2010-2012 Yamaha WaveRunner VX1100 VX Cruiser VX Deluxe VX Sport Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

REPAIR MANUAL 2010-2015

WaveRunner

F2N-28197-1M-11

VX Sport

VX1100 (F2N)

VX Cruiser

VX1100A (F2N)

VX Deluxe

VX1100B (F2N)

LIT-18616-03-22

Preface

This manual has been prepared by Yamaha primarily for use by Yamaha dealers and their trained

mechanics when performing maintenance procedures and repairs to Yamaha equipment. It has

been written to suit the needs of persons who have a basic understanding of the mechanical and

electrical concepts and procedures inherent in the work, for without such knowledge attempted

repairs or service to the equipment could render it unsafe or unfit for use.

Because Yamaha has a policy of continuously improving its products, models may differ in detail

from the descriptions and illustrations given in this publication. Use only the latest edition of this

manual. Authorized Yamaha dealers are notified periodically of modifications and significant

changes in specifications and procedures, and these are incorporated in successive editions of this

manual. Also, up-to-date parts information is available on YPEC-web. Additional information and

up-to-date information on Yamaha products and services are available on Yamaha Service Portal.

Important information

Particularly important information is distinguished in this manual by the following notations:

The Safety Alert Symbol means ATTENTION! BECOME ALERT! YOUR SAFETY IS

INVOLVED!

A WARNING indicates a hazardous situation which, if not avoided, could result in death or

serious injury.

A NOTICE indicates special precautions that must be taken to avoid damages to the water-

craft or other property.

TIP:

A TIP provides key information to make procedures easier or clearer.

WaveRunner

VX Sport, VX Cruiser, VX Deluxe

SERVICE MANUAL

©2010 by Yamaha Motor Corporation, U.S.A.

1st Edition, January 2010

All rights reserved.

Any reprinting or unauthorized use

without the written permission of

Yamaha Motor Corporation, U.S.A.

is expressly prohibited.

Printed in U.S.A.

LIT-18616-03-22

Contents

General information

GEN

INFO

Specification

SPEC

Maintenance

MNT

Fuel system

FUEL

Power unit

POWR

Jet pump unit

JET

PUMP

Electrical system

ELEC

Hull and hood

HULL

HOOD

Troubleshooting

TRBL

SHTG

Appendix

– +

1

2

3

4

5

6

7

8

9

A

GEN

INFO

1

General information

Safety while working ..................................................... 1-1

Rotating part ............................................................................... 1-1

Hot part ....................................................................................... 1-1

Electric shock ............................................................................. 1-1

Impeller ....................................................................................... 1-1

Handling of gasoline ................................................................... 1-1

Ventilation................................................................................... 1-2

Self-protection ............................................................................ 1-2

Working with crane ..................................................................... 1-2

Handling of heat gun .................................................................. 1-3

Part, lubricant, and sealant ......................................................... 1-3

Handling of sealant ..................................................................... 1-3

Special service tool .................................................................... 1-3

Tightening torque ....................................................................... 1-3

Non-reusable part ....................................................................... 1-3

Disassembly and assembly ........................................................ 1-4

How to use this manual ..................................................... 1-5

Manual format ............................................................................ 1-5

Abbreviation ............................................................................... 1-6

Adhesive, lubricant, sealant,

and thread locking agent ................................................... 1-7

Symbol ....................................................................................... 1-7

Special service tool ............................................................ 1-8

Model feature .................................................................... 1-15

General feature ........................................................................ 1-15

Identification number ................................................................ 1-16

Deck and hull ............................................................................ 1-17

Intermediate drive shaft ............................................................ 1-18

ECM and rectifier regulator ...................................................... 1-19

Multifunction meter unit ............................................................ 1-20

Multifunction display warning ................................................... 1-21

Yamaha Security System (VX Cruiser and VX Deluxe) ........... 1-22

Technical tips ................................................................... 1-23

Engine control .......................................................................... 1-23

Engine control system .............................................................. 1-28

1-1

GEN

INFO

General information

Safety while working

To prevent an accident or injury and to pro-

vide quality service, observe the following

safety procedures.

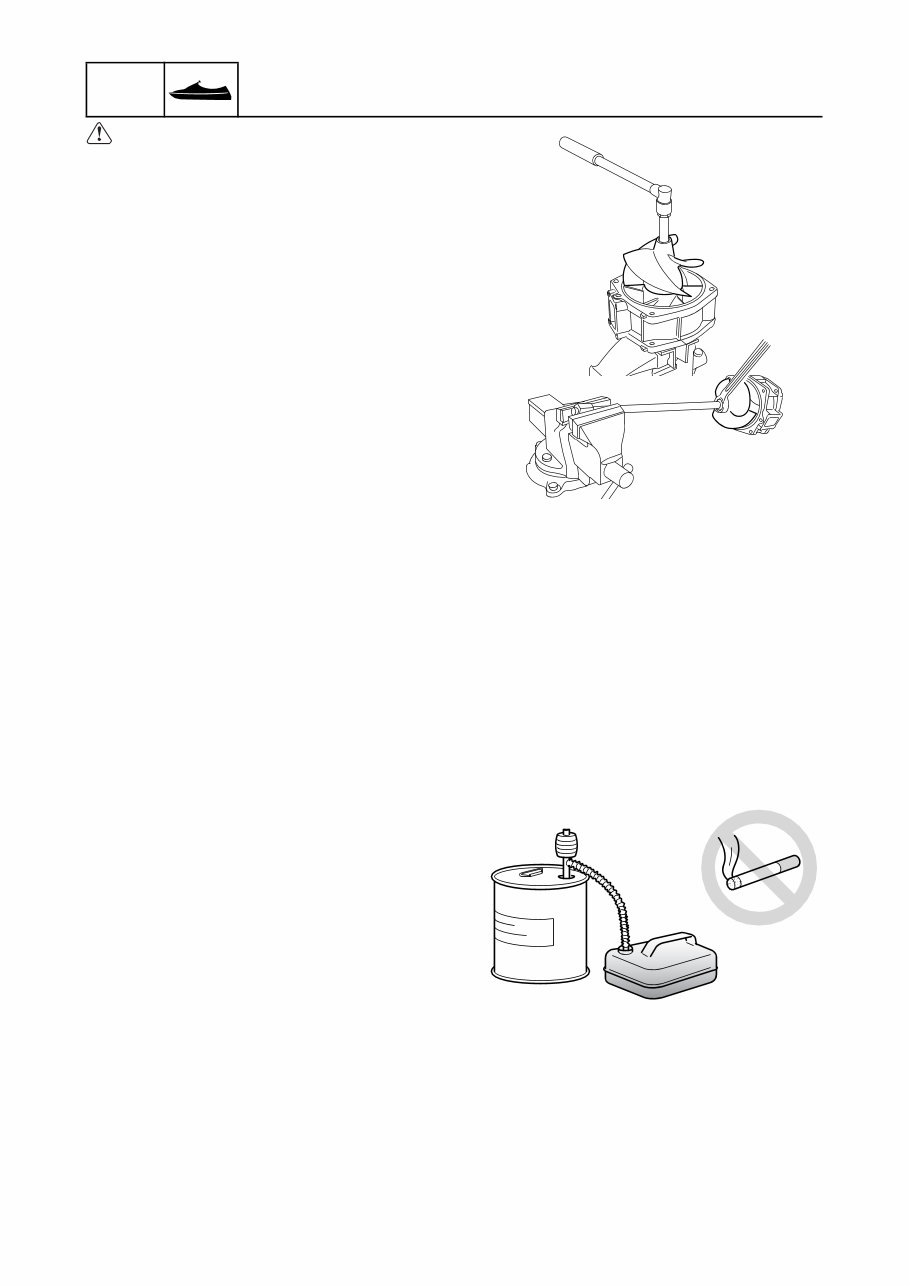

Rotating part

• Hands, feet, hair, jewelry, clothing, per-

sonal flotation device straps, and so on,

can become entangled with internal rotating

parts of the engine or jet pump unit, result-

ing in serious injury or death.

• Keep hands, feet, hair, jewelry, clothing,

personal flotation device straps, and so on,

away from any exposed moving parts when

operating the engine with the seat

removed.

• Keep away from intake grate while engine

is on. Items such as hair, clothing, or per-

sonal flotation device straps can become

entangled in moving parts resulting in

severe injury.

Hot part

During and after operation, engine parts are

hot enough to cause burns. Do not touch any

parts in the engine compartment until the

engine has cooled.

Electric shock

Do not touch any electrical parts while start-

ing or operating the engine. Otherwise, shock

or electrocution could result.

Impeller

Do not hold the impeller with your hands

when loosening or tightening the impeller.

Handling of gasoline

• Gasoline is highly flammable. Keep gaso-

line and all flammable products away from

heat, sparks, and open flames.

• Gasoline is poisonous and can cause injury

or death. Handle gasoline with care. Never

siphon gasoline by mouth. If you swallow

some gasoline, inhale a lot of gasoline

vapor, or get some gasoline in your eyes,

see your doctor immediately. If gasoline

spills on your skin, wash with soap and

water. If gasoline spills on your clothing,

change your clothes.

1-2

1

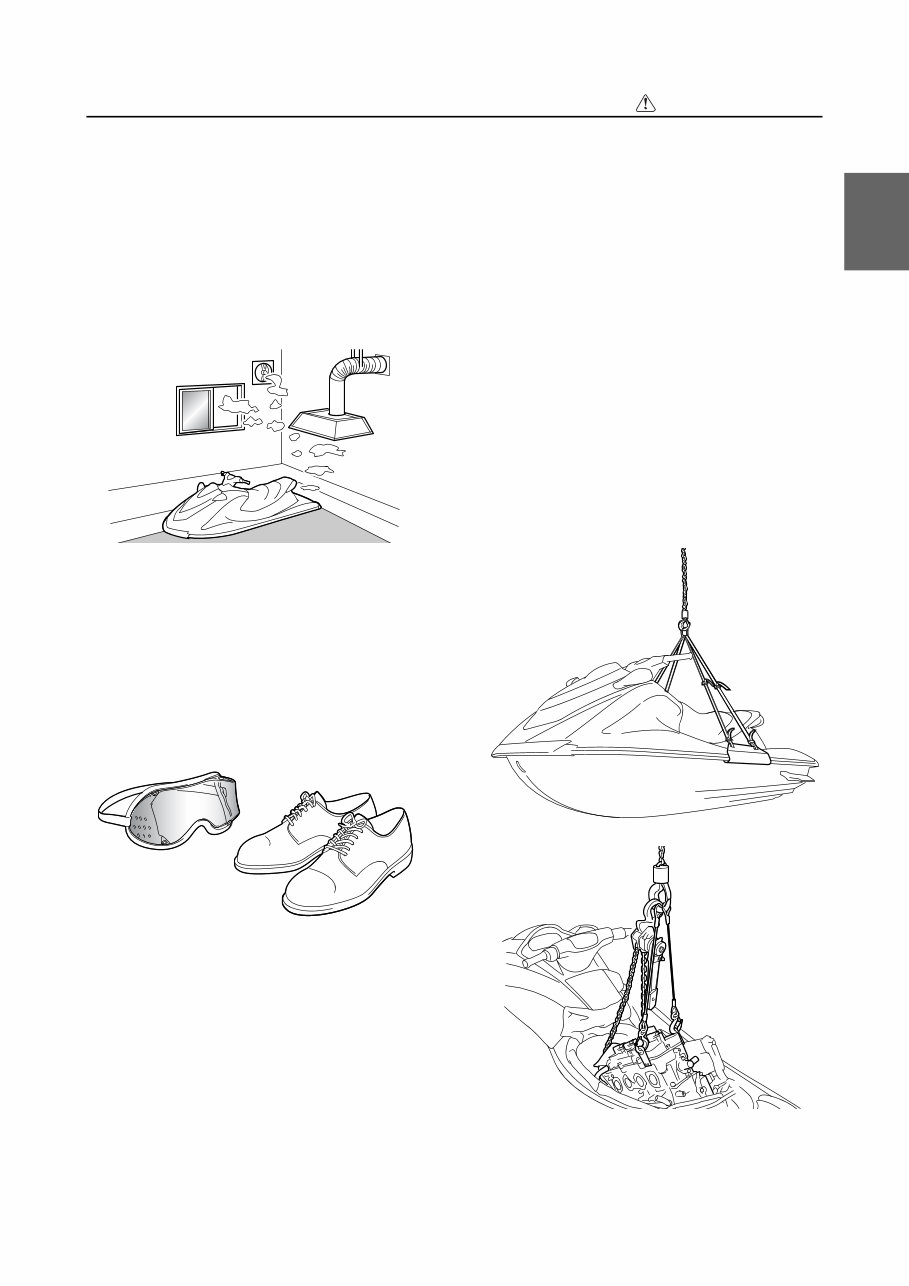

Ventilation

• Gasoline vapor and exhaust gas are

heavier than air and extremely poisonous.

If gasoline vapor or exhaust gas is inhaled

in large quantities, it may cause loss of con-

sciousness and death within a short time.

• When test running an engine indoors (for

example, in a water tank) make sure to do

so where adequate ventilation can be main-

tained.

Self-protection

• Protect your eyes by wearing safety

glasses or safety goggles during all opera-

tions involving drilling and grinding, or when

using an air compressor.

• Protect your hands and feet by wearing

protective gloves and safety shoes when

necessary.

Working with crane

• When moving the watercraft, or when lifting

the engine during removal or installation,

make sure to use a crane with a lifting

capacity that is equal to or more than the

weight of the watercraft or engine respec-

tively.

• When lifting the watercraft, use the water-

craft lift harness and make sure that the

watercraft is in a stable position when mov-

ing it.

• Use the wire ropes of adequate strength,

and lift up the engine unit using the three

point suspension.

• If the engine unit does not have three or

more points to be suspended, support it

using additional ropes or the like so that the

engine unit can be lifted and carried in a

stable manner.

Safety while working

1-3

GEN

INFO

General information

Handling of heat gun

• Improper handling of a heat gun may result

in burns. For information on the proper han-

dling of the heat gun, see the operation

manual issued by the manufacturer.

• When using a heat gun, keep it away from

the gasoline and oil, to prevent a fire.

• Components become hot enough to cause

burns. Do not touch any hot components

directly.

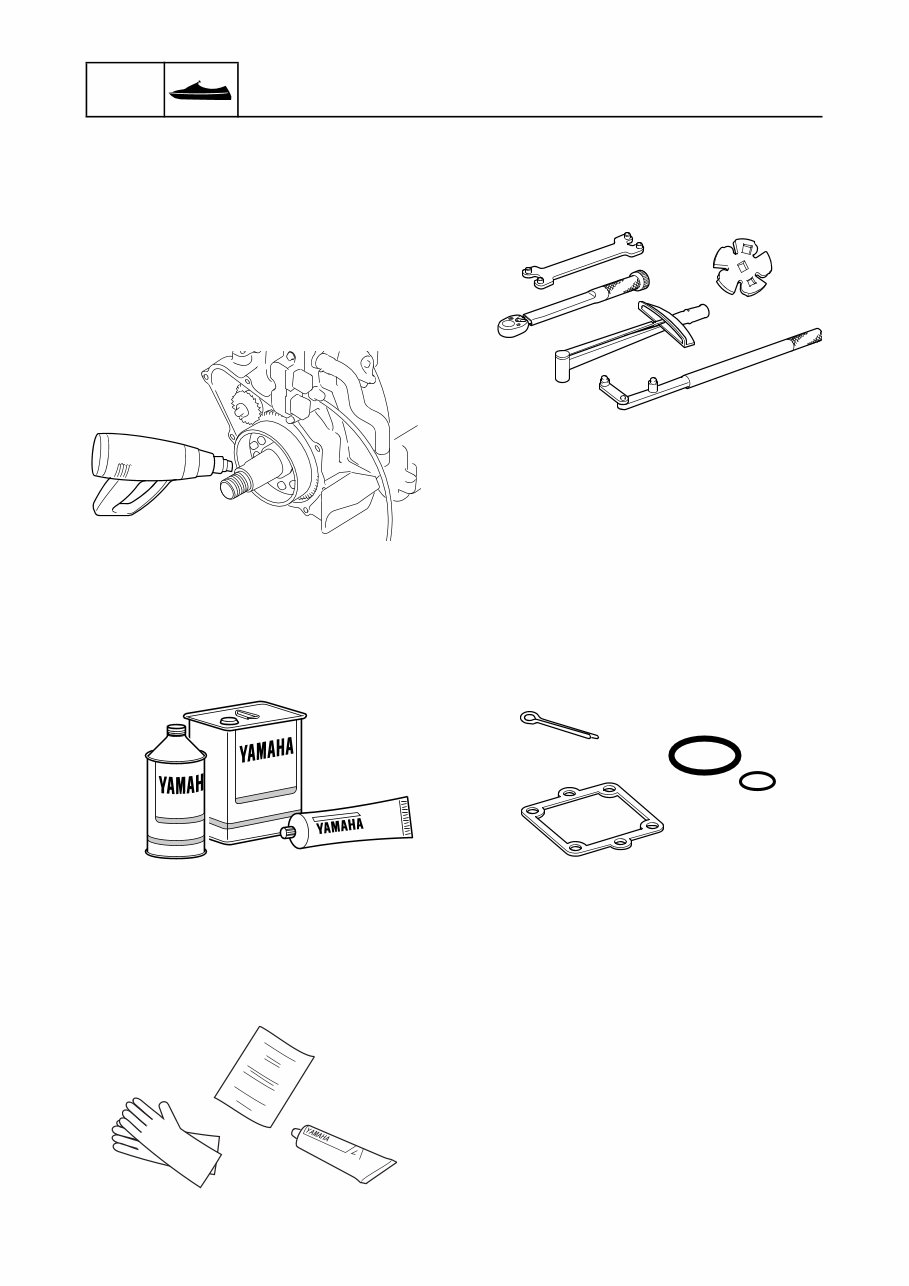

Part, lubricant, and sealant

Use only genuine Yamaha parts, lubricants,

and sealants, or those recommended by

Yamaha, when servicing or repairing the

watercraft.

Handling of sealant

• Wear protective gloves to protect your skin,

when using the sealants.

• See the material safety data sheet issued

by the manufacturer. Some of the sealants

may be harmful to human health.

Special service tool

Use the recommended special service tools

to work safely, and to protect parts from dam-

age.

Tightening torque

Follow the tightening torque specifications

provided throughout the manual. When tight-

ening nuts, bolts, and screws, tighten the

large sizes first, and tighten fasteners starting

in the center and moving outward.

Non-reusable part

Always use new gaskets, seals, O-rings, cot-

ter pins, and so on, when installing or assem-

bling parts.

1-4

1

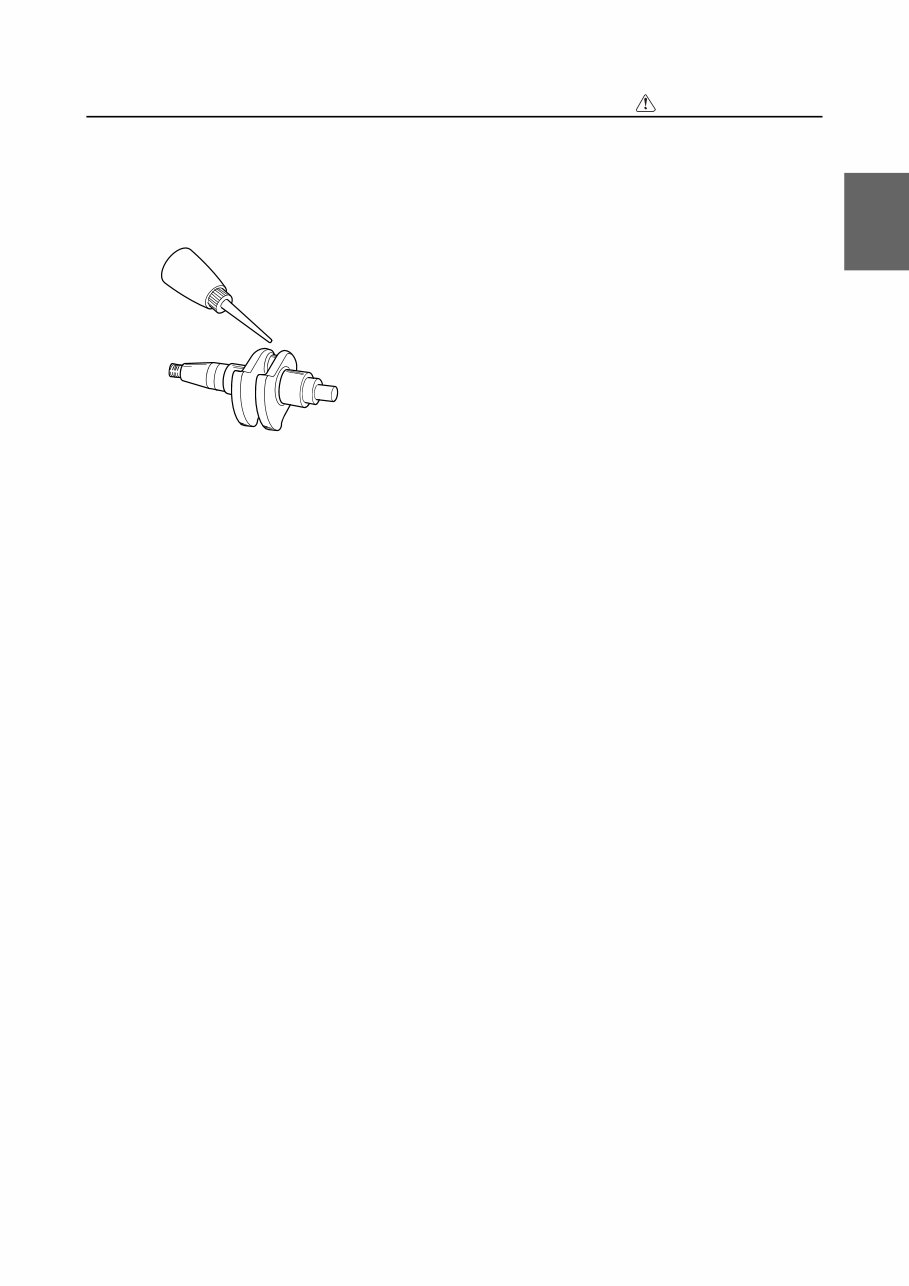

Disassembly and assembly

• Use compressed air to remove dust and dirt

during disassembly.

• Apply engine oil to the contact surfaces of

moving parts before assembly.

• Install bearings so that the bearing identifi-

cation mark is facing in the direction indi-

cated in the installation procedure. In

addition, make sure to lubricate the bear-

ings liberally.

• Apply a thin coat of water resistant grease

to the lip and periphery of an oil seal before

installation.

• Check that moving parts operate normally

after assembly.

Safety while working

1-5

GEN

INFO

General information

How to use this manual

Manual format

The format of this manual has been designed to make service procedures clear and easy to under-

stand. Use the information below as a guide for effective and quality service.

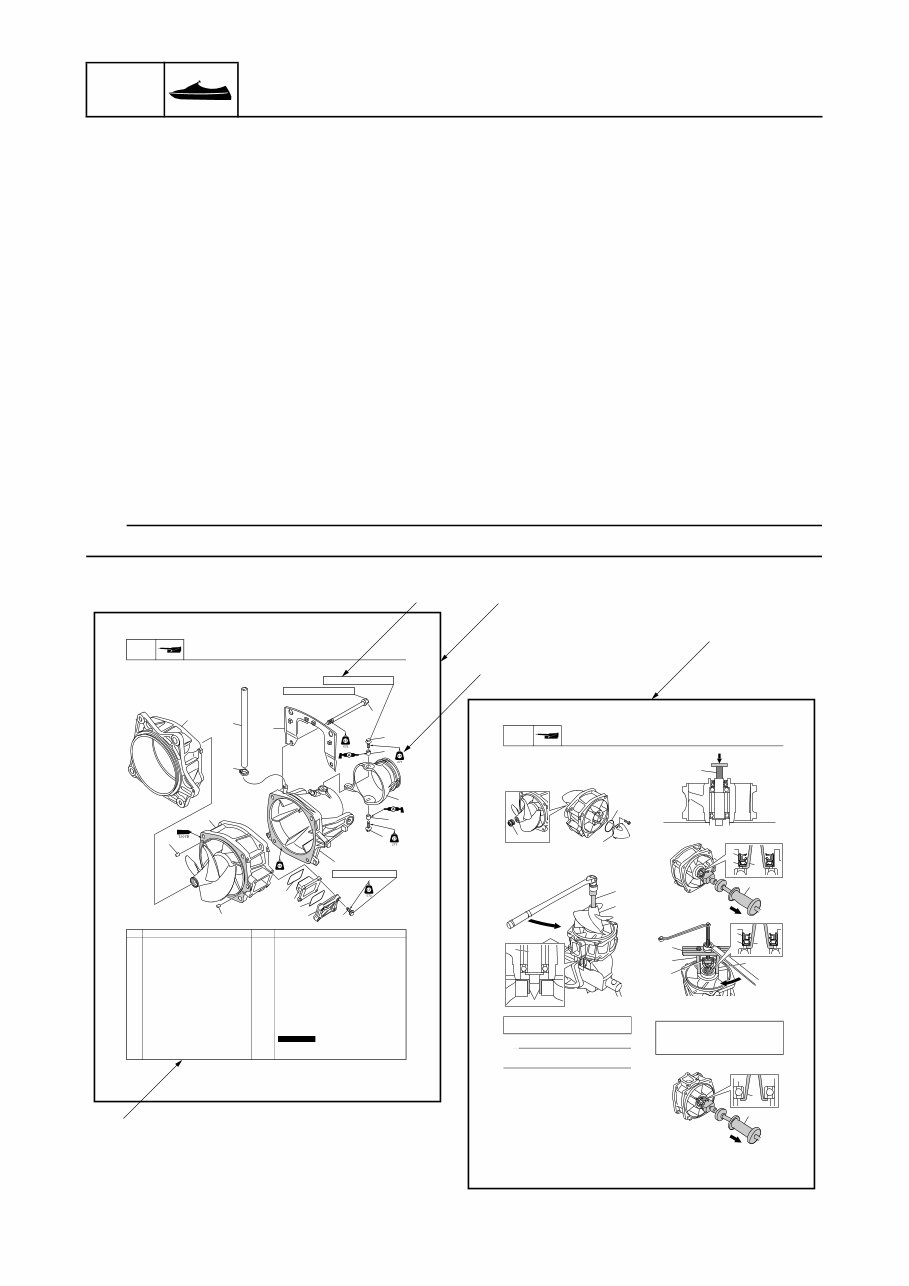

• Parts are shown and detailed in an exploded diagram and are listed in the component list (see 1

in the following figure for an example page).

• The component list consists of part names and quantities, as well as bolt and screw dimensions

(see 2 in the following figure). To assemble or install the components, reverse the steps indicated

in the component list.

• Symbols are used to indicate important aspects of a procedure, such as the grade of lubricant and

the lubrication point (see 3 in the following figure).

• Tightening torque specifications are provided in the exploded diagrams (see 4 in the following fig-

ure), and in the related detailed instructions. Some torque specifications are listed in stages as

torque figures or angles in degrees.

• Separate procedures and illustrations are used to explain the details of removal, checking, and

installation where necessary (see 5 in the following figure for an example page).

TIP:

For troubleshooting procedures, see Chapter 9, “Troubleshooting.”

6-7

JET

PUMP Jet pump unit

Nozzle, impeller housing, and impeller duct assy.

No. Part name Q’ty Remarks

1 p m a l C 1

1 e s o h t u o p S 2

8 M 2 t l o B 3 × 25 mm

2 r a l l o C 4

1 e l z z o n t s u r h t t e J 5

0 1 M 4 t l o B 6 × 125 mm

1 t e k c a r B 7

1 e l z z o N 8

1 g n i s u o h r e l l e p m I 9

2 n i p l e w o D 0 1

6 M 4 t l o B 1 1 × 35 mm

1 r e v o c t e l n i r e t a W 2 1

2 g n i k c a P 3 1 Not reusable

1 r e n i a r t s t e l n i r e t a W 4 1

1 . y s s a t c u d r e l l e p m I 5 1

4

3

5

8

11 10

10

9

2

1

7

6

15

12

13

14

13

4

3

7 N·m (0.7 kgf·m, 5.2 ft·Ib)

15 N·m (1.5 kgf·m, 11.1 ft·Ib)

40 N·m (4.0 kgf·m, 29.5 ft·Ib)

6-9

JET

PUMP Jet pump unit

Impeller duct assy. disassembly

1. Remove the cap 1, O-ring 2, and

impeller cap 3.

2. Remove the impeller 4.

TIP:

Hold the drive shaft 6 in a vise between two

aluminum plates a.

3. Remove the drive shaft 6 using a press.

NOTICE: Do not press the drive shaft

threads directly.

4. Remove the oil seals 7 and 8.

È U.S.A. and Canada

É Worldwide

5. Remove the rear bearing C.

Crankshaft holder 5: YB-06552

Crankshaft holder 20 5: 90890-06552

3

1

2

a

6

5

4

Slide hammer 9: YB-06096

Stopper guide plate 0: 90890-06501

Bearing puller assembly A: 90890-06535

Stopper guide stand B: 90890-06538

6

9

9

7

8

È

0

B

B

A

A

7

8

É

9

9

C

È

1

5

3

2

4

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 68 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get access to the complete factory service repair workshop manual without any extra fees or expiry dates. This professional manual is available for instant access on your computer, tablet, or smartphone. It covers all repairs, servicing, and troubleshooting procedures with detailed photos and diagrams, making it suitable for both professional mechanics and DIY enthusiasts. The manual contains step-by-step instructions, highly detailed exploded diagrams, and pictures to guide you through every job correctly.

Frequently Asked Questions:

- Q. Can I print out a page?

A. Yes, you can print out a single page or the entire manual as per your choice. - Q. Can I use this manual on more than one computer?

A. Yes, this manual can be used on as many computers as required. - Q. Is this a trial or a limited version?

A. No, this is the full manual without any limitations or trial periods and can be used for life. - Q. Will this manual expire in 12 months or will I have to pay a renewal fee?

A. NO, absolutely not! You can continue to use this manual for life without the need to renew or pay any extra. - Q. Will this manual work on Windows & MAC computers?

A. Yes, it is fully compatible with all Windows & all MAC computers.

Thanks for looking at this item, please click on the button to get started.