2007-2012 Iveco NEF Marine Engine N40 N60 Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

1

ENGLISH

NEF SERIES

ELECTRONIC INJECTION

SYSTEM

N40 ENT (TIER 2)

N45 ENT (TIER 3)

N60 ENT (TIER 2)

N67 ENT (TIER 3)

NEF 60 TE2

USE AND MAINTENANCE

INTRODUCTION

We would like to thank you for buying an IVECO MOTORS product,

and compliment you on your choice of engine.

Before you carry out any operation involving the engine or its fittings,

please read the contents of this manual carefully; compliance with the

instructions provided in the manual is the best way to guarantee

trouble-free, long term operation of the engine.

The contents of this manual refer to the standard configuration of the

engine, and the illustrations are purely indicative. Some instructions are

provided by giving the sequence of operations to be carried out in

order to allow the engine and/or its fittings to perform in a certain way.

In some cases they will be dependent on the configuration of the

commands and the set-up of the machine on which the engine is

installed; for any points that differ from the contents of this manual,

please consult the instructions provided by the machine Manufacturer

or a specific manual.

The information provided below was current at the date of

publication.

The Manufacturer reserves the right to make modifications at any time

without prior notice, for technical or commercial reasons or to update

the engines to comply with legal requirements in the various

Countries.

The Manufacturer declines all liability for any errors or omissions.

Please remember that the IVECO MOTORS Technical Service

Network is available to offer you its experience and professional skills,

wherever you may be.

2

TABLE OF CONTENTS Page

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Engine technical data N40 ENT - N45 ENT . . . . . . . . . . . . . . . . . . 4

Engine technical data N60 ENT - N67 ENT . . . . . . . . . . . . . . . . . . 6

Engine technical data NEF 60 TE2 . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

USE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Preliminary checks. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Starting and stopping the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Recognising alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Engine management and diagnosis from the instrument panel. .15

Engine pre-heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

For proper use of the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Special warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Running in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Refuelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

CONTROLS AND MAINTENANCE . . . . . . . . . . . . . . . . . . . . . 19

Maintenance personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Accident prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

How to proceed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Moving the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Disposal of waste . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

LONG PERIODS OF INACTIVITY . . . . . . . . . . . . . . . . . . . . . . . 31

Preparing the engine for a long period of inactivity . . . . . . . . . . . 31

Restarting the engine after a long period of inactivity . . . . . . . . . 32

Page

ENGINE MALFUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

BEHAVIOUR IN AN EMERGENCY. . . . . . . . . . . . . . . . . . . . . . .34

IN APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil viscosity level according to surrounding temperatures . . . . . . .

3

ENGLISH

GENERAL INFORMATION

GUARANTEE

In order to ensure that your engine gives the best possible

performance and to take advantage of the IVECO MOTORS

guarantee, you must follow the indications provided in this publication

with great care; failure to do so may result in invalidation of the

guarantee.

SPARE PARTS

Always use Original IVECO MOTORS Spare parts. This is essential to

keep the engine in original running order.

The use of non-original spare parts will not only invalidate the

guarantee, but will mean that IVECO MOTORS will not be considered

liable in any way during the whole working life of the engine.

LIABILITY

The Manufacturer will only be considered liable subject to

performance of the control and maintenance operations indicated and

described in this manual; to this effect, proof that these operations

have been performed must be provided. Any special maintenance

operations that may be necessary must be carried out by qualified

technicians from authorised Workshops in the IVECO MOTORS

Network, using the instruments and equipment provided for the

purpose.

SAFETY

The following information is intended to encourage caution when

using the engine, so as to avoid damage to persons or property as a

result of improper or incorrect behaviour.

The engines must only be used for the purposes indicated by the

Manufacturer.

Any tampering, modification and use of non-original spare parts

may compromise proper operation and safe use of the engine;

never, under any circumstances make modifications to

the wiring and to the units equipping the engine, or connect them

to other power systems.

Pay particular attention to moving parts of the engine, to high

temperature components and to circuits containing pressurised

fluids; its electrical equipment houses electrical currents and

voltage.

The exhaust fumes produced by the engine are bad for your health.

Tackle, making use of the U-bolts provided on the engine for that

purpose.

The engine must not be started up and used until the machine in

which it installed has satisfied all necessary safety requirements, or

until the machine has been guaranteed to comply with local laws

and regulations.

The operations required to guarantee the best possible use and

preservation of the engine must only be carried out by persons of

proven experience, equipment with tools considered suitable by

IVECO MOTORS.

For the purpose of safety, further recommendations are given in the

chapter CONTROLS AND MAINTENANCE.

4

ENGINE TECHNICAL DATA N40 ENT - N45

ENT

The technical code and serial number are indicated on a plate, which

is located on different parts of the engine, according to the model:

flywheel casing, tappet cover, other.

(*)Net power to the flywheel in compliance with ISO 3046-1. Test

conditions: temperature 25 °C; atmospheric pressure 100 kPa;

relative humidity 30%.

Code N40 ENT N45 ENT

Engine family F4

Cycle 4-stroke diesel

Number and arrangement

of cylinders 4, in line

Bore x stroke 102 x 120 mm 104 x 132 mm

Total displacement 3,900 cm

3

4,500 cm

3

Air system Supercharged aftercooled

Injection type Common Rail, electronically managed

Engine direction of rotation Anticlockwise

(seen from flywheel side)

Dry weight 410 kg 410 kg

Electrical system 24 V

Accumulator/s

- capacity

- discharge current

130 Ah or above

500 A or above

Performance: Maximum power (*)

Maximum torque

N40 ENT 107 kW (145 CV) @ 2300 rpm

490 Nm (50 Kgm) @ 1200 rpm

N45 ENT 104 kW (141 CV) @ 2200 rpm

560 Nm (57 Kgm) @ 1400 rpm

WARNING

Any alteration of the above mentioned characteristics, in particular

modification of the data stored in the injection system electronic units

or the characteristics of the engine and its fittings, is strictly prohibited,

penalty invalidation of the guarantee and absence of all liability on the

part of IVECO MOTORS.

5

ENGLISH

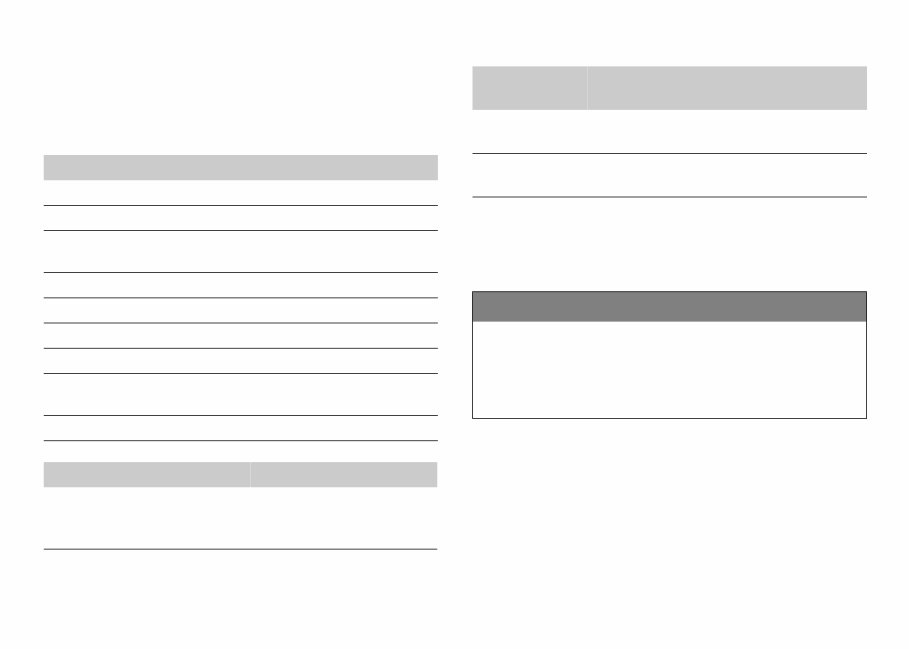

Engine N40 ENT - N45 ENT

1. Auxiliary member drive belt - 2. Engine air inlet - 3. Fuel inlet

manifold from tank - 4. Common rail - 5. Lifting U-bolt - 6. Common

rail high pressure pump - 7. Fuel outlet connector to tank - 8. Fuel filter

- 9. Oil drainage plug - 10. Oil dipstick - 11. Engine electronic control

unit - 12. Sensor on drive shaft phonic wheel.

Engine N40 ENT - N45 ENT

1. Turbocharger air intake - 2. Turbocharger - 3. Turbocharging air

outlet to after-cooler - 4. Exhaust manifold - 5. Turbocharger exhaust

outlet - 6. Lifting U-bolt - 7. Oil filler cap - 8. Coolant outlet to heat

exchanger - 9. Thermostat valve location - 10. Alternator - 11. Coolant

inlet from heat exchanger - 12. Lubricant oil filter - 13. Electrical starter

motor.

05_573_N 05_574_N

6

ENGINE TECHNICAL DATA N60 ENT - N67

ENT

The technical code and serial number are indicated on a plate, which

is located on different parts of the engine, according to the model:

flywheel casing, tappet cover, other.

(*)Net power to the flywheel in compliance with ISO 3046-1. Test

conditions: temperature 25 °C; atmospheric pressure 100 kPa;

relative humidity 30%.

Code N60 ENT N67 ENT

Engine family F4

Cycle 4-stroke diesel

Number and arrangement

of cylinders 6, in line

Bore x stroke 102 x 120 mm 104 x 132 mm

Total displacement 5,900 cm

3

6,700 cm

3

Air system Supercharged aftercooled

Injection type Common Rail, electronically managed

Engine direction of rotation Anticlockwise

(seen from flywheel side)

Dry weight 520 kg 520 kg

Electrical system 24 V

Accumulator/s

- capacity

- discharge current

130 Ah or above

500 A or above

Performance: Maximum power (*)

Maximum torque

N60 ENT 169 kW (230 CV) @ 2300 rpm

810 Nm ( 83 Kgm) @ 1200 rpm

N67 ENT 175 kW (238 CV) @ 2200 rpm

1020 Nm (104 Kgm) @ 1400 rpm

WARNING

Any alteration of the above mentioned characteristics, in particular

modification of the data stored in the injection system electronic units

or the characteristics of the engine and its fittings, is strictly prohibited,

penalty invalidation of the guarantee and absence of all liability on the

part of IVECO MOTORS.

7

ENGLISH

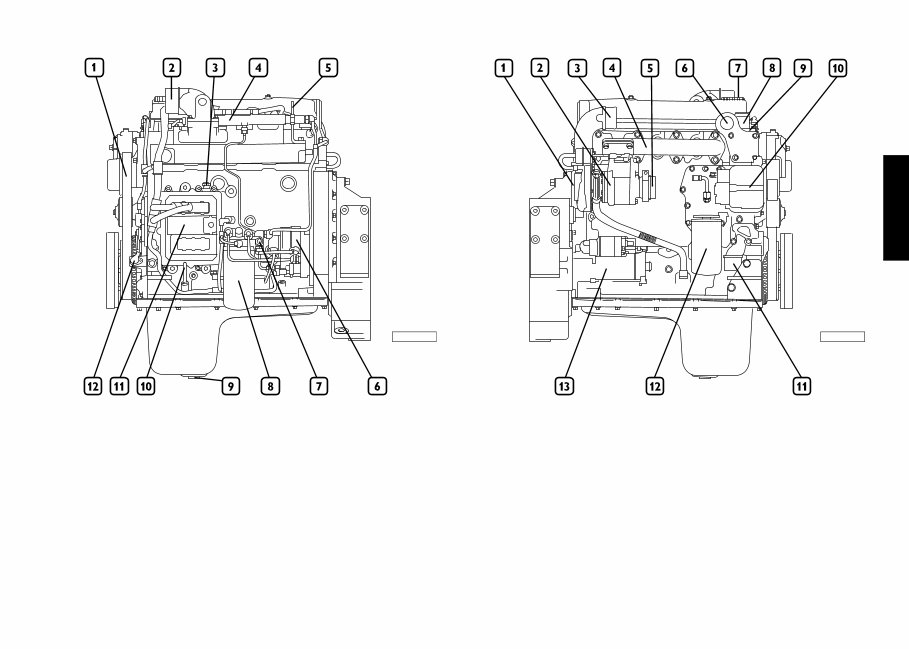

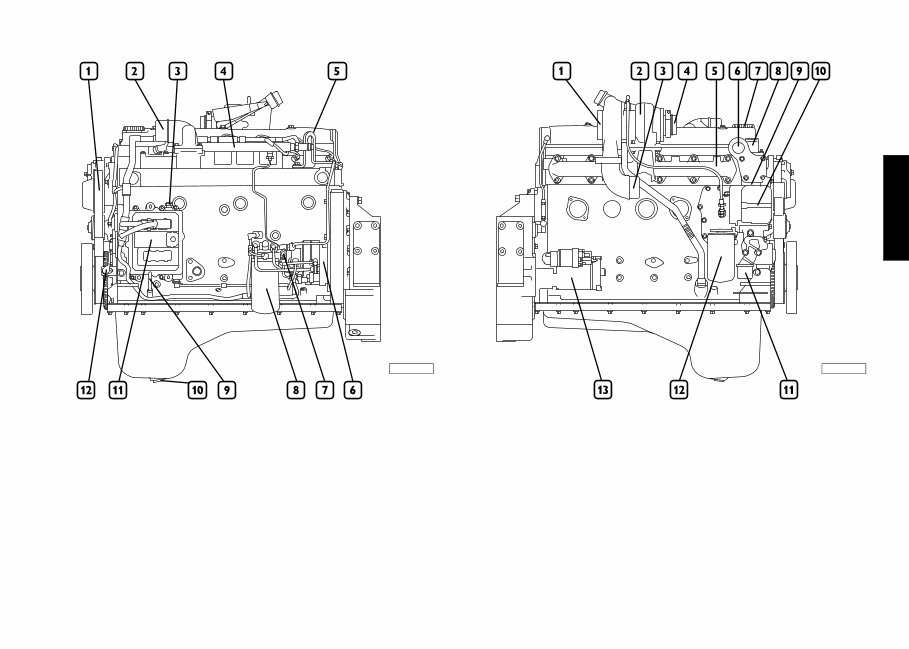

Engine N60 ENT - N67 ENT

1. Auxiliary member drive belt - 2. Engine air inlet - 3. Fuel inlet

manifold from tank - 4. Common rail - 5. Lifting U-bolt - 6. Common

rail high pressure pump - 7. Fuel outlet connector to tank - 8. Fuel filter

- 9. Oil dipstick - 10. Oil drainage plug- 11. Engine electronic control

unit - 12. Sensor on drive shaft phonic wheel.

Engine N60 ENT - N67 ENT

1. Turbocharger air intake - 2. Turbocharger - 3. Turbocharging air

outlet to after-cooler - 4. Turbocharger exhaust outlet - 5. Exhaust

manifold - 6. Lifting U-bolt - 7. Oil filler cap - 8. Coolant outlet to heat

exchanger - 9. Thermostat valve location - 10. Alternator - 11. Coolant

inlet from heat exchanger - 12. Lubricant oil filter - 13. Electrical starter

motor.

05_575_N 05_576_N

8

ENGINE TECHNICAL DATA NEF 60 TE2

The technical code and serial number are indicated on a plate, which

is located on different parts of the engine, according to the model:

flywheel casing, tappet cover, other.

(*)Values in compliance with ISO 8528.

SELECTING THE RUNNING SPEED

The running speed can be preselected (1500 or 1800 rpm) by

inserting a resistor between terminals 87 and 32 of the 89-pin

connector on the engine's electronic control unit. The prescribed

resistor values are as follows:

- 1500 rpm : 1330 Ohm

- 1800 rpm : 820 Ohm

For incorrect values or in the total absence of a resistor the running

speed will be kept at minimum, equivalent to 800 rpm.

Code NEF 60 TE2

Engine family F4

Cycle 4-stroke diesel

Number and arrangement

of cylinders 6, in line

Bore x stroke 102 x 120 mm

Total displacement 5.900 cm

3

Air system Supercharged aftercooled

Injection type Common rail,

electronically managed

Engine direction of rotation Anticlockwise

(seen from flywheel side)

Isochronous speed regulator Electronically controlled

Dry weight 630 kg

Electrical system 12 V

Accumulator/s

- capacity

- discharge current

185 Ah or above

1200 A or above

Performance

(*)

(50 Hz) Prime 175 kWm @ 1500 rpm

Stand by 193 kWm @ 1500 rpm

(60 Hz) Prime 195 kWm @ 1800 rpm

Stand by 215 kWm @ 1800 rpm

WARNING

Any alteration of the above mentioned characteristics, in particular

modification of the data stored in the injection system electronic units

or the characteristics of the engine and its fittings, is strictly prohibited,

penalty invalidation of the guarantee and absence of all liability on the

part of IVECO MOTORS.

9

ENGLISH

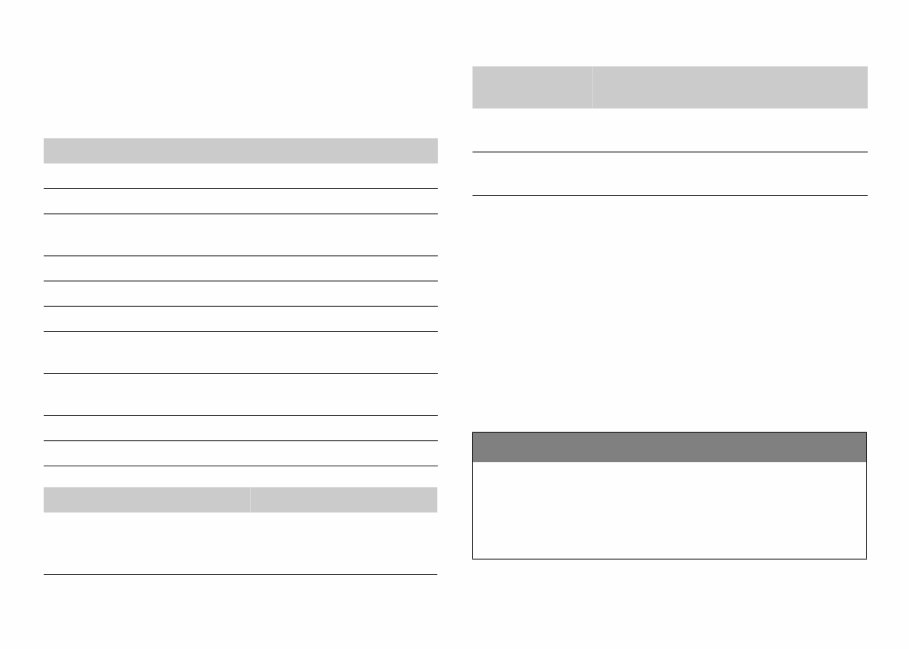

NEF 60 TE2

1. Coolant filler cap - 2. Heat exchangers - 3. Oil filler cap - 4. Engine

air inlet - 5. Common rail - 6. Lifting U-bolt - 7. Air filter - 8. Common

rail high pressure pump - 9. Fuel outlet connector to tank - 10. Fuel

filter - 11. Fuel prefilter - 12. Fuel inlet manifold from tank - 13. Oil

drainage plug - 14. Oil dipstick - 15. Engine electronic control unit

NEF 60 TE2

1. Exhaust manifold - 2. Turbocharger air inlet - 3. Turbocharging air

outlet to after-cooler - 4. Turbocharger - 5. Turbocharger exhaust

outlet - 6. Lifting U-bolt - 7. Coolant outlet to heat exchanger -

8. Thermostat valve location - 9. Radiator fan - 10. Alternator -

11. Coolant inlet sleeve from heat exchanger - 12. Oil filter -

13. Electric starter motor.

05_577_N 05_578_N

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 83 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get instant access to the Complete Factory Service Repair Workshop Manual without any extra fees or expiry dates. This Professional Manual is suitable for both professional Mechanics and DIY enthusiasts, covering all repairs, servicing, and troubleshooting procedures with step-by-step instructions, detailed photos, diagrams, and highly detailed exploded diagrams & pictures.

Print out a single page or the entire manual as per your choice. The Manual can be used on multiple computers without any limitations or trial periods and can be used for life without the need to renew or pay any extra. It is fully compatible with all Windows & MAC Computers.

Click the button to get your hands on this comprehensive manual.