2007 Evinrude E-Tec 40HP/50HP/60HP Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SAFETY INFORMATION

Before working on any part of the outboard, read the SAFETY section at the end of this manual.

This manual is written for qualified, factory-trained

technicians who are already familiar with the use

of Evinrude

®

/Johnson

®

Special Tools. This man-

ual is not a substitute for work experience. It is an

organized guide for reference, repair, and mainte-

nance of the outboard(s).

This manual uses the following signal words iden-

tifying important safety messages.

IMPORTANT: Identifies information that will help

prevent damage to machinery and appears next

to information that controls correct assembly and

operation of the product.

These safety alert signal words mean:

ATTENTION!

BECOME ALERT!

YOUR SAFETY IS INVOLVED!

Always follow common shop safety practices. If

you have not had training related to common shop

safety practices, you should do so to protect your-

self, as well as the people around you.

It is understood that this manual may be trans-

lated into other languages. In the event of any dis-

crepancy, the English version shall prevail.

To reduce the risk of personal injury, safety warn-

ings are provided at appropriate times throughout

the manual.

DO NOT make any repairs until you have read the

instructions and checked the pictures relating to

the repairs.

Be careful, and never rush or guess a service pro-

cedure. Human error is caused by many factors:

carelessness, fatigue, overload, preoccupation,

unfamiliarity with the product, and drugs and alco-

hol use, to name a few. Damage to a boat and

outboard can be fixed in a short period of time, but

injury or death has a lasting effect.

When replacement parts are required, use

Evinrude/Johnson Genuine Parts or parts with

equivalent characteristics, including type, strength

and material. Using substandard parts could result

in injury or product malfunction.

Torque wrench tightening specifications must be

strictly followed. Replace any locking fastener

(locknut or patch screw) if its locking feature

becomes weak. Definite resistance to turning

must be felt when reusing a locking fastener. If

replacement is specified or required because the

locking fastener has become weak, use only

authorized Evinrude/Johnson Genuine Parts.

If you use procedures or service tools that are not

recommended in this manual, YOU ALONE must

decide if your actions might injure people or dam-

age the outboard.

DANGER

Indicates an imminently hazardous situa-

tion which, if not avoided, WILL result in

death or serious injury.

WARNING

Indicates a potentially hazardous situation

which, if not avoided, CAN result in severe

injury or death.

CAUTION

Indicates a potentially hazardous situation

which, if not avoided, MAY result in minor

or moderate personal injury or property

damage. It also may be used to alert

against unsafe practices.

DANGER

Contact with a rotating propeller is likely to result in serious injury or death. Assure the

engine and prop area is clear of people and objects before starting engine or operating boat.

Do not allow anyone near a propeller, even when the engine is off. Blades can be sharp and

the propeller can continue to turn even after the engine is off. Remove propeller before ser-

vicing and when running the outboard on a flushing device.

DO NOT run the engine indoors or without adequate ventilation or permit exhaust fumes to

accumulate in confined areas. Engine exhaust contains carbon monoxide which, if inhaled,

can cause serious brain damage or death.

WARNING

Wear safety glasses to avoid personal injury, and set compressed air to less than 25 psi (172

kPa).

The motor cover and flywheel cover are machinery guards. Use caution when conducting

tests on running outboards. DO NOT wear jewelry or loose clothing. Keep hair, hands, and

clothing away from rotating parts.

During service, the outboard may drop unexpectedly. Avoid personal injury; always support

the outboard’s weight with a suitable hoist or the tilt support bracket during service.

To prevent accidental starting while servicing, disconnect the battery cables at the battery.

Twist and remove all spark plug leads.

The electrical system presents a serious shock hazard. DO NOT handle primary or secondary

ignition components while outboard is running or flywheel is turning.

Gasoline is extremely flammable and highly explosive under certain conditions. Use caution

when working on any part of the fuel system.

Protect against hazardous fuel spray. Before starting any fuel system service, carefully

relieve fuel system pressure.

Do not smoke, or allow open flames or sparks, or use electrical devices such as cellular

phones in the vicinity of a fuel leak or while fueling.

Keep all electrical connections clean, tight, and insulated to prevent shorting or arcing and

causing an explosion.

Always work in a well ventilated area.

Replace any locking fastener (locknut or patch screw) if its locking feature becomes weak.

Definite resistance to tightening must be felt when reusing a locking fastener. If replacement

is indicated, use only authorized replacement or equivalent.

4

T ABLE

OF

CONTENTS

SECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . PAGE

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1 SERVICE SPECIFICATIONS AND SPECIAL TOOLS . . 17

2 INSTALLATION AND PREDELIVERY . . . . . . . . . . . . . . 31

3 MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

4 ENGINE MANAGEMENT MODULE (EMM) . . . . . . . . . . 85

5 SYSTEM ANALYSIS . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

6 ELECTRICAL AND IGNITION . . . . . . . . . . . . . . . . . . . . 123

7 FUEL SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

8 OILING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

9 COOLING SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

10 POWERHEAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

11 MIDSECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

12 GEARCASE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 263

13 TRIM AND TILT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 289

14 MANUAL STARTER . . . . . . . . . . . . . . . . . . . . . . . . . . . 299

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . S–1

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index–1

TROUBLE CHECK CHART . . . . . . . . . . . . . . . . . . . . . . . . T–1

DIAGRAMS

EMM SERVICE CODE CHART

INTRODUCTION

5

INTRODUCTION

CONTENTS

MODELS COVERED IN THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

IDENTIFYING MODEL AND SERIAL NUMBERS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

MODEL DESIGNATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

TYPICAL PAGE – A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

TYPICAL PAGE – B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

TYPICAL PAGE – C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

TYPICAL PAGE – D . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

ABBREVIATIONS USED IN THIS MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

UNITS OF MEASUREMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

LIST OF ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

ENGINE EMISSIONS INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MANUFACTURER’S RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

DEALER’S RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

OWNER’S RESPONSIBILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

EPA EMISSION REGULATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

PRODUCT REFERENCE AND ILLUSTRATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SYMBOLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

VALUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

NOTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6

INTRODUCTION

MODELS COVERED IN THIS MANUAL

MODELS COVERED IN

THIS MANUAL

This manual covers service information on all 2-

cylinder, 52.7 cubic inch, Evinrude E-TEC™ mod-

els.

Use this manual together with the proper Parts

Catalog for part numbers and for exploded views

of the outboard, which are a valuable aid to disas-

sembly and reassembly. This manual presents the

U.S. values and dimensions first and the metric

values and dimensions second, inside parenthe-

ses ( ).

Identifying Model and Serial

Numbers

Outboard model and serial numbers are located

on the swivel bracket and on the powerhead.

Model Number Start Shaft Steer

E40DRLSUM Rope 20” Tiller

E40DPLSUM Electric 20” Remote

E50DPLSUM Electric 20” Remote

E60DPLSUM Electric 20” Remote

1. Model and serial number 002224

1. Serial number 002225

1

1

7

INTRODUCTION

MODEL DESIGNATION

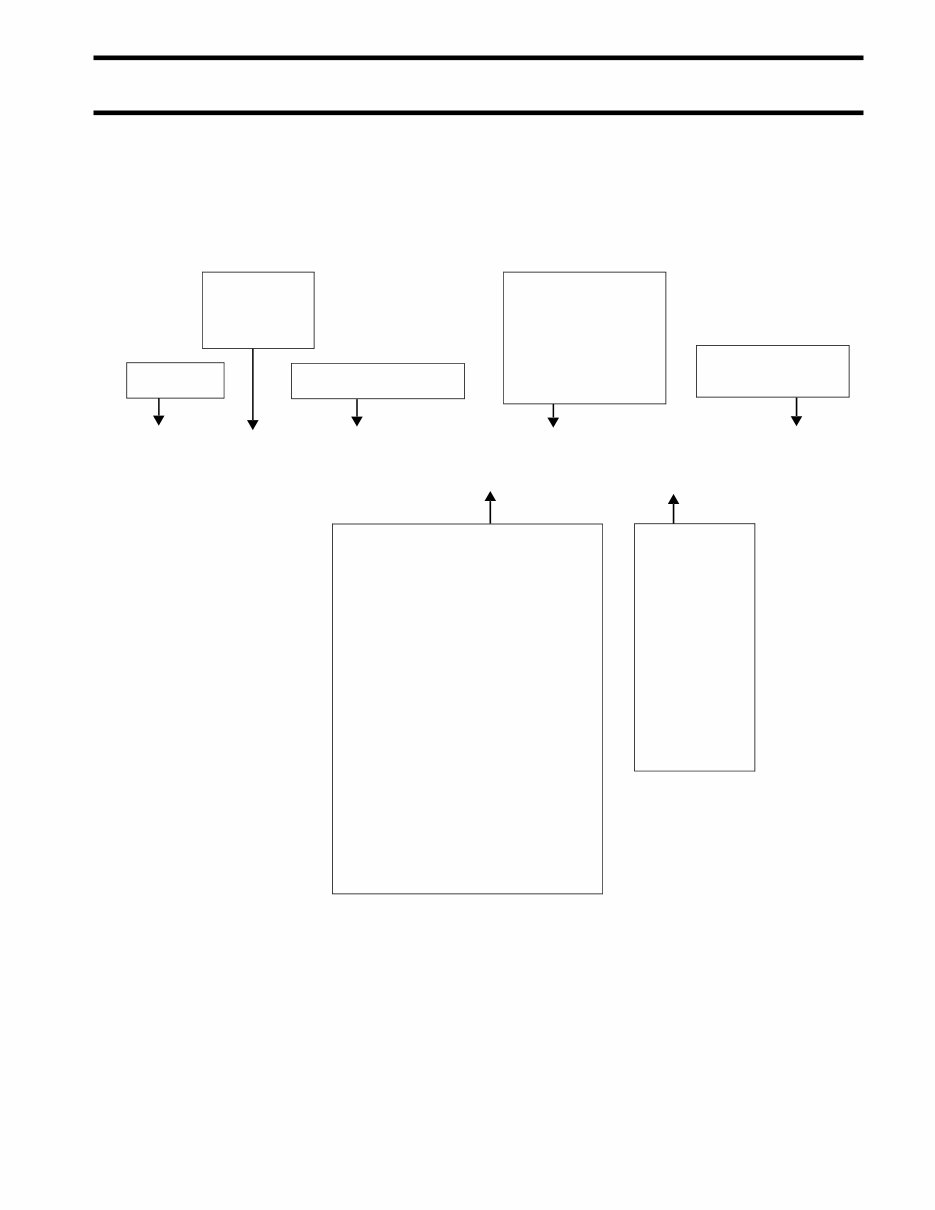

MODEL DESIGNATION

B E 40 DPL SU M

PREFIX

STYLE:

J = Johnson

E = Evinrude

HORSEPOWER

LENGTH:

= 15” Std.

L = 20” Long

Y = 22.5” Special

X = 25” X-long

Z = 30” XX-long

MODEL YR:

I = 1

N = 2

T = 3

R = 4

O = 5

D = 6

U = 7

C = 8

E = 9

S = 0

Ex: SU = 2007

MODEL RUN

or SUFFIX

DESIGN FEATURES:

AP = Advanced Propulsion

B = Blue Paint

C = Counter Rotation

D = Evinrude E-TEC™

E = Electric Start w/Remote Steering

F = Direct-Injection

G = Graphite Paint

H = High Output

J = Jet Drive

M = Military

P = Power Trim and Tilt

R = Rope Start w/Tiller Steering

S = Saltwater Edition

T = Tiller Steering

TE = Tiller Electric

V = White Paint

W = Commercial Model

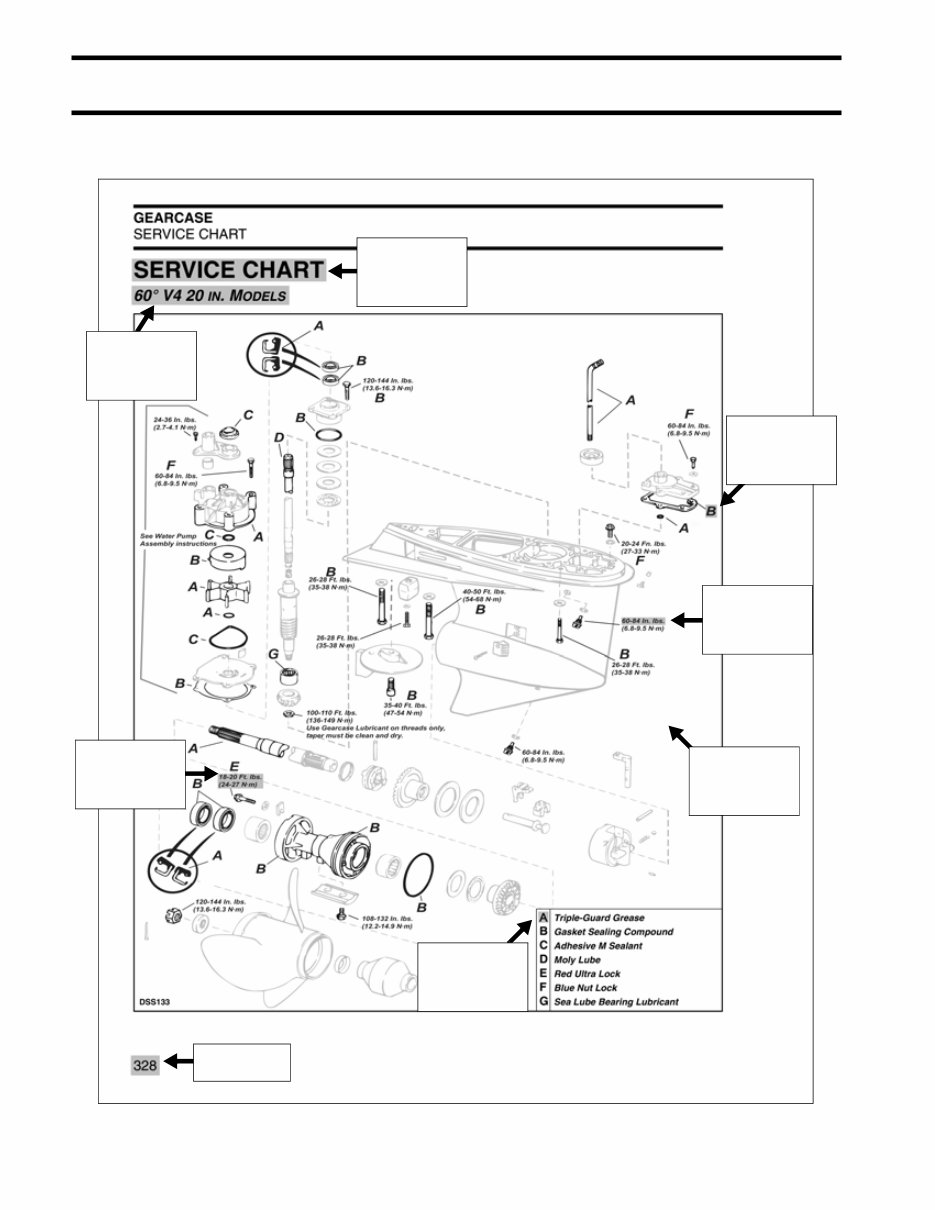

8

INTRODUCTION

TYPICAL PAGE – A

TYPICAL PAGE – A

Page Number

Bold letter indicates

liquid product to be

applied to a surface

Pay attention to

torque specifications.

Some units appear

as in. lbs. Use

appropriate torque.

Tightening torque for

a fastener.

Subsection title

indicates beginning of

the subsection.

Italic subheading

above Service Chart

indicates pertaining

models.

Indicates list

corresponding to

applicable letter in

exploded view of the

Service Chart.

Exploded view of

Service Chart assists

in identifying parts

and positions

INTRODUCTION

TYPICAL PAGE – B

9

TYPICAL PAGE – B

47

INSTALLATION AND PREDELIVERY

OUTBOARD RIGGING PROCEDURE

2

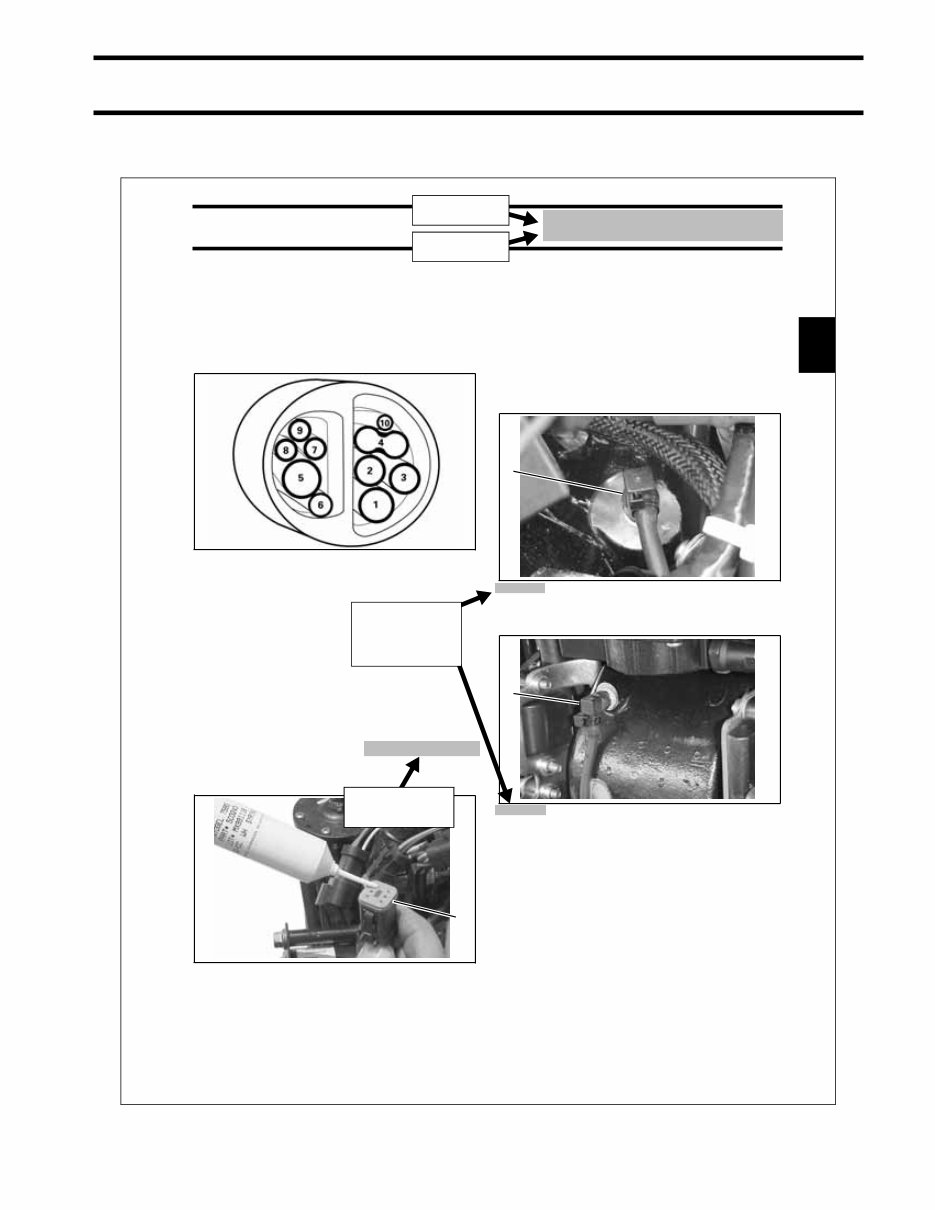

Cable, Hose, and Wire Routing

Route all hoses, control cables, and wiring

through a protective sleeve or conduit into the

boat and through the grommet.

Refer to the following diagram to ensure proper

positioning of rigging components in grommet.

Connect outboard main wire harness to boat main

wire harness.

Before installing electrical connectors, check that

the seal is in place. Clean off any dirt from con-

nectors. Apply a light coat of Electrical Grease™

to the seal. Push connectors together until

latched.

If a water pressure gauge is to be used, install the

water pressure hose fitting in the cylinder block.

Use Pipe Sealant with Teflon (P/N 910048) on the

threads of the hose fitting. Refer to installation

instructions supplied with gauge.

Route the water pressure hose through cover

grommet with oil tank sending unit harness. Route

hose along battery cables toward the back of the

powerhead. Use tie straps to fasten in place.

If temperature gauge is to be used, route sending

unit wire through grommet with hose for water

pressure gauge. Follow the path of battery cables.

Provide adequate length to reach cylinder head.

Refer to installation instructions supplied with

gauge.

1. Fuel supply hose

2. Oil return hose

3. Oil supply hose

4. Battery cables

5. Main wire harness (MWS)

6. Throttle cable

7. Shift cable

8. Oil tank sending unit harness

9. Water pressure hose

10. Accessory charge wire

000084

1. Seal DP0824

1

V4 Models

1. Water pressure fitting location: top, starboard side

of cylinder/crankcase assembly, below throttle

position sensor.

DP0827

V6 Models

1. Water pressure fitting location: rear of cylin-

der/crankcase assembly

DP0828

1

1 Section Title Subsection Title

Model specific

illustrations

designated with

image captions

Products and

lubricants italicized

10

INTRODUCTION

TYPICAL PAGE – C

TYPICAL PAGE – C

272

POWERHEAD

INSTALLATION

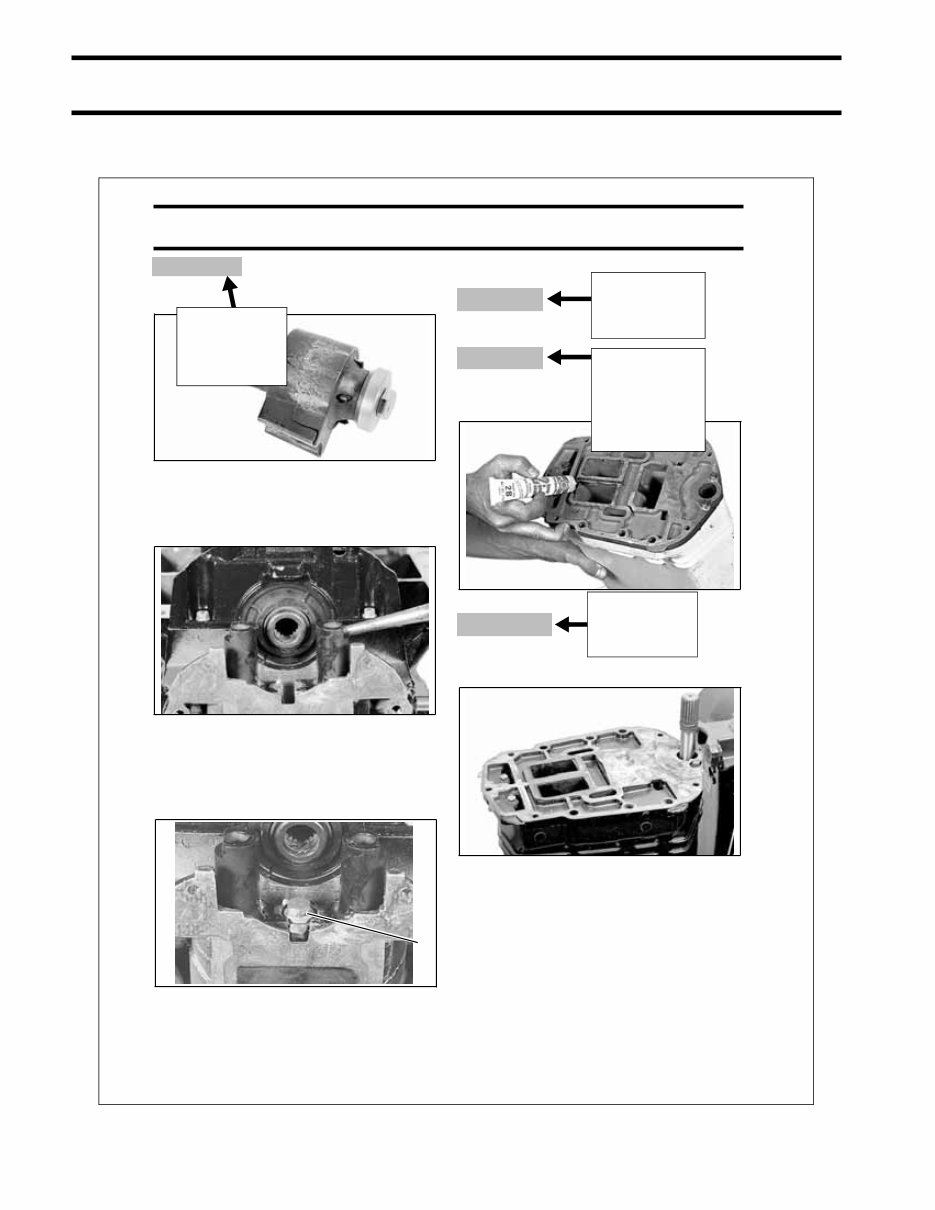

IMPORTANT: The motor mount, washer, and

screw are serviced as an assembly. Do not disas-

semble.

Installation

Place mount assemblies in position, with flats fac-

ing away from each other.

Apply Extreme Pressure Grease to all sides of

retainer and install between mounts.

Apply Nut Lock to retainer screw, install the screw,

and torque to 15 to 20 ft. lbs. (20 to 27 N·m).

INSTALLATION

V4 MODELS

Install base gasket dry. Do not use Permatex

No. 2 or Gasket Sealing Compound.

V6 MODELS

Apply Permatex No. 2 gasket sealant to inner

exhaust housing flange. Coat both sides of a new

base gasket with Gasket Sealing Compound.

ALL MODELS

Install a new base gasket on adapter. To ensure

proper sealing, mating surfaces must be clean

and free of oil, grease, and foreign matter.

Coat the driveshaft splines with Moly Lube. Do not

apply lubricant to end of driveshaft.

39820

49557

1. Mount retainer screw 49556

1

23079

23497

Title in italics indicates

a procedure

concerning a

particular model

Title indicates

from this point,

All Models

are concerned

Denotes necessary

step or information to

prevent damage or

control correct

procedure

Title indicates the

procedure specific to

V4 Models is

finished. From this

point, this particular

procedure concerns

V6 Models.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Viewed 28 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

This workshop manual for the Evinrude E-Tec 40HP/50HP/60HP 2007 is the same manual used by local dealers for repairs. It contains detailed illustrations and step-by-step instructions, and all pages are printable for easy reference in the garage or workshop. These manuals are designed for both do-it-yourself enthusiasts and experienced mechanics, providing an inexpensive way to ensure proper motor functionality.

Each manual offers comprehensive service and repair information, including:

- Introduction

- Service specifications and special tools

- Installation and pre-delivery

- Maintenance

- Engine management module (EMM)

- System analysis

- Electrical and ignition

- Fuel system

- Oiling system

- Cooling system

- Powerhead

- Midsection

- Gearcase

- Trim and tilt

- Safety

- Index

- Trouble check chart

- Diagrams

- EMM service code chart

File Format: PDF

Compatible: All Versions of Windows & Mac

Language: English

Requirements: Adobe Reader

This manual provides instant access without shipping costs or the need to wait for a CD-ROM.