2000-2007 Suzuki 25/30HP (DF25/DF30) 4-Stroke Outboards OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

99500-89J02-01E

1

Downloaded from www.Manualslib.com manuals search engine

This manual contains an introductory description on

SUZUKI Outboard motor DF25/30 and procedures

for the inspection, service and overhaul of its main

components.

General knowledge information is not included.

Please read the GENERAL INFORMATION sec-

tion to familiarize yourself with basic information

concerning this motor. Read and refer to the other

sections in this manual for information regard-

ing proper inspection and service procedures.

This manual will help you better understand this out-

board motor so that you may provide your custom-

ers with optimum and quick service.

GENERAL INFORMATION

PERIODIC MAINTENANCE

ENGINE CONTROL SYSTEM

ENGINE ELECTRICAL

FUEL SYSTEM

RECOIL STARTER

POWER UNIT

MID UNIT

POWER TRIM AND TILT

LOWER UNIT

WIRE / HOSE ROUTING

DF25/30 “K3” (’03) MODEL

Marine & Power Products Division

GROUP INDEX

Apprentice mechanics or do-it-yourself me-

chanics that don’t have the proper tools and

equipment may not be able to properly per-

form the services described in this manual.

Improper repair may result in injury to the

mechanic and may render the engine unsafe

for the boat operator and passengers.

FOREWORD

1

2

3

4

5

6

7

8

9

10

• This manual has been prepared using the lat-

est information available at the time of publi-

cation.

If a modification has been made since then,

differences may exist between the content of

this manual and the actual outboard motor.

• Illustrations in this manual are used to show

the basic principles of operation and work pro-

cedures and may not represent the actual out-

board motor in exact detail.

• This manual is intended for use by technicians

who already possess the basic knowledge and

skills to service SUZUKI outboard motors.

Persons without such knowledge and skills

should not attempt to service an outboard en-

gine by relying on this manual only.

Instead, please contact your nearby autho-

rized SUZUKI outboard motor dealer.

COPYRIGHT SUZUKI MOTOR CORPORATION 2002

NOTE:

This manual is compiled based on 2000 (Y) model.

11

12

2

Downloaded from www.Manualslib.com manuals search engine

HOW TO USE THIS MANUAL

TO LOCATE WHAT YOU ARE

LOOKING FOR:

1. The text of this manual is divided into sections.

2. The section titles are listed on the previous page

in a GROUP INDEX. Select the section needed

for reference.

3. Holding the manual as shown at the right will al-

lowyou to find the first page of the section easily.

4. The first page of each section lists a table of con-

tents to easily locate the item and page you need.

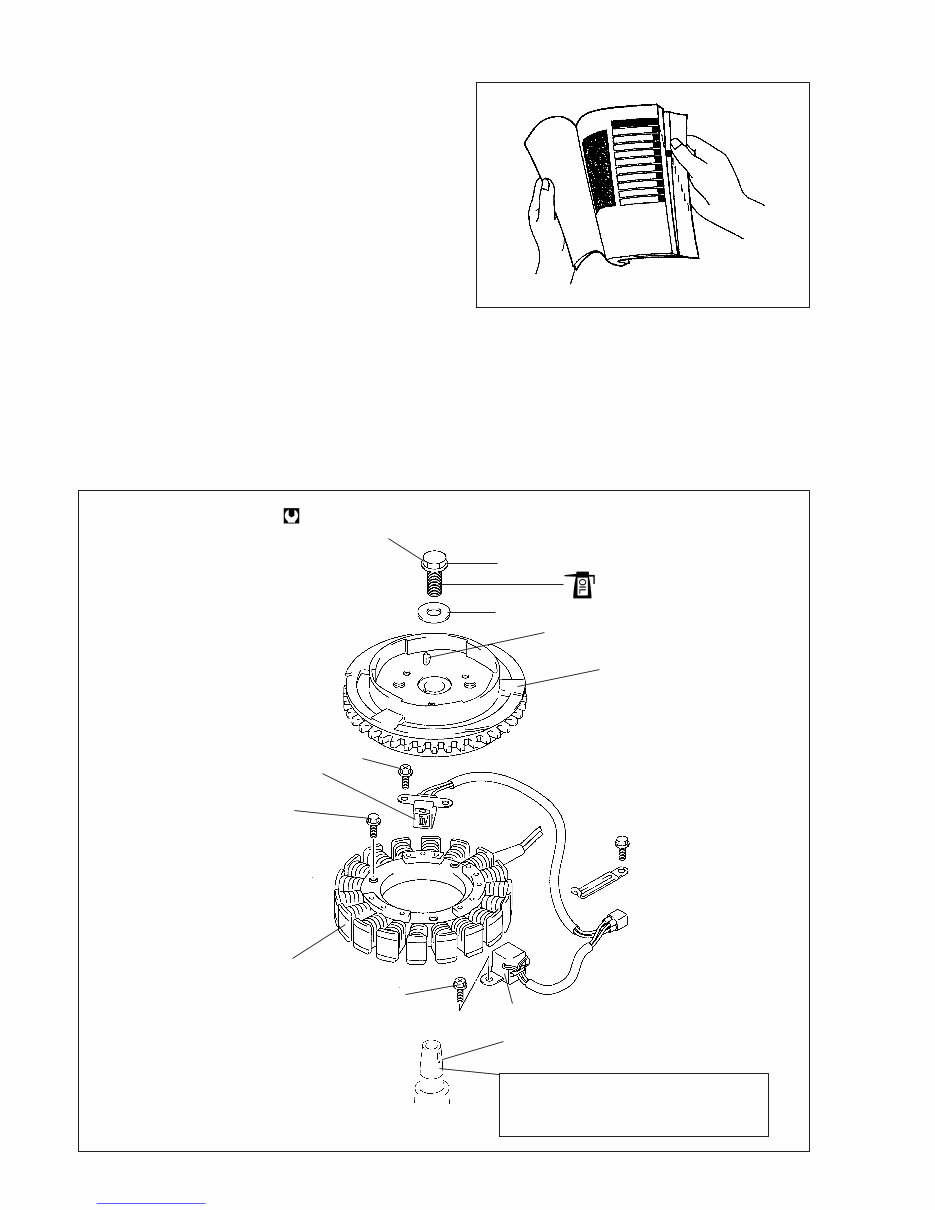

COMPONENT PARTS AND IMPORTANT ITEM ILLUSTRATIONS

Under the name of each system or unit, an exploded view is provided with work instructions and other

service information such as the tightening torque, lubrication and locking agent points.

Example :

1 Flywheel bolt

2 Washer

3 Key

4 Flywheel

5 CKP sensor

6 Screw

7 Battery charge &

Power source coil

8 Bolt

1

2

3

4

5

5

6

7

8

190 N

.

m

(19.0 kg-m, 137.5 lb.-ft.)

6

NOTE:

Clean flywheel and crankshaft mating sur-

faces with cleaning solvent.

Crankshaft

3

Downloaded from www.Manualslib.com manuals search engine

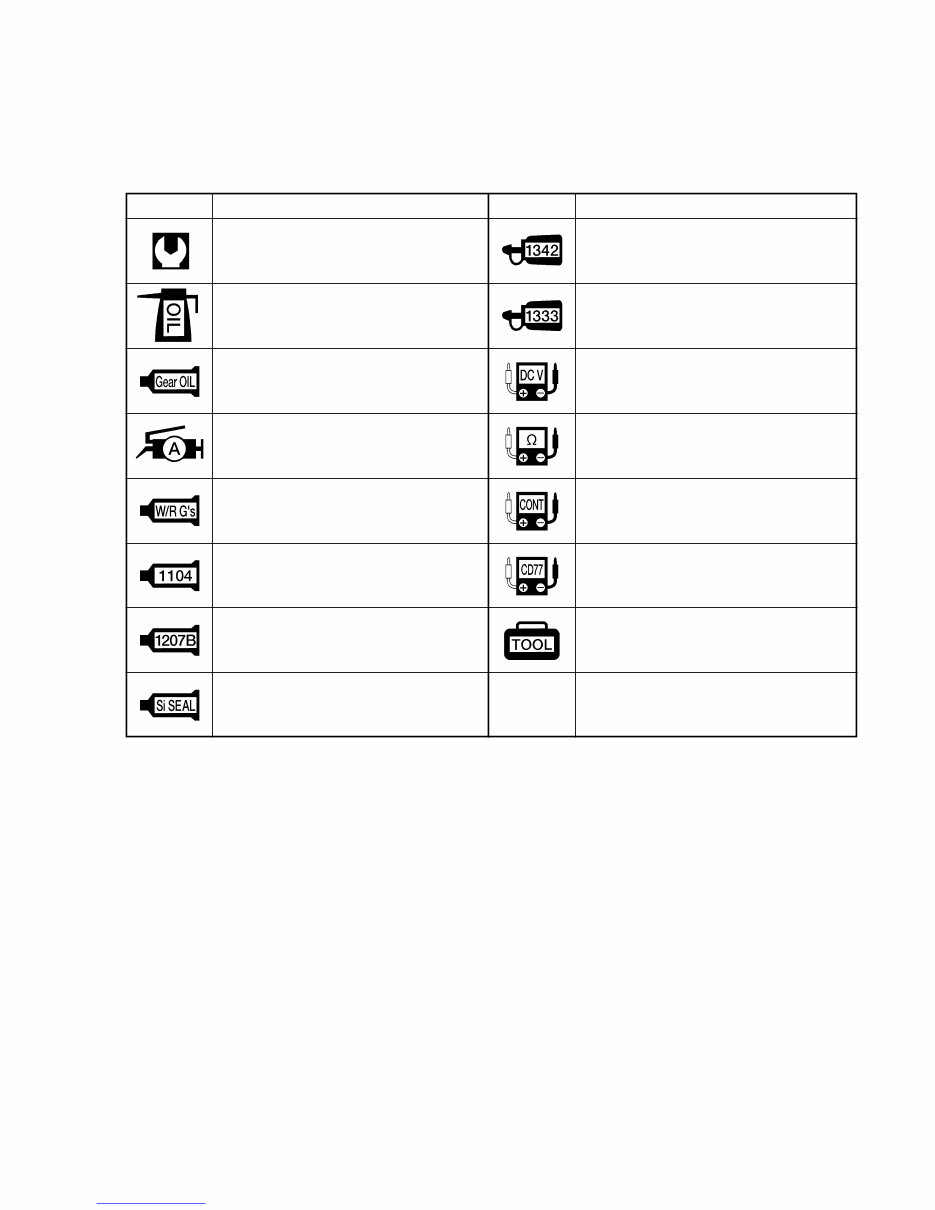

SYMBOL

Listed in the table below are the symbols indicating instructions and other important information neces-

sary for proper servicing. Please note the definition for each symbol. You will find these symbols used

throughout this manual. Refer back to this table if you are not sure of any symbol(s) meanings.

Apply THREAD LOCK “1342”.

Apply THREAD LOCK SUPER

“1333B”.

Measure in DC voltage range.

Measure in resistance range.

Measure in continuity test range.

Use peak voltmeter

“Stevens CD-77”.

Use special tool.

Torque control required.

Data beside it indicates specified

torque.

Apply oil. Use engine oil unless

otherwise specified.

Apply SUZUKI OUTBOARD

MOTOR GEAR OIL.

Apply SUZUKI SUPER GREASE “A”.

Apply SUZUKI WATER

RESISTANT GREASE.

Apply SUZUKI BOND “1104”.

Apply SUZUKI BOND “1207B”.

Apply SUZUKI SILICONE SEAL.

SYMBOL DEFINITION SYMBOL DEFINITION

4

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 1-1

GENERAL INFORMATION

1

WARNING/CAUTION/NOTE__________________________________ 1- 2

GENERAL PRECAUTIONS __________________________________ 1- 2

IDENTIFICATION NUMBER LOCATION ________________________ 1- 4

FUEL AND OIL ____________________________________________ 1- 4

GASOLINE RECOMMENDATION ................................................................. 1- 4

ENGINE OIL .................................................................................................... 1- 4

ENGINE BREAK-IN ________________________________________ 1- 5

PROPELLERS ____________________________________________ 1- 6

SPECIFICATIONS _________________________________________ 1- 7

SERVICE DATA____________________________________________ 1-11

TIGHTENING TORQUE _____________________________________ 1-18

SPECIAL TOOLS __________________________________________ 1-20

MATERIALS REQUIRED ____________________________________ 1-23

CONTENTS

5

Downloaded from www.Manualslib.com manuals search engine

1-2 GENERAL INFORMATION

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the symbol

and the words WARNING, CAUTION and NOTE have special meanings. Pay special attention to the mes-

sages highlighted by these signal words.

Indicates a potential hazard that could result in death or injury.

Indicates a potential hazard that could result in motor damage.

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

Please note, however, that the warnings and cautions contained in this manual cannot possibly cover all

potential hazards relating to the servicing, or lack of servicing, of the outboard motor. In addition to the

WARNING and CAUTION stated, you must also use good judgement and observe basic mechanical safety

principles.

GENERAL PRECAUTIONS

• Proper service and repair procedures are important for the safety of the service mechanic and

the safety and reliability of the outboard motor.

• To avoid eye injury, always wear protective goggles when filing metals, working on a grinder, or

doing other work, which could cause flying material particles.

• When 2 or more persons work together, pay attention to the safety of each other.

• When it is necessary to run the outboard motor indoors, make sure that exhaust gas is vented

outdoors.

• When testing an outboard motor in the water and on a boat, ensure that the necessary safety

equipment is on board. Such equipment includes : flotation aids for each person, fire extin-

guisher, distress signals, anchor, paddles, bilge pump, first-aid kit, emergency starter rope,

etc.

• When working with toxic or flammable materials, make sure that the area you work in is well-

ventilated and that you follow all of the material manufacturer’s instructions.

• Never use gasoline as a cleaning solvent.

• To avoid getting burned, do not touch the engine, engine oil or exhaust system during or

shortly after engine operation.

• Oil can be hazardous. Children and pets may be harmed from contact with oil. Keep new and

used oil away from children and pets. To minimize your exposure to oil, wear a long sleeve

shirt and moisture-proof gloves (such as dishwashing gloves) when changing oil. If oil con-

tacts your skin, wash thoroughly with soap and water. Launder any clothing or rags if wet with

oil. Recycle or properly dispose of used oil.

• After servicing fuel, oil/engine cooling system and exhaust system, check all lines and fittings

related to the system for leaks.

• Carefully adhere to the battery handling instructions laid out by the battery supplier.

6

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 1-3

• If parts replacement is necessary, replace the parts with Suzuki Genuine Parts or their equiva-

lent.

• When removing parts that are to be reused, keep them arranged in an orderly manner so that

they may be reinstalled in the proper order and orientation.

• Be sure to use special tools when instructed.

• Make sure that all parts used in assembly are clean and also lubricated when specified.

• When use of a certain type of lubricant, bond, or sealant is specified, be sure to use the speci-

fied type.

• When removing the battery, disconnect the negative cable first and then the positive cable.

When reconnecting the battery, connect the positive cable first and then the negative cable.

• When performing service to electrical parts, if the service procedures do not require using

battery power, disconnect the negative cable at the battery.

• Tighten cylinder head and case bolts and nuts, beginning with larger diameter and ending with

smaller diameter. Always tighten from inside to outside diagonally to the specified tightening

torque.

• Whenever you remove oil seals, gaskets, packing, O-rings, locking washers, locking nuts, cot-

ter pins, circlips, and certain other parts as specified, always replace them with new. Also,

before installing these new parts, be sure to remove any left over material from the mating

surfaces.

• Never reuse a circlip. When installing a new circlip, take care not to expand the end gap larger

than required to slip the circlip over the shaft. After installing a circlip, always ensure that it is

completely seated in its groove and securely fitted.

• Use a torque wrench to tighten fasteners to the torque values when specified.

Remove grease or oil from screw / bolt threads unless a lubricant is specified.

• After assembly, check parts for tightness and operation.

• To protect the environment, do not unlawfully dispose of used motor oil, other fluids, and bat-

teries.

• To protect the Earth’s natural resources, properly dispose of used motor parts.

7

Downloaded from www.Manualslib.com manuals search engine

1-4 GENERAL INFORMATION

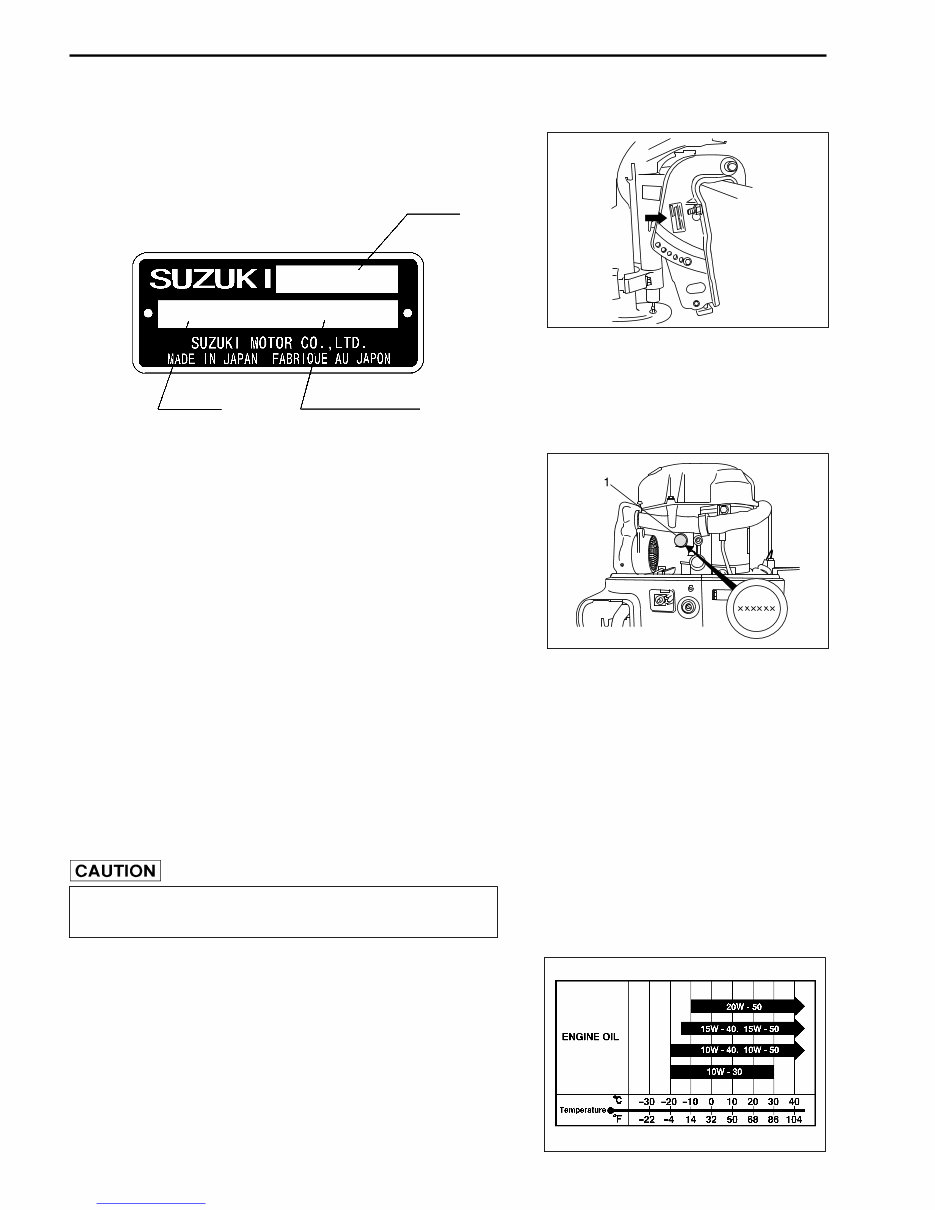

IDENTIFICATION NUMBER LOCATION

MODEL, PRE-FIX, SERIAL NUMBER

The MODEL, PRE-FIX and SERIAL NUMBER of motor are

stamped on a plate attached to the clamp bracket.

Example

FUEL AND OIL

GASOLINE RECOMMENDATION

Suzuki highly recommends that you use alcohol - free un-

leaded gasoline with a minimum pump octane rating of 87

(R+M / 2 method) or 91 (Research method). However, blends

of unleaded gasoline and alcohol with equivalent octane con-

tent may be used.

Allowable maximum blend of a single additive (not combina-

tion) :

5% Methanol, 10% Ethanol, 15% MTBE

If leaded gasoline is used, engine damage may re-

sult. Use only unleaded gasoline.

ENGINE OIL

Use only oils that are rated SE, SF, SG, SH, or SJ under the

API (American Petroleum Institute) classification system.

The viscosity rating should be SAE 10W-40.

If an SAE 10W-40 motor oil is not available, select an alterna-

tive according to the chart at right.

MODEL

PRE-FIX SERIAL NUMBER

DF 30

03001F–XXXXXX

ENGINE SERIAL NUMBER

A second engine serial number plate is pressed into a boss

on the crankcase.

1. Serial number plate

8

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 1-5

ENGINE BREAK-IN

The first 10 hours are critically important to ensure correct

running of either a brand new motor or a motor that has been

reconditioned or rebuilt. How the motor is operated during this

time will have direct bearing on its life span and long-term

durability.

Break-in period : 10 hours

WARM-UP RECOMMENDATION

Allow sufficient idling time (more than 5 minutes) for the en-

gine to warm up after cold engine starting.

THROTTLE RECOMMENDATION

NOTE:

Avoid maintaining a constant engine speed for an extended

period at any time during the engine break-in by varying the

throttle position occasionally.

1. FIRST 2 HOURS

For first 15 minutes, operate the engine in-gear at idling

speed.

During the remaining 1 hour and 45 minutes, operate the

engine in-gear at less than 1/2 (half) throttle (3000 r/min).

NOTE:

The throttle may be briefly opened beyond the recommended

setting to plane the boat, but must be reduced to the recom-

mended setting immediately after planing.

2. NEXT 1 HOUR

Operate the engine in-gear at less than 3/4 (three-quar-

ter) throttle (4000 r/min).

3. LAST 7 HOURS

Operate the engine in-gear at desired engine speed.

However, do not operate continuously at full throttle for

more than 5 minutes.

9

Downloaded from www.Manualslib.com manuals search engine

1-6 GENERAL INFORMATION

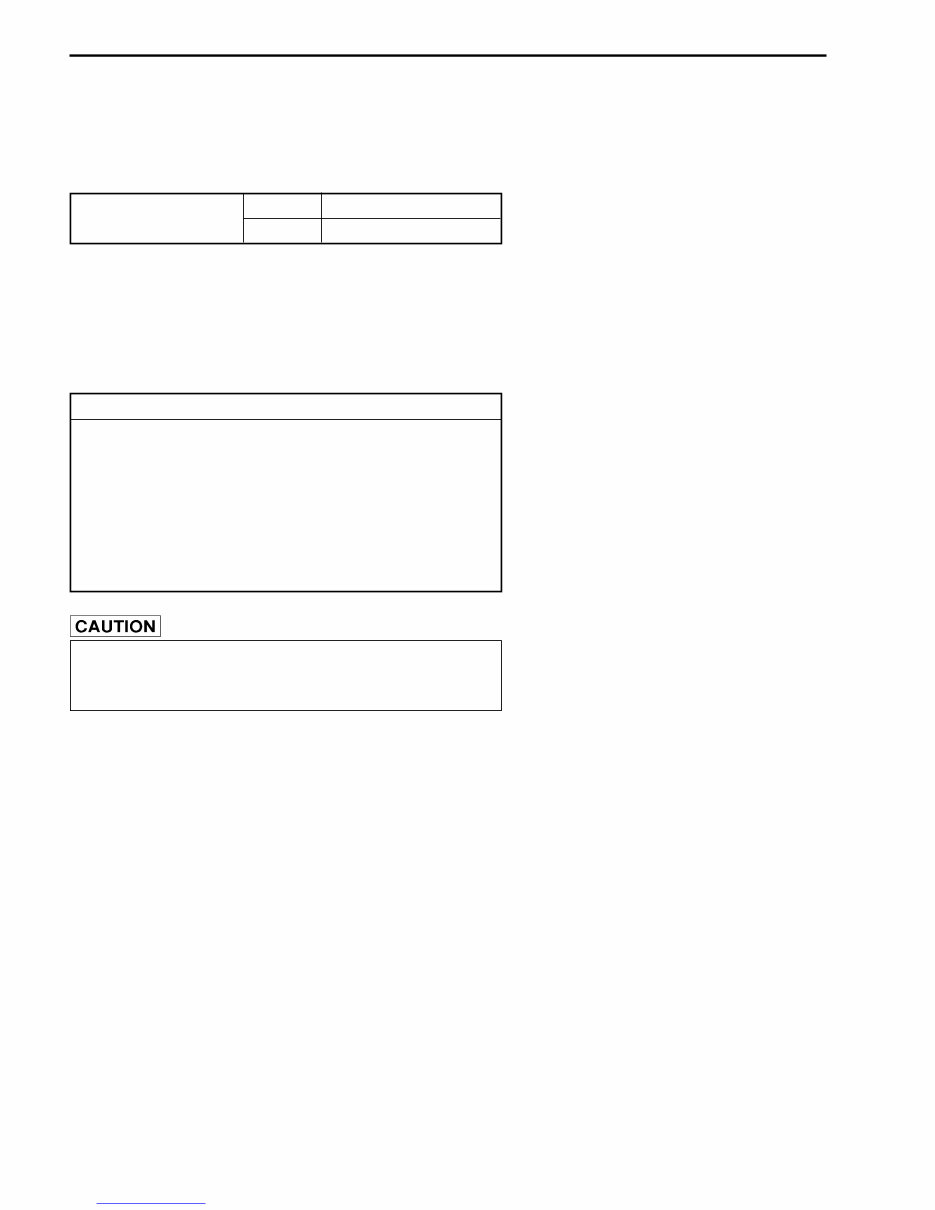

PROPELLERS

An outboard motor is designed to develop its rated power within

a specified engine speed range. The maximum rated power

delivered by the DF25 / 30 models are shown below.

Blade × Diam. (in.) × Pitch (in.)

3 × 10 - ¼ × 9 (P901)

3 × 10 - ¼ × 10 (P1001)

3 × 10 - ¼ × 11 (P1101)

3 × 10 - ¼ × 12 (P1201)

3 × 10 - ¼ × 13 (P1301, PS1301)

3 × 10 - ¼ × 14 (P1401)

3 × 10 - ¼ × 15 (P1501)

If the standard propeller fails to meet the above requirement,

use another pitch propeller to hold the engine speed within

the range specified above.

Propeller selection chart

Recommended full

throttle speed range

DF25 5000 – 5600 r/min

DF30 5500 – 6100 r/min

Installing a propeller with pitch either too high or too

low will cause incorrect maximum engine speed, which

may result in severe damage to the motor.

10

Downloaded from www.Manualslib.com manuals search engine

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

Viewed 28 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

This manual offers comprehensive service, repair, and maintenance guidance for 2000-2007 Suzuki 25/30HP (DF25/DF30) 4-Stroke Outboard motors. It is the essential resource for technicians, mechanics, and DIY enthusiasts working with these specific outboard models.

- Detailed illustrations and step-by-step instructions cover critical areas, including general information, specifications, maintenance, fuel system, ignition system, powerhead, gear case, shaft/engine coupling/drive shaft, tilt and trim systems, midsection, impeller housing/water pump, remote control system, and trolling motor system.

- Designed to support both professional mechanics and DIY enthusiasts, the manual contains clear diagrams and instructions for easy comprehension and reliable troubleshooting.

- It features easy-to-read exploded views that help facilitate repairs by clearly identifying each component and corresponding part numbers.

- Available for instant download, this digital manual ensures immediate access to essential service and repair procedures for your Suzuki outboard motor.

- The comprehensive and detailed content equips professionals with the knowledge required to effectively service and repair the 2000-2007 Suzuki DF25/DF30 4-Stroke Outboard motor.

Please note: This is a .PDF manual.