1095

Notice

Throughout this publication, “Dangers”, “Warnings”

and “Cautions” (outlined in a border and accompa-

nied by the International HAZARD Symbol ) are

used to alert the mechanic to special instructions con-

cerning a particular service or operation that may be

hazardous if performed incorrectly or carelessly.

OBSERVE THEM CAREFULLY!

These “Safety Alerts” alone cannot eliminate the

hazards that they signal. Strict compliance to these

special instructions when performing the service, plus

“common sense” operation, are major accident

prevention measures.

DANGER

DANGER — Immediate hazards which WILL result

in severe personal injury or death.

WARNING

WARNING - Hazards or unsafe practices which

COULD result in severe personal injury or death.

CAUTION — Hazards or unsafe practices which

could result in minor personal injury or product or

property damage.

CAUTION

Notice to Users of This Manual

This service manual has been written and published

by the service department of Mercury Marine to aid

our dealers’ mechanics and company service person-

nel when servicing the products described herein.

It is assumed that these personnel are familiar with

the servicing procedures of these products, or like or

similar products manufactured and marketed by Mer-

cury Marine, that they have been trained in the recom-

mended servicing procedures of these products

which includes the use of mechanic’s common hand

tools and the special Mercury Marine or recom-

mended tools from other suppliers.

We could not possibly know of and advise the service

trade of all conceivable procedures by which a ser-

vice might be performed and of the possible hazards

and/or results of each method. We have not under-

taken any such wide evaluation. Therefore, anyone

who uses a service procedure and/or tool, which is

not recommended by the manufacturer, first must

completely satisfy himself that neither his nor the

product’s safety will be endangered by the service

procedure selected.

All information, illustrations and specifications con-

tained in this manual are based on the latest product

information available at the time of publication. As re-

quired, revisions to this manual will be sent to all deal-

ers contracted by us to sell and/or service these prod-

ucts.

It should be kept in mind, while working on the

product, that the electrical system and ignition system

is capable of violent and damaging short circuits or

severe electrical shocks. When performing any work

where electrical terminals could possibly be

grounded or touched by the mechanic, the battery

cables should be disconnected at the battery.

Any time the intake or exhaust openings are exposed

during service they should be covered to protect

against accidental entrance of foreign material which

could enter the cylinders and cause extensive inter-

nal damage when the engine is started.

It is important to note that, during any maintenance

procedure, replacement fasteners must have the

same measurements and strength as those re-

moved, whether metric or customary. Numbers on the

heads of the metric bolts and on surfaces of metric

nuts indicate their strength. Customary bolts use ra-

dial lines for this purpose, while most customary nuts

do not have strength markings. Mismatched or incor-

rect fasteners can result in damage or malfunction, or

possible personal injury. Therefore, fasteners re-

moved should be saved for re-use in the same loca-

tions whenever possible. Where the fasteners are not

satisfactory for re-use care should be taken to select

a replacement that matches the original.

Cleanliness and Care of

Outboard Motor

A marine power product is a combination of many ma-

chined, honed, polished and lapped surfaces with tol-

erances that are measured in the ten thousands of an

inch. When any product component is serviced, care

and cleanliness are important. Throughout this

manual, it should be understood that proper cleaning,

and protection of machined surfaces and friction

areas is a part of the repair procedure. This is consid-

ered standard shop practice even if not specifically

stated.

Whenever components are removed for service, they

should be retained in order. At the time of installation,

they should be installed in the same locations and

with the same mating surfaces as when removed.

Before raising or removing an outboard engine from a

boat, the following precautions should be adhered to:

1. Check that flywheel is secured to end of

crankshaft with a locknut and lifting eye is

threaded into flywheel a minimum of 5 turns.

2. Connect a hoist of suitable strength to the lifting

eye.

In addition, personnel should not work on or under an

engine which is suspended. Engines should be at-

tached to work stands, or lowered to ground as soon

as possible.

We reserve the right to make changes to this manual

without prior notification.

Refer to dealer service bulletins for other pertinent in-

formation concerning the products described in this

manual.

Service Manual Outline

1 - General Information and Specifications

2 - Electrical and Ignition

A - Ignition System

B - Battery, Charging System and

Starting System

C - Timing/Synchronizing and Adjusting

D - Wiring Diagrams

3 A - Fuel System and Carburetion

B - Oil Injection System

4 A - Powerhead (3-Cylinder Engines)

B - Powerhead (4-Cylinder Engines)

5 - Lower Unit

A - Gear Housing

B - Mid Section

C - Shock Absorber

6 - Power Trim

A - Design I (Side Fill Reservoir)

B - Design II (Aft Fill Reservoir)

C - Single Ram

7 - Outboard Motor Installation/Attachments

A - Engine Attachments/Engine Installation

B - Tiller Handle and Co-Pilot

GENERAL INFORMATION

AND SPECIFICATIONS

1

90-13645-2 495

Table Of Contents

Page Page

General Specification 1-1 . . . . . . . . . . . . . . . . . . . . . .

Cowl Removal 1-3 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filling Oil Injection System 1-3 . . . . . . . . . . . . . . . . . .

Power Trim General Information 1-4 . . . . . . . . . . . . .

Trim “In” Angle Adjustment 1-4 . . . . . . . . . . . . . . . . .

Models with Power Trim 1-4 . . . . . . . . . . . . . . . .

Checking Trim System Fluid Level 1-5 . . . . . . . . . . .

Tilt Angle Adjustment 1-5 . . . . . . . . . . . . . . . . . . . . . .

Models without Power Trim 1-5 . . . . . . . . . . . . . .

Connecting Engine Wiring Harness and

Routing of Engine Battery Cables 1-6 . . . . . . . .

Ride-Guide Steering Cable and

Pivot Points Lubrication 1-7 . . . . . . . . . . . . . . . . .

Following Complete Submersion 1-8 . . . . . . . . . . . .

Salt Water Submersion

(Special Instructions) 1-8 . . . . . . . . . . . . . . . .

Submerged While Running

(Special Instructions) 1-8 . . . . . . . . . . . . . . . .

Submerged Engine (Fresh Water)

(Plus Special Instructions) 1-8 . . . . . . . . . . .

Out-of-Season Outboard Storage 1-9 . . . . . . . . . . .

How Weather Affects Engine Performance 1-10 . .

Conditions Affecting Operation 1-11 . . . . . . . . . . . . .

Detonation: Causes and Prevention 1-12 . . . . . . . .

Compression Check 1-12 . . . . . . . . . . . . . . . . . . . . . .

1-1 90-13645--2 1095 GENERAL INFORMATION AND SPECIFICATIONS

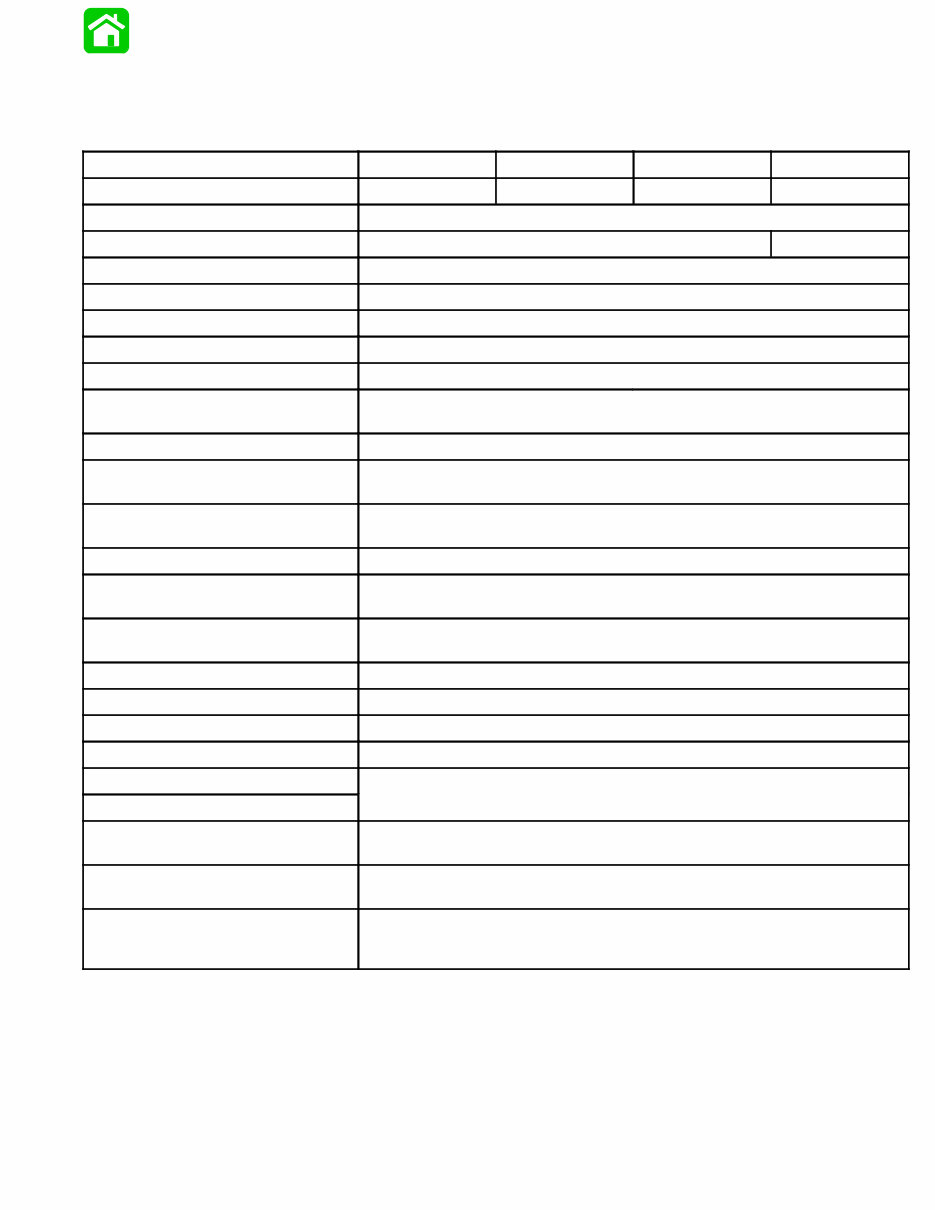

General Specification

NOTE: Other specification (torques, etc.) are listed in

the respective sections.

Model 70 Model 75 Model 80 Model 90

Horsepower 70 (52.2 kw) 75 (55.9 kw) 80 (59.6 kw) 90 (67.1 kw)

Idle RPM (in forward gear) 650 - 700

Full Throttle RPM Range 4750 - 5250 5000 - 5500

Piston Replacement 71.12 (1165.7cc)

Cylinder Bore 3.375 (85.7mm)

Stroke 2.65 (67.3mm)

Engine Type 3 Cylinder, 2 Cycle

Ignition Type C.D. Breakerless

Recommended Spark Plug

NGK-BUHW-2 or AC-V40 FFK or

Champion L78V

Inductor Plugs: NGK-BUZHW-2 or

Champion QL78V

Cylinder Firing Order 1-3-2

Recommended Power Trim Fluid

Quicksilver Power Trim & Steering Fluid or Automotive Transmission

Fluid (ATF) Type F, FA or Dexron II

Recommended Gasoline

Regular Leaded, Premium, Low-Lead and Lead-Free automotive gaso-

lines with a minimum pump posted octane rating of 86

Recommended Oil Quicksilver TC-WII or TC-W3 2-Cycle Outboard Oil

Engine Weight ELO

ELOPT

260 lbs.

280 lbs.

Fuel Tank Capacity

6.6 U.S. Gallons

(5 Imp. Gals.; 25 Liters)

Gear Housing Lubricant Capacity 22.5 fl. oz. (665.3ml)

Gasoline/Oil Ratio at Idle 80:1

Gasoline/Oil Ratio at W.O.T. 50:1

Gear Ratio 2.3:1

Oil Injection Tank Capacity

Tank Capacity 1 gal. (3.78 liter)

Maximum operation per tank

full of oil at W.O.T.

6 hours

Oil remaining when warning

buzzer sounds

1 qt. (.95 liter)

Operating time remaining at

wide open throttle when warn-

ing buzzer sounds

1 Hour

1-2 90-13645--2 1095 GENERAL INFORMATION AND SPECIFICATIONS

General Specification

(continued)

NOTE: Other specification (torques, etc.) are listed in

the respective sections.

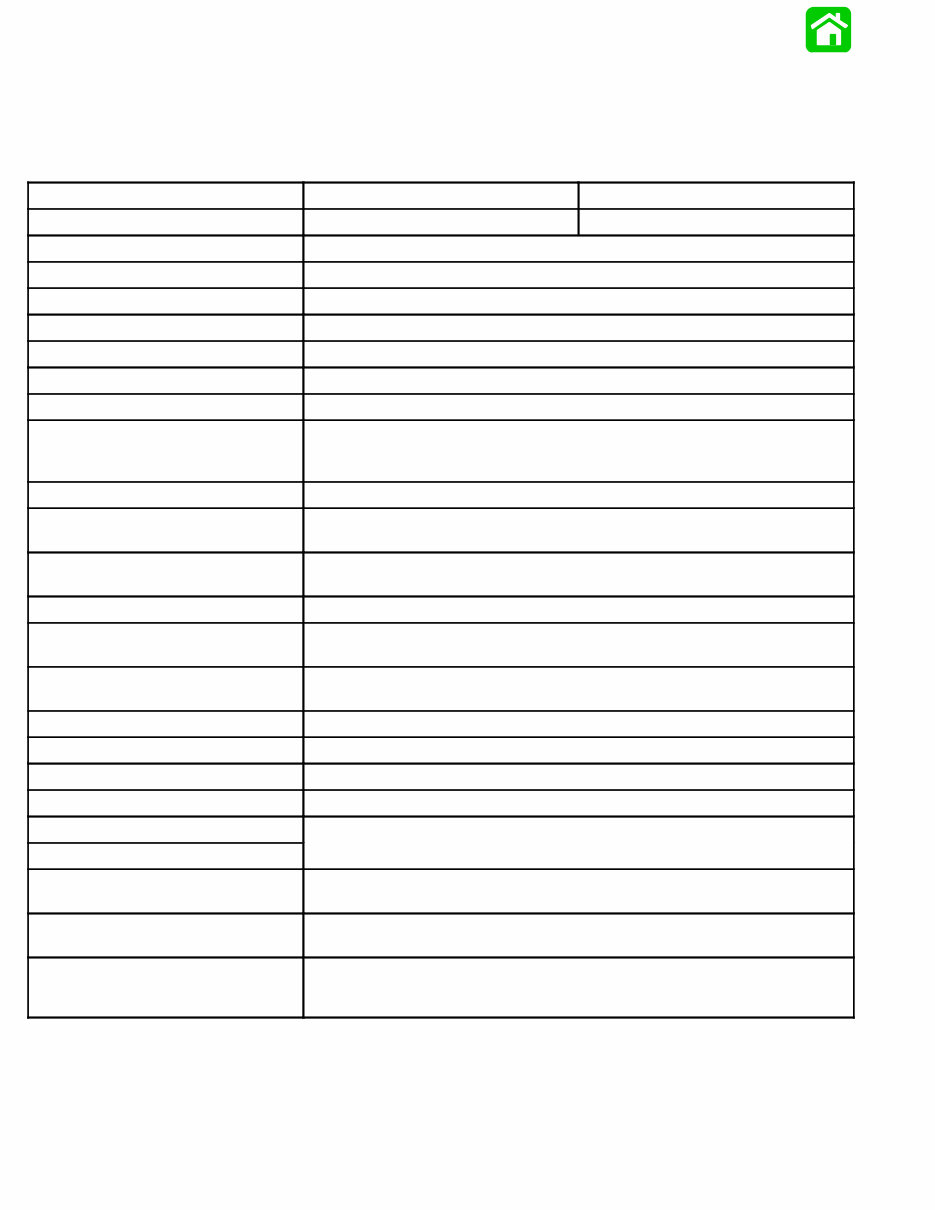

Model 100 Model 115

Horsepower 100 (74.6 kw) 115 (85.8 kw)

Idle RPM (in forward gear) 650 - 700

Full Throttle RPM Range 4750 - 5250

Piston Replacement 105 (1720.9cc)

Cylinder Bore 3.375 (85.7mm)

Stroke 2.930 (74.4mm)

Engine Type 4 Cylinder, 2 Cycle

Ignition Type C.D. Breakerless

Recommended Spark Plug

NGK-BPH8H-N-10* Gap - 0.040 in. (1.0mm)

Inductor Plug NGK BPZ 8H-N-10* Gap - 0.040 in. (1.0mm)

NGK-BUHW

Cylinder Firing Order 1-3-2-4

Recommended Power Trim Fluid

Quicksilver Power Trim & Steering Fluid or Automotive Transmission

Fluid (ATF) Type F, FA or Dexron II

Recommended Gasoline

Regular Leaded, Premium, Low-Lead and Lead-Free automotive gaso-

lines with a minimum pump posted octane rating of 86

Recommended Oil Quicksilver 2-Cycle Outboard Oil

Engine Weight ELO

ELOPT

340 lbs.

360 lbs.

Fuel Tank Capacity

6.6 U.S. Gallons

(5 Imp. Gals.; 25 Liters)

Gear Housing Lubricant Capacity 22.5 fl. oz. (665.2ml)

Gasoline/Oil Ratio at Idle 80:1

Gasoline/Oil Ratio at W.O.T. 50:1

Gear Ratio 2.07:1

Oil Injection Tank Capacity

Tank Capacity 1.4 gal. (5.3 liters)

Maximum operation per tank

full of oil at W.O.T.

5 hours

Oil remaining when warning

buzzer sounds

1 qt. (.95 liter)

Operating time remaining at

wide open throttle when warn-

ing buzzer sounds

50 min. approx.

*Improves running quality between 1800 – 2000 RPM.

90-13645--2 495 1-3 GENERAL INFORMATION AND SPECIFICATIONS

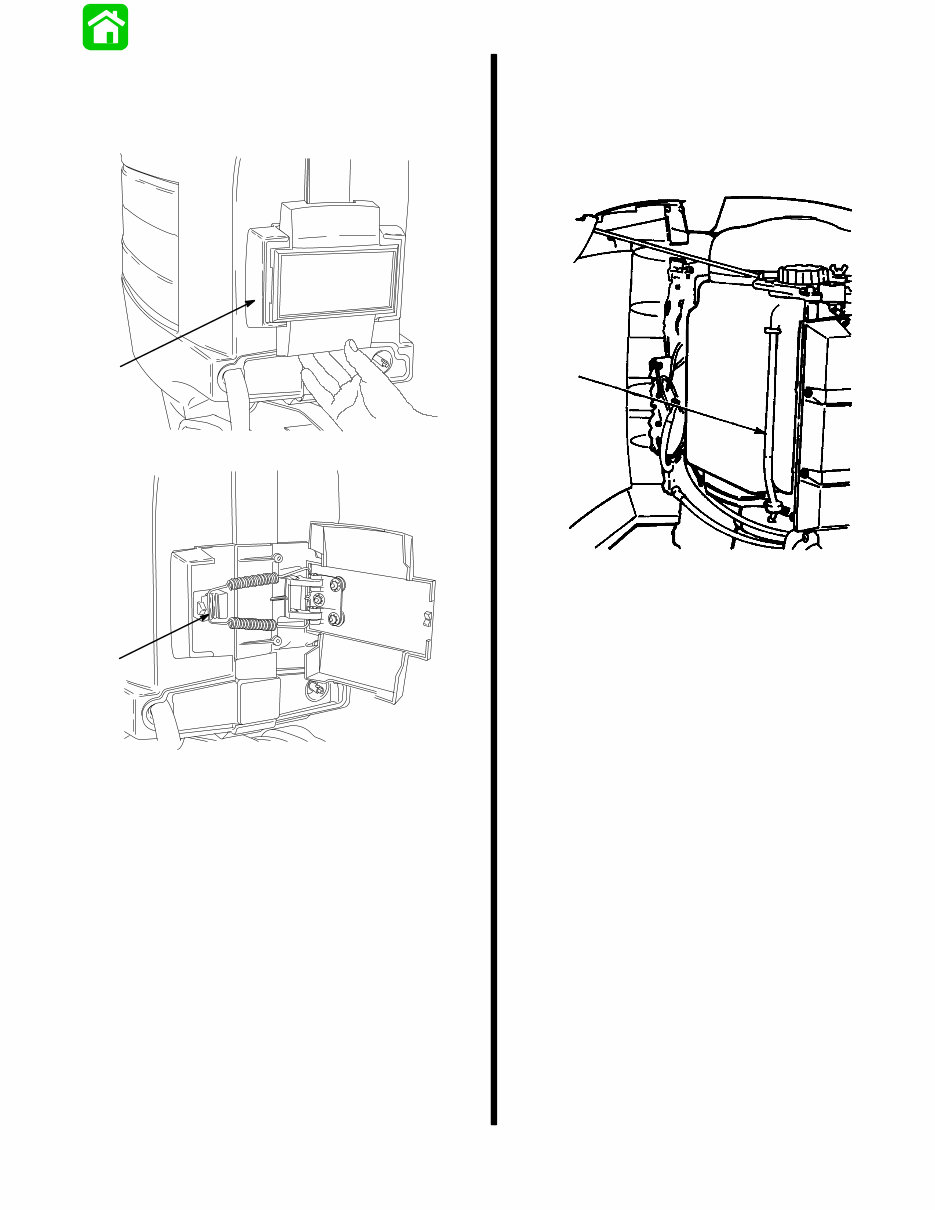

Cowl Removal

Pull outward on starboard side of front shield (a).

Remove spring (b) from latch and open cowls.

18291

a

18292

b

Filling Oil Injection System

Open starboard cowl (refer to cowl removal on this

page). Some earlier outboards will have a cowl brack-

et to hold cowl open as shown.

Fill tank with recommended oil.

a

a - Oil Tank Tube

1-4 90-13645--2 495 GENERAL INFORMATION AND SPECIFICATIONS

Power Trim System

GENERAL INFORMATION

The power trim system is filled at the manufacturer

and is ready for use.

Trim outboard through entire trailering range several

times to remove any air from the system.

The trim system is pressurized and is not externally

vented. The outboard can be raised or lowered manu-

ally by loosening the manual release valve four turns.

The trim “out” angle of this outboard is not adjustable.

The trim system has an internal valve which will

automatically stop the outward trim travel at 20_ when

engine RPM is approximately 2000 RPM or higher;

outboard also has to be in water and in gear.

The outboard can be operated beyond the 20_ trim

limit for operating outboard in shallow water if engine

RPM is kept below approximately 2000 RPM.

a

b

23321

a - Fill Screw (System is Pressurized, DO NOT Open Unless

Outboard is Tilted to Full Up Position)

b - Manual Release Valve

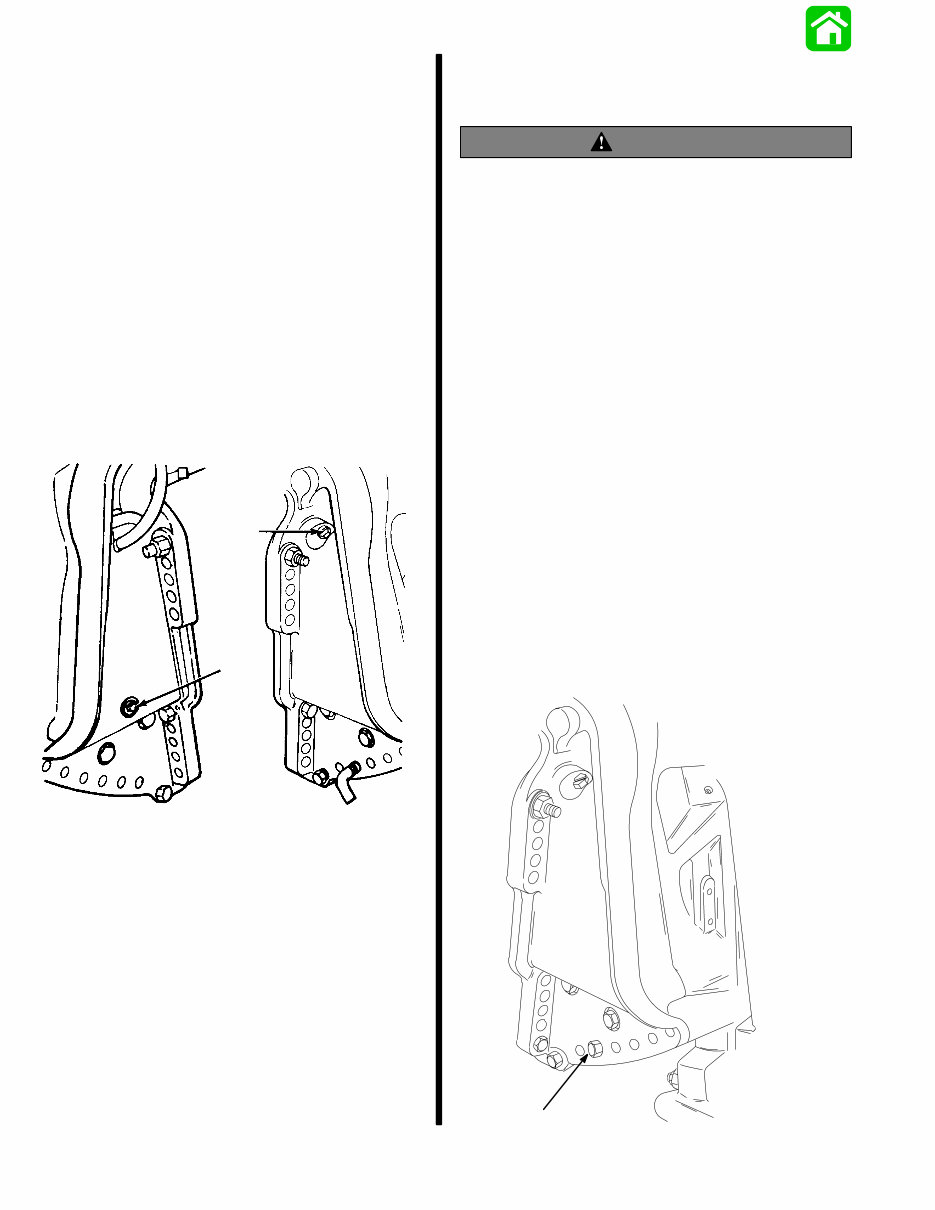

Trim “In” Angle Adjustment

MODELS WITH POWER TRIM

WARNING

Operating some boats with outboard trimmed to the

full “in” trim angle [not using trim adjustment bolt

(a)] at planing speed will cause undesirable and/or

unsafe steering conditions. Each boat MUST BE

water tested for handling characteristics after

outboard installation and after any trim adjust-

ments.

IMPORTANT: Some boat/motor combinations,

that do not use the trim adjustment bolt (a) and are

trimmed to the full “in” trim angle, will not experi-

ence any undesirable and/or unsafe steering

conditions during planing speed. Thus, not using

trim adjustment bolt may be desired. However,

some boats with outboard trimmed to the full “in”

trim angle at planing speeds will cause undesir-

able and/or unsafe steering conditions. If these

steering conditions are experienced, under no

circumstances should the outboard be operated

without the trim adjustment bolt and without the

bolt adjusted in the proper holes to prevent un-

safe handling characteristics.

Water test the boat not using the trim adjustment bolt.

If undesirable and/or unsafe steering conditions are

experienced (boat runs with nose down), install trim

adjustment bolt in proper hole to prevent unsafe han-

dling characteristics.

22744

a

90-13645--2 495 1-5 GENERAL INFORMATION AND SPECIFICATIONS

Checking Trim System Fluid Level

IMPORTANT: This trim system is pressurized.

Remove fill screw (b) when outboard is trimmed

to the full “up” position. Retighten fill screw

securely.

1. Trim outboard to full “up” position. Engage tilt lock

lever. Trim system fluid can only be checked when

outboard is in this position.

2. Remove fill screw and check fluid level. Fluid level

should be visible in fill tube.

3. If necessary, add Quicksilver Power Trim and

Steering Fluid; or Automatic Transmission Fluid

(ATF) Type F, FA or Dextron II.

20319

a

b

a - Tilt Lock Lever

b - Fill Screw

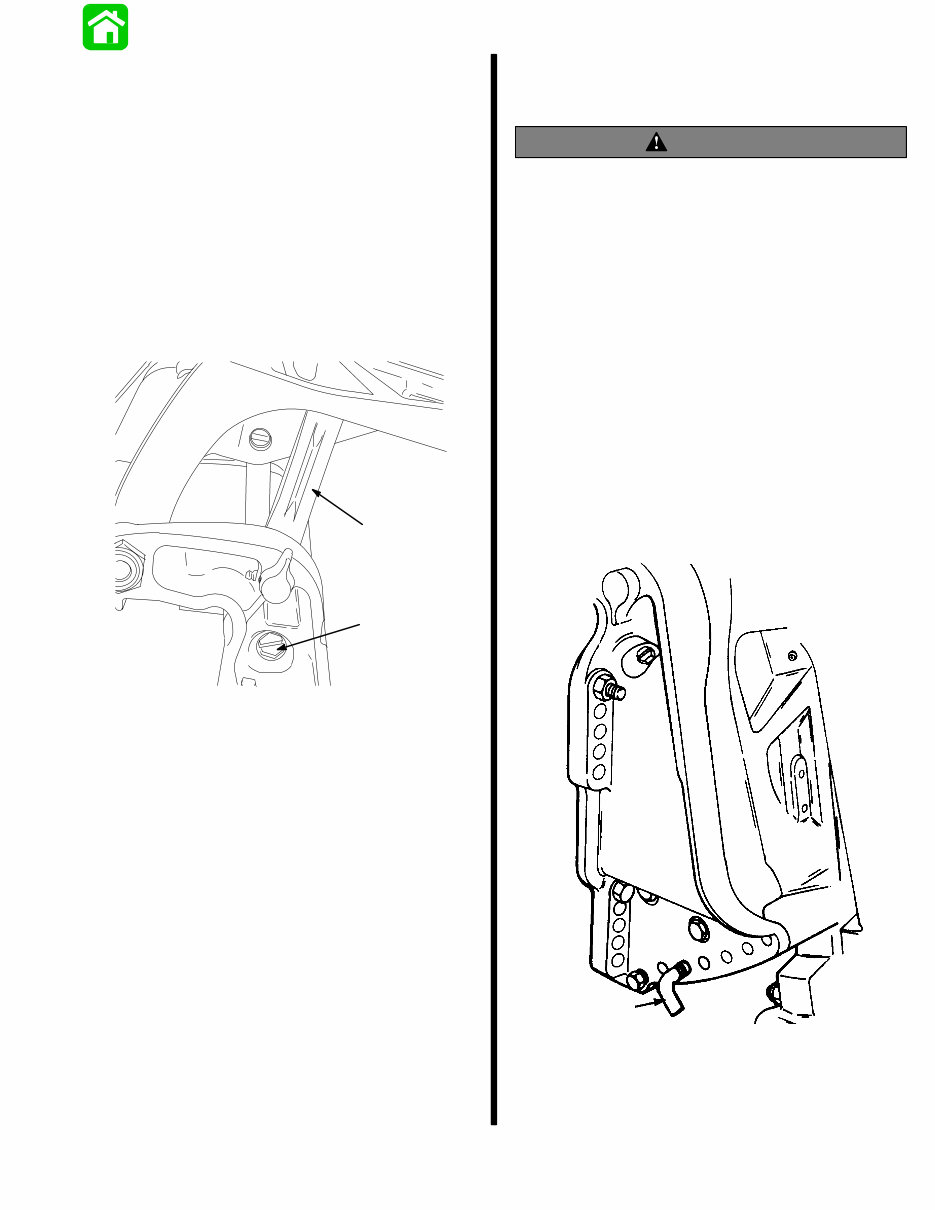

Tilt Angle Adjustment

MODELS WITHOUT POWER TRIM

WARNING

Operating some boats at minimum trim “In” at

planing speeds will cause undesirable and/or

unsafe steering conditions. Each boat should be

tested for handling characteristics after any

adjustment is made to the tilt angle.

DO NOT OPERATE motor with tilt lock pin removed.

Adjust tilt angle of motor on transom with tilt lock pin

so that anti-ventilation plate is about parallel and even

with bottom of boat. Speed sometimes may be im-

proved by tilting motor out one tilt pin hole to raise bow

and reduce wetted surface. If motor is tilted in, boat

will ride bow down, wetting more of the bottom and re-

ducing speed, which generally will improve operation

in rough water. Under ideal conditions, efficiency is

best with lower unit operating in level position. Opera-

tion with excessive tilt angle will reduce performance

noticeably and may induce ventilation. It is preferable

to level boat by proper loading rather than by extreme

adjustment of tilt angle.

22744

a

a - Tilt Lock Pin

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 90 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

- This service repair manual is designed for the Mercury Mariner Outboard 70 75 80 90 100 115 HP models, covering 3/4 cylinder models from 1987 to 1993.

- It includes detailed maintenance and repair procedures, making it suitable for professional mechanics and DIY enthusiasts.

- The manual covers general information, specifications, electrical and ignition systems, fuel system, powerhead, lower unit, power trim, outboard motor installation, and more.

- It features step-by-step instructions, highly detailed exploded pictures, and diagrams to ensure correct and efficient completion of repair procedures.

- With instant access, there are no shipping costs or waiting for physical delivery. The manual is compatible with all versions of Windows and Mac, and it is available in English language.

- Upon payment completion via a secure processor, the manual can be received instantly and all pages are printable for convenience.

File Format:

.PDF (Portable Document Format)