WESTERBEKE W-13 & W-18 Marine Diesel Engine Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

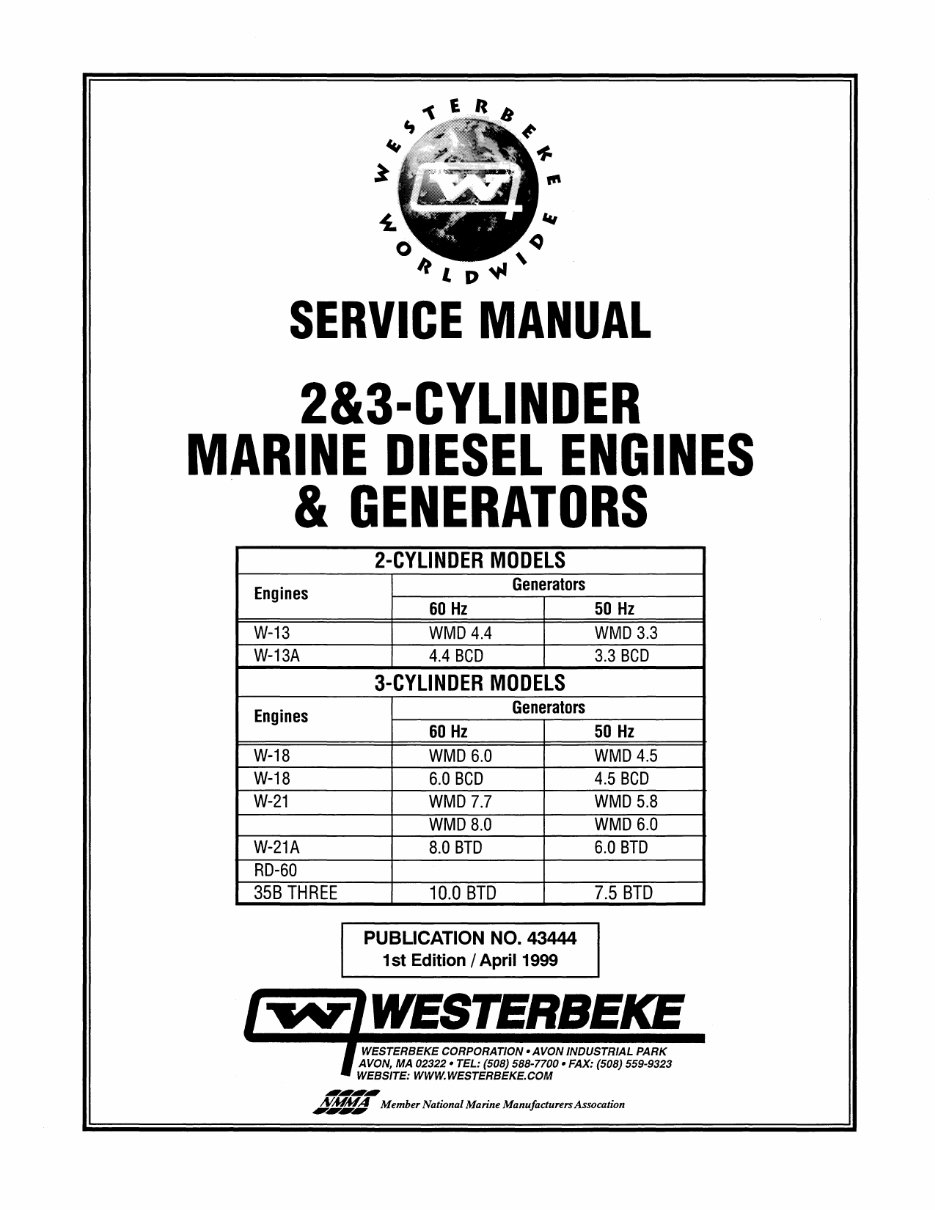

SERVICE MANUAL

2&3·CYLINDER

MARINE DIESEL ENGINES

& GENERATORS

2-CYLINDER MODELS

Engines

Generators

60 Hz 50 Hz

W-13 WMD 4.4 WMD 3.3

W-13A 4.4 BCD 3.3 BCD

3-CYLINDER MODELS

Engines

Generators

60 Hz 50 Hz

W-18 WMD 6.0 WMD 4.5

W-18 6.0 BCD 4.5 BCD

W-21 WMD 7.7 WMD 5.8

WMD 8.0 WMD 6.0

W-21A 8.0 BTD 6.0 BTD

RD-60

35B THREE 10.0 BTD 7.5 BTD

PUBLICATION NO. 43444

1st Edition / April 1999

J

WESTERBEKE CORPORATION· AVON INDUSTRIAL PARK

AVON, MA 02322· TEL: (508) 588-7700. FAX: (508) 559-9323

WEBSITE: WWW.WESTERBEKE.COM

----

§.JI9 Member National Marine ManufacturersAssocation

CALIFORNIA

PROPOSITION 65 WARNING

Diesel engine exhaust and some

of its constituents are known to

the State of California to cause

cancer, birth defects, and other

reproductive harm.

A WARNING

Exhaust gasses cDntain CarbDn MDnDxide, an DdDrless an,d

cDIDriess gas. CarbDn MDnDxide is pDisonDus and can cause

uncDnsciDusness and death. SymptDms Df CarbDn MDnDxide

expDsure can include:

-Dizziness

-Nausea

-Headache

- Weakness and Sleepiness

- ThrDbbing in Temples

- Muscular Twitching

- Vomiting

-Inability to Think CDherently

IF YOU OR ANYONE ELSE EXPERIENCE ANY OF THESE SYMPTOMS,

GET OUT INTO THE FRESH AIR IMMEDIATELY. «symptoms persist,

seek medical attentiDn. Shut dDwn the unit and dD nDt restart

until it has been inspected and repaired.

SAFETY INSTRUCTIONS

INTRODUCTION

Read these safety instructions carefully. Most accidents are

caused by failure to follow fundamental rules and precau-

tions. Know when dangerous conditions exist and take the

necessary precautions to protect yourself, your personnel,

and your machinery.

The following safety instructions are in compliance with

the American Boat and Yacht Council (ABYC) standards.

PREVENT ELECTRIC SHOCK

A WARNING: Do not touch AC electrical connections

while engine is running, or when connected to shore

power. Lethal voltage is present at these connections!

• Do not operate this machinery without electrical

enclosures and covers in place.

• Shut off electrical power before accessing electrical

equipment.

• Use insulated mats whenever working on electrical

equipment.

• Make sure your clothing and skin are dry, not damp

(particularly shoes) when handling electrical equipment.

• Remove wristwatch and all jewelry when working on

electrical equipment.

• Do not connect utility shore power to vessel's AC

circuits, except through a ship-to-shore double throw

transfer switch. Damage to vessel's AC generator may

result if this procedure is not followed.

• Electrical shock results from handling a charged capacitor.

Discharge capacitor by shorting terminals together with

an insulated tool.

PREVENT BURNS - HOT ENGINE

A WARNING: Do not touch hot engine parts or

exhaust system components. A running engine gets

very hot!

• Always check the engine coolant level at the coolant

recovery tank.

A WARNING: Steam can cause injury or death!

• In case of an engine overheat, allow the engine to cool

before touching the engine or checking the coolant.

PREVENT BURNS - FIRE

A WARNING: Fire can cause injury or death!

• Prevent flash fires. Do not smoke or permit flames or

sparks to occur near the carburetor, fuel line, filter, fuel

pump, or other potential sources of spilled fuel or fuel

vapors. Use a suitable container to catch all fuel when

removing the fuel line, carburetor, or fuel filters.

• Do not operate with a Coast Guard Approved flame

arrester removed. Backfire can cause severe injury or

death.

• Do not operate with the air cleaner/silencer removed.

Backfire can cause severe injury or death.

• Do not smoke or permit flames or sparks to occur near the

fuel system. Keep the compartment and the engine/gener-

ator clean and free of debris to minimize the chances of

fire. Wipe up all spilled fuel and engine oil.

• Be aware - diesel fuel will burn.

PREVENT BURNS - EXPLOSION

A WARNING: Explosions from fuel vapors can cause

injury or death!

• Follow re-fueling safety instructions. Keep the vessel's

hatches closed when fueling. Open and ventilate cabin

after fueling. Check below for fumes/vapor before run-

ning the blower. Run the blower for four minutes before

starting your engine.

• All fuel vapors are highly explosive. Use extreme care when

handling and storing fuels. Store fuel in a well-ventilated

area away from spark-producing equipment and out of

the reach of children.

• Do not fill the fuel tank(s) while the engine is running.

• Shut off the fuel service valve at the engine when servicing

the fuel system. Take care in catching any fuel that might

spill. DO NOT allow any smoking, open flames, or other

sources of fire near the fuel system or engine when servic-

ing. Ensure proper ventilation exists when servicing the

fuel system.

• Do not alter or modify the fuel system.

• Be sure all fuel supplies have a positive shutoff valve.

• Be certain fuel line fittings are adequately tightened and

free of leaks.

• Make sure a fire extinguisher is installed nearby and is

properly maintained. Be familiar with its proper use.

Extinguishers rated ABC by the NFPA are appropriate

for all applications encountered in this environment.

Engines & Generators

SAFETY INSTRUCTIONS

ACCIDENTAL STARTING

A WARNING: Accidental starting can cause injury

Dr death!

• Disconnect the battery cables before servicing the engine/

generator. Remove the negative lead first and reconnect

it last.

• Make certain all personnel are clear of the engine before

starting.

• Make certain all covers, guards, and hatches are re-

installed before starting the engine.

BAmRY EXPLOSION

A WARNING: Battery explosion can cause injury

Dr death!

• Do not smoke or allow an open flame near the battery

being serviced. Lead acid batteries emit hydrogen, a

highly explosive gas, which can be ignited by electrical

arcing or by lit tobacco products. Shut off all electrical

equipment in the vicinity to prevent electrical arcing dur-

ing servicing.

• Never connect the negative (-) battery' cable to the posi-

tive (+) connection terminal of the starter solenoid. Do

not test the battery condition by shorting the terminals

together. Sparks could ignite battery gases or fuel vapors.

Ventilate any compartment containing batteries to prevent

accumulation of explosive gases. To avoid sparks, do not

disturb the battery charger connections while the battery

is being charged.

• Avoid contacting the terminals with tools, etc., to prevent

bums or sparks that could cause an explosion. Remove

wristwatch, rings, and any other jewelry before handling

the battery.

• Always tum the battery charger off before disconnecting

the battery connections. Remove the negative lead first

and reconnect it last when servicing the battery.

BATTERY ACID

A WARNING: Splphuric acid in batteries can cause

severe injury Dr death!

• When servicing the battery or checking the electrolyte

level, wear rubber gloves, a rubber apron, and eye protec-

tion. Batteries contain sulfuric acid which is destructive. If

it comes in contact with your skin, wash it off at once

with water. Acid may splash on the skin or into the eyes

inadvertently when removing electrolyte caps.

TOXIC EXHAUST GASES

A WARNING: Carbon monoxide (CO) is a deadly gas!

• Ensure that the exhaust system is adequate to expel gases

discharged from the engine. Check the exhaust system

regularly for leaks and make sure the exhaust manifolds

are securely attached and no warping exists. Pay close

attention to the manifold, water injection elbow, and

exhaust pipe nipple.

• Be sure the unit and its surroundings are well ventilated.

• In addition to routine inspection of the exhaust system,

install a carbon monoxide detector. Consult your boat

builder or dealer for installation of approved detectors.

• For additional information refer to ABYC T-22 (educa-

tional information on Carbon Monoxide).

A WARNING: Carbon monoxide (CO) is an invisible

odorless gas. Inhalation produces flu-like symptoms,

nausea Dr death!

• Do not use copper tubing in diesel exhaust systems. Diesel

fumes can rapidly destroy copper tubing in exhaust sys-

tems. Exhaust sulfur causes rapid deterioration of copper

tubing resulting in exhaust/water leakage.

• Do not install exhaust outlet where exhaust can be drawn

through portholes, vents, or air conditioners. If the engine

exhaust discharge outlet is near the waterline, water could

enter the exhaust discharge outlet and close or restrict the

flow of exhaust. Avoid overloading the craft.

• Although diesel engine exhaust gases are not as toxic as

exhaust fumes from gasoline engines, carbon monoxide

gas is present in diesel exhaust fumes. Some of the symp-

toms or signs of carbon monoxide inhalation or poison-

ing are:

Vomiting

Dizziness

Throbbing in temples

Muscular twitching

Intense headache

Weakness and sleepiness

AVOID MOVING PARTS

A WARNING: Rotating parts can cause injury

Dr death!

• Do not service the engine while it is running. If a situation

arises in which it is absolutely necessary to make operat-

Engines & Generators

ii

SAFETY INSTRUCTIONS

ing adjustments, use extreme care to avoid touching

moving parts and hot exhaust system components.

• Do not wear loose clothing or jewelry when servicing

equipment; avoid wearing loose jackets, shirts, sleeves,

rings, necklaces or bracelets that could be caught in

moving parts.

• Make sure all attaching hardware is properly tightened.

Keep protective shields and guards in their respective

places at all times.

• Do not check fluid levels or the drive belt's tension while

the engine is operating.

• Stay clear of the drive shaft and the transmission coupling

when the engine is running; hair and clothing can easily

be caught in these rotating parts.

HAZARDOUS NOISE

A WARNING: High noise levels can cause hearing

loss!

• Never operate an engine without its muffler installed.

• Do not run an engine with the air intake (silencer)

removed.

• Do not run engines for long periods with their enclosures

open.

A WARNING: 00 not work on machinery when you

are mentally or physically incapacitated by fatigue!

OPERATORS MANUAL

Many of the preceding safety tips and warnings are repeated

in your Operators Manual along with other cautions and

notes to highlight critical information. Read your manual

carefully, maintain your equipment, and follow all safety

procedures.

ENGINE INSTALLATIONS

Preparations to install an engine should begin with a thor-

ough examination of the American Boat and Yacht Council's

(ABYC) standards. These standards are a combination of

sources including the USCG and the NFPA.

Sections of the ABYC standards of particular interest are:

H-2 Ventilation

P-l Exhaust systems

P-4 Inboard engines

E-9 DC Electrical systems

AIl installations must comply with the Federal Code of

Regulations (FCR).

ABYC, NFPA AND USCG PUBLICATIONS FOR

INSTAlliNG DIESEL ENGINES

Read the following ABYC, NFPA and USCG publications

for safety codes and standards. Follow their recommenda-

tions when installing your engine/generator.

ABYC (American Boat and Yacht Council)

"Safety Standards for Small Craft"

Order From:

ABYC

3069 Solomon's Island Road

Edgewater, MD 21037

NFPA (National Fire Protection Association)

"Fire Protection Standard for Motor Craft"

Order From:

NFPA

11 Tracy Drive

Avon Industrial Park

Avon, MA 02322

USCG (United States Coast Guard)

"USCG 33CFR183"

Order From:

U.S. Government Printing Office

Washington, D.C. 20404

Engines & Generators

iii

Engines & Generators

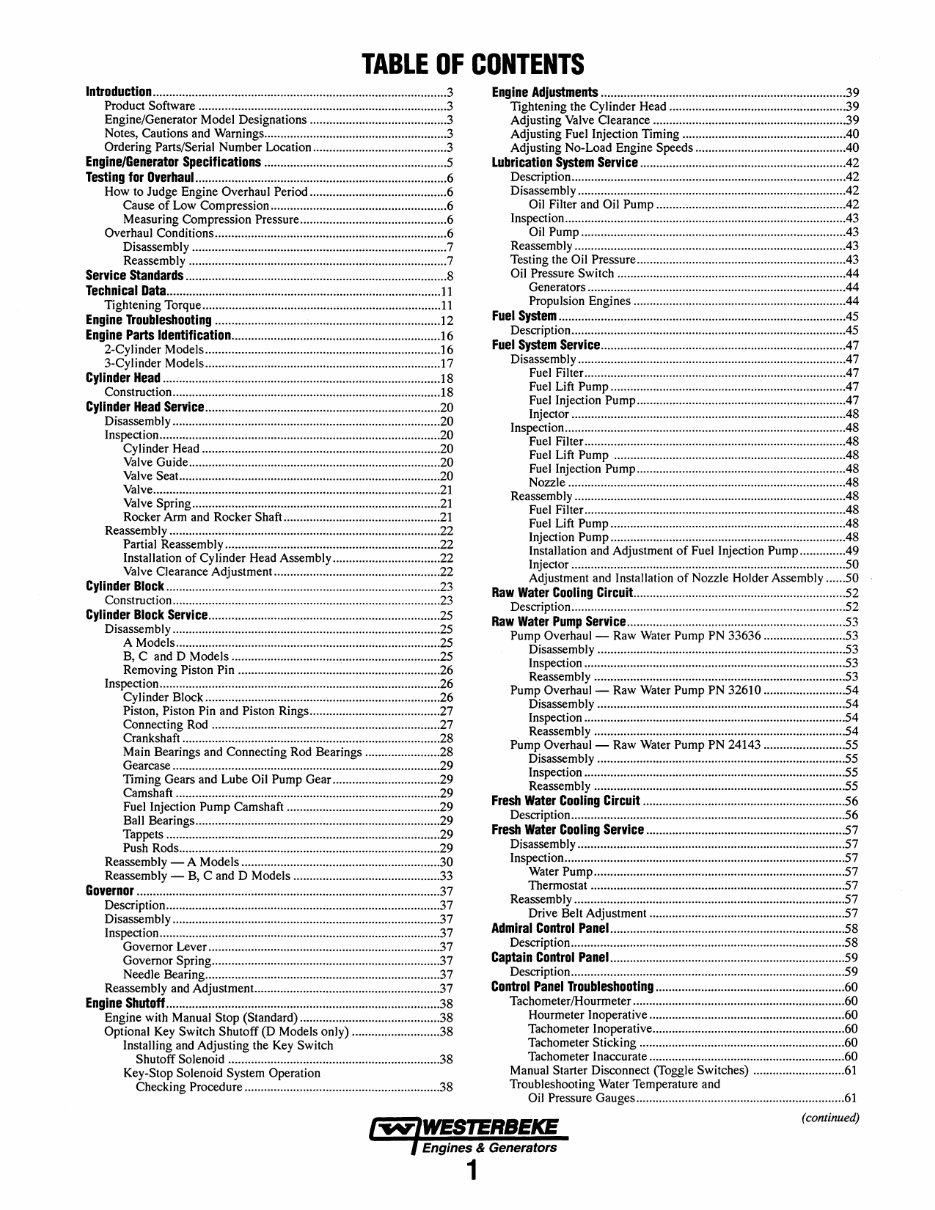

TABLE OF CONTENTS

Introduction .......................................................................................... 3 Engine Adjustments .......................................................................... .39

Product Software ............................................................................3 Tightening the Cylinder Head ......................................................39

Engine/Generator Model Designations ..........................................3 Adjusting Valve Clearance ...........................................................39

Notes, Cautions and Warnings........................................................ 3 Adjusting Fuel Injection Timing ................................................. .40

Ordering Parts/Serial Number Location .........................................3 Adjusting No-Load Engine Speeds ............................................. .40

Engine/Generator Specifications ....................................................... .5 Lubrication System Service .............................................................. .42

Testing for Overhaul ............................................................................. 6 Description ................................................................................... .42

How to Judge Engine Overhaul Period .......................................... 6 Disassembly ................................................................................. .42

Cause of Low Compression ...................................................... 6 Oil Filter and Oil Pump ......................................................... .42

Measuring Compression Pressure ............................................. 6 Inspection ..................................................................................... .43

Overhaul Conditions ....................................................................... 6 Oil Pump .................................................................................43

Disassembly .............................................................................. 7 Reassembly .................................................................................. .43

Reassembly ............................................................................... 7 Testing the Oil Pressure ............................................................... .43

Service Standards ................................................................................ 8

Oil Pressure Switch ..................................................................... .44

Technical Data .................................................................................... ]]

Tightening Torque ......................................................................... 11

Engine Troubleshooting ..................................................................... ]2

Engine Parts Identification ................................................................ 16

2-Cylinder Models ........................................................................ 16

3-Cylinder Models ........................................................................ 17

Cylinder Head ..................................................................................... 18

Construction .................................................................................. 18

Cylinder Head Service ........................................................................ 20

Disassembly .................................................................................. 20

Inspection ..................................................................................... .20

Cylinder Head ......................................................................... 20

Valve Guide ............................................................................. 20

Valve Seat ............................................................................... .20

Valve ....................................................................................... . 21

Valve Spring ............................................................................ 21

Rocker Arm and Rocker Shaft ................................................ 21

Reassembly .................................................................................. .22

Partial Reassembly ................................................................. .22

Installation of Cylinder Head Assembly .................................22

Valve Clearance Adjustment .................................................. .22

Cylinder Block .................................................................................... 23

Construction .................................................................................. 23

Cylinder Block Service ....................................................................... 25

Disassembly ..................................................................................25

A Models ................................................................................ .25

B, C and D Models ............................................................... .25

Removing Piston Pin .............................................................. 26

Inspection ...................................................................................... 26

Cylinder Block ........................................................................26

Piston, Piston Pin and Piston Rings ........................................ 27

Connecting Rod ......................................................................27

Crankshaft ............................................................................... 28

Main Bearings and Connecting Rod Bearings ....................... 28

Gearcase .................................................................................. 29

Timing Gears and Lube Oil Pump Gear .................................29

Camshaft ................................................................................ .29

Fuel Injection Pump Camshaft ............................................... 29

Ball Bearings ........................................................................... 29

Tappets ................................................................................... .29

Push Rods ................................................................................ 29

Reassembly - A Models ............................................................. 30

Reassembly - B, C and D Models ............................................ .33

Governor ............................................................................................. 37

Description .................................................................................... 37

Disassembly .................................................................................. 37

Inspection ..................................................................................... .37

Governor Lever ....................................................................... 37

Generators .............................................................................. .44

Propulsion Engines ................................................................. 44

Fuel System ........................................................................................ 45

Description ................................................................................... .45

Fuel System Service .......................................................................... .47

Disassembly ................................................................................. .47

Fuel Filter ............................................................................... .47

Fuel Lift Pump ....................................................................... .47

Fuel Injection Pump .............................................. ,................ .47

Injector ................................................................................... .48

Inspection ..................................................................................... .48

Fuel Filter ............................................................................... .48

Fuel Lift Pump ...................................................................... .48

Fuel Injection Pump ............................................................... .48

Nozzle .................................................................................... .48

Reassembly .................................................................................. .48

Fuel Filter ............................................................................... .48

Fuel Lift Pump ....................................................................... .48

Injection Pump ........................................................................ 48

Installation and Adjustment of Fuel Injection Pump ............. .49

Injector .................................................................................... 50

Adjustment and Installation of Nozzle Holder Assembly ..... .50

Raw Water Cooling Circuit... ............................................................. .52

Description ................................................................................... .52

Raw Water Pump Service ................................................................... 53

Pump Overhaul - Raw Water Pump PN 33636 .........................53

Disassembly ........................................................................... .53

Inspection ................................................................................53

Reassembly .............................................................................53

Pump Overhaul - Raw Water Pump PN 32610 ......................... 54

Disassembly ............................................................................ 54

Inspection ................................................................................ 54

Reassembly ............................................................................ .54

Pump Overhaul - Raw Water Pump PN 24143 ........................ .55

Disassembly ........................................................................... .55

Inspection ................................................................................55

Reassembly ............................................................................ .55

Fresh Water Cooling Circuit .............................................................. 56

Description .................................................................................... 56

Fresh Water Cooling Service ............................................................ .57

Disassembly ................................................................................. .57

Inspection ...................................................................................... 57

Water Pump ............................................................................. 57

Thermostat ............................................................................. .57

Reassembly .................................................................................. .57

Drive Belt Adjustment ............................................................ 57

Admiral Control Panel ....................................................................... .58

Description ................................................................................... .58

Governor Spring ...................................................................... 37

Needle Bearing ........................................................................ 37

Reassembly and Adjustment. ....................................................... .37

Captain Control Panel ....................................................................... .59

Description ................................................................................... .59

Control Panel Troubleshooting .......................................................... 60

Engine Shutoff .................................................................................... 38

Engine with Manual Stop (Standard) .......................................... .38

Optional Key Switch Shutoff (D Models only) ........................... 38

Installing and Adjusting the Key Switch

Shutoff Solenoid ................................................................. 38

TachometerlHourmeter ................................................................. 60

Hourmeter Inoperative ............................................................ 60

Tachometer Inoperative ........................................................... 60

Tachometer Sticking ............................................................... 60

Tachometer Inaccurate ............................................................ 60

Key-Stop Solenoid System Operation

Checking Procedure ............................................................ 38

Manual Starter Disconnect (Toggle Switches) ............................ 61

Troubleshooting Water Temperature and

Oil Pressure Gauges ................................................................ 61

(continued)

Engines & Generators

1

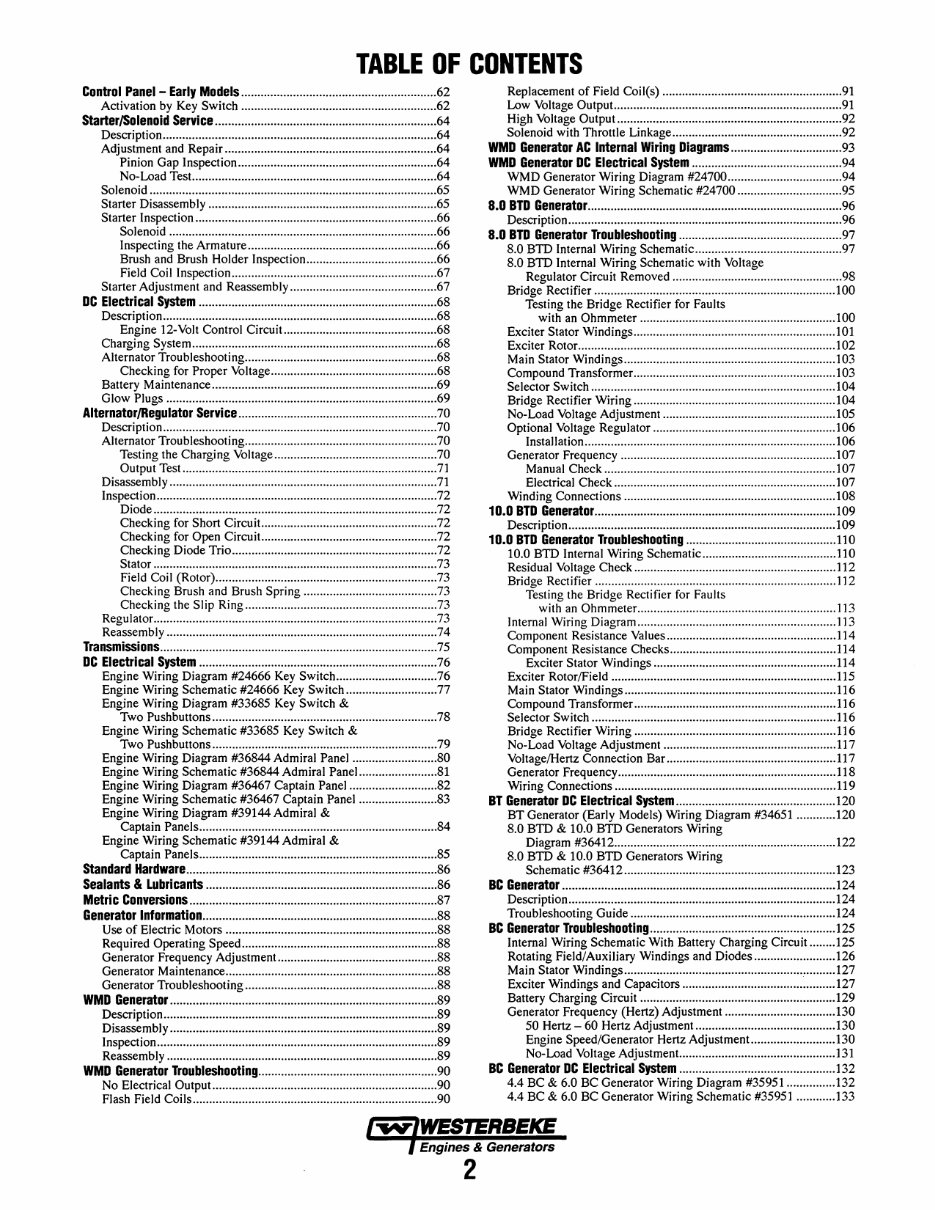

TABLE OF CONTENTS

Control Panel- Early Models ............................................................ 62 Replacement of Field Coil(s) ....................................................... 91

Activation by Key Switch ............................................................ 62 Low Voltage Output ...................................................................... 91

Starter/Solenoid Service .................................................................... 64

High Voltage Output ..................................................................... 92

Description .................................................................................... 64

Adjustment and Repair ................................................................. 64

Solenoid with Throttle Linkage .................................................... 92

WMD Generator AC Internal Wiring Diagrams .................................. 93

Pinion Gap Inspection ............................................................. 64 WMD Generator DC Electrical System .............................................. 94

No-Load Test ........................................................................... 64 WMD Generator Wiring Diagram #24700 ................................... 94

Solenoid ........................................................................................ 65 WMD Generator Wiring Schematic #24700 ................................ 95

Starter Disassembly ...................................................................... 65

8.0 BTD Generator .............................................................................. 96

Starter Inspection .......................................................................... 66

Solenoid .................................................................................. 66

Inspecting the Armature .......................................................... 66

Brush and Brush Holder Inspection ........................................ 66

Field Coil Inspection ............................................................... 67

Starter Adjustment and Reassembly ............................................. 67

DC Electrical System ......................................................................... 68

Description .................................................................................... 68

Description .................................................................................... 96

8.0 BTD Generator Troubleshooting .................................................. 97

8.0 BID Internal Wiring Schematic ............................................. 97

8.0 BID Internal Wiring Schematic with Voltage

Regulator Circuit Removed .................................................... 98

Bridge Rectifier .......................................................................... 100

Testing the Bridge Rectifier for Faults

with an Ohmmeter ............................................................ 100

Engine 12-Volt Control Circuit... ............................................ 68

Charging System ........................................................................... 68

Exciter Stator Windings .............................................................. 101

Exciter Rotor ............................................................................... 102

Alternator Troubleshooting........................................................... 68

Checking for Proper Voltage ................................................... 68

Battery Maintenance ..................................................................... 69

Main Stator Windings ................................................................. 103

Compound Transformer .............................................................. 103

Selector Switch ........................................................................... 104

Glow Plugs ................................................................................... 69

AlternatorJRegulator Service ............................................................. 70

Bridge Rectifier Wiring .............................................................. 104

No-Load Voltage Adjustment ..................................................... 105

Description .................................................................................... 70 Optional Voltage Regulator ........................................................ 106

Alternator Troubleshooting ........................................................... 70 Installation ............................................................................. 1 06

Testing the Charging Voltage .................................................. 70 Generator Frequency .................................................................. 1 07

Output Test .............................................................................. 71 Manual Check ....................................................................... 107

Disassembly .................................................................................. 71 Electrical Check .................................................................... 107

Inspection ...................................................................................... 72 Winding Connections ................................................................. 108

Diode ....................................................................................... 72

10.0 BTD Generator .......................................................................... 109

Checking for Short Circui!... ................................................... 72

Checking for Open Circui!... ................................................... 72

Checking Diode Trio ............................................................... 72

Stator ....................................................................................... 73

Field Coil (Rotor) .................................................................... 73

Checking Brush and Brush Spring ......................................... 73

Checking the Slip Ring ........................................................... 73

Description .................................................................................. 109

10.0 BTD Generator Troubleshooting .............................................. 110

10.0 BID Internal Wiring Schematic ......................................... ll0

Residual Voltage Check .............................................................. 112

Bridge Rectifier .......................................................................... 112

Testing the Bridge Rectifier for Faults

with an Ohmmeter ............................................................. 113

Regulator ....................................................................................... 73

Reassembly ................................................................................... 74

Transmissions ..................................................................................... 75

DC Electrical System ......................................................................... 76

Internal Wiring Diagram ............................................................. 113

Component Resistance Values .................................................... 114

Component Resistance Checks ................................................... 114

Exciter Stator Windings ........................................................ 114

Engine Wiring Diagram #24666 Key Switch ............................... 76 Exciter RotorlField ..................................................................... 115

Engine Wiring Schematic #24666 Key Switch ............................ 77 Main Stator Windings ................................................................. 116

Engine Wiring Diagram #33685 Key Switch & Compound Transformer .............................................................. 116

Two Pushbuttons ..................................................................... 78 Selector Switch ........................................................................... 116

Engine Wiring Schematic #33685 Key Switch & Bridge Rectifier Wiring .............................................................. 116

Two Pushbuttons .....................................................................79 No-Load Voltage Adjustment ..................................................... 117

Engine Wiring Diagram #36844 Admiral Panel .......................... 80 Voltage!Hertz Connection Bar .................................................... 117

Engine Wiring Schematic #36844 Admiral Panel ........................81 Generator Frequency ................................................................... 118

Engine Wiring Diagram #36467 Captain Panel ........................... 82 Wiring Connections .................................................................... 119

Engine Wiring Schematic #36467 Captain Panel ........................ 83

Engine Wiring Diagram #39144 Admiral &

Captain Panels ......................................................................... 84

Engine Wiring Schematic #39144 Admiral &

Captain Panels .........................................................................85

Standard Hardware ............................................................................. 86

BT Generator DC Electrical System ................................................. l20

BT Generator (Early Models) Wiring Diagram #34651 ............ 120

8.0 BID & 10.0 BID Generators Wiring

Diagram #36412 .................................................................... 122

8.0 BID & 10.0 BID Generators Wiring

Schematic #36412 ................................................................. 123

Sealants & Lubricants ....................................................................... 86 BC Generator .................................................................................... 124

Metric Conversions ............................................................................ 87 Description .................................................................................. 124

Generator Information ........................................................................ 88

Troubleshooting Guide ............................................................... 124

Use of Electric Motors ................................................................. 88 BC Generator Troubleshooting ......................................................... 125

Required Operating Speed ............................................................ 88 Internal Wiring Schematic With Battery Charging Circuit ........ 125

Generator Frequency Adjustment ................................................. 88 Rotating Field/Auxiliary Windings and Diodes ......................... 126

Generator Maintenance ................................................................. 88 Main Stator Windings ................................................................. 127

Generator Troubleshooting ........................................................... 88 Exciter Windings and Capacitors ............................................... 127

WMD Generator .................................................................................. 89

Battery Charging Circuit ............................................................ 129

Description .................................................................................... 89

Disassembly .................................................................................. 89

Inspection ...................................................................................... 89

Reassembly ................................................................................... 89

WMD Generator Troubleshooting ....................................................... 90

No Electrical Output ..................................................................... 90

Flash Field Coils ...........................................................................90

Generator Frequency (Hertz) Adjustment .................................. 130

50 Hertz - 60 Hertz Adjustment ........................................... 130

Engine Speed/Generator Hertz Adjustment... ....................... 130

No-Load Voltage Adjustment... ............................................. 131

BC Generator DC Electrical System ............................................... .132

4.4 BC & 6.0 BC Generator Wiring Diagram #35951 ............... 132

4.4 BC & 6.0 BC Generator Wiring Schematic #35951 ........... .133

Engines & Generators

2

INTRODUCTION

This service manual contains detailed information relating to

the proper operation of the major components and systems of

the engine or generator. Included are disassembly, inspection,

service, and reassembly instructions for the guidance of suit-

ably equipped and staffed marine engine service and rebuild-

ing facilities. The necessary procedures should be undertaken

only by such facilities and their personnel. Refer also to your

Westerbeke parts catalog when performing an engine over-

haul.

PRODUCT SOFTWARE

Product software (tech data, parts lists, manuals, brochures

and catalogs) provided from sources other than WESTER-

BEKE are not within WESTERBEKE'S control.

WESTERBEKE CANNOT BE RESPONSIBLE FOR THE

CONTENT OF SUCH SOFTWARE, MAKES NO WAR-

RANTIES OR REPRESENTATIONS WITH RESPECT

THERETO, INCLUDING ACCUR4CY, TIMELINESS OR

COMPLETENESS THEREOF AND WILL IN NO EVENT

BE LIABLE FOR ANY TYPE OF DAMAGE OR INJURY

INCURRED IN CONNECTION WITH OR ARISING OUT

OF THE FURNISHING OR USE OF SUCH SOFTWARE.

WESTERBEKE customers should also keep in mind the

time span between printings of WESTERBEKE product soft-

ware and the unavoidable existence of earlier WESTER-

BEKE manuals. In summation, product software provided

with WESTERBEKE products, whether from WESTER-

BEKE or other suppliers, must not and cannot be relied upon

exclusively as the definitive authority on the respective prod-

uct. It not only makes good sense but is imperative that

appropriate representatives of WESTERBEKE or the sup-

plier in question be consulted to determine the accuracy and

currentness of the product software being consulted by the

customer.

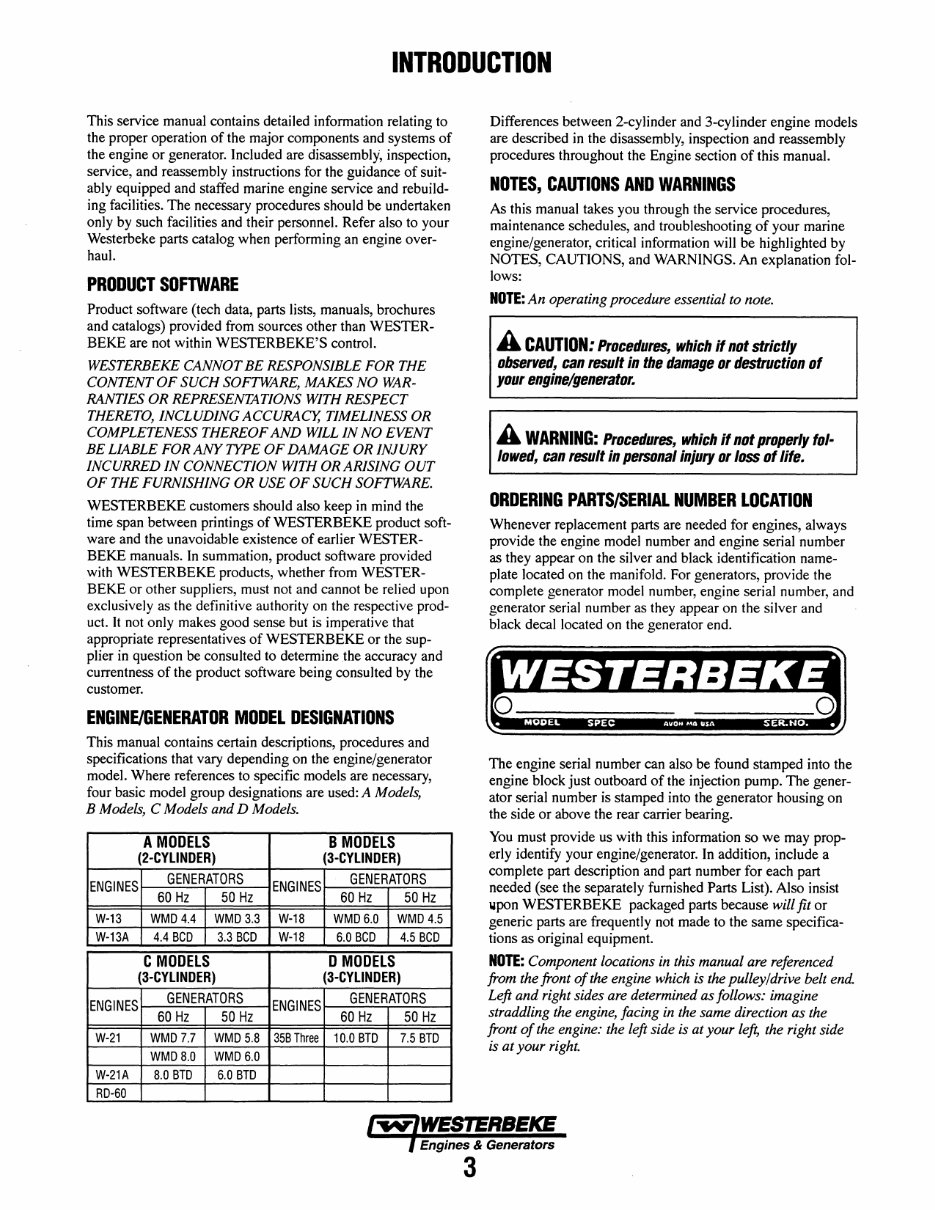

ENGINE/GENERATOR MODEL DESIGNATIONS

This manual contains certain descriptions, procedures and

specifications that vary depending on the engine/generator

model. Where references to specific models are necessary,

four basic model group designations are used: A Models,

B Models, C Models and D Models.

A MODELS B MODELS

(2-CYLINDER) (3-CYLINDER)

ENGINES

GENERATORS

ENGINES

GENERATORS

60 Hz 50 Hz 60 Hz 50 Hz

W-13 WMD 4.4 WMD 3.3 W-18 WMD 6.0 WMD 4.5

W-13A 4.4 BCD 3.3 BCD W-18 6.0 BCD 4.5 BCD

C MODELS D MODELS

(3-CYLINDER) (3-CYLINDER)

ENGINES

GENERATORS

ENGINES

GENERATORS

60 Hz 50 Hz 60 Hz 50 Hz

W-21 WMD 7.7 WMD 5.8 35B Three 10.0 BTD 7.5 BTD

WMD 8.0 WMD 6.0

W-21A 8.0 BTD 6.0 BTD

RD-60

Differences between 2-cylinder and 3-cylinder engine models

are described in the disassembly, inspection and reassembly

procedures throughout the Engine section of this manual.

NOTES, CAUTIONS AND WARNINGS

As this manual takes you through the service procedures,

maintenance schedules, and troubleshooting of your marine

engine/generator, critical information will be highlighted by

NOTES, CAUTIONS, and WARNINGS. An explanation fol-

lows:

NOTE: An operating procedure essential to note.

A CAUTION: Procedures, which if not strictly

observed, can result in the damage or destruction of

your engine/generator.

A WARNING: Procedures, which if not properly fol-

lowed, can result in personal injury or loss of life.

ORDERING PARTS/SERIAL NUMBER LOCATION

Whenever replacement parts are needed for engines, always

provide the engine model number and engine serial number

as they appear on the silver and black identification name-

plate located on the manifold. For generators, provide the

complete generator model number, engine serial number, and

generator serial number as they appear on the silver and

black decal located on the generator end.

The engine serial number can also be found stamped into the

engine block just outboard of the injection pump. The gener-

ator serial number is stamped into the generator housing on

the side or above the rear carrier bearing.

You must provide us with this information so we may prop-

erly identify your engine/generator. In addition, include a

complete part description and part number for each part

needed (see the separately furnished Parts List). Also insist

ijpon WESTERBEKE packaged parts because will fit or

generic parts are frequently not made to the same specifica-

tions as original equipment.

NOTE: Component locations in this manual are referenced

from the front of the engine which is the pulley/drive belt end.

Left and right sides are determined as follows: imagine

straddling the engine, facing in the same direction as the

front of the engine: the left side is at your left, the right side

is at your right.

Engines & Generators

3

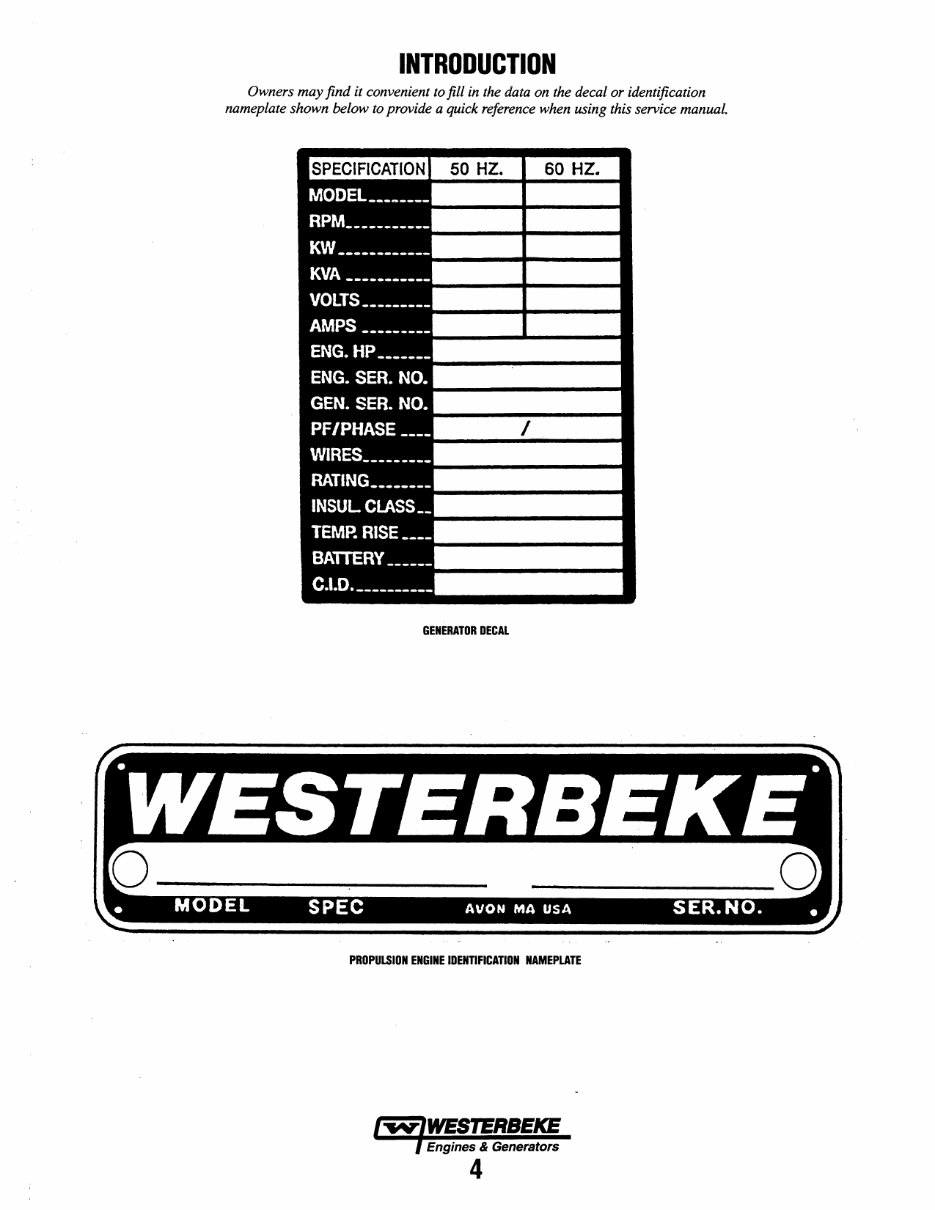

INTRODUCTION

Owners may find it convenient to fill in the data on the decal or identification

nameplate shown below to provide a quick reference when using this service manual.

SPECIFICATION

MODEL _______ _

RPM __________ _

KW ___________ _

KVA __________ _

VOLTS ________ _

AMPS ________ _

ENG. HP ______ _

ENG. SER. NO.

GEN. SER. NO.

PF IPHASE ___ _

WIRES ________ _

RATING _______ _

INSUL CLASS __

TEMP. RISE ___ _

BAITERY _____ _

C.'.O. _________ _

50 HZ.

GENERATOR DECAL

60 HZ.

I

PROPULSION ENGINE IDENnFICATION NAMEPLATE

Engines & Generators

4

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

Viewed 31 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

This is a comprehensive service repair manual for the WESTERBEKE W-13 & W-18 marine diesel engines. It is useful for both professional mechanics and DIY enthusiasts.

Applicable Models:

- W-13, W-13A Engine

- W-18, W-21 Engine

Engine Specifications:

- 0.60L 2-cylinder, 4-stroke, water-cooled, diesel

- 0.78L 3-cylinder, 4-stroke, water-cooled, diesel

- 0.98L 3-cylinder, 4-stroke, water-cooled, diesel

- 1.12L 3-cylinder, 4-stroke, water-cooled, diesel

Contents:

- Specifications

- Engine Overhaul

- Engine Disassembly

- Engine Assembly

- Cylinderhead-Valves

- Gearcase & Oil Pump

- Timing Gears

- Camshaft-Crankshaft

- Piston-Connecting Rod

- Fuel System

- Governor System

- Glow Plug System

- Cooling System

- Starter System

- Alternator System

- Marine Transmission

- Tightening Torque

- Troubleshooting

This manual is available in .PDF format and features detailed exploded views. It contains step-by-step procedures with pictures and diagrams, making it fully printable. It is the same manual used by technicians for engine repairs, maintenance, and servicing.