1992 Johnson Evinrude 2-300HP Outboards OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

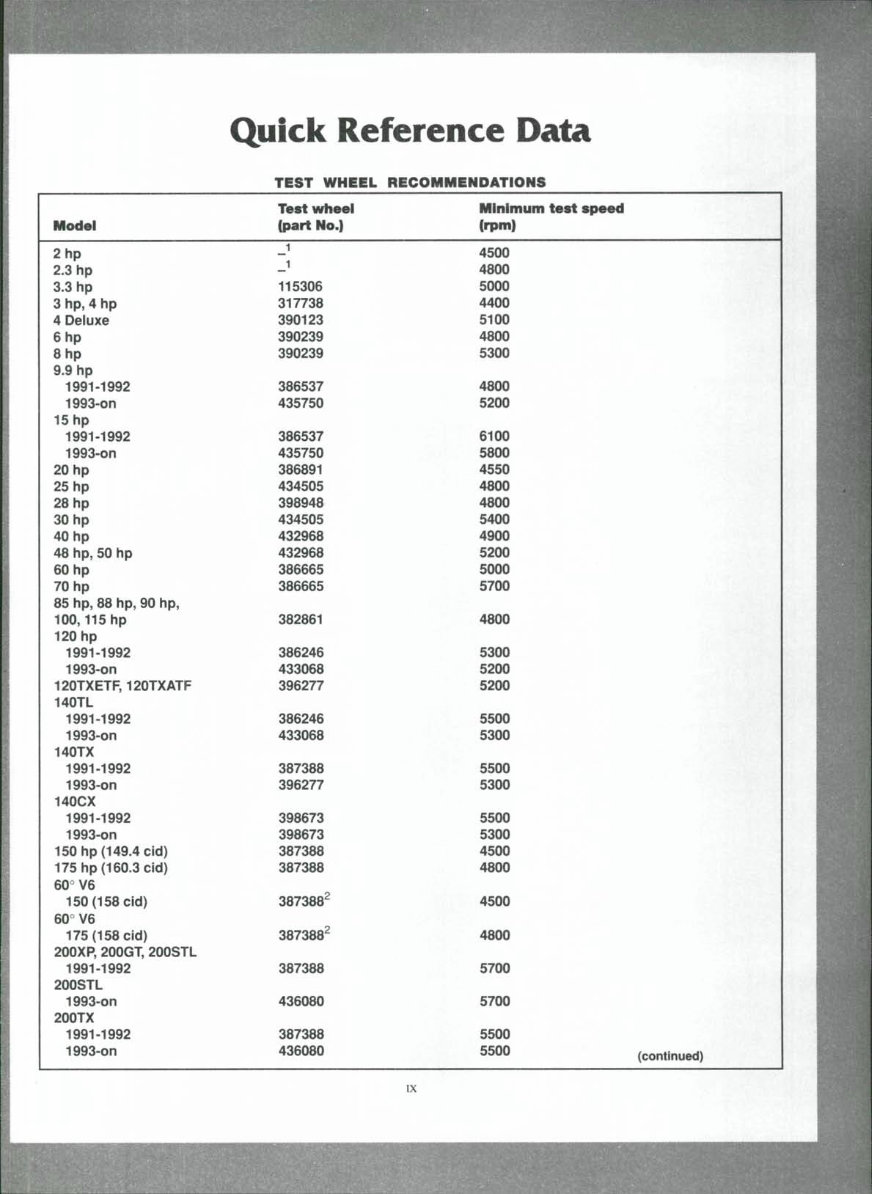

Quick Reference Data

Model

2hp

2.3 hp

3.3 hp

3 hp, 4 hp

4 Deluxe

6hp

8hp

9.9 hp

1991-1992

1993-on

15 hp

1991-1992

1993-on

20 hp

25 hp

28 hp

30 hp

40 hp

48 hp, 50 hp

60 hp

70 hp

85 hp, 88 hp, 90 hp,

100,115 hp

120 hp

1991-1992

1993-on

120TXETF, 120TXATF

140TL

1991-1992

1993-on

140TX

1991-1992

1993-on

140CX

1991-1992

1993-on

150 hp (149.4 ctd)

175 hp (160.3 cid)

60° V6

150 (158 cid)

60° V6

175 (158 cid)

200XP, 200GT, 200STL

1991-1992

200STL

1993-on

200TX

1991-1992

1993-on

TEST WHEEL

Test wheel

(part No.)

_i

_1

115306

317738

390123

390239

390239

386537

435750

386537

435750

386891

434505

398948

434505

432968

432968

386665

386665

382861

386246

433068

396277

386246

433068

387388

396277

398673

398673

387388

387388

387388^

387388^

387388

436080

387388

436080

RECOMMENDATIONS

Minimum test speed

(rpm)

4500

4800

5000

4400

5100

4800

5300

4800

5200

6100

5800

4550

4800

4800

5400

4900

5200

5000

5700

4800

5300

5200

5200

5500

5300

5500

5300

5500

5300

4500

4800

4500

4800

5700

5700

5500

^50^ (continued)

IX

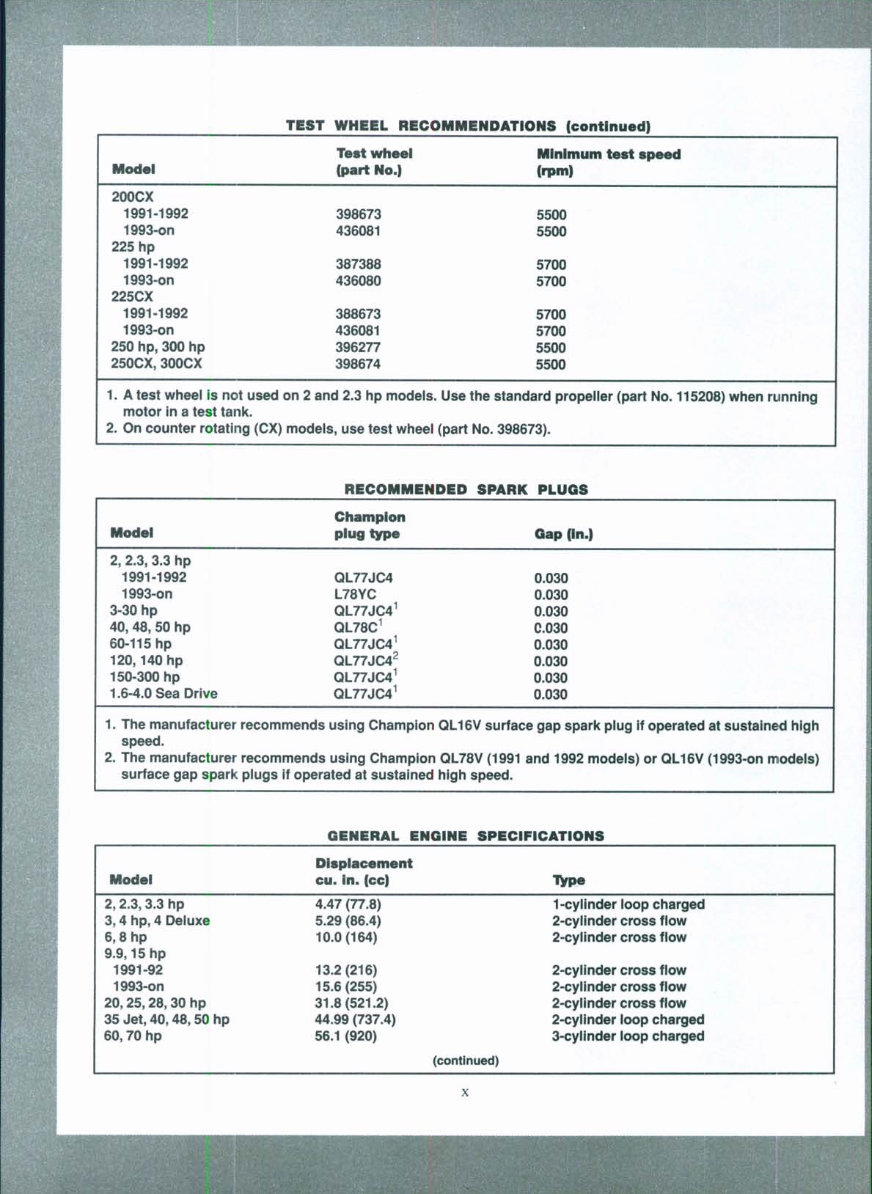

TEST WHEEL RECOMMENDATIONS (continued)

Model

200CX

1991-1992

1993-on

225 hp

1991-1992

1993-on

225CX

1991-1992

1993-on

250 hp, 300 hp

250CX, 300CX

1. A test wheef is not used

motor in a test tank.

2. On counter rotating (CX)

Test wheel

(part No.)

398673

436081

387388

436080

388673

436081

396277

398674

on 2 and 2.3 hp modeis.

modeis, use test wheei

Minimum test speed

(rpm)

5500

5500

5700

5700

5700

5700

5500

5500

Use the standard propeMer (part No. 115208) when running

(part No. 398673).

RECOMMENDED SPARK PLUGS

Model

2, 2.3, 3.3 hp

1991-1992

1993-on

3-30 hp

40, 48, 50 hp

60-115 hp

120,140 hp

150-300 hp

1.6-4.0 Sea Drive

1. The manufacturer recommends

speed.

2. The manufacturer recommends

Champion

plug type

QL77JC4

L78YC

QL77JC4^

QL78C^

QL77JC4^

QL77JC4^

QL77JC4^

QL77JC4^

using Champion

using Champion

surface gap spark piugs if operated at sustained

Gap (In.)

0.030

0.030

0.030

C.030

0.030

0.030

0.030

0.030

QL16V surface gap spark piug if operated at sustained high

QL78V (1991 and 1992 models) or QL16V (1993-on modeis)

high speed.

GENERAL ENGINE SPECIFICATIONS

Model

2,2.3,3.3 hp

3,4 hp, 4 Deiuxe

6,8hp

9.9,15hp

1991-92

1993-on

20,25,28,30 hp

35 Jet, 40,48,50 hp

60,70 hp

Displacement

cu. In. (cc)

4.47 (77.8)

5.29 (86.4)

10.0(164)

13.2(216)

15.6(255)

31.8(521.2)

44.99 (737.4)

56.1 (920)

(continued)

Type

1-cylinder ioop charged

2-cyiinder cross flow

2-cyiinder cross fiow

2-cyiinder cross fiow

2-cylinder cross fiow

2-cyiinder cross flow

2-cyiinder ioop charged

3-cylinder loop charged

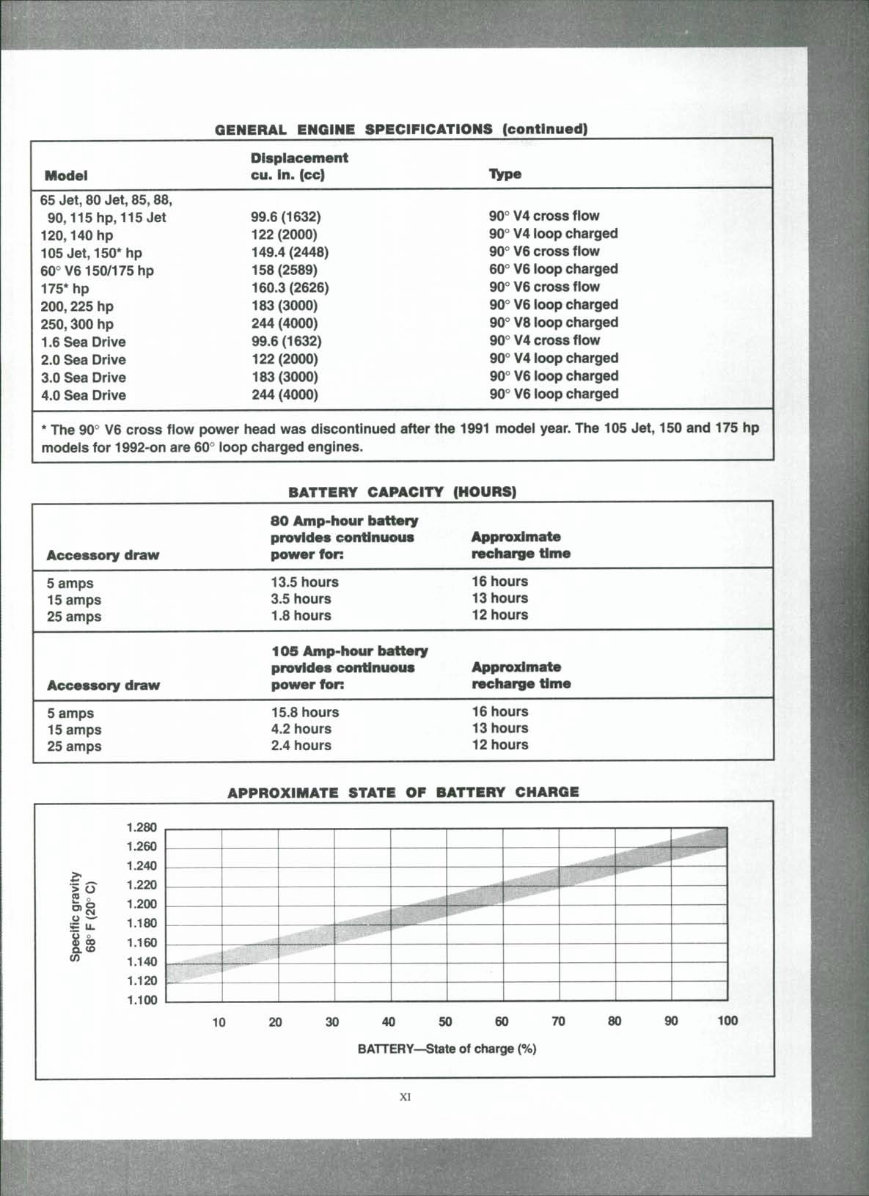

GENERAL ENGINE SPECIFICATIONS (continued)

Model

65 Jet, 80 Jet, 85,88,

90,115 hp, 115 Jet

120,140 hp

105 Jet, 150* hp

60° V6150/175 hp

175* hp

200,225 hp

250, dOO hp

1.6 Sea Drive

2.0 Sea Drive

3.0 Sea Drive

4.0 Sea Drive

Displacement

cu. In. (cc)

99.6(1632)

122(2000)

149.4(2448)

158(2589)

160.3(2626)

183(3000)

244 (4000)

99.6(1632)

122(2000)

183(3000)

244 (4000)

* The 90'' V6 cross flow power head was discontinued

modeis for 1992-on are 60'' ioop charged engines.

Type

90"" V4 cross flow

90° V4 loop charged

90° V6 cross fiow

60"" V6 ioop charged

90° V6 cross flow

90° V6 ioop charged

90° V8 ioop charged

90° V4 cross fiow

90° V4 ioop charged

90° V6 loop charged

90° V6 loop charged

after the 1991 model year. The 105 Jet, 150 and 175 hp

Accessory draw

5 amps

15 amps

25 amps

Accessory draw

5 amps

15 amps

25 amps

BATTERY CAPACITY

SO Amp"hour battmry

provides continuous

power foR

13.5 hours

3.5 hours

1.8 hours

109 Amp-hour battery

provides continuous

power foR

15.8 hours

4.2 hours

2.4 hours

(HOURS)

Approximate

recharge time

16 hours

13 hours

12 hours

Approximate

recharge time

16 hours

13 hours

12 hours

APPROXIMATE STATE OF BATTERY CHARGE

gravity

20° C)

Specific

68° F(

1.280

1.260

1.240

1.220

1.200

1.160

1.140

1.120

1.100

10 2 0 3 0 4 0 5 0 6 0 7 0 8 0 9 0 100

BATTERY'-State of charge (%)

XI

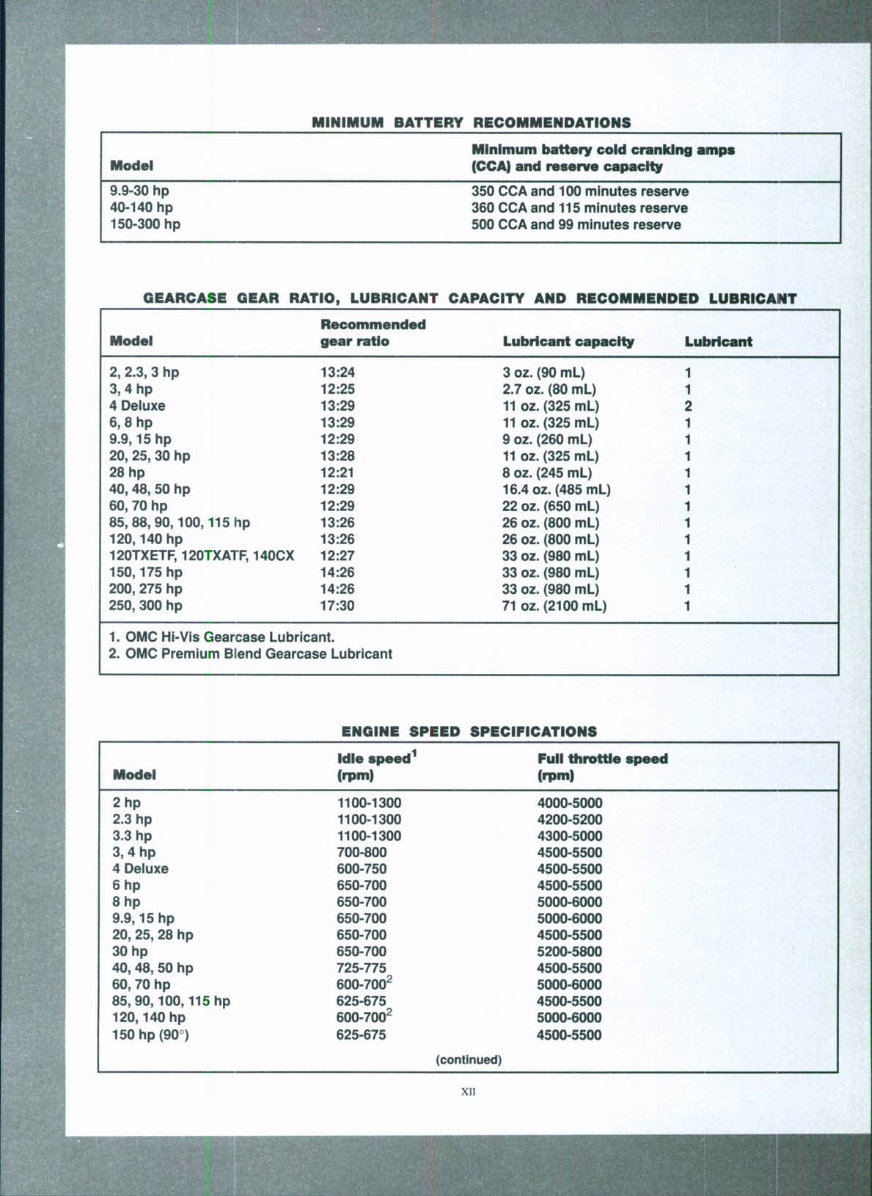

MINIMUM BATTERY RECOMMENDATIONS

Model

Minimum battery cold cranking amps

and reserve capacity

9.9-30 hp

40-140 hp

150-300 hp

350 CCA and 100 minutes reserve

360 CCA and 115 minutes reserve

500 CCA and 99 minutes reserve

GEARCASE GEAR

Model

2, 2.3, 3 hp

3,4hp

4 Deluxe

6,8hp

9.9,15 hp

20, 25, 30 hp

28 hp

40,48, 50 hp

60, 70 hp

85,88,90,100,115 hp

120,140 hp

RATIO, LUBRICANT

Recommended

gear ratio

13:24

12:25

13:29

13:29

12:29

13:28

12:21

12:29

12:29

13:26

13:26

120TXETF, 120TXATF, 140CX 12:27

150,175 hp

200, 275 hp

250,300 hp

14:26

14:26

17:30

1. OMC Hi-Vis Gearcase Lubricant.

2. OMC Premium Blend Gearcase Lubricant

CAPACITY AND RECOMMENDED LUBRICANT

Lubricant capacity 1

3 oz. (90 mL)

2.7 oz. (80 mL)

11 oz. (325 mL) :

11 oz. (325 mL)

9 oz. (260 mL)

11 oz. (325 mL)

8 oz. (245 mL)

16.4 oz. (485 mL)

22oz.(650mL)

26 oz. (800 mL)

26 oz. (800 mL)

33 oz. (980 mL)

33 oz. (980 mL)

33 oz. (980 mL) i

71 oz. (2100 mL)

Lubricant

1

1

2

1

1

1

1

ENGINE SPEED SPECIFICATIONS

Model

2hp

2.3 hp

3.3 hp

3, 4 hp

4 Deiuxe

6hp

8hp

9.9,15hp

20, 25, 28 hp

30 hp

40, 48, 50 hp

60, 70 hp

85,90,100,115 hp

120,140 hp

150hp(90°)

Idle speed^

(rpm)

1100-1300

1100-1300

1100-1300

700-800

600-750

650-700

650-700

650-700

650-700

650-700

725-775

600-700^

625-675

600-700^

625-675

(continued)

Full throttle speed

(rpm)

4000-5000

4200-5200

4300-5000

4500-5500

4500-5500

4500-5500

5000-6000

5000-6000

4500-5500

5200-5800

4500-5500

5000-6000

4500-5500

5000-6000

4500-5500

XII

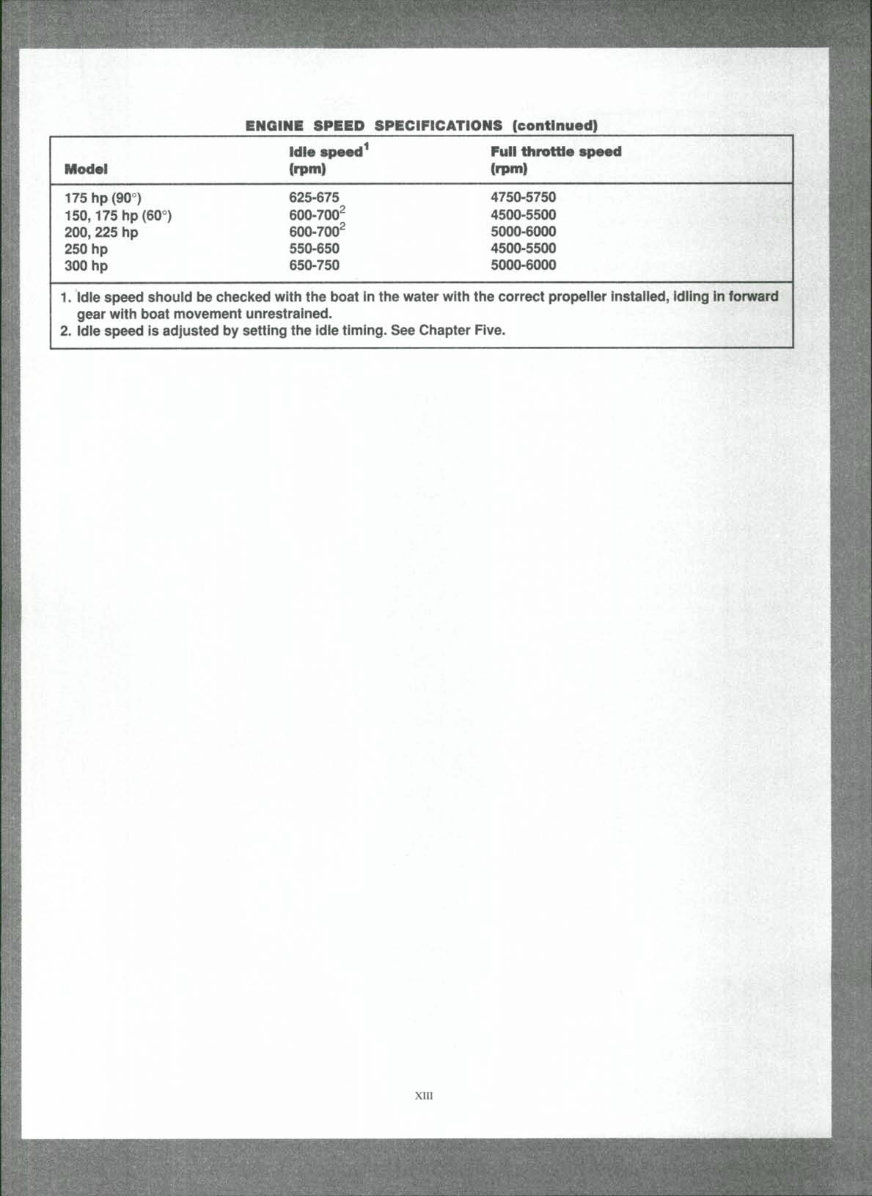

ENGINE SPEED SPECIFICATIONS (continued)

Model

175hp(90°)

150,175 hp (60°)

200, 225 hp

250 hp

300 hp

Idle speed^

(rpm)

625-675

600-700^

600-700^

550-650

650-750

1. Idie speed shouid be checked with the boat in the water with

gear with boat movement unrestrained.

2. Idle speed is adjusted by setting the idie timing. See Chapter

Full throttle speed

(rpm)

4750-5750

4500-5500

5000-6000

4500-5500

5000-6000

the correct propelier instailed, idiing in forward

Five.

xm

Chapter One

General Information

This detailed, comprehensive manual contains

complete information covering maintenance,

repair and overhaul. Hundreds of photos and

drawings guide you throughout every proce-

dure.

Troubleshooting, tune-up, maintenance and

repair are not difficult if you know what tools

and equipment to use and what to do. Anyone

not afraid to get their hands dirty, of average in-

telligence and with some mechanical ability can

perform most ofthe procedures in this manual.

See Chapter Two for more information on tools

and techniques.

A shop manual is a reference. You want to be

able to find information quickly. Clymer books

are designed with you in mind. All chapters are

thumb tabbed and important items are indexed

at the end ofthe manual. All procedures, tables,

photos and instructions in this manual assume

the reader may be working on the machine or us-

ing the manual for the first time.

Keep the manual in a handy place in your tool-

box or boat. It will help you to better understand

how your boat runs, lower repair and

maintenance costs and generally increase your

enjoyment of your boat.

MANUAL ORGANIZATION

This chapter provides general infonnation

useful to boat owners and marine mechanics.

Chapter Two discusses the tools and tech-

niques for preventative maintenance, trouble-

shooting and repair.

Chapter Three provides troubleshooting and

testing procedures for all systems and individual

components.

Following chapters describe specific systems,

providing disassembly, inspection, assembly

and adjustment procedures in simple step-by-

step form. Specifications concerning a specific

system are included at the end ofthe appropriate

chapter.

CHAPTER ONE

NOTES, CAUTIONS

AND WARNINGS

The terms NOTE, CAUTION and WARNING

have specific meanings in this manual. A NOTE

provides additional information to make a step

or procedure easier or more clear. Disregarding

a NOTE could cause inconvenience, but would

not cause damage or personal injury.

A CAUTION emphasizes areas where equip-

ment damage could cause permanent mechani-

cal damage; however, personal injury is

unlikely.

A WARNING emphasizes areas where per-

sonal injury or even death could result from neg-

ligence. Mechanical damage may also occur.

WARNINGS must be taken seriously. In some

cases, serious injury or death has resulted from

disregarding similar warnings.

TORQUE SPECIFICATIONS

Torque specifications throughout this manual

are given in foot-pounds (ft.-lb.), inch-pounds

(in.-lb.) and newton meters (N»m.). Newton me-

ters are being adopted in place of me-

ter-kilograms (mkg) in accordance with the

Intemational Modernized Metric System. Ex-

isting torque wrenches calibrated in me-

ter-kilograms can be used by performing a

simple conversion: move the decimal point one

place to the right. For example, 4.7 mkg = 47

N»m. This conversion is accurate enough for

most mechanical operations even though the ex-

act mathematical conversion is 3.5 mkg = 34.3

N»m.

ENGINE OPERATION

All marine engines, whether two or

four-stroke, gasoline or diesel, operate on the

Otto cycle of intake, compression, power and

exhaust phases.

Two-Stroke Cycle

A two-stroke engine requires one crankshaft

revolution (two strokes of the piston) to com-

plete the Otto cycle. All engines covered in this

manual are a two-stroke design. Figure 1 shows

gasoline two-stroke engine operation.

Four-Stroke Cycle

A four-stroke engine requires two crankshaft

revolutions (four strokes of the piston) to com-

plete the Otto cycle. Figure 2 shows gasoline

four-stroke engine operation.

FASTENERS

The material and design ofthe various fasten-

ers used on marine equipment are careftiUy

thought out and designed. Fastener design deter-

mines the type of tool required to work with the

fastener. Fastener material is carefully selected

to decrease the possibility of physical failure or

corrosion. See Galvanic Corrosion in this chap-

ter for information on marine materials.

Nuts, bolts and screws are manufactured in a

wide range of thread patterns. To join a nut and

bolt, the diameter ofthe bolt and the diameter of

the hole in the nut must be the same. It is just as

important that the threads are compatible.

The easiest way to determine if fastener

threads are compatible is to turn the nut on the

bolt, or bolt into its threaded opening, using fin-

gers only. Be sure both pieces are clean. If much

force is required, check the thread condition on

each fastener. If the thread condition is good but

the fasteners jam, the threads are not compati-

ble.

Four important specifications describe the

thread:

1. Diameter.

2. Threads per inch.

3. Thread pattern.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

$51.99

Viewed 14 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

$51.99

The 1992 Johnson Evinrude 2-300HP Outboards Service & Repair Manual is an essential resource for maintaining, servicing, and repairing Johnson Evinrude outboard motors ranging from 2 to 300 horsepower produced in 1992. This official manual provides detailed instructions for troubleshooting, routine maintenance checks, and complete disassembly and reassembly procedures. It includes clear diagrams and illustrations to guide users through every service and repair operation, from simple adjustments to complex rebuilds. This manual is indispensable for maintaining engine reliability and efficiency, making it a vital tool for professional mechanics and DIY enthusiasts alike.

- Printable: Yes

- Language: English

- Compatibility: Pretty much any electronic device, incl. PC & Mac computers, Android and Apple smartphones & tablet, etc.

- Requirements: Adobe Reader (free)