Yanmar Marine Diesel Engine 6GH-UTE Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

MllAINE DIESEi. ENGINE

MODEL

&GH-UTE

------------------------------------------------------------6GH-UTE

Foreword

This Service Manual describes the construction and functions of the major parts of the 6GH-UTE

engine and illustrates the disassembly and assembly procedures (standard servicing procedures) necessary

for maintaining and servicing the engine.

Please read this manual carefully so that you are completely familias with the construction and func-

tion of each part before you start actual servicing work.

The construction and servicing procedures described in this manual may be slightly modified for the

improvement of quality and performance without prior notice. Please do not hesitate to contact tis if

you have any queries or suggestions.

Prepare before you work !

For accurate and efficient service work, check and prepare the following:

1. Check the customers' service ledger

1) When was the machine last serviced?

2) How many months or hours has the machine been used since the previous servicing?

31 What was the previous trouble, and what parts were replaced?

4) Which parts should you replace this·time?

2. Prepare parts

Check the stock of parts which are needed for servicing.

3. Prepare recording forms

Check sheets, Parts measurement record sheet. Operation test record sheet

4. Prepare servicing measurement tools, containers~ etc.

Printed in Japan

AOA!959-8807

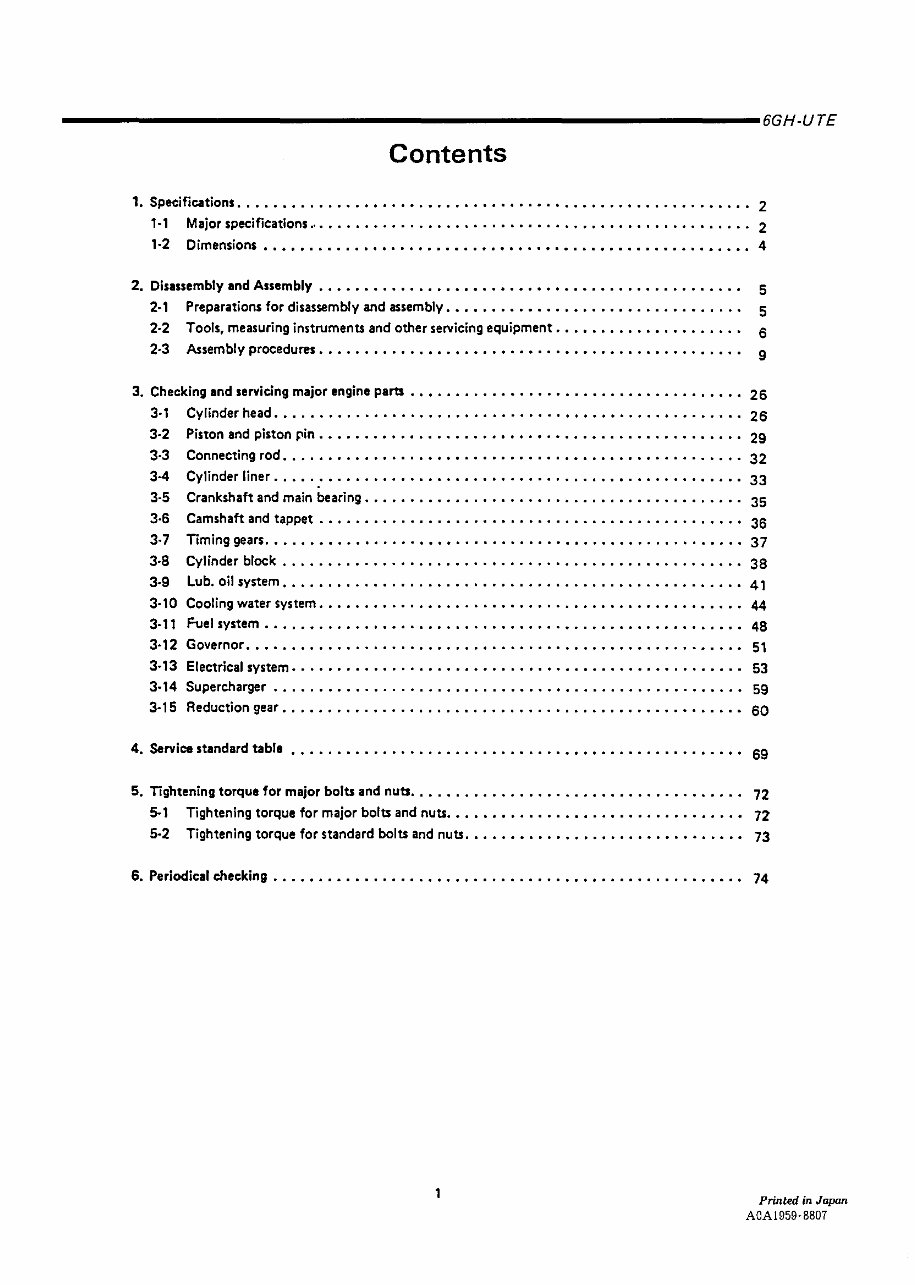

Contents

1. Specifications •.••••••.•••••••••••••••••••••••••••••••••••••••••••••••• 2

1·1 Majorspecifications ..••••.•••••..••••. • · • • • • • • · • • ••• • • • • • · • · • • • • • • • · · 2

1·2 Dimensions •••••••••••••••••••••••••••••••••••••••••••••••••••••• 4

2. Disassembly and Assembly • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 5

2· 1 Preparations for disassembly and assembly. • • • • • • • • • • • • • • • • • • • • • • • • • • • • . . • • 5

2·2 Toots, measuring instrumenu and other servicing equipment. . . . . . . . . . . . . . . . . . . . . 6

2·3 Assembly procedures •••••••••••••••••••• • • • • • • • • • • • • • • • • • • • • • • • • • • • 9

3. Checking and servicing major engine parts •••.••••••••••••••••••••••••••••.•••• 26

3·1 Cylinder head •••.••••.••••••••••.••••••• • • • · • • • •. • • • •••• • •••• • • •• 26

3·2 Piston and piston pin •••••••••••••••••• • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 29

3·3 Connecting rod •••.••••••••••.••••••••••••••••••••••••• • • • • • • . • • • • 32

3-4 Cylinder liner .•••. : • . • • • • • • • • • • • • • • • • • • . • • • • . • • • • • • • . • • • • • • • • • • • • 33

3.5 Crankshaft and main bearing ••••••••••••.•••••••.••.•.•.•••• • • • • • .• • • · 35

3·6 Camshaft and tappet .••••••••.••••••• • • • • · • • • • • • • • • • • • • • • • • • • • · • • • • 36

3.7 nming gears .••••••••••••••••••••••••••••••••••••••••••..••.••••• 37

3·8 Cylinder block ••.•.•..•.••.•••.•••••••••.•.••••••••••.••••••••••• 38

3.9 Lub. oil system • • • • • . • . . • • • . • . . • • . • • • • • • • • • • • • • . . • . . • • • . • • • • . • • • • • 41

3·10 Cooling watersystem ••••••••.•.•••••.••••••••..•••••••.•••••••••••• 44

3· 11 Fuel system • • • . • • • • • • • • • • • • • • • • • . • • . • • • • • • • • • . . • • . • • • • • • • • • • . • • • 48

3· 12 Governor. • • • • • • • • • • • . • . • • . • • • • • . • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 51

3· 13 Electrical system. • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • . • • • • • • . 53

3·14 Supercharger ••.•.•••••.•...•...•••..••••••••••••••••••••• · ••••• • 59

3· 15 Reduction gear • . • • • • • . • . • . • • • • . • • • • • • • • • • • . . • . • . • • . • • • • . • • • • • • • • • 60

4. Service standard tabla ••••.••••••••••••••••••••••••••••••••••••• • • • • • • • • 69

5. Tightening torque for major bolts and nuts. . • . • . • • • • • • • • • • • . . • • • • • • • • • • • • • • • • • • 72

5-1 Tightening torque for major bolts and nuts. • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • 72

5·2 Tightening torque forstandard bolts and nuts .•••••••••••••••••••••••••••••• 73

6. Periodical checking • • . • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • • . • • • • • • • • • 74

Printed in Japan

AOA1959-8807

I. Specifications

;._.:.... ............................................................................................................ ~6GH-UTE

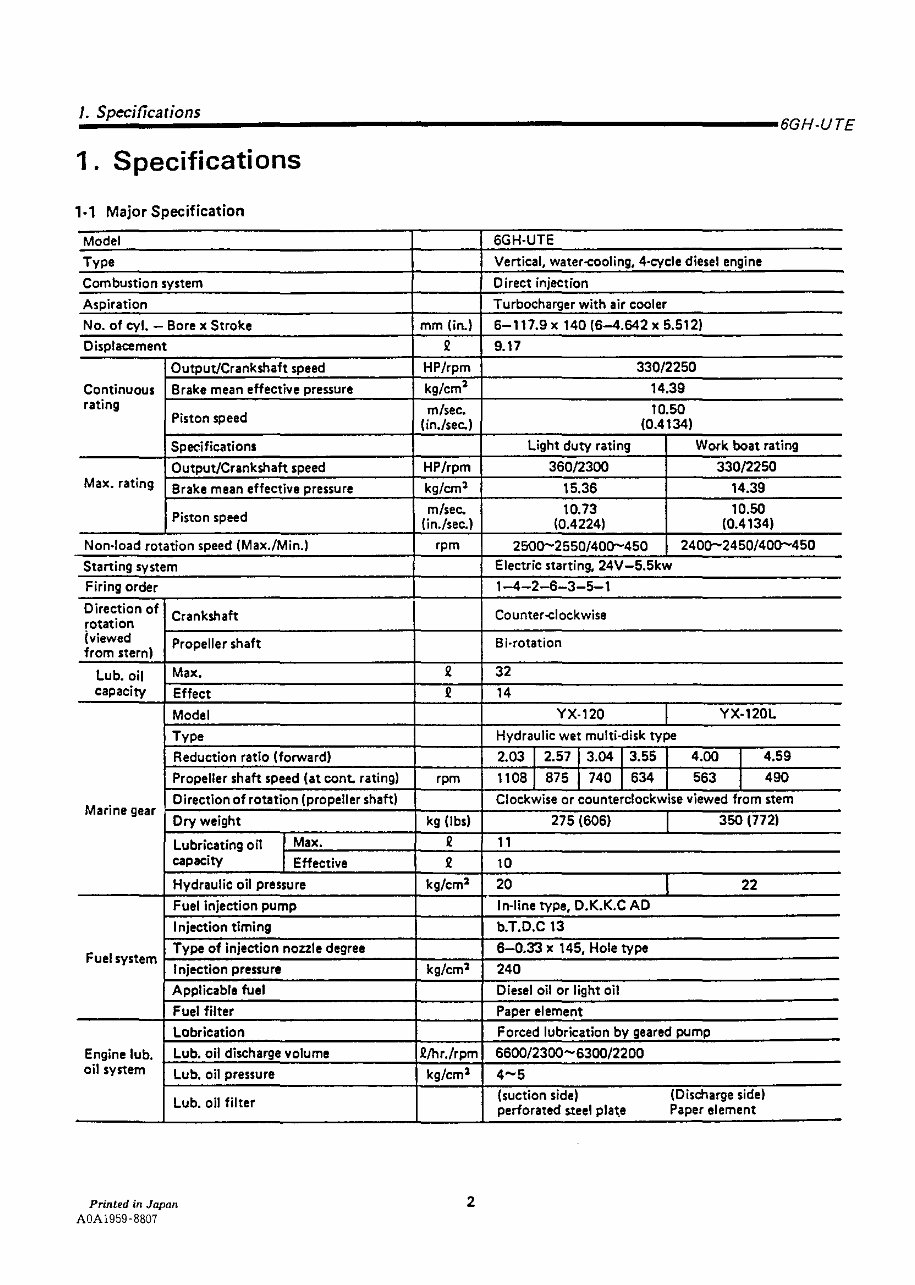

1 . Specifications

1·1 Major Specification

Model

Type

Combustion system

Aspiration

No. of cyl. - Bore x Stroke

Displacement

Output/Crankshaft speed

Continuous Brake mean effective pressure

rating

Piston speed

Specifications

Output/Crankshaft speed

Max. rating

Brake mean effective pressure

Piston speed

Non-load rotation speed (Max./Min.)

Starting system

Firing order

Direction of

Crankshaft

rotation

(viewed

Propeller shaft

from stern)

Lub. oil

Max.

capacity

Effect

Model

Type

Reduction ratio (forward)

Propeller shaft speed (at cont. rating)

Marine gear

Direction of rotation (propeller shaft)

Dry weight

Lubricating oil

I Max.

capacity

I Effective

Hydraulic oil pressure

Fuel injection pump

Injection timing

Fuel system

Type of injection nozzle degree

Injection pressure

Applicable fuel

Fuel filter

Labrication

Engine lub. Lub. oil discharge volume

oil system

Lub. oil pressure

Lub. oil filter

Printed in Japan

AOA1959·8807

mm (in.)

2

HP/rpm

kg/cm

2

m/sec.

(in./sec.)

HP/rpm

kg/cm

2

m/sec.

(in./sec.)

rpm

2

2

rpm

kg (lbs)

2

2

kg/cm

2

kg/cm

2

2/hr./rpm

kg/cm

2

2

6GH-UTE

Vertical, water-cooling, 4·cycle diesel engine

0 irect injection

Turbocharger with air cooler

6-117.9 x 140 (6-4.642 x 5.512)

9.17

330/2250

14.39

10.50

(0.4134)

Light duty rating Work boat rating

360/2300 330/2250

15.36 14.39

10.73 10.50

(0.4224) (0.4134)

2500-2550/400-450 2400-2450/400-450

Electric starting, 24V-5.5kw

1-4-2-6-3-5-1

Counter-clockwise

Bi·rotation

32

14

YX-120 YX·120L

Hydraulic wet multi-disk type

2.03 2.57 3.04 3.55 4.00 4.59

1108 875 740 634 563 490

Clockwise or counterclockwise viewed from stem

275 (606) 350 (772)

11

10

20 22

In-line type, D.K.K.C AD

b.T.D.C 13

6-0.33 x 145, Hole type

240

Diesel oil or light oil

Paper element

Forced lubrication by geared pump

6600/2300-6300/2200

4-5

(suction side) (Discharge side)

perforated steel plat.e Paper element

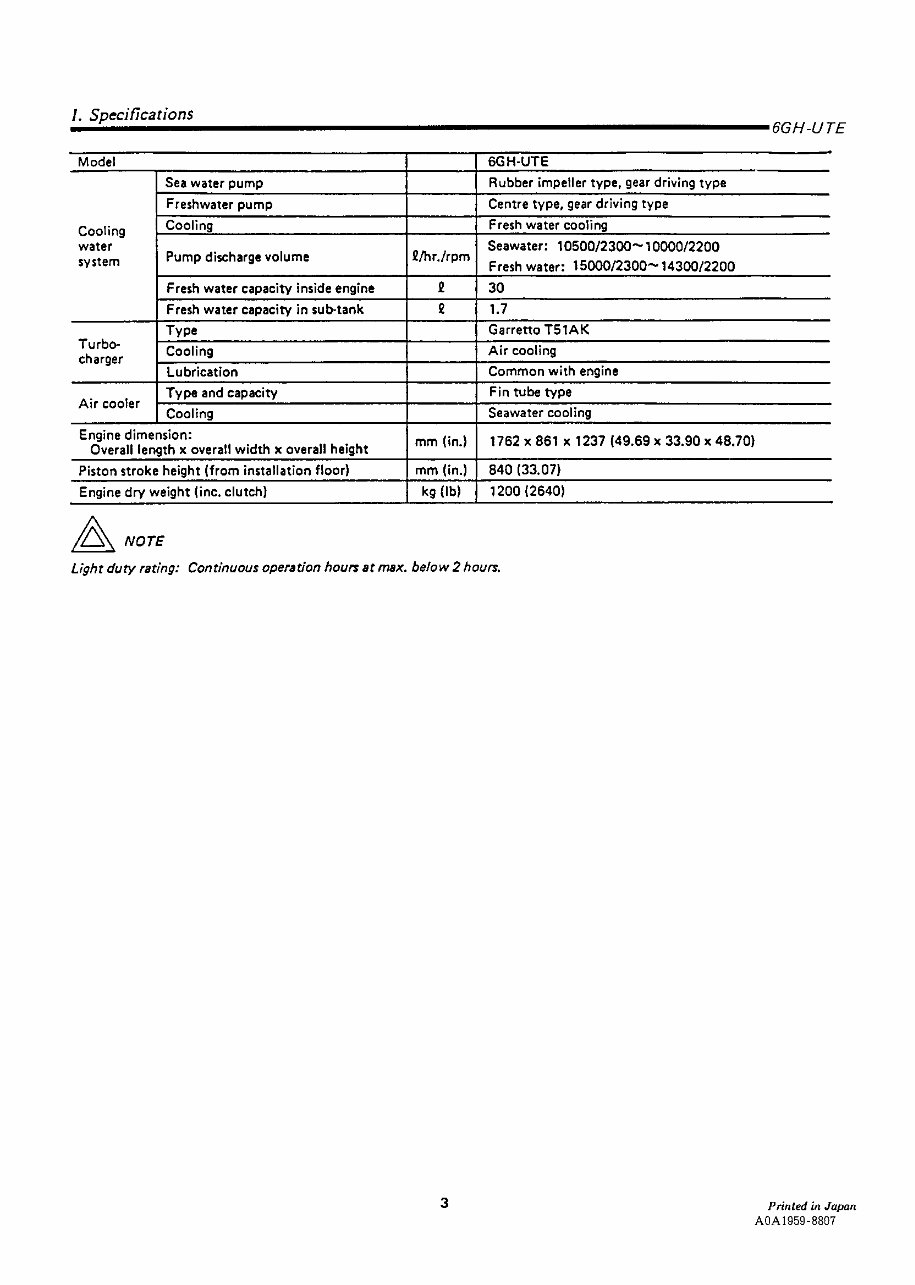

Model 6GH-UTE

Sea water pump Rubber impeller type, gear driving type

Freshwater pump Centre type, gear driving type

Cooling

Cooling Fresh water cooling

water

2/hr./rpm

Seawater: 10500/2300-10000/2200

system

Pump discharge volume

Fresh water: 15000/2300-14300/2200

Fresh water capacity inside engine 2 30

Fresh water capacity in sub-tank 2 1.7

Type Garrette T51AK

Turbo-

Cooling Air cooling

charger

Lubrication Common with engine

Air cooler

Type and capacity Fin tube type

Cooling Seawater cooling

Engine dimension:

mm (in.) 1762 x 861 x 1237 (49.69 x 33.90 x 48.70)

Overall length x overall width x overall height

Piston stroke height (from installation floor) mm(in.) 840 (33.07)

Engine dry weight (inc. clutch) kg (lb) 1200 (2640)

A NOTE

light duty rating: Continuous operation hours at max. below 2 hours.

3

Printed in Japan

AOA1959-8807

/. Specifications

--------------------------------------------------------------------------------------------------------------------------------------------6GH-UTE

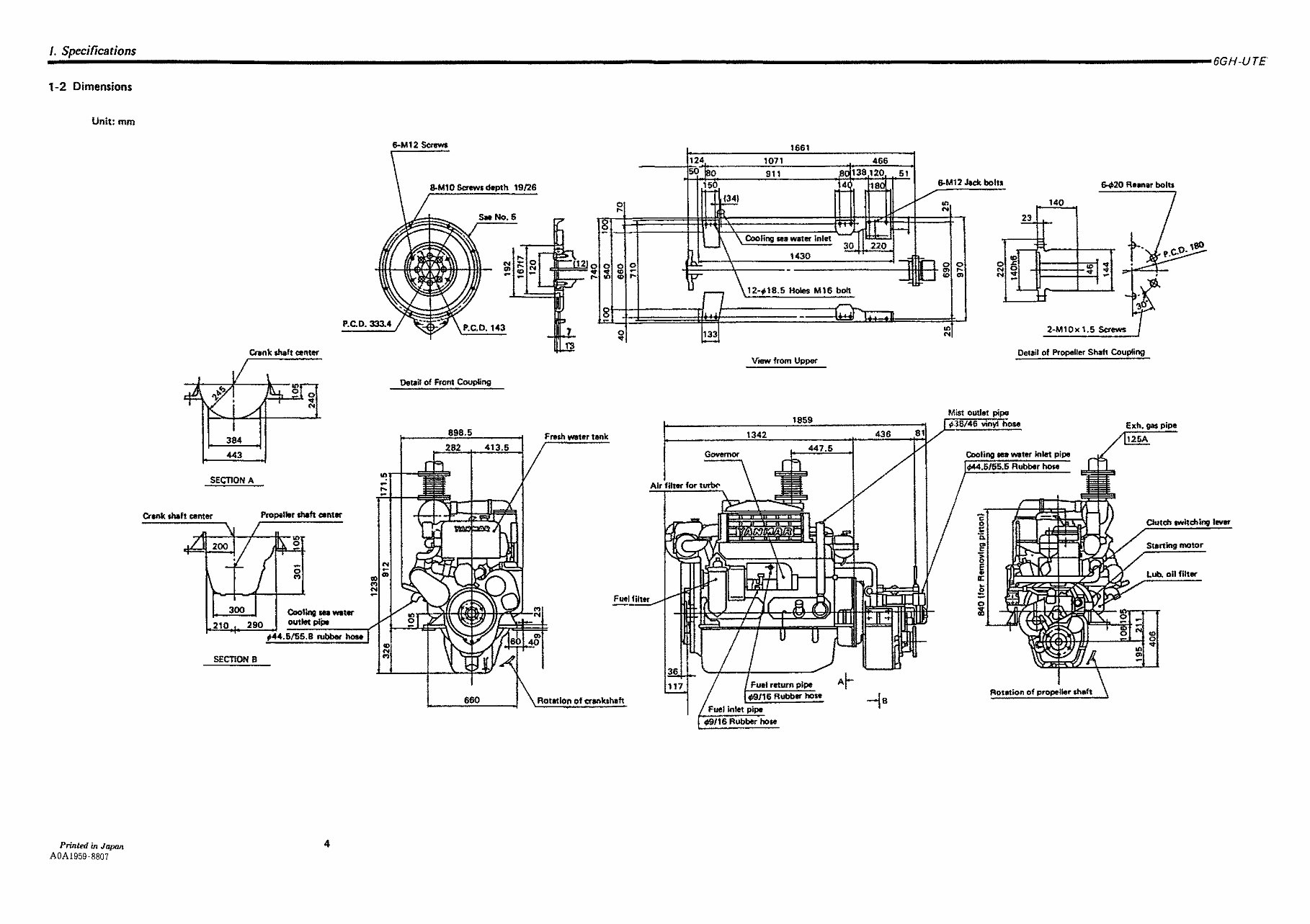

1-2 Dimensions

Unit: mm

Printed in Japan.

AOA1959-8807

P.C.D. 333.4

Crank shaft center

384

443

SECTION A

Crank shaft center

Ptopeller shaft .. nter

300

Cooling ,.. woter

21 O 2 90 outlet pli>o

1-""=..i--="'--'

•44.5/55.8 rubber -

SECTION B

4

"'

N

.,

6-M12 Screws

S.M10 Screws depth 19/26

DetaU of Front Coupling

660

7

1'3

0

0

"

"'

8

fresh ttW11ter tank

0

...

oo

.. ~

... ...

·-

0

..

Rotation of Cfankshaft

1661

124 1071 466

50 180

911 er 138 120

150 4

ill

-

-

. ~

)

'

..

I

\. Cooling sea water inlet

30 I 220

J

...._ \

,_,-

l

n

133

-

Air fiher for turt>c-

36

117

\

1430

-

12-•18.5 Holes M16 bolt

-

View from Upper

1859

1342

447.5

fuel return pipe

~/16 Rubbw hos•

I· ,,

..

436

--je

51

6-M12 Jack bolts

W20 Re•nar bolts

/

I/

on

N

140

23

H

-=iii gi

0 0

... N

.. N

on

N

2-MlOx 1.5 Screwo

Detail of Propeller Shaft Coupling

Mist outlat pipe

p.JS/46 .,ny1 ho ..

COOiing see water inlet pipe

~.5/55.5 Rubber hosa

Aot.tion of propeller shaft

Exh.pspipe

125A

Starting motor

Lub. oll filter

2. Disassembly and Assembly

--------..;.---------------------------------------------------6GH-UTE

2. Disassembly and Assembly

2-1 Preparations for Disassembly and Assembly

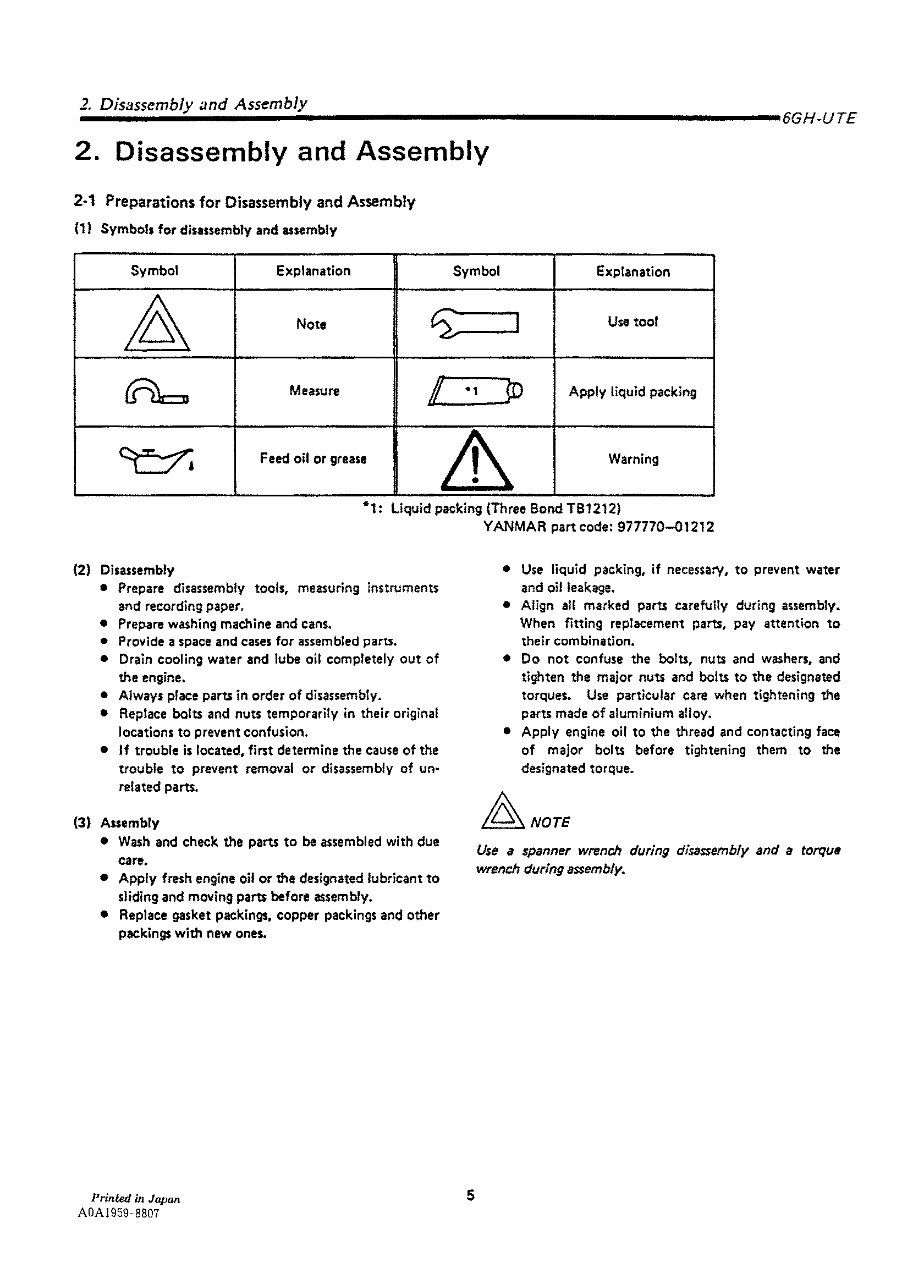

(1 l Symbol• for disassembly and assembly

Symbol Explanation Symbol Explanation

~

Note

C2:

I

Use tool

~

Measure

l

•1

}D

Apply liquid packing

~

Feed oil or grease

&

Warning

•1: Liquid packing {Three Bond TB1212)

{21 Disassembly

• Prepare disassembly tools, measuring instruments

and recording paper.

• Prepare washing machine and cans.

• Provide a space and cases for assembled parts.

• Drain cooling water and lube oil completely out of

the engine.

• Always place parts in order of disassembly.

• Replace bolts and nuts temporarily in their original

locations to prevent confusion.

• If trouble is located, first determine the cause of the

trouble to prevent removal or disassembly of un·

related parts.

(3) Assembly

• Wash and check the parts to be assembled with due

care.

• Apply fresh engine oil or the designated lubricant to

sliding and moving parts before assembly.

• Replace gasket packings, copper packings and other

packings with new ones.

Printed in Japan

ADA!959·8807

5

YANMAR part code: 977770--01212

• Use liquid packing, if necessary, to prevent water

and oil leakage.

• Align all marked parts carefully during assembly.

When fitting replacement parts, pay attention to

their combination.

• Do not confuse the bolU, nuts and washers. and

tighten the major nuts and bolts to the designated

torques. Use particular care when tightening the

parts made of aluminium alloy.

• Apply engine oil to the thread and contacting face

of major bolts before tightening them to the

designated torque.

A NOTE

Use a spanner wrench during disassembly and a torqu11

wrench during assembly.

1. Disassembly and Assembly.

------------------..;..--------------------------------------~6GH-UTE

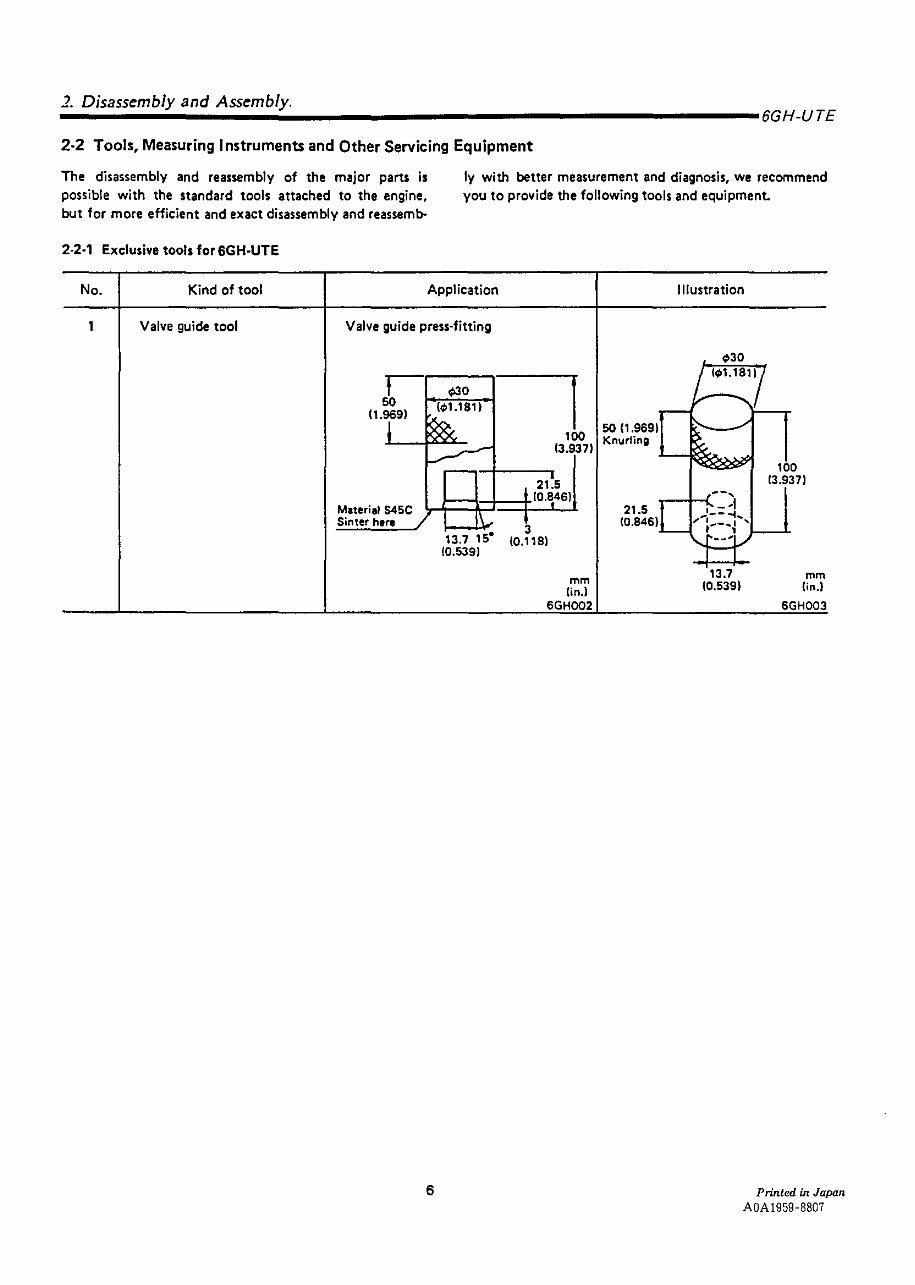

2-2 Tools, Measuring Instruments and Other Servicing Equipment

The disassembly and reassembly of the major parts is

possible with the standard tools attached to the engine,

but for more efficient and exact disassembly and reassemtr

ly with better measurement and diagnosis, we recommend

you to provide the following tools and equipment.

2·2·1 Exclusive tools for 6GH-UTE

No. Kind of tool

Valve guide tool

Application

Valve guide press-fitting

Materiel S45C

Sinter here

~o --i

....,1~'"'t,... t"'8"'t"'1 -1 I

6

13.7 t 5•

10.5391

3

too

13.9371

21.5

I0.8461

10. t 181

mm

(in.)

6GH002

50 It .9691

Knurling

21.5

I0.8461

Illustration

~30

1~1.1811

13.7

10.5391

too

13.9371

mm

(in.)

6GH003

Printed in Japan

AOA1959·8807

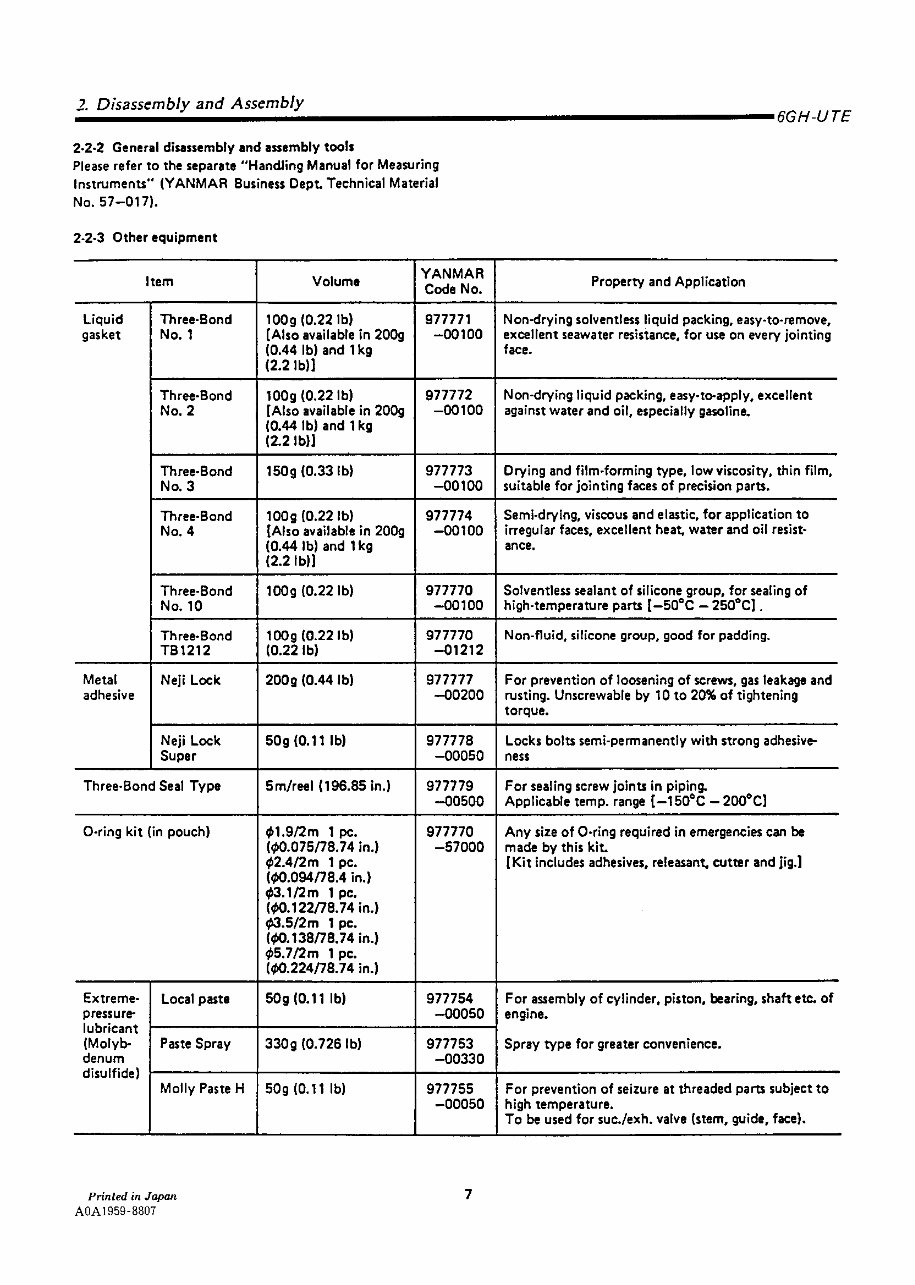

2·2·2 General disassembly and assembly tools

Please refer to the separate "Handling Manual for Measuring

Instruments" (YANMAR Business Dept. Technical Material

No. 57-017).

2·2·3 Other equipment

Item

Liquid Three·Bond

gasket No. 1

Three·Bond

No. 2

Three· Bond

No. 3

Three· Bond

No. 4

Three·Bond

No. 10

Thre .. Bond

TB1212

Metal Neji Lock

adhesive

Neji Lock

Super

Three·Bond Seal Type

O·ring kit (in pouch)

Extreme· Local paste

pressure-

lubricant

(Molyb- Paste Spray

den um

disulfide)

Molly Paste H

Printed in Japan

AOA1959·8807

Volume

YANMAR

Code No.

100g (0.22 lb) 977771

[Also available in 200g -00100

(0.44 lb) and 1 kg

(2.2 lb))

100g (0.22 lb) 977772

[Also available in 200g -00100

(0.44 lb) and 1 kg

(2.2 lb))

150g (0.33 lb) 977773

-00100

100g (0.22 lb) 977774

[Also available in 200g -00100

(0.44 lb) and 1 kg

(2.2 lb)]

100g (0.22 lb) 977770

-00100

1009 (0.22 lb) 977770

(0.22 lb) -01212

200g (0.44 lb) 977777

-00200

50g (0.11 lb) 977778

-00050

Sm/reel (196.85 in.) 977779

-00500

~1.9/2m 1 pc. 977770

(~0.075nB.74 in.) -57000

¢2.4/2m 1 pc.

l~.o94nB.4 in.)

~.1/2m 1 pc.

(~.122ns. 74 in.)

~.5/2m 1 pc.

(~.13BnB.74 in.)

¢5.7/2m 1 pc.

l~.224nB.74 in.)

50g (0.11 lb) 977754

-00050

330g (0.726 lb) 977753

-00330

50g (0.11 lb) 977755

-00050

7

Property and Application

Non-drying solventless liquid packing. easy-to-remove,

excellent seawater resistance, for use on every jointing

face.

Non·drying liquid packing, easy·to-apply, excellent

against water and oil, especially gasoline.

Drying and film.forming type, low viscosity, thin film,

suitable for jointing faces of precision parts.

Semi-drying, viscous and elastic, for application to

irregular faces, excellent heat, water and oil resist-

ance.

Solventless sealant of silicone group, for sealing of

high·temperature parts [-so•c - 2so

0

cJ.

Non-fluid, silicone group, good for padding.

For prevention of loosening of screws, gas leakage and

rusting. Unscrewable by 10 to 20% of tightening

torque.

Locks bolts semi·permanently with strong adhesiv ..

ness

For sealing screw joints in piping.

Applicable temp. range [-150°C -200°C]

Any size of 0-ring required in emergencies can be

made by this kit.

[Kit includes adhesives, releasant, cuttsr and jig.)

For assembly of cylinder, piston, bearing, shaft etc. of

engine.

Spray type for greater convenience.

For prevention of seizure at threaded paru subject to

high temperature.

To be used for suc./exh. valve (stem, guide, face).

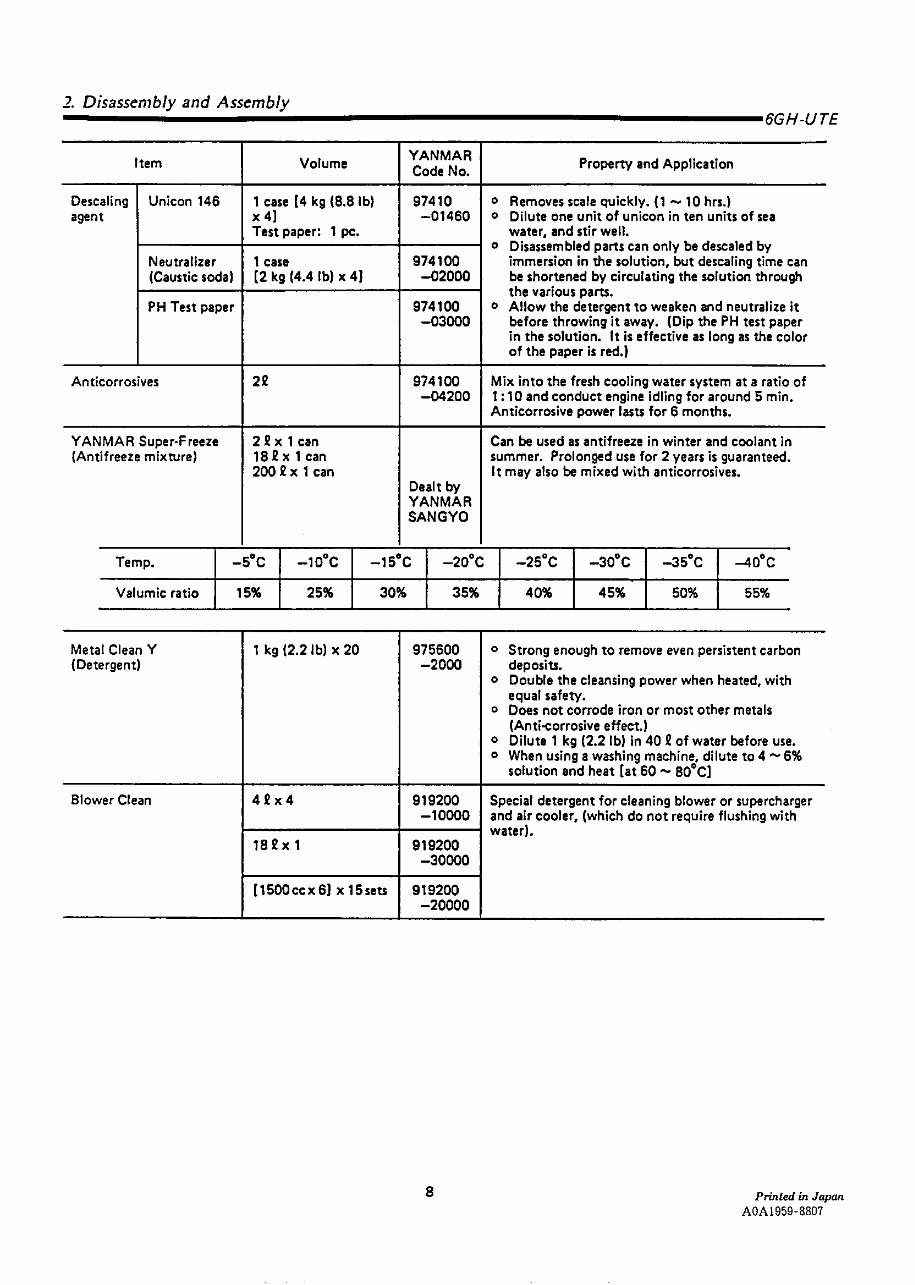

2. Disassembly and Assembly

----------------------------------------------------------~6GH-UTE

Item Volume

YANMAR

Code No.

Descaling Unicon 146 1 case [4 kg (8.8 lb) 97410

agent x 4] -01460

Test paper: 1 pc.

Neutralizer 1 case 974100

(Caustic soda) [2 kg (4.4 lb) x 4] -02000

PH Test paper 974100

-03000

Anticorrosives 22 974100

-04200

YANMAR Super·Freeze 22x1can

(Antifreeze mixture) 182x 1 can

2002x 1 can

Dealt by

YANMAR

SANG YO

Temp. -5°c -10°c -15°c -20°c

Valumic ratio 15% 25% 30% 35%

Metal Clean Y 1 kg (2.2 lb) x 20 975600

(Detergent) -2000

Blower Clean 42x4 919200

-10000

18 2 x 1 919200

-30000

[1500ccx6] x 15seu 919200

-20000

B

Property and Application

0

Removes scale quickly. (1 - 10 hrs.)

0

Dilute one unit of unicon in ten units of sea

water, and stir well.

0

Disassembled parts can only be descaled by

immersion in the solution, but descaling time can

be shortened by circulating the solution through

the various parts.

o Allow the detergent to weaken and neutralize it

before throwing it away. (Dip the PH test paper

in the solution. It is effective as long as the color

of the paper is red.)

Mix into the fresh cooling water system at a ratio of

1: 10 and conduct engine idling for around 5 min.

Anticorrosive power lasu for 6 months.

Can be used as antifreeze in winter and coolant in

summer. Prolonged use for 2 years is guaranteed.

It may also be mixed with anticorrosives.

-25°c -30°c -35°c -40°C

40% 45% 50% 55%

o Strong enough to remove even persistent carbon

deposiu.

0

Double the cleansing power when heated, with

equal safety.

0

Does not corrode iron or most other metals

(Anti-corrosive effect.)

0

Dilute 1 kg (2.2 lb) in 40 2 of water before use.

o When using a washing machine, dilute to 4 - 6%

solution and heat [at 60 - 80°C]

Special detergent for cleaning blower or supercharger

and air cooler. (which do not require flushing with

water).

Printed in Japan

AOA1959-8807

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 70 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This service repair manual is a comprehensive guide for Yanmar Marine Diesel Engine 6GH-UTE. It contains easy-to-read text sections, along with high-quality diagrams and instructions.

The manual covers the following:

- INDEX

- CHAPTER 1 SPECIFICATIONS

- Major Specifications

- Dimensions

- CHAPTER 2 DISASSEMBLY AND ASSEMBLY

- Preparations for Disassembly and Assembly

- Tools, Measuring Instruments and Other Servicing Equipment

- Assembly Procedures

- CHAPTER 3 CHECKING AND SERVICING OF MAJOR ENGINE PARTS

- Cylinder Head

- Piston and Piston Pin

- Connecting Rod

- Cylinder Liner

- Crankshaft and Main Bearing

- Camshaft and Tappet

- Timing Gear

- Cylinder Block

- Lub. Oil System

- Cooling Water System

- Fuel System

- Governor

- Electrical System

- Supercharger

- Reduction gear

- CHAPTER 4 SERVICE STANDARD TABLE

- CHAPTER 5 TIGHTENING TORQUE FOR MAJOR BOLTS AND NUTS

- CHAPTER 6 PERIODICAL CHECKING

This manual is available in a high-quality format, and all pages are printable. It is instantly accessible without any shipping costs or the need to wait for a CD-ROM.

File Format: PDF

Language: English

Compatible: All Versions of Windows & Mac

Requirements: Adobe Reader

For immediate access to this manual, simply make the payment. If you have any questions, feel free to contact us.