TABLE OF CONTENTS

1 SAFETY

INTRODUCTION

CLEANING, WAXING,

AND POLISHING

CONTROLLING CORROSION

PROPELLERS

FUEL SYSTEM

LOADING

HORSEPOWER

FLOTATION

EMERGENCY EQUIPMENT

COMPASS

STEERING

ANCHORS

MISCELLANEOUS EQUIPMENT

BOATING ACCIDENT REPORTS

NAVIGATION

2 N NING

INTRODUCTION

TUNE - UP SEQUENCE

COMPRESSION CHECK

SPARK PLUG INSPECTION

IGNITION SYSTEM

SYNCHRONIZING

BATTERY SERVICE

CARBURETOR ADJUSTMENTS

FUEL PUMPS

STARTER AND SOLENOID

INTERNAL WIRING HARNESS

WATER PUMP CHECK

PROPELLER

LOWER UNIT

BOAT TESTING

3 POWERHEAD

INTRODUCTION

Theory of Operation

CHAPTER ORGANIZATION

POWERHEAD DISASSEMBLING

HEAD SERVICE

REED SERVICE

Description

Cleaning and Service

Reed Assembling

Installation

EXHAUST COVER

Cleaning

TOP SEAL

Removal - - V4 Engine

Removal - - 3 - Cylinder Engine

BOTTOM SEAL

Inspec tion

CENTERING PINS

MAIN BEARING BOLTS AND

CRANKCASE SIDE BOLTS

CRANKCASE COVER

CONNECTING RODS

AND PISTONS

Removal

Disassembling

Rod Inspection and Service

Piston and Ring

Inspection and Service

Cleaning and Inspecting

Assembling

CRANKSHAFT

Removal

Cleaning and Inspecting

Assembling

CYLINDER BLOCK SERVICE

Honing Procedures

POWERHEAD A SS E M B L I N G

PISTON AND ROD ASSEMBLY

INSTALLATION

CRANKSHAFT INSTALLATION

NEEDLE MAIN AND

ROD BEARINGS

CRANKCASE COVER

BOTTOM SEAL INSTALLATION

TYPE ATTACHED TO LOWER

END OF CRANKCASE 3 - 43

© eblue-dist 2007

EXHAUST COVER AND

BYPASS COVER

INSTALLATION 3 - 44

REED BOX INSTALLATION 3 - 44

HEAP INSTALLATION 3 - 45

BREAK - IN PR.OCEDURES 3 - 46

4 FUEL

INTPODUCTICPN 4 - 1

GENERAL CARBIJR ETIPN

INFORMATION 4 - 1

FUEL SYSTEM 4 - 3

TROUBLESHOOTING 4 - 3

Fuel Pump Tests 4 - 5

Fuel Line Test 4 - 6

Rough Engine Idle 4 - 7

Excessive Fuel Consumption 4 - 7

Engine Surge 4 - 8

JOHNSCaW/EVINW UTPE

CAFBURETQPS 4-8

TYPE IA CARPURETOR

HBOWNCPRAFT, CaOUBLE BRL.

WITH HIGFJ- APJD LOW -

SPEED NEEDLE VALVES

50 HP -- 1958 AP'D IF39 1

60 HP -- 1964 ANC 1965 ) 4 - 9

75 HP -- 1960

1

TYPE IB CARBURETQR

SAME AS TYPE IA

EXCEPT WITH FIGF-SPEED

FIXED ORIFICE

60 WP - - 1366 ANP 1367 1

65 HP -- 196% 1

75 HP - - - 1961 TVRU 1965 1 4 - 9

80 IIP -- 1966 ANP 1967 1

85 MI? - - 196% 1

DESCRIPT1C)N

REMOVAL

CARBURETOR PISASSEMBLIP.'G 4 - 1 1

CLEANING AND IblSPECTIPJG 4 - 14

ASSEMBLING 4 - 17

TYPE I1 CARBURETOR

30 HP - - 1964 AND 1965

) 4 - 22

100 I-?P -- 1966 TMRU 1968 1

DESCRIPTION

Choke System

REEK OVAL

DISASSEMBLING

CEOKE SYSTEF"SEFV1CE 4-3$

Peat/Electric Choke

I? ernoval 4 - 35

Installation 4 - 37

All Electric Choke

F emovall & Pisassembling It-?.?

Assembling

Water Choke

Pescriptim

P ernoval

Installation

ASSEhWPWG

IVYFALLATION

Fl EL PUVP SERVICE

Trsubleshaot ing

Removal an8 Repair

Cleaninp and Inspecting

Assernbline, and Installation

FUEL TAWK SERVICE

© eblue-dist 2007

5 IGNITION

INTRODUCTION 5 - 1

Ignition Systems 5 - 2

SPARK PLUG EVALUATION 5 - 3

Removal 5 - 3

EXAMINATI@N 5-3

OTHER IGNITION PARTS 5 - 5

Description 5-5

TYPE I IGNITION

DISTRIRlJTOF VAGNETO

50 HP - - 1958 AND 1959

60 HP -- 1964 TVRIJ 1?66 )

75 HP -- 196Q TI4RtI 1965 )

80 HP -- 1966 1

Description

TRCPUALESHOOTI1\?G

SERVICING

General Information

Removal

Servicing

Cleaning: and Inspecting

Installation

BELT REPLACEMENT

Engine M istimed

TYPE I1 IGNITIQN

DISTRIBUTOR BATTEP Y

75 HI? -- 1961 THRU 1965

)

80 HP -- 1966 AND 1967

90 HP - - 1964 AND 1965 1

108 HP -- 1966

Description

TROUBLESHOOTING

SERVICING

Removal -

Cleaning and Inspecting

Installation

BELT REPLACEMENT

Engine Mistimed

Installation

TYPE I11 IGNITION

CAPACITOR lXSCHARGE (CLd)

WITM SENSOR

100 MP - - 1967, 1968,

AND 1972 )

115 HP -- 1969 AND 1970

125 HP - - 1971 AND 1972 )

TROUBLESHOQTING

100 HP -- 1967 AND 1968

TROUBLESHOOTING

115 HP -- 1969 AND 1370

TROLJBLESHQOTHNG

108 HP -- 1972

125 HP -- 1971 AN@ 1972

COVPONENT REPLACEMENT

Rotor Replacement

100 hp - - 1967

Sensor Replacement

100 hp -- 1967

Powerpack Replacement

100 hp -- 1967

COMPONENT REPLACEArENT

IGNITION PARTS UNPEF

FLY WHEEL: STATOR,

CISTRIBUTOR CAP,

EIST WIBUTOR ROTCW,

SENSOR ROTOR, APE? SEE1%

100 MP - - 8968 ANC 1972

115 HP -- 8969 ANP 1970

125 HP -- 1971 ANE 1972

W emoval

Cleaning and Inspecting

Assembling

CAPACITOR DISCWAR GE (CG)

WITM BREAKER P(3IbT5

55 HP 3 - CYL. -- 1968

AND 1969

60 HP 3-CYL. -- 1 978

AND 1971

6 5 MP V4 -- 19653

$5 EP V4 -- 1968 TEIRU 1972

100 MP V4 -- 197 1

Cescription

Safety

General Troubleshootiwe

All CD Wodels

Troubles hooting

55 hp - - 1968 and 1969

65 hp - - 1968

85 hp -- 1968

Troubles hooting

85 h~ - - 1969 thru 6972

100 hp -- 1971

Troubles hooting

40 hp - - 1970 and 197 1

CL IGNITION SYSTEV

PARTS REPLACEWENT

AND AEJUSTMENT

55 HP 3 - CYL - - 1968 eC 1969

60 HP 3-CYL -- 1570 & 1571

65 HP V4 -- 1968

85 flP V4 -- 1968 THRU 1972

100 HP V4 -- 1971

Removal

Cleaning and Inspecting

© eblue-dist 2007

5 IGNITION (CONT)

SYWCFRCNIZING

C"ISTRIBUT0R ANC CARBURETOR

hvP,Gh'FTQ IGNITION MGPELS

50 tiP 1958 ANL" 1959 5 - 92

SYNCH-'RCNIZING

CISTRIBUTOR AND CARBURETOR

BATTERY IGNITION

NAGNETQ IGNITION

60 HP - - 1964 THRU 1966

75 PI? -- 1960 THRU 6963

$0 HI' - - 1906 ANI3 1967

90 IF? -- 3964 ANE 1965

100 E? - - 1966 ANC 1967

6 ELECTRICAL

INTROIPUCTICPJ 6 - 1

BATTEPIES 6 - 1

Jumper Cables 6-5

Pual Battery Installatic\n 6 - 5

GAUGES AND FORPS 6 - 7

FUEL SYSTEbb

Fuel Gauge 6 - 8

Fuel Gauge Poskup 6-8

Fuel Gauge Troubleshooting 6 - 9

TACFOPJETER 6 - 10

KOWNS 6 - 10

ELECTRICAL SYSTEM

GENERAL IPIF(?Ri?4ATI@N 6-1 1

GENER ATCF CPARGIFG CIRCIJIT

Troubleshooting 6 - 12

Generator Service 6 - 10

Cleaning and Inspecting 6 - 18

Assemhli ng 6 - 20

ALTER NATPR CpAP GIPG CIRCUIT

Pperation 6 - 22

Troubleshooting 6 - 24

ALTERblATOFs WIW

PATTER Y IGb'.'ITI[ON

WC9PEkS 190 1 THR tJ 1967 6 - 25

ALTER PIPTOP VJITF" CP IGWITION

100 FP -- 1907 AND

ALL cp IGPIITIC\P. 1968

TPFelir 1972 6 - 27

Troubleshootinp 6 - 27

CYPKE CIRCUIT SERVICE 6 - 31

STAP TEP FVTCP CIPCIJIT SEPVICE

Circuit Pescription 6 - 31

Starter P'otor Description 6 - 32

Tr~ubleshsstin 6 - 34

Testim 6 - 34

STAP T E PCTCP, rmvE G E A R

Starter Removal

All \'hts 1958 Thru 1958 6 - 37

Starter Crive Removal 6 - 37

Cleanine and Inspecting 6 - 38

Installation 6 - 38

STARTEFF PRIVE GEAR SEW VICE

55 HE ' 3-CYLIIWPEP

1968 AFT 1965 1

60 WP 3-CXLIP.!@ER

1970 AND lQ71 1

85 HP W4 -- lQ49 TFRU 1972 ) 6 - 39

115 HP V4 -- 1969 ANT31 1870 )

125 VP Yk - - 1971 AND 1972 )

R ernoval 6 - 39

Pisassemblinp 6 - 40

Cleaning and Inspecting 6 - 41

Assembling 6 - 41

© eblue-dist 2007

PELCO-W EF4Y SERVICE

R ernoval 64 1

Disassembling 6-k2

Armature Testing 6 - 43

Cleaning and Inspecting 6 - 44

Assembling 6 - 45

AUTOLITE SERVICE

Removal 6 - 47

Disassembling 6 - 48

Armature Testing 6-48

Cleaning and Inspecting 6 - 50

PR ESTOLITE SER VICE

Removal from Starboard

Installation with

Separate Drive Gear 6 - 52

Removal from Port Side

Installation with

Drive Gear on

Armature Shaft 6 - 52

Disassembling 6 - 53

Armature Testing 6 - 53

Cleaning and Inspecting 6 - 55

Assembling 6 - 56

STARTER MOTOR TESTIP'G 6 - 57

STARTER MOTOR INSTALLATION 6 - 57

7 ACCESSORIES

DESCRIPTION 7 - 1

SHIFT BOXES 7 - 1

OLD - STYLE DOUBLE LEVER

Troubleshooting 7 - 3

h)isassembling 7 - 4

Cleaning and Inspecting 7 - 5

Assembling 7 - 5

NEW - STYLE SWIFT LEI'EF.

Troubleshooting 7 - 6

Removal 7 - 8

Disassembling 7 - 8

Cleaning and Inspecting 7-0

Assembling 7 - 10

ELECTRIC GEAR BOXES

AbJD SINGLE LEVER CONTROL

JOHNSON I JNITS 7 - 12

Troubleshooting 7 - 12

Disassembling 7 - 15

Cleaning and Inspecting 7 - 16

Assembling 7 - 17

PUSHBUTTON SHIFT BOX

EVINRUDE UNITS Ob'LY 7 - 1 "

Troubleshooting 7 - 20

Disassembling 7 - 22

Cleaning and Inspecting 7 - 24

Assembling 7-74

Troubleshooting 7-26

Disassembling 7 - 29

clean in^ and inspect in^ 7 - 31

Assembling 7 - 32

CABLE ENP FITTIPIG

IPJSTALEPTION AT

EWGIF'E EFT" 7 - 34

8 LOWER UNIT

DESCRIPTICN 8 - 11

CPAPTER COVERAGE 8 - 1

ILLUSTRATIONS 8 - 2

PROPELLER SERVICE 8 - 2

Propeller with Shear Pin

Removal 8 - 2

Installation 8 - 3

Exhaust Propeller 8 - 3

Removal 8-4

Installation 8 - 4

WATER PUMP REMOVAL 8-1 8

Lower Unit Pisassemblinp 8 - 1 E

Cleaning and Inspectinn $-

Lower Unit Assembling: 8 - 16

WATER PUMP INSTALLATIQN 8 - 19

Lower Unit %nstallatio 8 - 20

© eblue-dist 2007

8 LOWER UNIT (CONTI

TYPE H I L@lVJE hThTIT SEPVICE

VAPJUAL SFWT

SIPfGEE ENCLOSEI" RQLJSIIPJG

48 PP - - 1964 TERU BQR7 1

65 I-'P -- 1068

75 PF -- 1968 TFRU 1965 ) 8 - 22

80 PP -- 1066 ANP 1967 'B

85 EP - - l"68 )

WATER PUMP REMOVAL 8 - 24

Lower 1Jnit Pisassembliw p-sk

clean in^ and Inspecting 8-3"

kewer (Init Assemhline 8 - 31

WATER PUMP INSTALLATION P-36

Lower [!nit Installatio P- ?P

Pescription

Type I11 and Type IV Units 8 - 40

Troubles hooting

Type I11 and Type IV Units 8 - 48

Removal

Type III Units 8 - 43

WATER PUMP REMOVAL 8-Sg

Pisassembling 8-44

Cleaninp an8 Inspectinp $-50

Assembling 8 - 52

WATER PUMP INSTALLATION 8 - 60

Lower llnit lInstallaticm 8 - 6 1

TYPE 1IV LCYUER UP1.'IT

EkECTROKATIlr

BOO FB -- 1906 TPR P_I 11968 8 - 62

Troubleshooti~ 8 - 63

WATER PUMP REMOVAL 8 - 64

Lower Unit Pisassembling 8-h@

CBeanin and Inspecting 8-Go

Lower ifnit Asse~blinp 8 - 7 1

WATER PUMP INSTALLATICN 8 - 80

Lower Unit Installation 8-8 1

Description

Troubleshooting

Lower Unit Removal

WATER PUMP REMOVAL 8 - 86

Lower Unit Pisassembling 8 - 87

"Frozen'Tropeller Shaft 8 - 83

Cleaning and Inspecting 8 - 93

Lower Unit Assembling 8 - 95

WATER PUMP INSTALLATION 8- 105

Lower Unit Ynstallation 8-108

'FFFOZEf."T!?OPEkkER

Description 8-1 18

P emaval 8 - 1 10

9 HAND STARTER

10 MAINTENANCE

© eblue-dist 2007

APPENDIX

A-4

A - 8

A- 10

A-IC

A-P B

75 hp V4 with Papnets,

Generator, and

Standard Shift -- 1 O6 1

75 hp thru 90 hp V4

with Electric Shift

1961 thru 1965

80 hrz V4

with Generator -- 1966

88 hp V4 -- 1367

80 hp V4

with Electric Shift -- 1?67

85 hp V4 -- 15568

85 hp V4

with Electric Shift -- 1?68

$5 hp V4 with PJternator

%?69 and 1970

85 hp Y4 with Alternator -- 1972

$5 hp and 100 hp Vk

with Alternator -- 1.971

100 hp V4 with CD Ignition

I967 and 1968

100 hp V4 and 125 hp V4

with Alternator -- 1972

1 15 hp V4 -- 1969 and 1970

125 hp Y4 -- 1971

© eblue-dist 2007

SAFETY

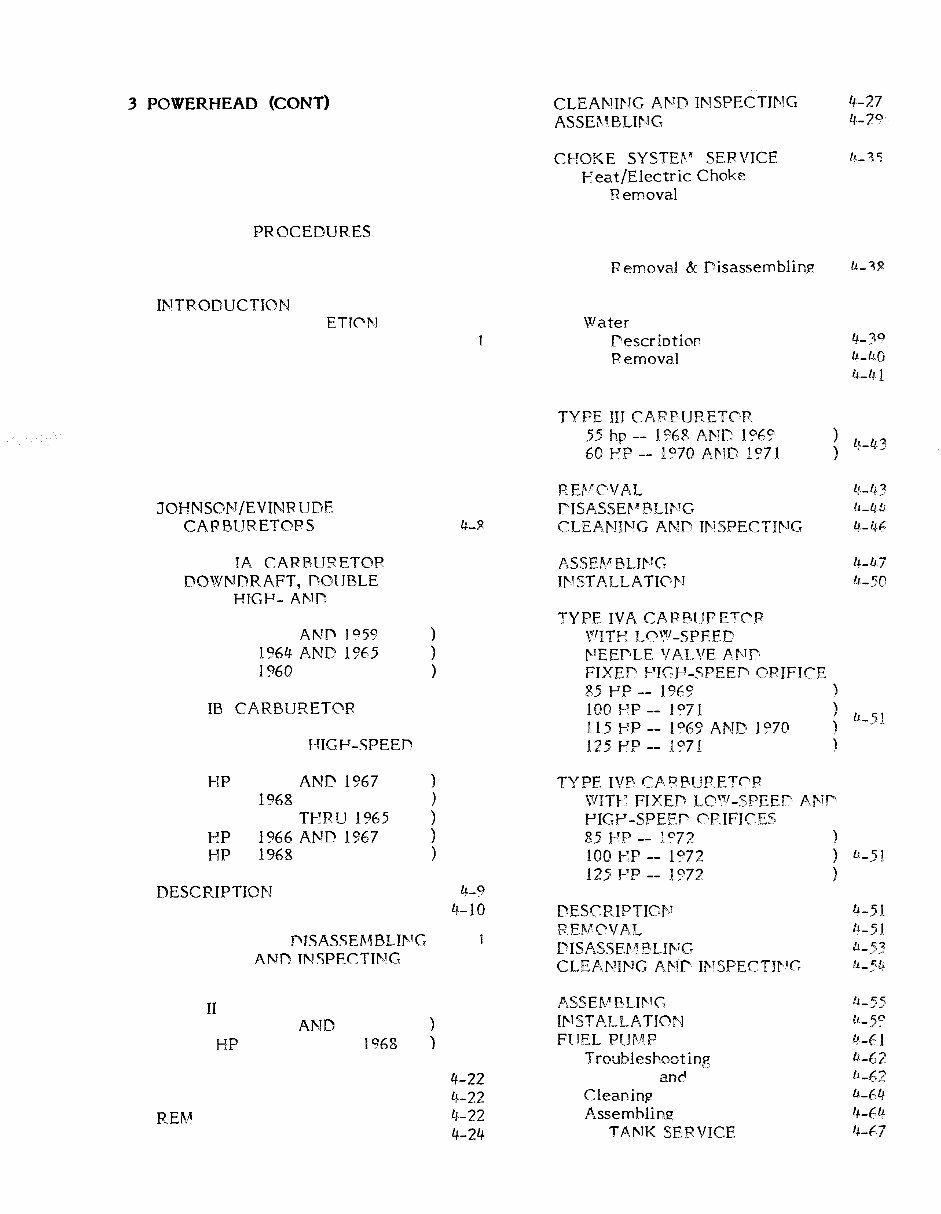

1 - 1 INTRODUCTION

Your boat probably represents a sizeable

investment for you. In order to protect this

investment and to receive the maximum

amount of enjoyment from your boat it must

be cared for properly while being used and

when it is out of the water. Always store

your boat with the bow higher than the stern

and be sure to remove the transom drain

plug and the inner hull drain plugs. If you

use any type of cover to protect your boat,

plastic, canvas, whatever, be sure to allow

for some movement of air through the hull.

Proper ventilation will assure evaporation of

any condensation that may form due to

changes in temperature and humidity.

1 - 2 CLEANING, WAXING, AND POLISHING

An outboard boat should be washed with

clear water after each use to remove sur -

face dirt and any salt deposits from use in

salt water. Regular rinsing will extend the

time between waxing and polishing. It will

also give you " pride of ownership " , by

having a sharp looking piece of equipment.

Elbow grease, a mild detergent, and a brush

Whenever the boat is stored, for long or short

periods, the bow should be slightly higher than the stern

and the drain plug in the transom removed to ensure

proper drainage of rain water.

will be required to remove stubborn dirt, oil,

and other unsightly deposits.

Stay away from harsh abrasives or strong

chemical cleaners. A white buffing com -

pound can be used to restore the original

gloss to a scratched, dull, or faded area.

The finish of your boat should be thoroughly

cleaned, buffed, and polished at least once

each season. Take care when buffing or

polishing with a marine cleaner not to over -

heat the surface you are working, because

you will burn it.

A small outboard engine mounted on an

aluminum boat should be removed from the

boat and stored separately. Under all cir -

cumstances, any outboard engine must AL -

WAYS be stored with the powerhead higher

than the lower unit and exhaust system.

This position will prevent water trapped in

the lower unit from draining back through

the exhaust ports into the powerhead.

Lower unit badly corroded because the zinc was not

replaced. Once the zinc is destroyed, more costly parts

will be damaged. Attention to the zinc condition is

extremely important during boat operation in salt

water.

© eblue-dist 2007

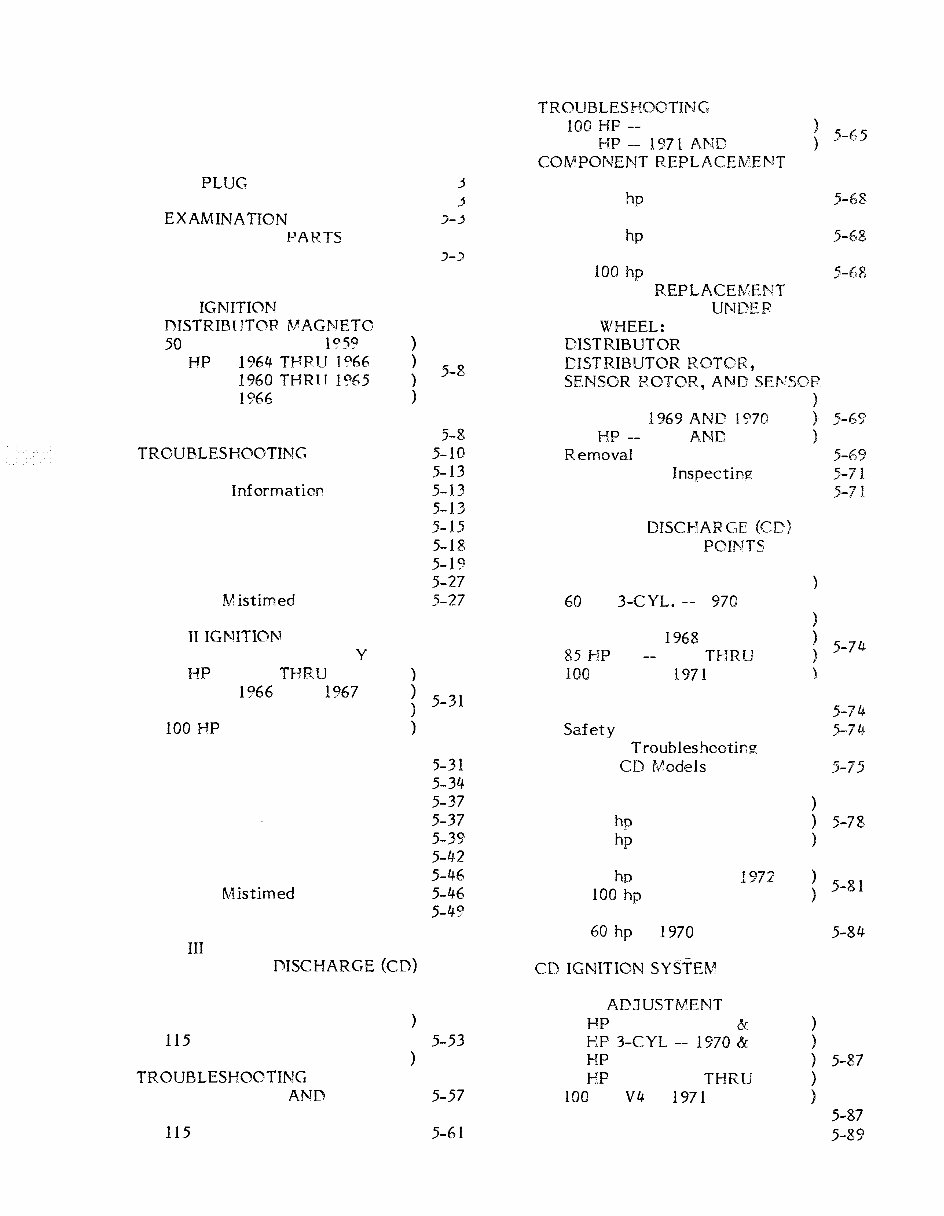

I--2 SAFETY

A new zinc prior to installation. This inexpensive

item will save corrosion on more valuable parts.

Most outboard engines have a flat area

on the back side of the powerhead. When

the engine is placed with the flat area on

the powerhead and the lower unit resting on

the floor, the engine will be in the proper

altitude with the powerhead higher than the

lower unit.

1 - 3 CONTROLLING CORROSION

Since man first started out on the water,

corrosion on his craft has been his enemy.

The first form was merely rot in the wood

and then it was rust, followed by other

forms of destructive corrosion in the more

modern materials. One defense against cor -

rosion is to use similar metals throughout

the boat. Even though this is difficult to do

in designing a new boat, particularily the

undersides, similar metals should be used

whenever and wherever possible.

A second defense against corrosion is to

insulate dissimilar metals. This can be done

by using an exterior coating of Sea Skin or

by insulating them with plastic or rubber

gaskets.

Using Zinc

The proper amount of zinc attached to a

boat is extremely important. The use of too

much zinc can cause wood burning by plac -

ing the metals close together and they be -

come " hot " . On the other hand, using too

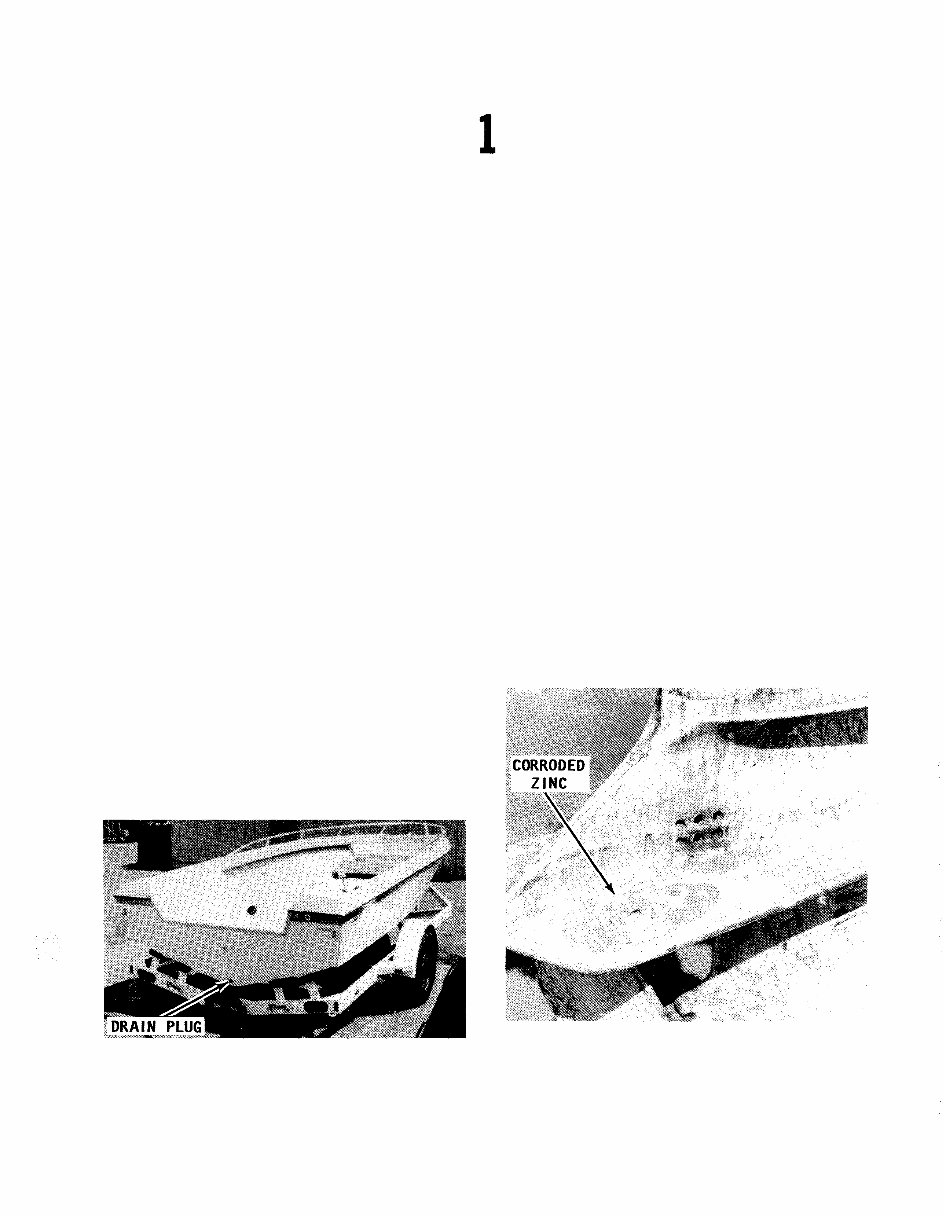

Diameter and pitch are the two basic dimensions of

a propeller. The diameter is measured across the

circumference of a circle scribed by the propeller

blades, as shown.

small a zinc plate will cause more rapid

deterioration of the metal you. are trying to

protect. If in doubt, consider the fact that

is is far better to replace the zincs than to

replace planking or other expensive metal

parts from having an excess of zinc.

When installing zinc plates, there are

two routes available. One is to install many

different zincs on all metal parts and thus

run the risk of wood burning. Another

route, is to use one large zinc on the tran -

som of the boat and then connect this zinc

to every underwater metal part through

internal bonding. Of the two choices, the

one zinc on the transom is the better way to

go-

Small outboard engines have a zinc plate

attached to the cavitation plate. Therefore,

the zinc remains with the engine at all

times.

1 - 4 PROPELLERS

As you know, the propeller is actually

what moves the boat through the water.

This is how it is done. The propeller oper -

ates in water in much the manner as a wood

screw does in wood. The propeller " bites "

into the water as it rotates. Water passes

between the blades and out to the rear in

the shape of a cone. The propeller " biting "

through the water in much the same manner

as a wood auger is what propels the boat.

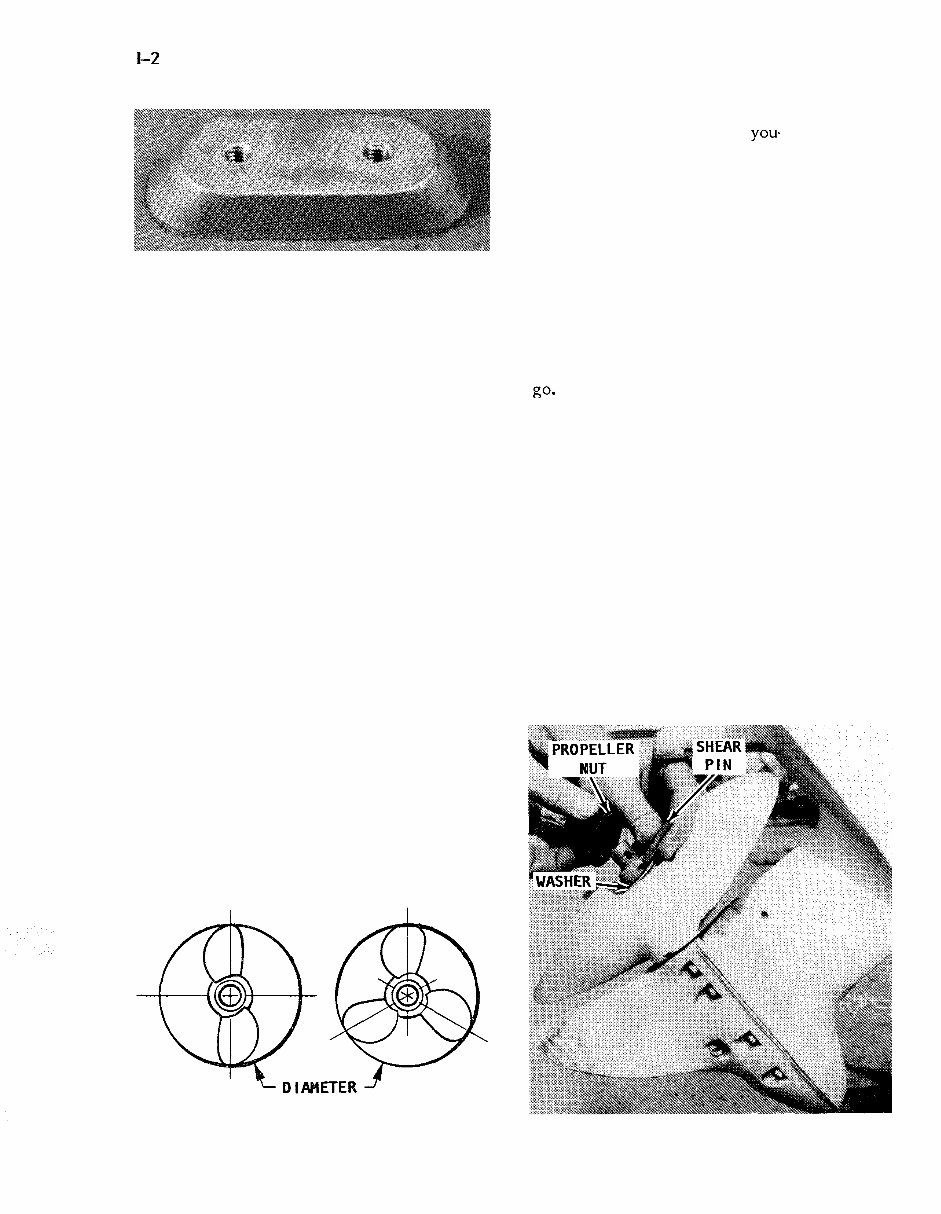

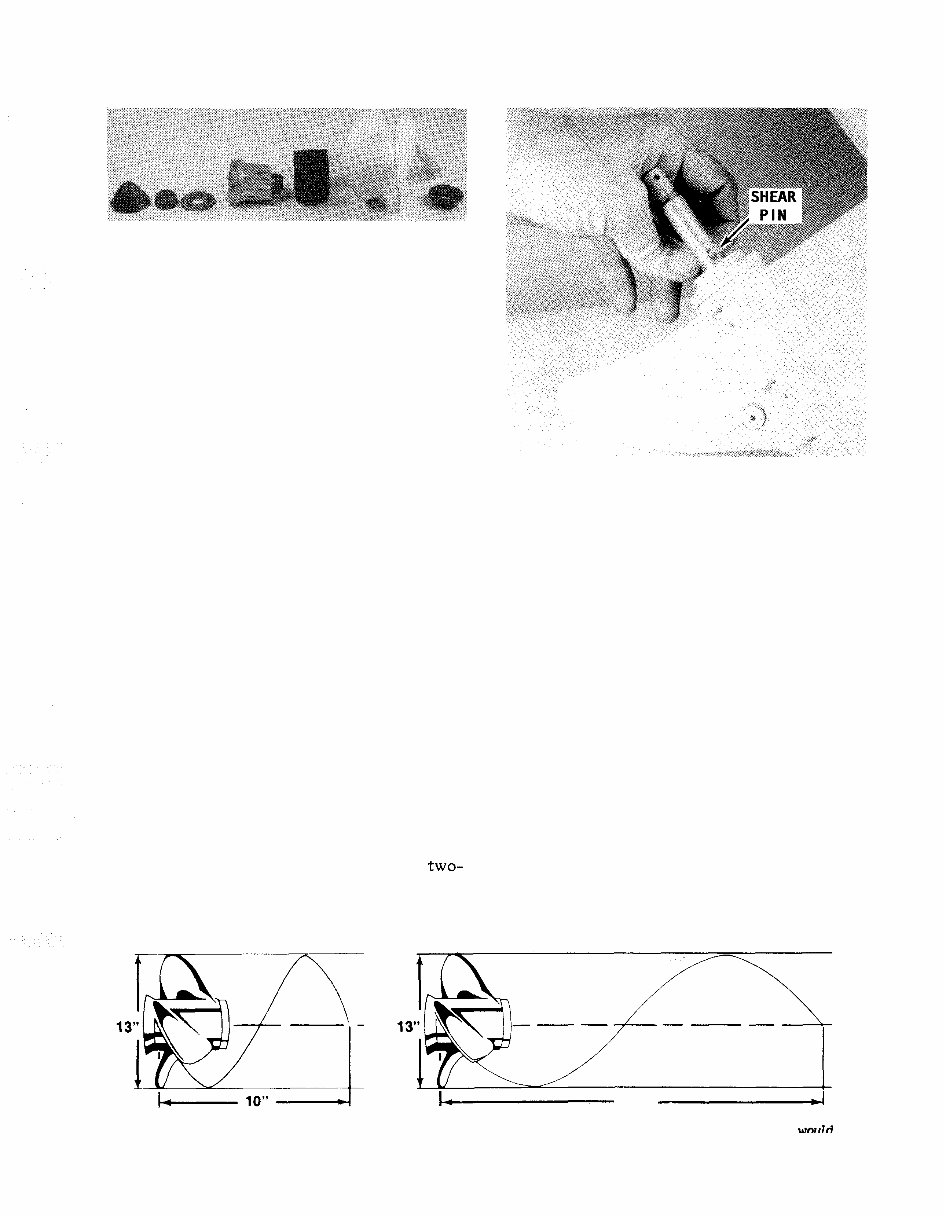

Propeller and associated parts in order, washer,

snear - pin, and nut, ready for installation.

© eblue-dist 2007

PROPELLERS 1 - 3

Arrangement of propeller and associated parts, in

order, for a small horsepower engine.

Diameter and Pitch

Only two dimensions of the propeller are

of real interest to the boat owner: the

diameter and the pitch. These two dimen -

sions are stamped on the propeller hub and

always appear in the same order: the diam -

eter first and then the pitch. For instance,

the number 15 - 19 stamped on the hub,

would mean the propeller had a diameter of

15 inches with a pitch of 19.

The diameter is the measured distance

from the tip of one blade to the tip of the

other as shown in the accompanying illus -

tration.

The pitch of a propeller is the angle at

which the blades are attached to the hub.

This figure is expressed in inches of water

travel for each revolution of the propeller.

In our example of a 15 - 19 propeller, the

propeller should travel 19 inches through the

water each time it revolves. If the propel -

ler action was perfect and there was no

slippage, then the pitch multiplied by the

propeller rpms would be the boat speed.

Most outboard manufacturers equip their

units with a standard propeller with a diam -

eter and pitch they consider to be best

suited to the engine and the boat. Such a

propeller allows the engine to run as near to

the rated rpm and horsepower (at full throt -

tle) as possible for the boat design.

The blade area of the propeller deter -

mines its load - carrying capacity. A two-

blade propeller is used for high - speed run -

ning under very light loads.

Shear - pin installed behind the propeller instead of in

front of the propeller.

A four - blade propeller is installed in

boats intended to operate at low speeds

under very heavy loads such as tugs, barges,

or large houseboats. The three - blade pro -

peller is the happy medium covering the

wide range between the high performdnce

units and the load carrying work horses.

Propeller Selection

There is no standard propeller that will

do the proper job in very many cases. The

list of sizes and weights of boats is almost

endless. This fact coupled with the many

boat - engine combinations makes the propel -

ler selection for a specific purpose a diffi -

cult job. In fact, in many cases the propel -

ler is changed after a few test runs. Proper

selection is aided through the use of charts

set up for various engines and boats. These

charts should be studied and understood

when buying a propeller. However, bear in

mind, the charts are based on average boats

Diagram to explain the pitch dimension

through the water if there was no slippage.

1- 21 " -1

of a propeller. The pitch is the theoretical distance a propeller would

travel

© eblue-dist 2007

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual