2003-2007 Honda Aquatrax F-12 ARX1200 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

•

•

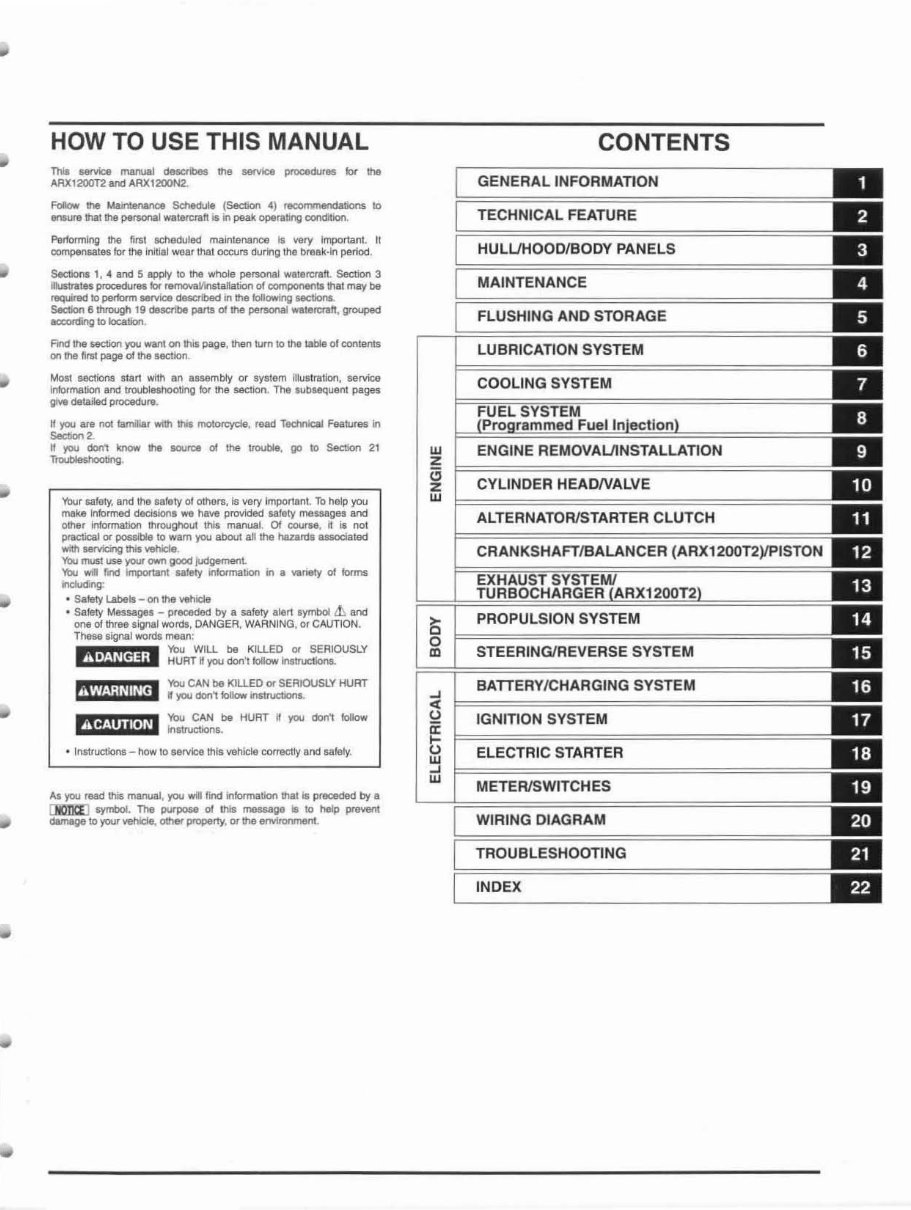

HOW TO USE THIS MANUAL

TNt IWYice manual deaetbs Ihto ~ procedufes lor !he

ARXl200T2 Md ARX 1200N2.

R*Jw !he t.tanenance ScheduIIo (Section .) r.commendalions to

..ure It\a! !he pt<SOnIIl WI1l8";:IlI11. • In peal< optrallng condition.

Pe~iog the fllSl IICheduIed maintenance Is WI)' ImportanL It

a:JmP"II&ate& lot the Initial wear thaI occurs oomlllhe break -In period.

S«tionII " 4 and S IIPPfV 10 me whole pGfSOnal waterer,lt Sttctiofl 3

~tn procedu_ lor .....-.cMIWlstallation 01 componentslhat may be

I1IQUIf8d 10 pertarm MrVice descrtled In the ~ MCtJons.

s.c.ion 61hrough 19 deserIbe pans oIlt1e per$OnIII walercratt, ~

~ to IDeation.

FIf'Id lhIIl*.1ion you want Ot\ this p6g6, then turn 10 the ta~ of contents

on !he first page oIlhe section

Mo~ MCtiof1s SIan with an aasembly Of system IHlJltration, seNicu

InIoImatkln and trouIMshooIlng bI the SIlCIlon. The tubaequen! pages

gIW detdtd procedure.

" )IOU are no! IamiIIIIr with IhiI moIt>reycIe, read Technical Features In

S."",,,

n )IOU don' know the .ouroe 01 the \roUbIIf, 00 10 S&ct!Dn 21

T~.

Your safely, and 1M nlety 04 0Ih9f11, is very Imponanl To help you

maI<e Inbmled decisions wa have provided salllly messa1i/98 and

other information Ihrooghoul this manual. 01 courH, ~ • nol

paICIicaI Of poujbIe to warn you abcxJ1 •• !he hazards associated

wtIh S8tYIc;rIg thiS vehic:Ie.

'ItIu rn.ISI use '/OUI' own good ~l

'ttIu .... fnd important talett W!fom1abOr) In • "'neIY 01 forms

irIcIu!ing:

• S.laty L.abelll- on the l'8hicle

• safely Menage. - preoedGd by II safety .len lymboI If; and

one o1lhree signal worm, DANGER, WARNING, or CAUTION.

ThetwislgrIal words mean:

You Wlu.. be KILLED Of SERIOUSLY

!'Il

l

1±] nS'i;' HURT W you don~ IoI\OW ..... !I'I.K:tlor ..

'tbu CAN be KILLED Of SERIOUSlY HURT

m.,.Wf! ! £lfl • you don't bIIowNuucuons.

You CAN be HURT 11 you don~ follow

r! Wlnl' J f' ""I\ruCtion •.

• IfI5tructiooa - how to 5&rVIce this YIIhicie correctly Ind lately.

,.. you lead this manual, you wi find inlormauon tIlIt '- preceded by e

0i0'Jll::(} symbol. The pI.II"J)(Ite 01 INs ITI8IIIgII '- to help preYMt

dImIpe to YOUI YIIhic:Ie. 0!Mr ~Ity, or the erMronment.

w

z

a

z

w

~

o

CD

..J

<

o

~

..J

W

CONTENTS

GENERAL INFORMATION

TECHNICAL FEATURE

HULUHOOD/BODY PANELS

MAINTENANCE

FLUSHING AND STORAGE

LUBRICATION SYSTEM

COOLING SYSTEM

======

ENGINE REMOVAL/INSTALLATION

CYLINDER HEADNALVE

ALTERNATORISTARTER CLUTCH

CRANKSHAFTIBALANCER (ARX1200T2)IPISTON

PROPULSION SYSTEM

STEERING/REVERSE SYSTEM

BATTERY/CHARGING SYSTEM

IGNITION SYSTEM

ELECTRIC STARTER

METERISWITCHES

WIRING DIAGRAM

TROUBLESHOOTING

INDEX

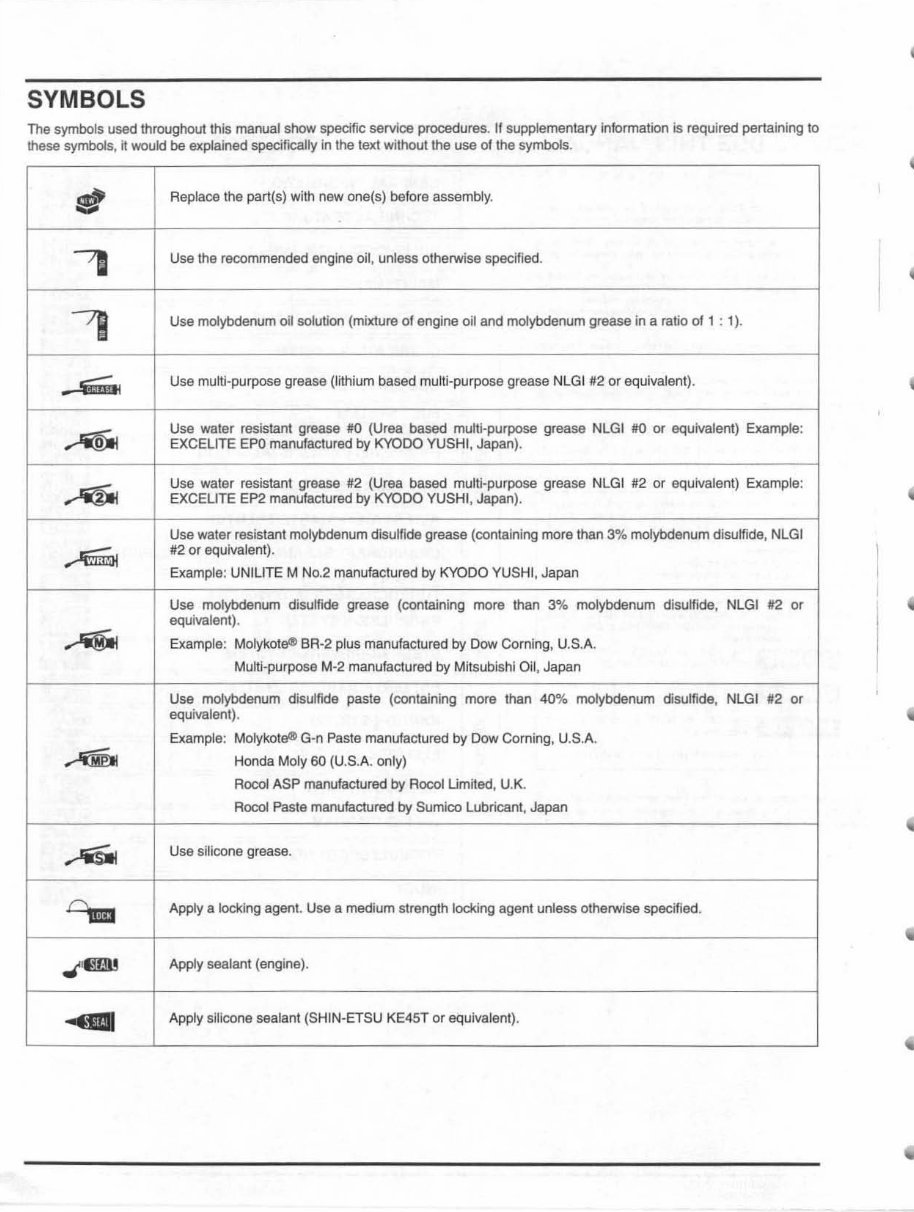

SYMBOLS

The symbols used throughout this manual show specific service procedures. If supplementary Information is requ ired pertaini ng to

these symbol s, it would be explaIned specifically In the text without the use of the symbols.

fI

Replace the part(s) with new one(5) before assembly.

'I

Use the recommended engine oit, unless otherwise specified.

7!

Use molybdenum oil solution (mixture of engine oil and molybdenum grease in a ratio of 1 : 1) .

. -

Use multi-purpose grease (lithium based mutti-purpose grease NLGI #2 or equivalent).

~

Use water resistant grease #0 (Urea based multi-purpose grease NLGI #0 Of equivalent) Example:

EXCEUTE EPO manufactured by KYODO YUSHI . Japan).

~

Use water resistant grease #2 (Urea based multi·purpose grease NLGI #2 or equivalent) Example:

EXCEUTE EP2 manufactured by KYODO YUSHI , Japan).

Use water resistant molybdenum disulfide grease (containing more than 3 "10 molybdenum disulfide, NLGI

...-'i'iiiJI

#2 or equivalent) .

Example: UNIUTE M No.2 manufactured by KYODO YUSHI, Japan

Use molybdenum disulfide grease (containing more than 3"10 molybdenum disulfide, NlGI #2 or

equivalent).

~

Example: Molykoteill BR·2 plus manufactured by Dow Corning, U.S.A.

Multi-purpose M·2 manufactured by Mitsubishl Oil, Japan

Use molybdenum disulfide paste (containing more than 40"10 molybdenum disulfide, NlGI #2 or

equivalent).

Example: Molykoteill G-n Paste manufactured by Dow Corning, U.S.A.

.AWl Honda Moly 60 (U.S.A. only)

Rocol ASP manufactured by Rocol Umited, U.K.

Rocol Paste manufactured by Sumico lubricant , Japan

.AiSlII

Use silicone grease.

') MI

Apply a locking agent. Use a medium strength locking agent unless otherwise specified .

.,('1mI!

Apply sealant (engine).

411

Apply silicone sealant (SHIN-ETSU KE45T or equivalent).

1. GENERAL INFORMATION

SERVICE RULES ......................................... '-2

MODEL IDENTIFiCATION··· ·· ····················· · '-2

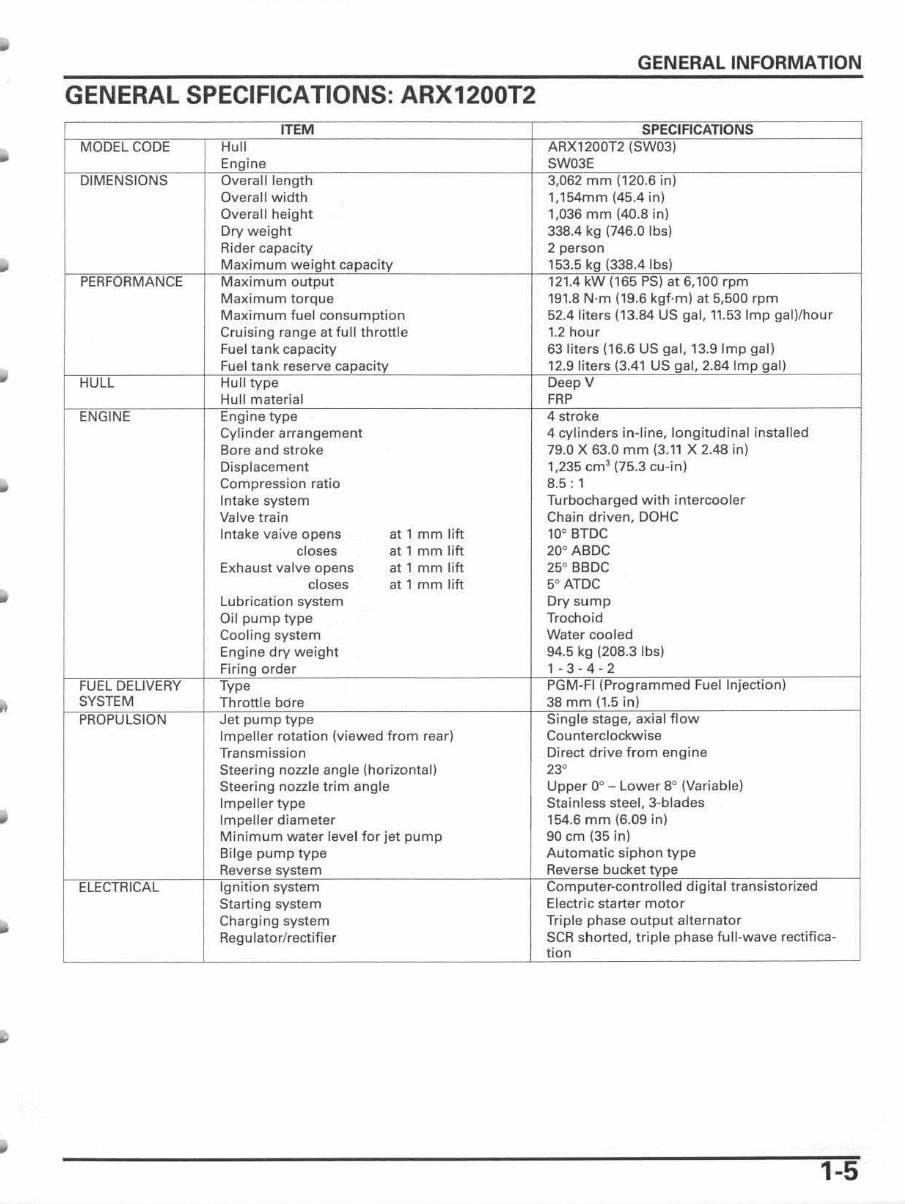

GENERAL SPECIFICATIONS: ARX'200T2 '-5

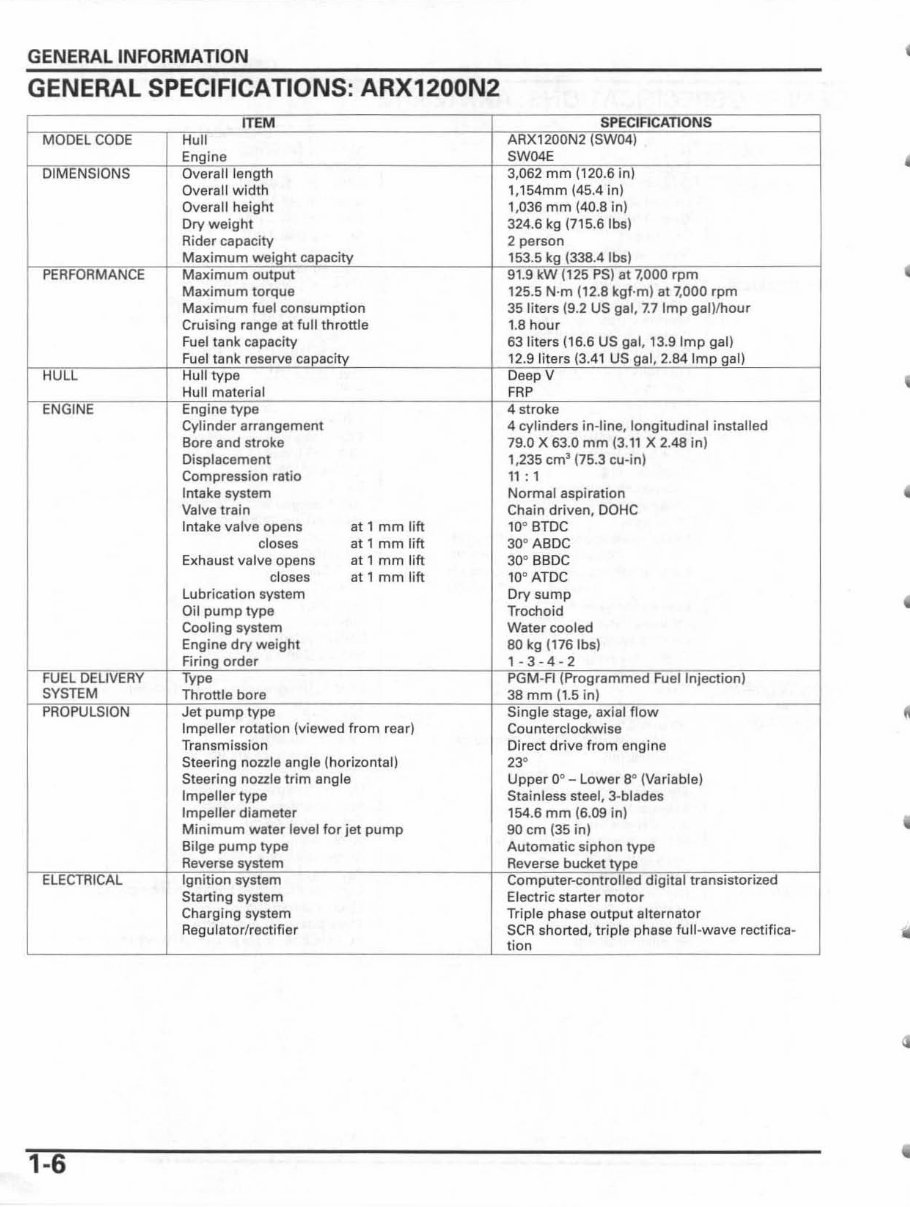

GENERAL SPECIFICATIONS: ARX,200N2 '-6

LUBRICATION SYSTEM SPECIFICATIONS'-7

FUEL SYSTEM (Programmed Fuel Injection)

SPECiFiCATiONS ··· ·· ··································· '-7

CYLINDER HEADIVALVE

SPECiFiCATIONS ·· ··············· ·· ···· ······· ·· ·· ··· ·· · '-8

ALTERNATOR/STARTER CLUTCH

SPECiFiCATIONS ························· ·· ··· ········· · '-8

CRANKSHAFT/BALANCER (ARX'200T2)/

PISTON SPECIFICATIONS ........................ . '-9

PROPULSION SYSTEM SPECIFICATIONS'-'O

BATTERY/CHARGING SYSTEM

SPECIFICATIONS ............................... ...... '- '0

IGNITION SYSTEM SPECiFiCATiONS ···· '-'0

ELECTRIC STARTER SPECIFICATIONS ·· '- '0

METER/SWITCHES SPECiFiCATiONS···· '-'0

STANDARD TORQUE VALUES ······· ·· ·· .... ,-"

ENGINE & BODY TORQUE VALUES ... .. . ,-"

LUBRICATION & SEAL POINTS .............. '-'6

CABLE & HARNESS ROUTING:

ARX'200T2 ............................................... '-20

CABLE & HARNESS ROUTING:

ARX'200N2 .............................................. '-38

EMISSION CONTROL SYSTEMS ............ ' -54

EMISSION CONTROL INFORMATION

LABEL .................... · .......... · .. · .... · .... ·· .......... '-55

1-1

GENERAL INFORMATION

SERVICE RULES

1. Use genuine Honda or Honda-recommended parts and lub ricants or their equivalents. Parts that do not meet Honda's

design specifications may cause damage to the watercraft.

2. Use the special tools designed for this product to avoid damage and incorrect assembly.

3. Use only metric tools when servicing the watercraft. Metric bolts, nuts and screws are not interchangeable with English

fasteners.

4. Install new gaskets, O-rings, cotter pins. and lock plates when reassembling.

5. When tightening bolts or nut s, begin with the larger diameter or inner bolt first. Then tighten to the specified torque

diagonally in incremental steps unless 8 particular sequence is specified.

6. Clean parts in cleaning solve nt upon disassembly. lubri cate any slid ing surfaces before reassembly.

7. After reassembly, check all parts for proper installation and operation.

8. Rou te all electrical wires as shown in the Cable and Harness Routing (page 1-20 or 1-38).

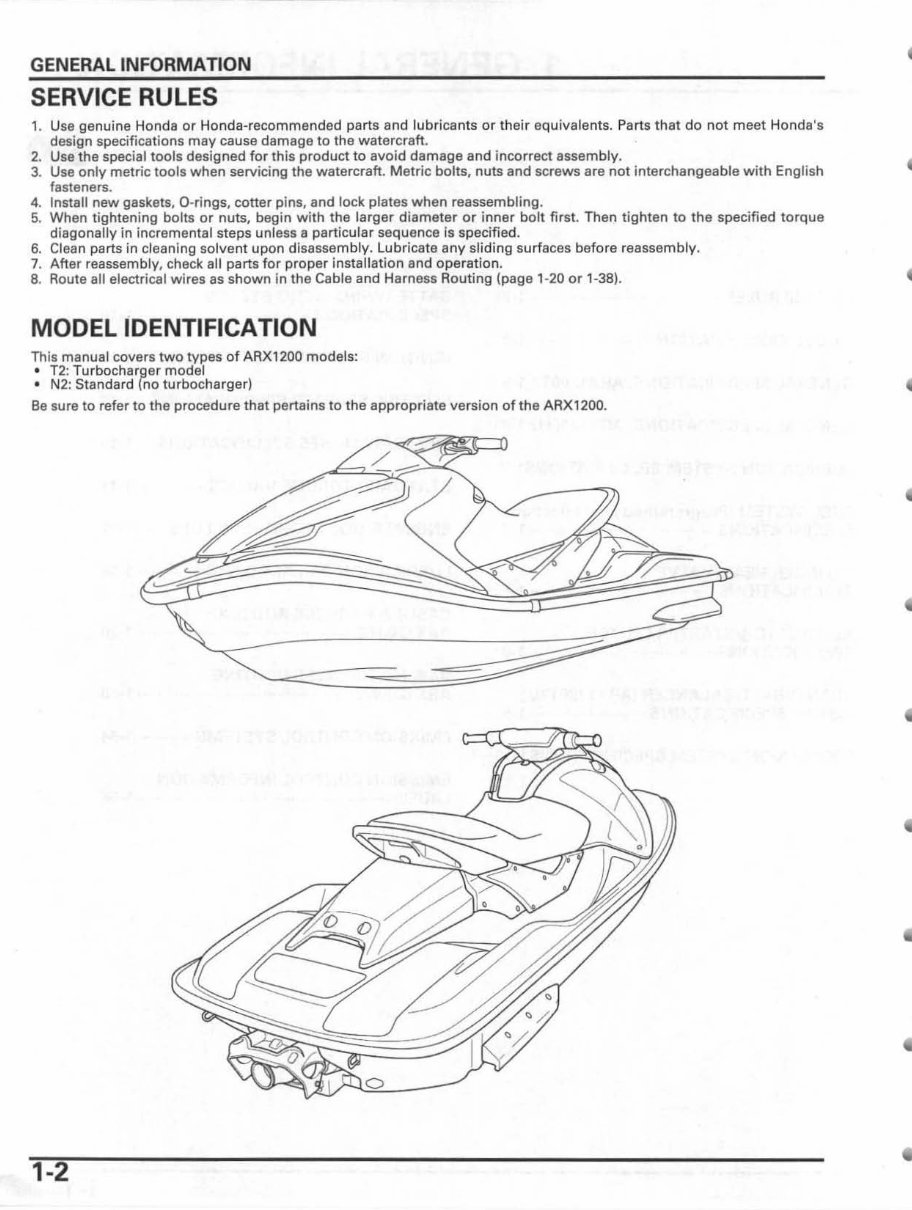

MODEL IDENTIFICATION

This manual covers two types of ARX1200 models:

• T2: Turbocharaer model

• N2: Standard (no turbocharger)

Be sure to refer to the procedure that pertains to the appropriate version of the ARX1200.

1-2

GENERAL INFORMATION

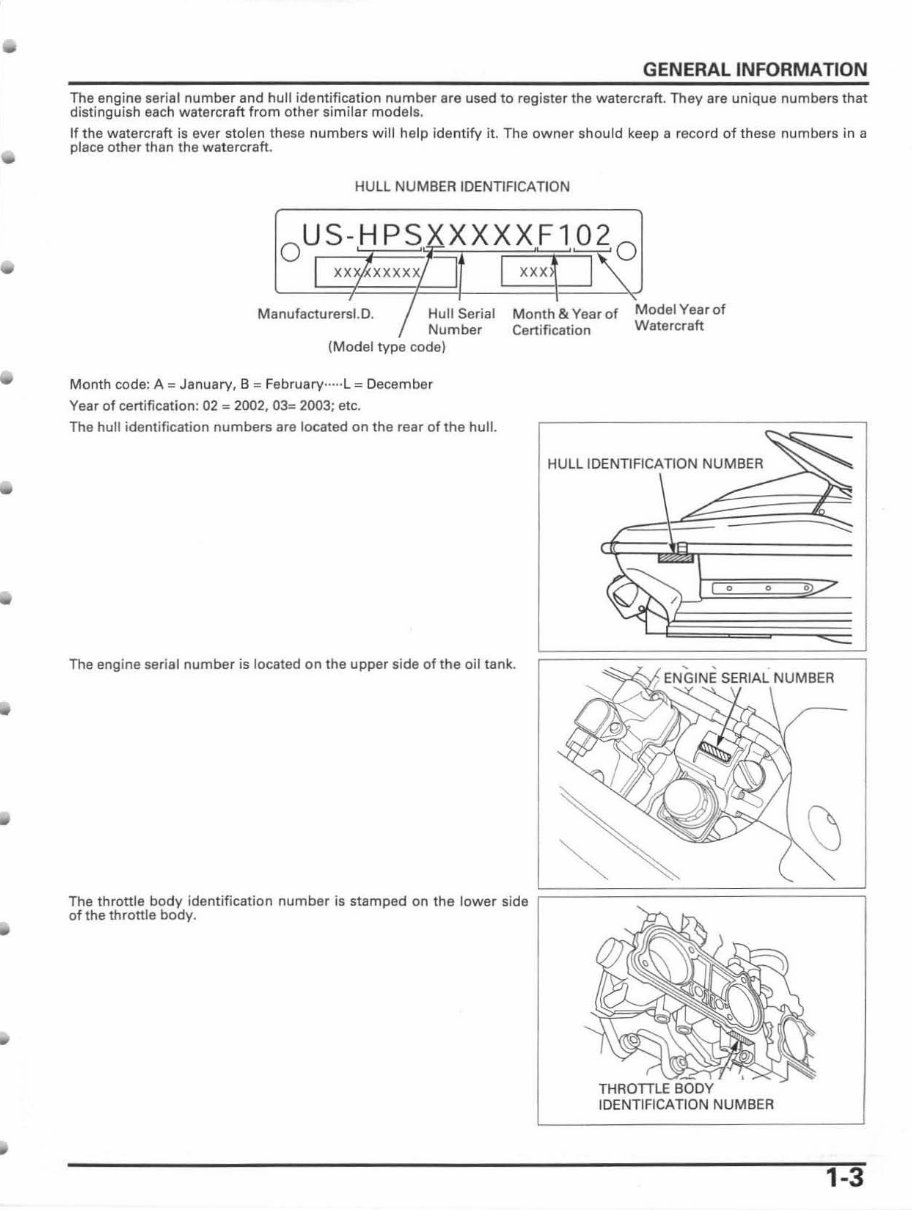

The engine serial number and hull identification number are used to register the watercraft. They are unique numbers that

distinguish each watercraft from other similar models .

If the watercraft is ever stolen these numbers will help identify it. The owner should keep a record of these numbers in a

place other than the watercraft.

HULL NUMBER IDENTIFICATION

OUS-HPS XXXXF1~ O

xxx

ManufaC1urersI.O. Hull Serial

Number

(Model type code)

Month & Year of

Certification

Model Year of

Watercraft

Month code: A '" January, B = February·····L = December

Year of certification: 02 '" 2002, 03= 2003; etc.

The hull ident ification numbers are located on the rear of the hull.

The engine serial number is located on the upper side of the oil tank.

The throttle body identification number is stamped on the lower side

of the throttle body.

HULL IDENTIFICATION NUMBER

THROTTLE

IDENTIFICATION NUMBER

1-3

GENERAL INFORMATION

The color label is attached on the inside of the fr on t hood. When order-

ing color-coded parts, always specify the designated col or code.

1-4

•

•

•

GENERAL INFORMATION

GENERAL SPECIFICATIONS: ARX1200T2

SYSTEM

Overall

Overall height

Dry weight

Rider capacity

I ou t put

Maximum torque

Maximum fuel consumpt ion

Cr uising range at full throttle

Fuel tan k capacity

Fuel tank reserve

type

Cylinder arrangement

Bore and stroke

Displacement

Comp ression ratio

Intake system

Valve train

Intake vaive opens

closes

Exhaust valve ope ns

closes

Lubrication system

Oil pump type

Cool ing system

dry weight

at 1 mm l ift

at 1 mm lift

at 1 mm lift

at 1 mm lift

Impeller rotation (viewed from rear)

Transmission

Steering nozzle angle (horizontal)

Steering nozzle trim angle

Impeller type

Impeller diameter

Minimum water level for jet pump

Bilge pump type

SW03E

mm i

1,154mm (45.4 in)

1,036 mm (40.S i n)

338.4 kg (746.0 lbs)

2 pe", on

at rpm

191.8 N-m (1S.6 kgf.m) at 5,500 rpm

52.4 liters (13.84 US gal, 11.53 Imp gall/ hour

1.2 hour

63 liters (16.6 US gal, 13.Slmp gal)

12.9lilers (3.41 US I I

4 cylinders in-line, l ongitudinal installed

79.0 X 63.0 mm (3.11 X 2.48 in)

1, 235 cm

3

(75.3 cu- in)

8.5: 1

Turbocharged with intercooler

Chain driven, DDHC

10° BTDC

20° ABDC

25° BBDC

5° ATDC

Dry su mp

Trochoid

Water cooled

94.5 kg (208.3 Ibs)

1- 3-4-2

stage, ill

Counterclockwise

Direct drive fr om engine

23"

Upper 0" - Lower 8" (Variable)

Stainless steel, 3-blades

154.6 mrn (6.09 in)

90 cm (35 in)

Automatic siphon type

rru;QFRTCA"L--~~:~~system ;C------------+-;': Electric st~a~rt~e~ '~m ~oITt~o~,di!liU""""""""'''''"'-1

Charging system Triple phase outp ut alterna tor

Regulator/rect ifier SeA shorted, triple phase fu l l-wave rectifica-

tion

1-5

GENERAL INFORMATION

GENERAL SPECIFICATIONS: ARX1200N2

1-6

Overall width

Overall height

Dry weight

Rider capacity

Maximum torque

Maximum fuel consumption

Cruising range at full throttle

Fuel tank capacity

I

I I

Cyllncl., arrangement

Bore and stroke

Displacement

Compression ratio

Intake system

Valve train

Intake valve opens

closes

Exhaust valve opens

closes

lubrication system

Oil pump type

Cooling system

Engine weight

bore

pump

at 1 mm lift

at 1 mm lift

at 1 mm lift

at 1 mm lift

Impeller rotati on (viewed from rearl

Tran smission

Steering noule angle (horizontal)

Steering nozzle trim angle

Impeller type

Impeller diameter

Minimum water level for jet pump

Bilge pump type

i system

Starting system

Charging system

Regu I ato rlrect ifier

mm

1,154mm (45.4 in)

1,036 mm (40.8 in)

324.6 kg (71S.B lbs)

2 person

153.5

'pm

125.5 N·m (12.8 at 7,000 rpm

35 liters (9.2 US gal. 7.7 Imp gal)n-tour

1.8 hour

631;lers (16.6 US

4 cylinders in-line, longitudinal installed

79.0 X 63.0 mm (3.11 X 2. 48 in)

1,235 em] 175.3 cu-in)

11 : 1

Normal aspiration

Chain driven, DOHe

10

0

BTDC

30° ABDC

30° BBDC

10° AIDC

Dry sump

Trochoid

Water cooled

80 kg (176Ibs)

Direct dri ve from engine

23'

Upper 0

0

- Lower eo (Variable)

Stainless steel, 3-blades

154.6 mm (6.09 in)

90 em (35 in)

Automatic type

Electric starter motor

phase outpu t alternator

shorted, triple phase full-wave rectifica-

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 54 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

A comprehensive repair manual for the 2003-2007 Honda Aquatrax 2-seat personal watercraft is available. This manual covers both turbo and non-turbo models and includes detailed instructions for complete tear down and rebuild, along with pictures and part diagrams, torque specifications, maintenance procedures, and troubleshooting guidelines. With 458 pages, it provides extensive information for professional mechanics and DIY enthusiasts.

The manual features clickable chapters and is searchable, allowing users to easily locate specific information. It also offers the flexibility to print or save/burn to disc without any restrictions.

- Complete tear down and rebuild instructions

- In-depth pictures and part diagrams

- Torque specifications

- Maintenance procedures

- Troubleshooting guidelines