Sea-Doo Challenger 1800 1997 Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

1997

Shop Manual

Volume 2

Speedster, Challenger/1800

R

219 100 059

Legal deposit:

National Library of Quebec

1

st

trimester 1997

National Library of Canada

All rights reserved. No parts of this manual may be repro-

duced in any form without the prior written permission of

Bombardier Inc.

©

Bombardier Inc. 1997

Printed in Canada

®

*Registered trademarks of Bombardier Inc.

Loctite

®

is a trademark of Corporation.

Snap-on

®

is a trademark of Snap-on Tools Corporation.

Gelcote

®

is a trademark of Gelcote International Limited.

I

SECTION SUB-SECTION PAGE

SAFETY NOTICE .................................................................................................................................. III

INTRODUCTION ................................................................................................................................... IV

01 MAINTENANCE 01 – Table of Contents ..................................................................... 01-01-1

02 – Periodic Inspection Chart ......................................................... 01-02-1

03 – Flushing and Care ..................................................................... 01-03-1

04 – Water-Flooded Engine .............................................................. 01-04-1

05 – Storage ..................................................................................... 01-05-1

02 TROUBLESHOOTING ................................................................................................................ 02-01-1

03 ENGINE 01 – Table of Contents ..................................................................... 03-01-1

02 – Leak Test .................................................................................. 03-02-1

03 – Removal and Installation .......................................................... 03-03-1

04 – Magneto System...................................................................... 03-04-1

05 – Top End .................................................................................... 03-05-1

06 – Bottom End .............................................................................. 03-06-1

07 – Rotary Valve ............................................................................. 03-07-1

08 – Exhaust System ....................................................................... 03-08-1

04 COOLING SYSTEM 01 – Table of Contents ..................................................................... 04-01-1

02 – Components ............................................................................. 04-02-1

03 – Circuit ....................................................................................... 04-03-1

05 FUEL SYSTEM 01 – Table of Contents ..................................................................... 05-01-1

02 – Fuel Circuit ............................................................................... 05-02-1

03 – Air Intake .................................................................................. 05-03-1

04 – Carburetors............................................................................... 05-04-1

06 LUBRICATION

SYSTEM

01 – Table of Contents ..................................................................... 06-01-1

02 – Oil Injection Reservoir .............................................................. 06-02-1

03 – Oil Injection Pump .................................................................... 06-03-1

07 ELECTRICAL 01 – Table of Contents ..................................................................... 07-01-1

02 – Overview .................................................................................. 07-02-1

03 – Ignition System ........................................................................ 07-03-1

04 – Spark Plugs............................................................................... 07-04-1

05 – The DESS (Digitally Encoded Security System) ....................... 07-05-1

06 – MPEM (Multi-Purpose Electronic Module) ............................... 07-06-1

07 – Charging System ...................................................................... 07-07-1

08 – Starting System........................................................................ 07-08-1

09 – Instruments and Accessories ................................................... 07-09-1

TABLE OF CONTENTS

II

SECTION SUB-SECTION PAGE

08 PROPULSION AND

DRIVE SYSTEMS

01 – Table of Contents..................................................................... 08-01-1

02 – Jet Pump.................................................................................. 08-02-1

03 – Drive System ........................................................................... 08-03-1

04 – Reverse System....................................................................... 08-04-1

05 – Weedless System.................................................................... 08-05-1

06 – Variable Trim System (VTS)...................................................... 08-06-1

09 STEERING SYSTEM 01 – Table of Contents..................................................................... 09-01-1

02 – Steering System ...................................................................... 09-02-1

03 – Alignment................................................................................. 09-03-1

04 – Throttle/Shifter/VTS Controller ................................................. 09-04-1

10 HULL/DECK 01 – Table of Contents..................................................................... 10-01-1

02 – Components ............................................................................ 10-02-1

03 – Hull and Deck Repair................................................................ 10-03-1

04 – Painting .................................................................................... 10-04-1

11 TECHNICAL DATA ..................................................................................................................... 11-01-1

12 WIRING DIAGRAMS.................................................................................................................. 12-01-1

TABLE OF CONTENTS

III

SAFETY NOTICE

This manual was primarily published to be used by jet boat technicians trained by the manufacturer who

are already familiar with all service and maintenance procedures relating to Bombardier made Sea-Doo

jet boat.

Please note that the instructions will apply only if proper hand tools and special service tools are used.

It is understood that this manual may be translated into local language upon certain conditions and fur-

thermore agreed that in the event of any discrepancy among the two versions, the English version shall

prevail.

The content depicts parts and/or procedures applicable to the particular product at its time of manufac-

ture. It does not include dealer modifications, whether authorized or not by Bombardier, after manufac-

turing the product.

The use of Bombardier parts is most strongly recommended when considering replacement of any com-

ponent. Dealer and/or distributor assistance should be sought in case of doubt.

Torque wrench tightening specifications must be strictly adhered to. Locking devices (ex.: locking disk,

lock nut) must be installed or replaced with new ones, where specified. If the efficiency of a locking

device is impaired, it must be renewed.

This manual emphasizes particular information denoted by the wording and symbols:

NOTE: Indicates supplementary information needed to fully complete an instruction.

Although the mere reading of such information does not eliminate the hazard, your understanding of the

information will promote its correct use. Always use common shop safety practice.

This information relates to the preparation and use of Bombardier jet boat and has been utilized safely

and effectively by Bombardier Inc. However, Bombardier Inc. disclaims liability for all damages and/or

injuries resulting from the improper use of the contents. We strongly recommend that any services be

carried out and/or verified by a highly skilled professional technician. It is understood that certain modifi-

cations may render use of the boat illegal under existing federal, provincial and state regulations.

◆

WARNING

Identifies an instruction which, if not followed, could cause serious personal injury including

possibility of death.

-

CAUTION

Denotes an instruction which, if not followed, could severely damage boat components.

SAFETY NOTICE

IV

INTRODUCTION

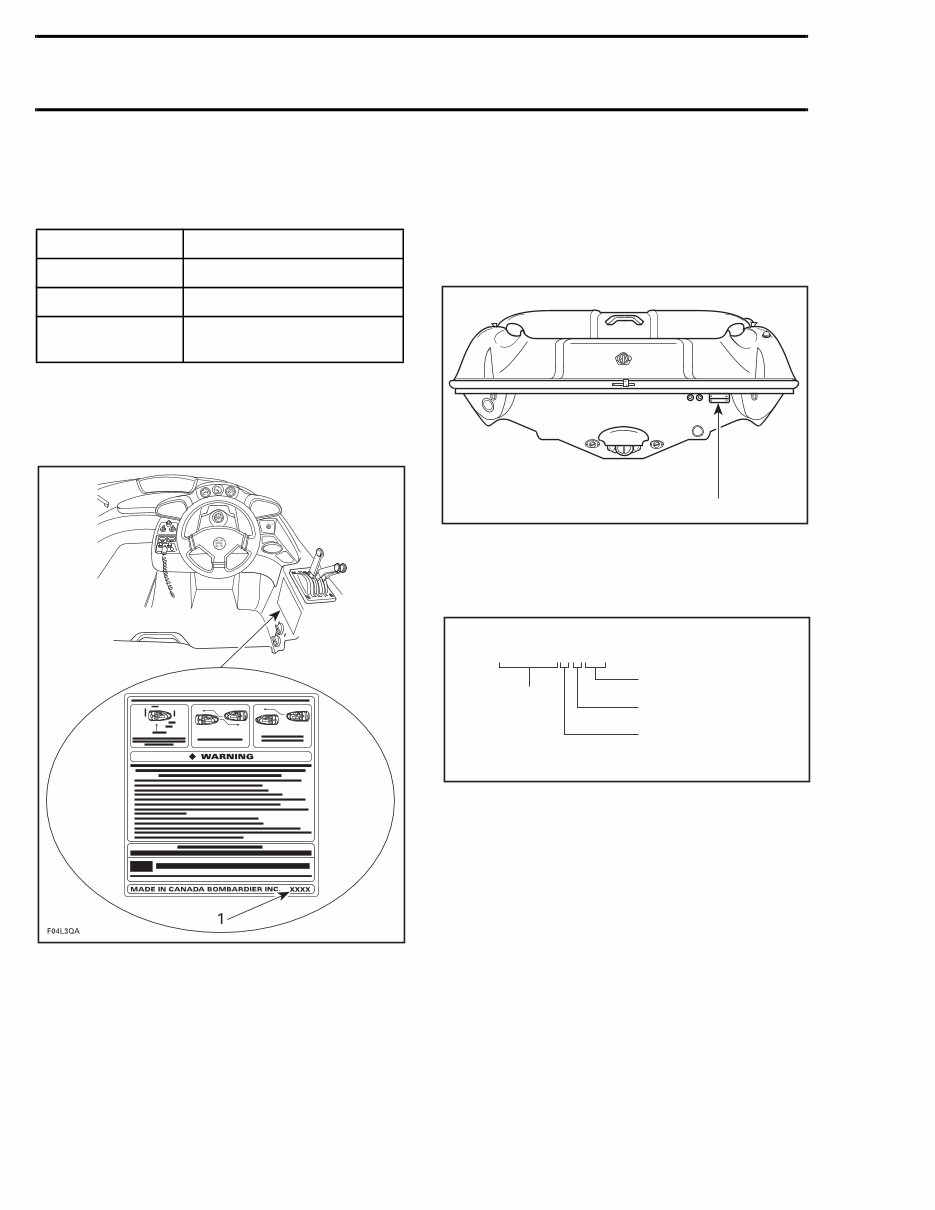

This Shop Manual covers the following BOMBAR-

DIER made SEA-DOO

®

jet boats.

BOAT MODEL NUMBER

The jet boat model number can be found on RH

side of operator position.

TYPICAL

1. Model number

HULL IDENTIFICATION NUMBER

(H.I.N.)

The Hull Identification Number (H.I.N.) is located

at right hand rear side of hull.

TYPICAL

1. Hull Identification Number (H.I.N.)

Refer to the illustration for a description of the se-

rial number.

Some boats may have a serial number beginning

with CEC. CEC boats are manufactured in USA

and ZZN boats are manufactured in Canada.

MODEL MODEL NUMBER

SPEEDSTER 5602/5608

CHALLENGER 5603/5606

CHALLENGER

1800

5600/5601

F04L2SB

1

Z Z N 1 2 3 4 5 L 4 9 5

Model year

Serial

number*

*A letter may also be used as a digit.

F00A0CA

Month of production

Year of production

*A letter may also be used as a digit.

1997 BOMBARDIER JET BOAT

SHOP MANUAL

V

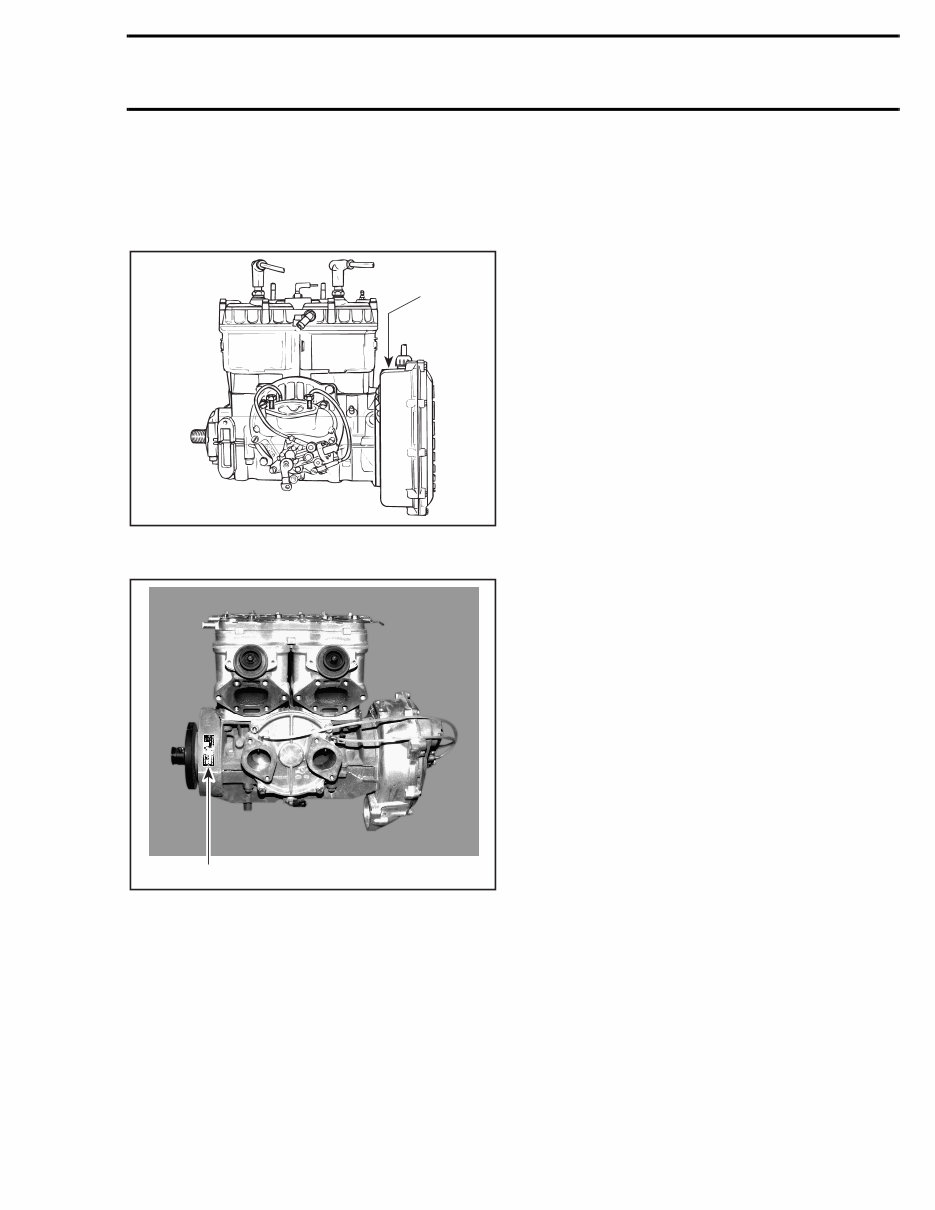

ENGINE IDENTIFICATION

NUMBER (E.I.N.)

It is located on the upper side of the magneto

housing.

TYPICAL — 717 ENGINE

1. Engine Identification Number (E.I.N.)

787 ENGINE

1. Engine Identification Number (E.I.N.)

ARRANGEMENT OF THIS

MANUAL

The manual is divided into 12 major sections:

01 MAINTENANCE

02 TROUBLESHOOTING

03 ENGINE

04 COOLING SYSTEM

05 FUEL SYSTEM

06 LUBRICATION SYSTEM

07 ELECTRICAL

08 PROPULSION SYSTEM

09 STEERING SYSTEM

10 HULL/DECK

11 TECHNICAL DATA

12 WIRING DIAGRAMS

Each section is divided in various sub-sections,

and again, each sub-section has one or more divi-

sion. A table of contents is included at the begin-

ning of most sections.

1

F01D01A

F01D87A

1

1997 BOMBARDIER JET BOAT

SHOP MANUAL

VI

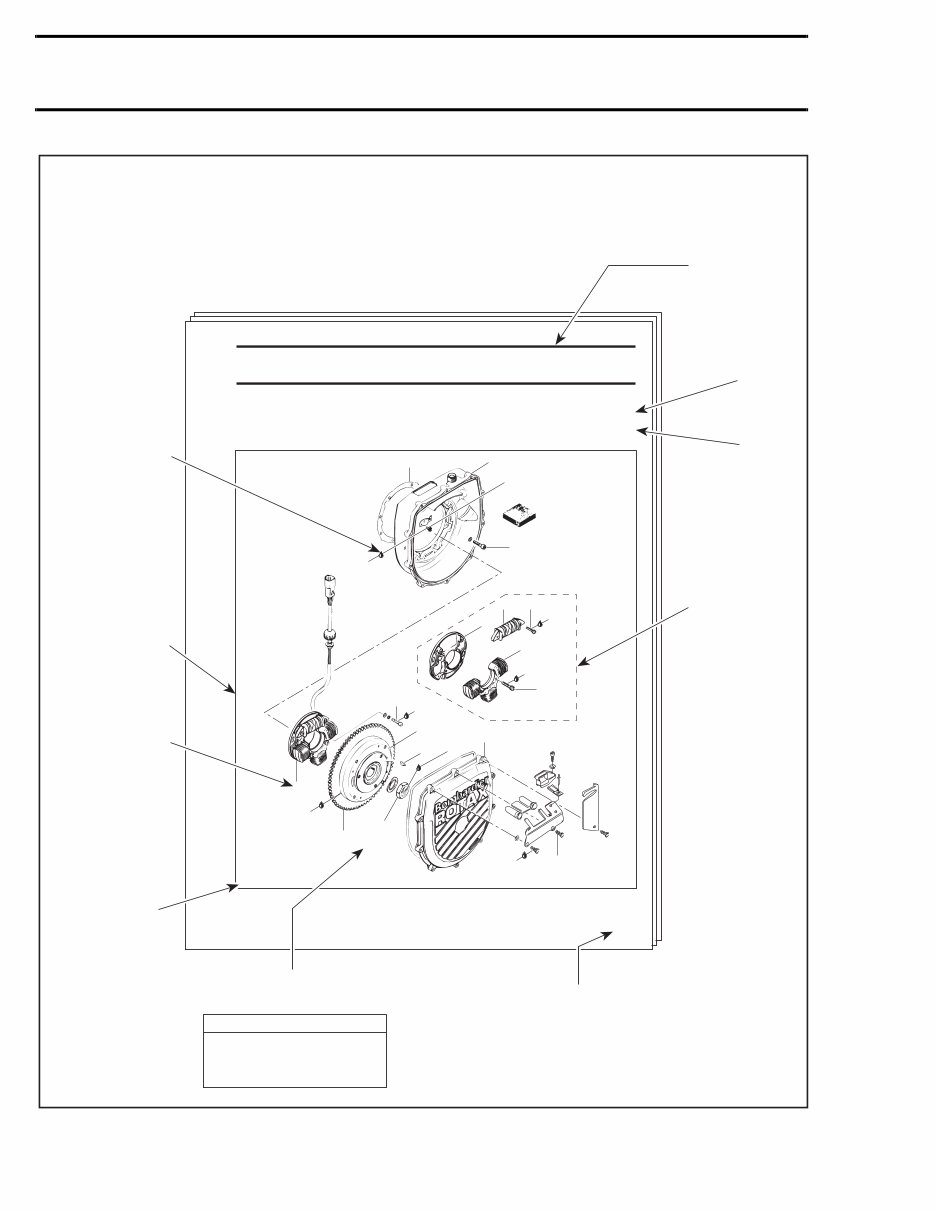

Section 03 ENGINE

Sub-Section 04 (MAGNETO SYSTEM)

MAGNETO SYSTEM

717 Engine

03-04-1

F01D4WS

12 11

5 N•m

(44 lbf•in)

13

9 N•m

(80 lbf•in)

Loctite

242

4

6 8

Loctite

242

7

6 N•m

(53 lbf•in)

Loctite

242

6 N•m

(53 lbf•in)

9

Loctite

242

5

6 N•m

(53 lbf•in)

3

14

Loctite

242

4

Loctite

648

10

15

145 N•m

(107 lbf•ft)

Anti-seize

lubricant

2

9 N•m

(80 lbf•in)

1

Page heading

indicates section

and sub-section

detailed.

Tightening torque nearby fastener.

In this case, nut must be torqued to

145 N•m (107 lbf•ft).

Exploded view assists

you in identifying

parts and related

positions.

TYPICAL PAGE

F04A09S

Illustration number

for publishing

process.

Sub-section title

indicates

beginning of the

sub-section.

Dotted box

contains parts of

a particular

model or an

exploded view.

Page numbering system:

03: ENGINE section

04: MAGNETO SYSTEM sub-section

1: First page of this sub-section

Italic sub-title

above exploded

view indicate

pertaining models.

Drop represents a

liquid product to be

applied to a surface.

In this case Loctite

242 to screw

threads.

Bold face number

indicates special

procedure

concerning this part.

Pay attention to torque specifi-

cations. Some of these are in

lbf•in instead of lbf•ft. Use appro-

priate torque wrench.

CAUTION ▼

1997 BOMBARDIER JET BOAT

SHOP MANUAL

VII

1

2

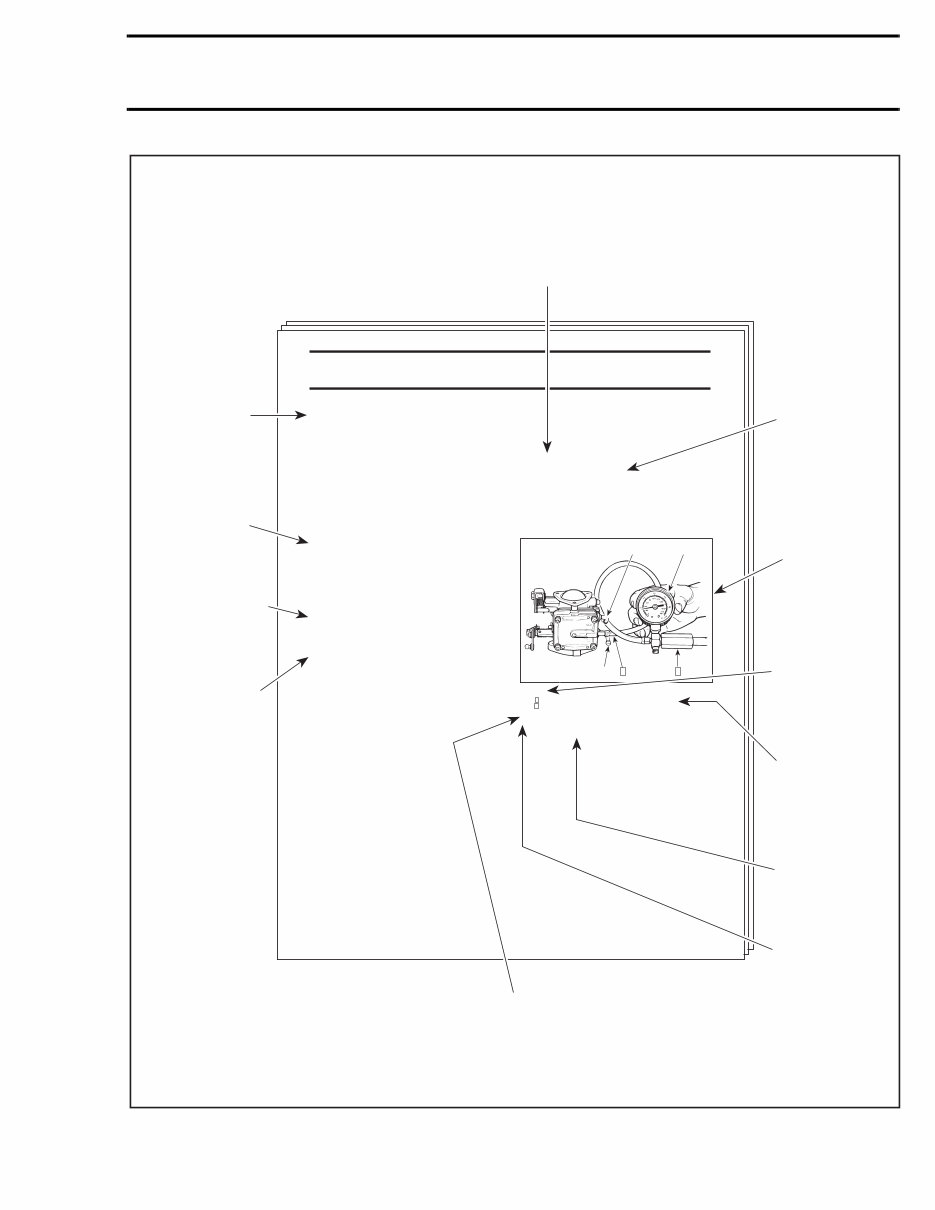

Section 06 FUEL SYSTEM

Sub-Section 03 (CARBURETORS)

06-03-4

Step : Install pump gauge tester to pulse nipple

Step : Pump tester until it reaches the desired pressure

1. Fuel outlet nipple

2. Fuel inlet nipple

A. 28 kPa (4 PSI)

Diaphragm

Challenger Model Only

CARBURETOR REMOVAL

Inspect parts for corrosion dammage (shaft, butterfly,

spring screw, check valve housing, etc.).

Pump Diaphragm Leak Test

TYPICAL

To remove carburetors from engine, proceed as fol-

lows:

Remove air vent tube support.

Unlock retaining slides holding air intake silencer base.

Remove air intake silencer base from watercraft.

Remove screws holding flame arrester base support

to cylinder head cover.

Unscrew base retaining screws then remove base from

carburetors and move to front of watercraft.

Turn the valve to OFF position.

NOTE: For fuel line removal, use pliers (P/N 295 000

054).

Disconnect pulse line from fuel pump.

Disconnect fuel fuel supply line from fuel pump.

Disconnect fuel return line.

Disconnect oil injection pump cable, throttle cable and

choke cable.

Remove screws and lock washers retaining carburetors.

Remove carburetors from intake manifold.

All Others Models

Remove 4 bolts and lock washers from rotary valve

cover then move carburetors and rotary valve cover on

top of engine.

NOTE: When removing rotary valve cover , pay attention

that the rotary valve stay in place, otherwise it must be

timed.

Remove carburetors from intake manifold.

Disconnect fuel bypass line between carburetors (twin

carburetors).

Remove carburetor(s) from rotary valve cover.

DISASSEMBLY AND INSPECTION

Using a suitable pump gauge tester, perform the fol-

lowing test proceeding as follows:

- Install pump gauge tester (P/N 295 000 083) on pulse

nipple.

- Pump tester until it reaches 28 kPa (4 PSI).

Diaphragm no. 3 must stand pressure for 10 seconds.

If pressure drops, replace diaphragm.

TYPICAL PAGE

Sub-title indicates a

particular procedure for

the named part.

''TYPICAL'' caption

indicates a general

view which does not

represent full detail.

Italic bold face

setting in this case

indicates that

particular procedure

for Challenger is

finished, so from this

point, all others

models are

concerned.

Italic bold face setting

indicates a particular

procedure concerning

a model.

Service tool to be

used to perform a

certain procedure.

Title indicates main

procedure to be

carried-out.

F04A08S

Sub-sub-title

indicates a

particular testing,

adjustment or

repair procedure.

Illustration

always follows

text it is

pertained to.

Numbers in a frame

are used to give a

sequence to be

perfomed for above

illustration.

Numbers are used

for description of

components for

above illustration.

Letters are used for

any measures for

above illustration.

F01F0XB

A

2

1

1 2

Number: following

part name refers to

exploded view at

beginning of

sub-section.

1997 BOMBARDIER JET BOAT

SHOP MANUAL

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 22 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

The Sea-Doo Challenger 1800 1997 Service Repair Manual is a comprehensive factory manual designed for the maintenance and repair of the Sea-Doo Challenger 1800 watercraft. It is an invaluable resource for both professional mechanics and DIY enthusiasts.

- Complete and searchable for easy navigation

- Includes detailed information on maintenance, troubleshooting, engine, cooling system, fuel system, lubrication system, electrical components, propulsion and drive system, steering system, hull, technical data, and wiring diagrams

- Available in PDF format

- Language: English

- Compatible with Win/Linux/MAC operating systems

- Instant delivery