TABLE OF CONTENTS

1 SAFETY

INTRODUCTION

CLEANING, WAXING,

AND POLISHING

CONTROLLING CORROSION

PROPELLERS

FUEL SYSTEM

LOADING

HORSEPOWER

FLOTATION

EMERGENCY EQUIPMENT

COMPASS

STEERING

ANCHORS

MISCELLANEOUS EQUIPMENT

BOATING ACCIDENT REPORTS

NAVIGATION

2 TUNING

INTRODUCTION

TUNE - UP SEQUENCE

COMPRESSION CHECK

SPARK PLUG INSPECTION

IGNITION SYSTEM

SYNCHRONIZING

BATTERY SERVICE

CARBURETOR ADJUSTMENTS

FUEL PUMPS

STARTER AND SOLENOID

INTERNAL WIRING HARNESS

WATER PUMP CHECK

PROPELLER

LOWER UNIT

BOAT TESTING

INTRODUCTION

Theory of Operation

CHAPTER ORGANIZATION

POWERHEAD DISASSEMBLING

HEAD SERVICE

REED SERVICE

Description

Reed Valve Adjustment

Cleaning and Service

BYPASS COVERS

EXHAUST COVER

Cleaning

TOP SEAL

Removal

BOTTOM SEAL

Inspec tion

CENTERING PINS

MAIN BEARING BOLTS

AND CRANKCASE SIDE BOLTS 3 - 15

CRANKCASE COVER 3 - 16

Removal 3 - 16

Cleaning and Inspecting 3 - 16

CONNECTING RODS

AND PISTONS 3 - 16

Removal 3 - 17

Disassembly 3 - 18

Rod Inspection

and Service 3 - 21

Piston and Wing Inspection

and Service 3 - 22

Assembling 3 - 24

CRANKSHAFT 3 - 27

Removal 3 - 27

Cleaning and Inspection 3 - 27

Assembling 3 - 28

CYLINDER BLOCK SERVICE 3 - 28

Honing Procedures 3 - 29

Assembling 3 - 30

Piston and Rod Assembly

Inst allat ion 3 - 30

Crankshaft Installation

Large Horsepower Engines

15 hp to 40 hp 3 - 33

Crankshaft Installation

Small Horsepower Engines

1.5 hp, 5.0 hp, 5.5 hp,

6.0 hp, 9.5 hp 3 - 35

Crankshaft Installation

Small Horsepower Engines

3.0 hp, 4.0 hp, 7.5 hp 3 - 37

Crankcase Cover Installation 3 - 38

Main Bearing Bolt and Crankcase

Side Bolt Installation 3 - 39

Bottom Seal Installation

15 hp to 40 hp Engines 3 - 39

Exhaust Cover and Bypass

Cover Installation 3 - 40

Reed Box Installation 3 - 40

Head Installation 3 - 41

BREAK - IN PROCEDURES 3 - 41

EXPLODED DRAWINGS 3 - 42 - 3 - 50

U DO IT DATA©

4 FUEL

INTRODUCTION

GENERAL CARBURETION

INFORMATION

FUEL SYSTEM

TROUBLESHOOTING

Fuel Pump Tests

Fuel Line Test

Testing with Pressure Tank

Rough Engine Idle

Excessive Fuel Consumption

CARBURETORS

TYPE I CARBURETOR

Removal and Disassembling

Cleaning and Inspecting

Assembling

CHOKE SYSTEM SERVICE

HeatIElectric Choke

All Electric Choke

Water Choke

TYPE I1 CARBURETOR

Disassembling

Cleaning and Inspecting

Assembling

ASSEMBLING CHOKES TO

TYPE 11 CARBURETORS

Adjustments

TYPE 111 CARBURETORS

Removal

Cleaning and Inspecting

Assembling

Adjustments

FUEL PUMP SERVICE

Troubleshooting

Removal and Repair

Cleaning and Inspecting

Assembling and Installation

FUEL TANK AND LINE SERVIC

Disassembling

Cleaning and Inspecting

Assembling

LATE MODEL FUEL TANK

SERVICE

5 IGNITION

INTRODUCTION 5- 1

SPARK PLUG EVALUATION 5 - 2

POLARITY CHECK 5 - 3

WIRING HARNESS 5 - 4

FLYWHEEL MAGNETO IGNITION 5 - 5

TROUBLESHOOTING 5 - 6

SERVICING FLYWHEEL MAGNETO

IGNITION SYSTEM 5- 13

Removal 5- 13

Cleaning and Inspecting 5- 19

Assembling 5 - 20

SYNCHRONIZATION FUEL AND

IGNITION SYSTEMS 5 - 26

Primary Pickup Adjustments

and Locations 5 - 26

6 ELECTRICAL

INTRODUCTION 6 - 1

BATTERIES 6 - 1

Marine Batteries 6 - 1

Battery Construction 6 - 2

Battery Location 6 - 2

Battery Service 6 - 2

Jumper Cables 6 - 5

Dual Battery Installation 6 - 5

GAUGES AND HORNS 6 - 7

Constant - Voltage System 6 - 7

SERVICE PROCEDURES 6 - 7

Temper at ure Gauges 6 - 7

Warning Lights

Thermomelt Sticks 6 - 8

FUEL SYSTEM 6 - 8

Fuel Gauge 6 - 8

Fuel Gauge Hookup 6 - 8

Troubleshooting 6 - 9

TACHOMETER 6 - 10

HORNS 6 - 10

ELECTRICAL SYSTEM GENERAL

INFORMATION 6 - 11

CHARGING CIRCUIT SERVICE 6 - 12

Troubles hooting 6 - 12

Generator Service 6 - 16

Armature Testing 6 - 17

Cleaning and Inspecting 6 - 18

Assembling 6 - 20

CHOKE CIRCUIT SERVICE 6 - 22

STARTER MOTOR CIRCUIT

SERVICE 6 - 22

Circuit Description 6 - 22

Starter Motor Description 6 - 22

Troubleshooting 6 - 24

Testing 6 - 25

STARTER DRIVE GEAR SERVICE 6 - 26

Starter Removal 6 - 26

Drive Gear Disassembling 6 - 27

Cleaning and Inspecting 6 - 27

Assembling Type I Drive 6 - 28

Disassembling Type II 6 - 28

Cleaning and Inspecting 6 - 28

Assembling Type I1 Drive 6 - 28

DEECO-REMY SERVICE 6 - 29

Removal 6 - 29

Disassembling 6 - 29

Armature Testing 6 - 30

Cleaning and Inspecting 6 - 31

Assembling 6 - 32

U DO IT DATA©

6 ELECTRICAL (CONT)

AUTOLITE STARTER MOTOR

SERVICE

Removal

Disassembling

Armature Testing

Cleaning and Inspecting

Assembling

PRESTOLITE STARTER MOTOR

SERVICE

Removal

Disassembling

Armature Testing

Cleaning and Inspecting

Assembling

STARTER MOTOR TESTING

STARTER MOTOR

INSTALLATION

7 ACCESSORIES

INTRODUCTION 7 - 1

SHIFT BOXES 7 - 1

Description 7 - 1

OLD - STYLE DOUBLE LEVER 7 - 3

Troubleshooting 7 - 3

Disassembling 7 - 4

Cleaning and Inspection 7 - 5

Assembling 7 - 5

NEW - STYLE SHIFT LEVER 7 - 6

Troubleshooting 7 - 6

Removal 7 - 8

Disassembling 7 - 8

Cleaning and Inspecting 7 - 9

Assembling 7 - 10

ELECTRIC GEAR BOXES AND

SINGLE LEVER CONTROL 7 - 12

Troubleshooting 7 - 12

Disassembling 7 - 14

Cleaning and Inspecting 7 - 15

Assembling 7 - 16

PUSH BUTTON SHIFT BOX SERVICE

EVINRUDE UNITS ONLY 7 - 18

Troubleshooting 7 - 19

Disassembling 7 - 21

Cleaning and Inspecting 7 - 22

Assembling 7 - 22

CABLE END FITTING INSTALLA -

TION AT THE ENGINE END 7 - 24

8 LOWER UNIT

DESCRIPTION 8 - 1

Chapter Coverage 8 - 1

Illustrations 8 - 2

TROUBLESHOOTING

MANUAL SHIFT 8 - 2

PROPELLER REMOVAL 8 - 7

DRAINING LOWER UNIT

LOWER UNIT SERVICE

1.5 hp to 4.0 hp -- NO SI-IIFT

Lower Unit Removal

Water Pump Removal

Disassembling

Cleaning and Inspecting

Assembling

Water Pump Installation

Lower Unit Installation

Filling the Lower Unit

Propeller Installation

LOWER UNIT SERVICE

MANUAL SHIFT -- 5 HP

TO 25 HP

Removal

Water Pump Removal

Disassembling

Cleaning and Inspecting

Assembling

Water Pump Installation

Lower Unit Installation

LOWER UNIT SERVICE

MANUAL SHIFT -- 28 HP

TO 40 HP 8 - 36

Removal 8 - 37

Water Pump Removal 8 - 38

Disassembling 8 - 38

Cleaning and Inspecting 8 - 41

Assembling 8 - 46

Lower Unit Installation 8 - 50

EEECTROMATIC LOWER UNIT 8 - 53

Description 8 - 53

Troubleshooting 8 - 53

Removal 8 - 56

Disassembling 8 - 57

Cleaning and Inspecting 8 - 65

Assembling 8 - 66

Water Pump Installation 8 - 72

Lower Unit Installation 8 - 74

9 HAND STARTERS

INTRODUCTION 9 - 1

Operation 9 - 2

TYPE I STARTER

CYLINDER WITH PINION GEAR

5 HP and 6 HP ENGINES

9 - 3

Starter Rope Replacement 9 - 4

Removal 9 - 4

Installation 9 - 4

Starter Removal

9 - 5

Disassembling 9 - 7

Cleaning and Inspecting 9 - 7

Assembling 9 - 7 -

U DO IT DATA©

9 HAND STARTERS (CONTI

- TYPE I STARTER

CYLINDER WITH PINION GEAR

ALL 9.5 HP ENGINES 9 - 11

Starter Rope Replacement 9 - 1 1

Removal 9 - 1 1

Installation 9 - 12

Starter Removal 9 - 12

Cleaning and Inspecting 9 - 14

Assembling 9 - 14

Installation 9 - 15

TYPE I1 STARTER

COIL SPRING WITH SWING ARM

DRIVE GEAR

3 HP 1968

4 HP 1969 - 70 9 - 17

Removal 9 - 17

Disassembling 9 - 17

Cleaning and Inspecting 9 - 20

Assembling 9 - 20

TYPE I11 STARTER

MOUNTED ATOP FLYWHEEL

MODEL WITH RETURN SPRINGS

28 HP 1962 - 63

30 HP 1956

35 HP 1957 - 59

40 HP 1960-63 9 - 23

Removal 9 - 24

Cleaning and Inspecting 9 - 26

Assembling 9 - 27

Rope Installation 9 - 29

Starter Installation 9 - 30

TYPE I11 STARTER

MOUNTED ATOP FLYWHEEL

MODEL WITH NO RETURN SPRINGS

28 HP 1964

33 HP 1965 - 70

40 HP 1964 - 70 9 - 31

Removal 9 - 32

Cleaning and Inspecting 9 - 34

Assembling 9 - 34

Rope Installation 9 - 37

Starter Installation 9 - 39

TYPE I11 STARTER

MOUNTED ATOP FLYWHEEL

MODEL WITH ONE NYLON PAWL

3 HP 1956 - 68

5.5 HP 1956 - 64

7.5 HP 1956 - 58

10 HP 1956 - 63

15 HP 1956

18 HP 1956 - 70

20 HP 1966-70

25 HP 1969 - 70 9 - 39

Removal 9 - 40

Disassembling 9 - 40

Cleaning and Inspecting 9 - 42

Assembling 9 - 43

Rope Installation 9 - 43

Starter Installation 9 - 46

10 MAINTENANCE

INTRODUCTION

ENGINE SERIAL NUMBERS

FIBERGLASS HULLS

ALUMINUM HULLS

BELOW WATERLINE SERVICE

SUBMERGED ENGINE SERVICE

WINTER STORAGE

LOWER UNIT SERVICE

Propeller

BATTERY STORAGE

PRESEASON PREPARATION

APPENDIX

METRIC CONVERSION CHART A-1

DRILL SIZE CONVERSION CHART A - 2

TORQUE SPECIFICATIONS A - 3

POWERHEAD SPECS A - 4 & A - 5

TUNE - UP SPECS A - 6 to A10

GEAR OIL CAPACITIES A-11

STARTER MOTOR SPECS A - 12

REGULATOR SPECS A - 12

GENERATOR SPECS A - 12

CONDENSER SPECS A - 13

STARTER ROPE SPECS A - 14

WIRE INDENTIFICATION DRAWINGS

20 hp and 25 hp -- 197 1 - 72 A - 15

33 hp with Generator -- 1965 - 67 A - 16

33 hp with Generator -- 1968 A - 17

33 hp with Generator -- 1969 - 70 A - 18

35 hp - - 1957 - 59 A - 19

40 hp Standard Shift

with Generator -- 1960 - 66 A - 20

40 hp Standard Shift

with Generator -- 1967 - 68 A - 21

40 hp Standard Shift

with Generator -- 1969 - 70 A - 22

40 hp Electric Shift

with Generator - - 1961 - 66 A - 23

40 hp Electric Shift

with Generator -- 1967-68 A - 24

40 hp Electric Shift

with Generator -- 1969 - 70 A - 25

U DO IT DATA©

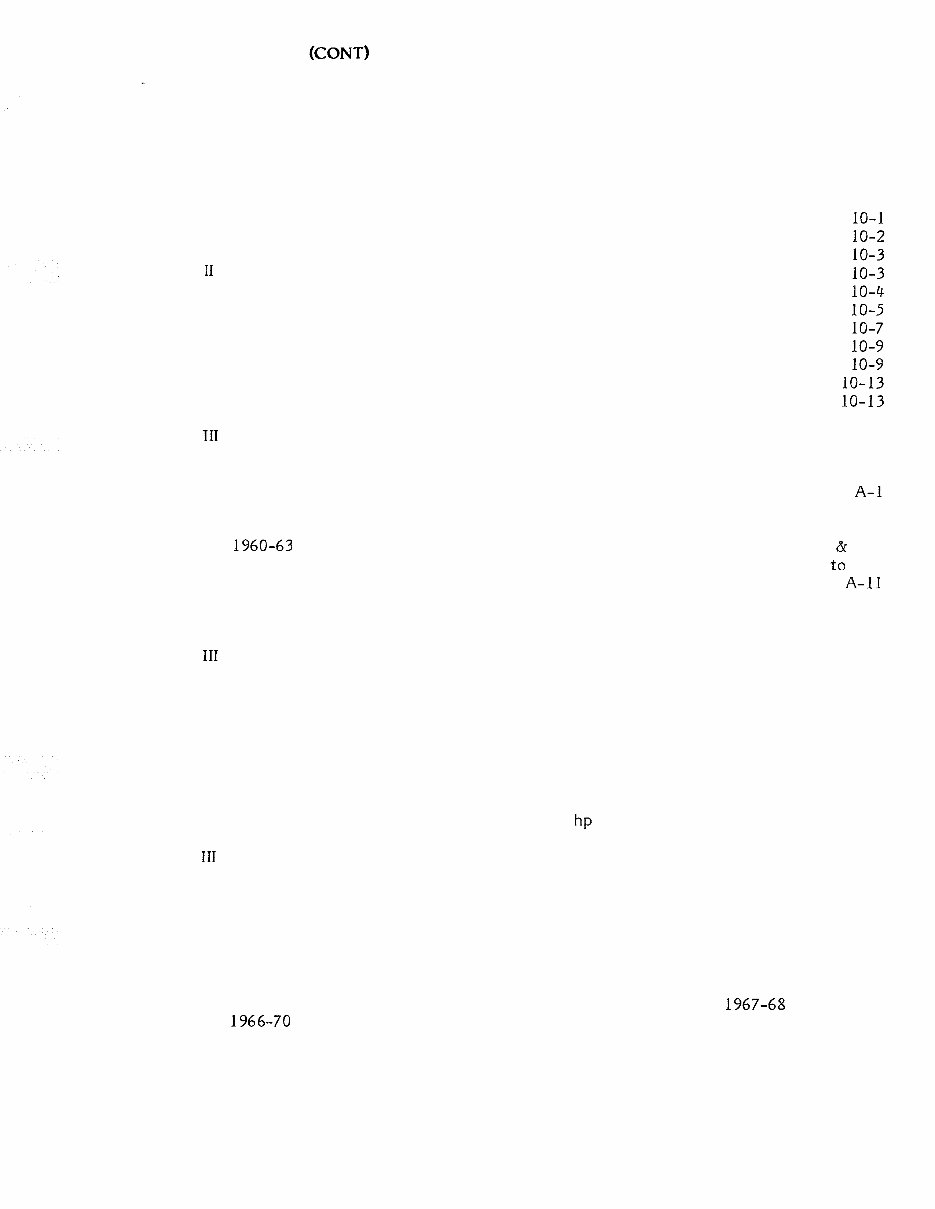

SAFETY

1 - 1 INTRODUCTION

Your boat probably represents a sizeable

investment for you. In order to protect this

investment and to receive the maximum

amount of enjoyment from your boat it must

be cared for properly while being used and

when it is out of the water. Always store

your boat with the bow higher than the stern

and be sure to remove the transom drain

plug and the inner hull drain plugs. If you

use any type of cover to protect your boat,

plastic, canvas, whatever, be sure to allow

for some movement of air through the hull.

Proper ventilation will assure evaporation of

any condensation that may form due to

changes in temperature and humidity.

1 - 2 CLEANING, WAXING, AND POLISHING

An outboard boat should be washed with

clear water after each use to remove sur -

face dirt and any salt deposits from use in

salt water. Regular rinsing will extend the

time between waxing and polishing. It will

also give you " pride of ownership " , by

having a sharp looking piece of equipment.

Elbow grease, a mild detergent, and a brush

Whenever the boat is stored, for long or short

periods, the bow should be slightly higher than the stern

and the drain plug in the transom removed to ensure

proper drainage of rain water.

will be required to remove stubborn dirt, oil,

and other unsightly deposits.

Stay away from harsh abrasives or strong

chemical cleaners. A white buffing com -

pound can be used to restore the original

gloss to a scratched, dull, or faded area.

The finish of your boat should be thoroughly

cleaned, buffed, and polished at least once

each season. Take care when buffing or

polishing with a marine cleaner not to over -

heat the surface you are working, because

you will burn it.

A small outboard engine mounted on an

aluminum boat should be removed from the

boat and stored separately. Under all cir -

cumstances, any outboard engine must AL -

WAYS be stored with the powerhead higher

than the lower unit and exhaust system.

This position will prevent water trapped in

the lower unit from draining back through

the exhaust ports into the powerhead.

Lower unit badly corroded because the zinc was not

replaced. Once the zinc is destroyed, more costly parts

will be damaged. Attention to the zinc condition is

extremely important during boat operation in salt

water.

U DO IT DATA©

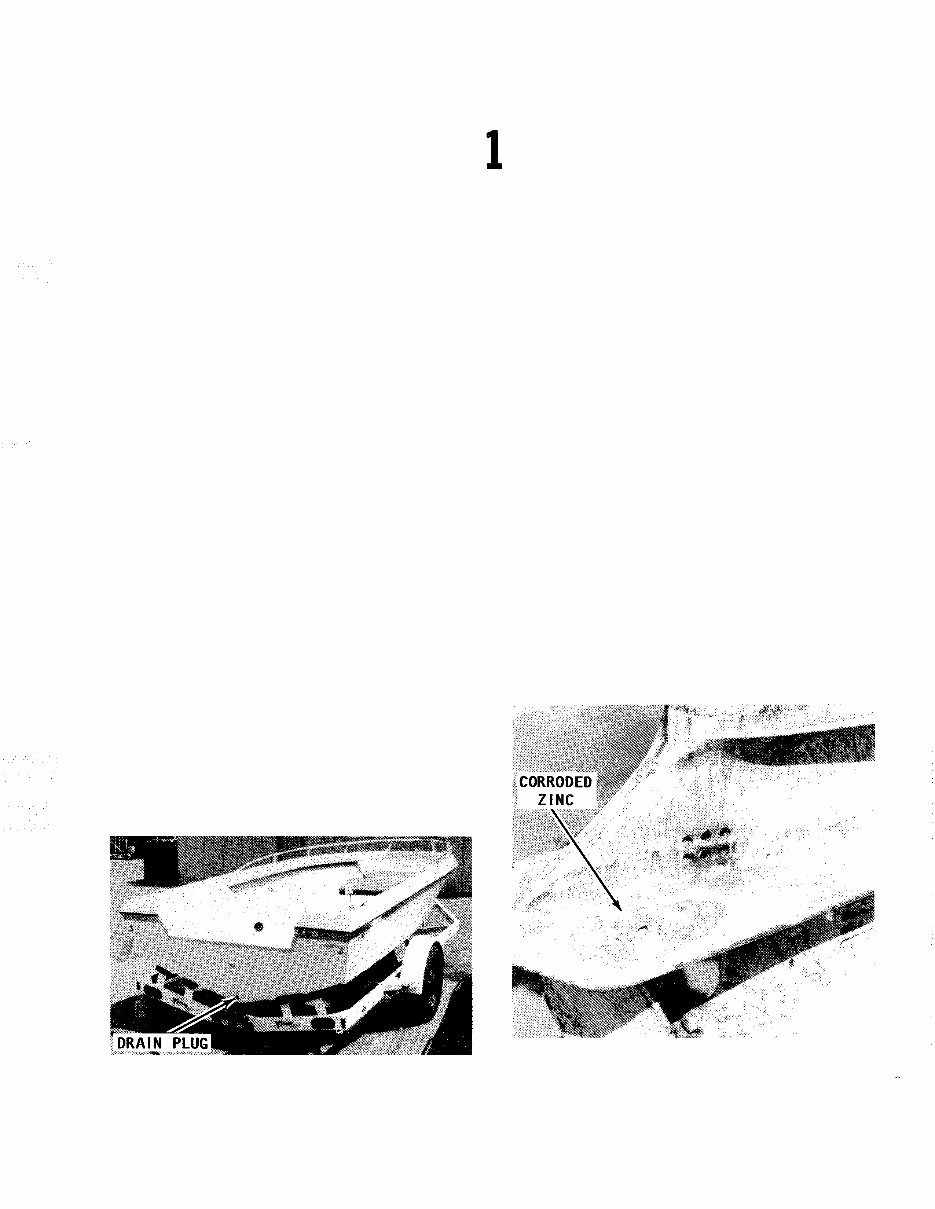

1 - 2 SAFETY

A new zinc prior to installation. This inexpensive

item will save corrosion on more valuable parts.

Most outboard engines have a flat area

on the back side of the powerhead. When

the engine is placed with the flat area on

the powerhead and the lower unit resting on

the floor, the engine will be in the proper

altitude with the powerhead higher than the

lower unit.

1 - 3 CONTROLLING CORROSION

Since man first started out on the water,

corrosion on his craft has been his enemy.

The first form was merely rot in the wood

and then it was rust, followed by other

forms of destructive corrosion in the more

modern materials. One defense against cor -

rosion is to use similar metals throughout

the boat. Even though this is difficult to do

in designing a new boat, particularily the

undersides, similar metals should be used

whenever and wherever possible.

A second defense against corrosion is to

insulate dissimilar metals. This can be done

by using an exterior coating of Sea Skin or

by insulating them with plastic or rubber

gaskets.

Using Zinc

The proper amount of zinc attached to a

boat is extremely important. The use of too

much zinc can cause wood burning by plac -

ing the metals close together and they be -

come "hot". On the other hand, using too

Diameter and pitch are the two basic dimensions of

a propeller. The diameter is measured across the

circumference of a circle scribed by the propeller

blades, as shown.

small a zinc plate will cause more rapid

deterioration of the metal you. are trying to

protect. If in doubt, consider the fact that

is is far better to replace the zincs than to

replace planking or other expensive metal

parts from hav& an excess of zinc.

When installihg zinc plates, there are

two routes available. One is to install many

different zincs on all metal parts and thus

run the risk of wood burning. Another

route, is to use one large zinc on the tran -

som of the boat and then connect this zinc

to every underwater metal part through

internal bonding. Of the two choices, the

one zinc on the transom is the better way to

go*

Small outboard engines have a zinc plate

attached to the cavitation plate. Therefore,

the zinc remains with the engine at all

times.

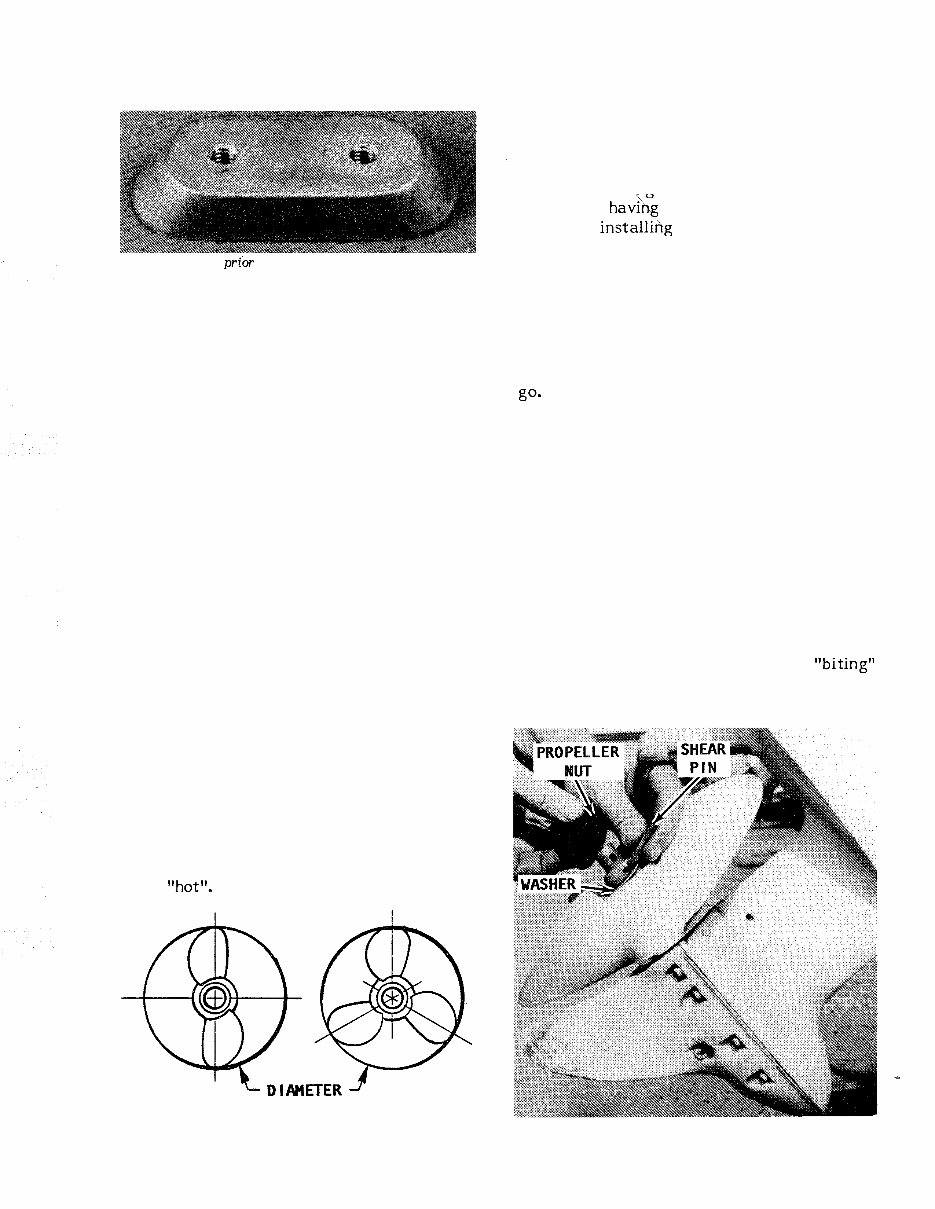

1 - 4 PROPELLERS

As you know, the propeller is actually

what moves the boat through the water.

This is how it is done. The propeller oper -

ates in water in much the manner as a wood

screw does in wood. The propeller " bites' "

into the water as it rotates. Water passes

between the blades and out to the rear in

the shape of a cone. The propeller "biting"

through the water in much the same manner

as a wood auger is what propels the boat.

Propeller and associated parts in order, washer,

shear - pin, and nut, ready for installation.

U DO IT DATA©

PROPELLERS 1 - 3

Arrangement of propeller and associated parts, in

order, for a small horsepower engine.

Diameter and Pitch

Only two dimensions of the propeller are

of real interest to the boat owner: the

diameter and the pitch. These two dimen -

sions are stamped on the propeller hub and

always appear in the same order: the diam -

eter first and then the pitch. For instance,

the number 15 - 19 stamped on the hub,

would mean the propeller had a diameter of

15 inches with a pitch of 19.

The diameter is the measured distance

from the tip of one blade to the tip of the

other as shown in the accompanying illus -

tration.

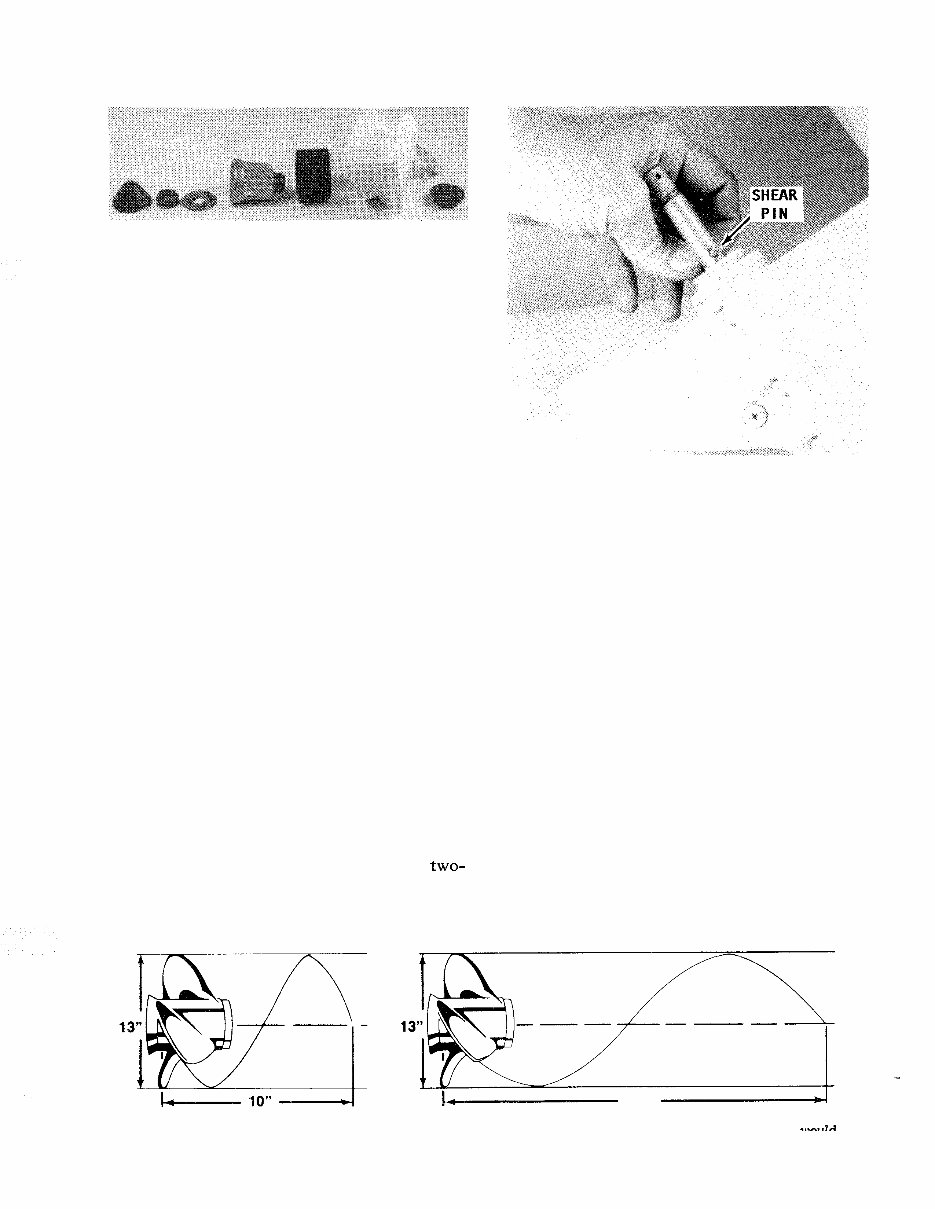

The pitch of a propeller is the angle at

which the blades are attached to the hub.

This figure is expressed in inches of water

travel for each revolution of the propeller.

In our example of a 15 - 19 propeller, the

propeller should travel 19 inches through the

water each time it revolves. If the propel -

ler action was perfect and there was no

slippage, then the pitch multiplied by the

propeller rpms would be the boat speed.

Most outboard manufacturers equip their

units with a standard propeller with a diam -

eter and pitch they consider to be best

suited to the engine and the boat. Such a

propeller allows the engine to run as near to

the rated rpm and horsepower (at full throt -

tle) as possible for the boat design.

The blade area of the propeller deter -

mines its load - carrying capacity. A two-

blade propeller is used for high - speed run -

ning under very light loads.

Shear - pin installed behind the propeller instead of in

front of the propeller.

A four - blade propeller is installed in

boats intended to operate at low speeds

under very heavy loads such as tugs, barges,

or large houseboats. The three - blade pro -

peller is the happy medium covering the

wide range between the high performa'nce

units and the load carrying workhorses.

Propeller Selection

There is no standard propeller that will

do the proper job in very many cases. The

list of sizes and weights of boats is almost

endless. This fact coupled with the many

boat - engine combinations makes the propel -

ler selection for a specific purpose a diffi -

cult job. In fact, in many cases the propel -

ler is changed after a few test runs. Proper

selection is aided through the use of charts

set up for various engines and boats. These

charts should be studied and understood

when buying a propeller. However, bear in

mind, the charts are based on average boats

Diagram to explain the pitch dimension

through the water if there was no slippage.

L_ 21 "

of a propeller. The pitch is the theoretical distance a propeller would

<.

travel

U DO IT DATA©

1 - 4 SAFETY

with average loads, therefore, it may be

necessary to make a change in size or pitch,

in order to obtain the desired results for the

hull design or load condition.

A wide range of pitch is available for

each of the larger horsepower engines. The

choice available for the smaller engines, up

to about 25 hp, is restricted to one or two

sizes. Remember, a low pitch takes a

smaller bite of the water than the high pitch

propeller. This means the low pitch propel -

ler will travel less distance through the

water per revolution. The low pitch will

require less horsepower and will allow the

engine to run faster and more efficiently.

It stands to reason, and it's true, that the

high pitch propeller will require more horse -

power, but will give faster boat speed if the

engine is allowed to turn to its rated rpm.

If a higher - pitched propeller is installed

on a boat, in an effort to get more speed,

extra horsepower will be required. If t h e

extra power is not available, the rpms will

be reduced to a less efficient level and the

actual boat speed will be less than if the

lower - pitched propeller had been left in -

stalled.

All engine manufacturers design their

units to operate with full throttle at, or

slightly above, the rated rpm. If you run

your engine at the rated rpm, you will

increase spark plug life, receive better fuel

economy, and obtain the best performance

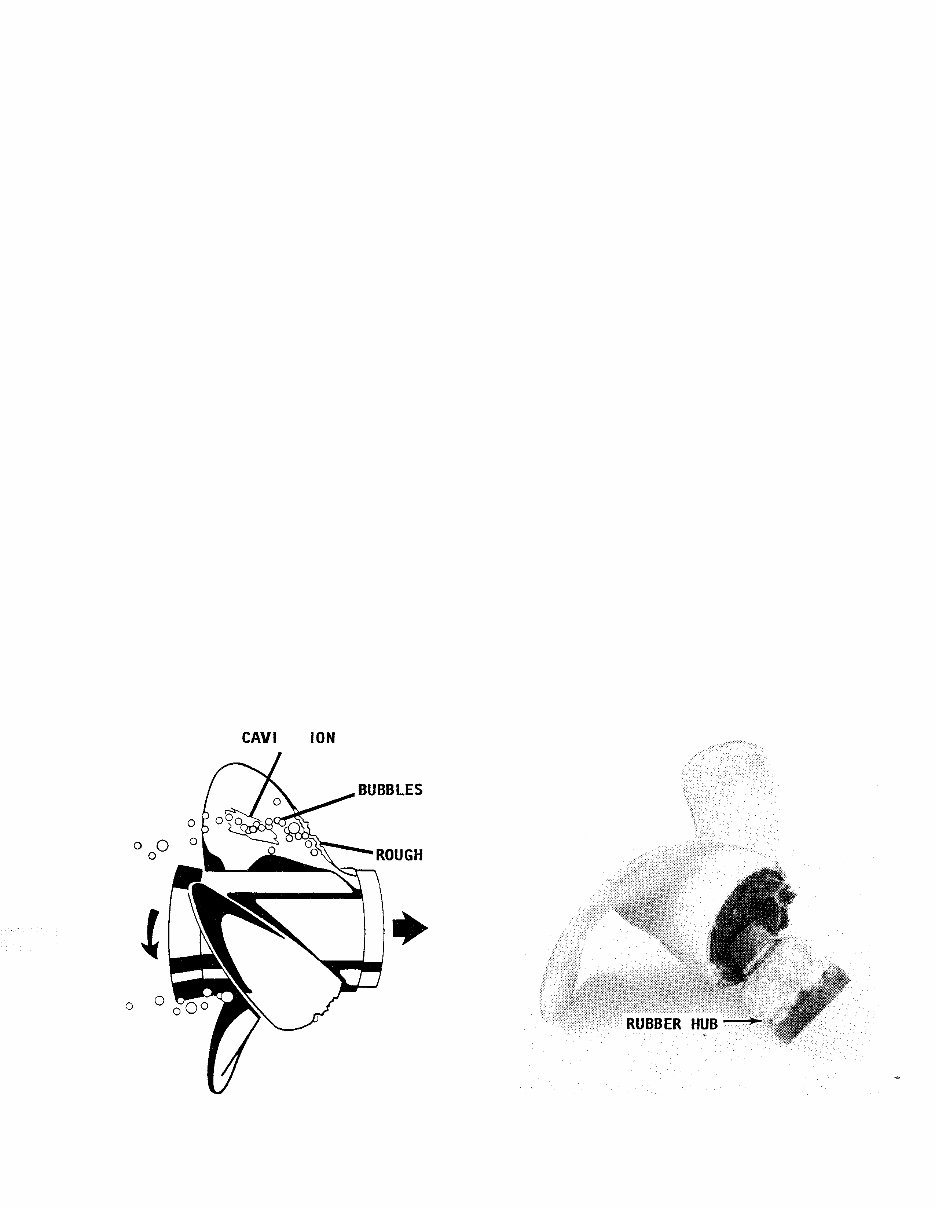

CAVl TAT ION BURN

from your boat and engine. Therefore, take

time to make the proper propeller selection

for the rated rprn of your engine at full

throttle with what you consider to be an

average load. Your boat will then be cor -

rectly balanced between engine and pro -

peller throughout the entire speed range.

A reliable tachometer must be used to

measure engine speed at full throttle to

ensure the engine will achieve full horse -

power and operate efficiently and safely.

To test for the correct propeller, make your

run in a body of smooth water with the

lower unit in forward gear at full throttle.

Observe the tachometer at full throttle.

NEVER run the engine at a high rprn when a

flush attachment is installed. If the reading

is above the manufacturer's recommended

operating range, you must try propellers of

greater pitch, until you find the one that

allows the engine to operate continually

within the recommended full throttle range.

If the engine is unable to deliver top

performance and you feel it is properly

tuned, then the propeller may not be to

blame. Operating conditions have a marked

effect on performance. For instance, an

engine will lose rprn when run in very cold

water. It will also lose rprn when run in salt

water as compared with fresh water. A hot,

low - barometer day will also cause your en -

gine to lose power.

EDGE

Cavitation (air bubbles) formed at the propeller. Example of a damaged propeller. This unit should

Manufacturers are constantly fighting this problem, as have been replaced long before this amount of damage

explained in the text. was sustained.

U DO IT DATA©

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual