Bukh Marine Diesel Lifeboat Engine type DV36 RME Owner's Handbook

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

009W4326-R08

OWNER'S HANDBOOK

FOR

BUKH MARINE DIESEL

LIFEBOAT ENGINE

TYPE DV36 RME

BUKH A/S

Aabenraavej 13 - 17

DK - 6340 Krusaa

Tel: +45 74 62 20 88

Fax: +45 74 62 74 07

E-mail: bukh@bukh.dk

www.bukh.dk

OPERATING MANUAL FOR BUKH DV36RME LIFEBOAT ENGINES

009W4326-R08

- 2 -

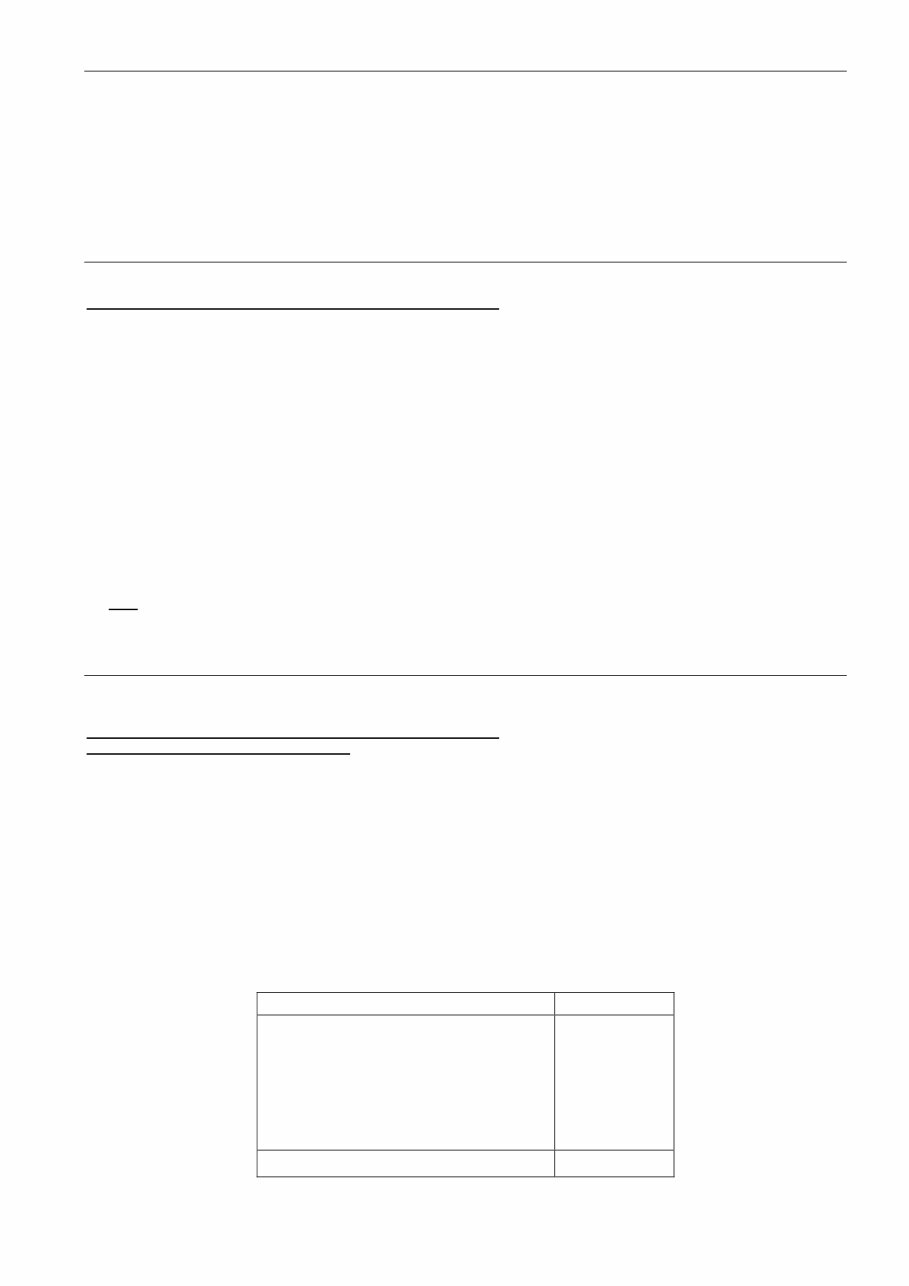

CONTENTS

Page

Pictures for recognition of engine ................................................ 3

Introduction .................................................................................. 4

Standard equipment ..................................................................... 4

Operating manual ......................................................................... 4

Preparation for the first start......................................................... 5

Before start ................................................................................... 5

Electric start ................................................................................. 5

Hand start ..................................................................................... 5

After start…………………………………………………….…… ..... 6

Maneuvering ................................................................................ 6

Stopping the engine ..................................................................... 6

Running in .................................................................................... 6

Maintenance ................................................................................. 6

Belt for alternator .......................................................................... 6

Air inlet filter ................................................................................. 6

Fuel filter....................................................................................... 6

Fuel lift pump ................................................................................ 7

Lubricating oil system................................................................... 7

Change of oil ................................................................................ 7

Recommended lubricating oil ...................................................... 7

Change of lubricating oil filter ....................................................... 7

Cooling water system ................................................................... 7

Frost precautions ......................................................................... 8

Electrical system .......................................................................... 8

Marine gear .................................................................................. 8

Starting instructions...................................................................... 8

Winter storage of the engine ........................................................ 9

Hydro – and Spring Starter ........................................................ .10

Lubricating oil quantities............................................................. .10

Instruction for Marine Diesel Fuel in cold climates .................... .10

Lubricating oil for Spray pump ................................................... .11

Technical data for engine and gearbox...................................... .12

Recommended maintenance and checklist ............................... .13

Irregular operation ...................................................................... .15

Lubricating oil chart .................................................................... .16

El-diagram (1 Battery system).................................................... .17

El-diagram (2 Batteries system) ................................................. .18

DV36 installation ........................................................................ .19

List of representatives ................................................................. 20

General Terms of Sale and Delivery .......................................... .24

OPERATING MANUAL FOR BUKH DV36RME LIFEBOAT ENGINES

009W4326-R08

- 3 -

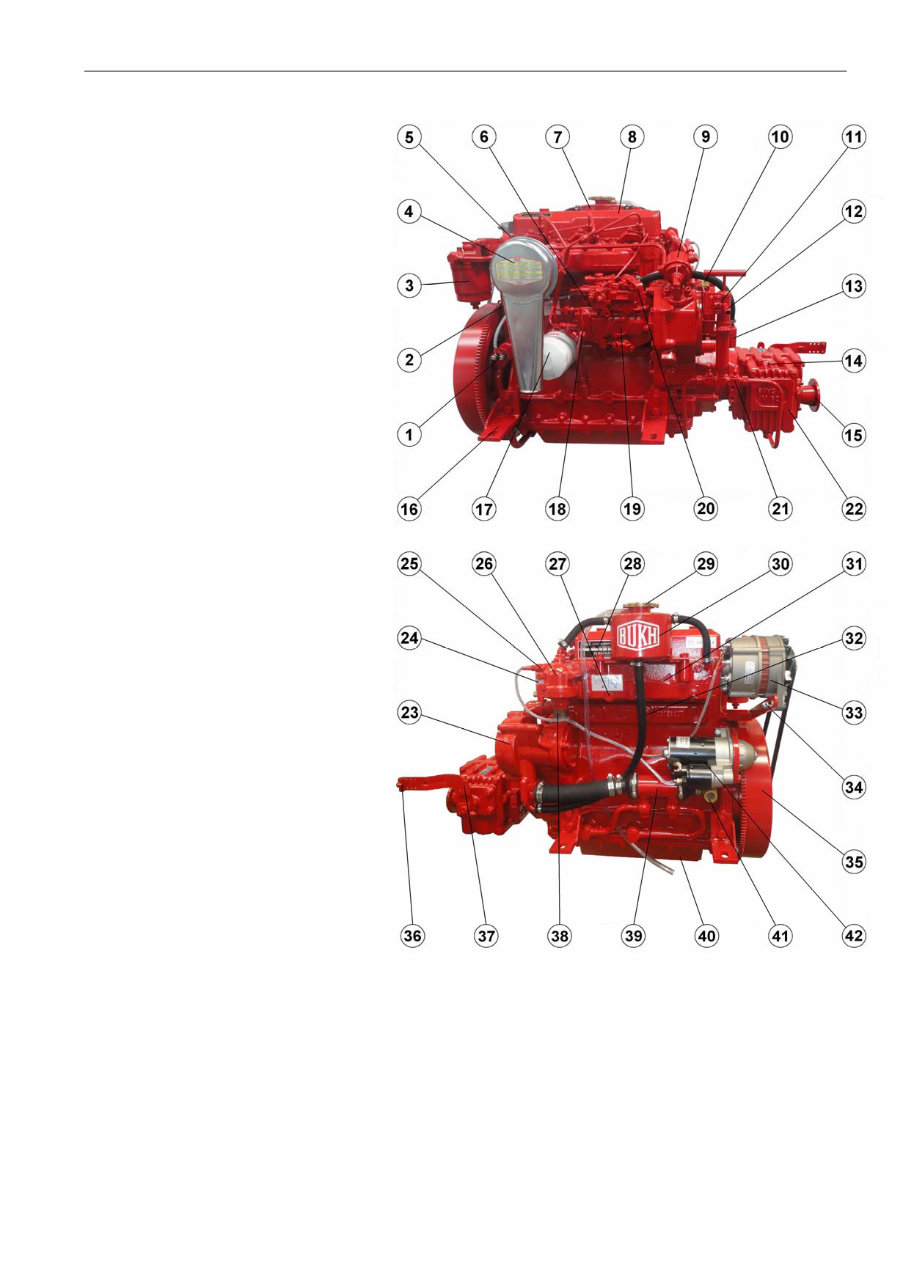

1. Oil pressure switch

2. Cooling water drain plug

3. Fuel filter

4. Air filter with noise suppression

5. Lifting fittings

6. Electric stop solenoid

7. Lubricating oil filling plug

8. Valve cover

9. Fuel lift pump

10. Electric multi plug

11. Bracket for control cable

12. Bilge pump for change of lub. oil

13. Housing for vacuum valve

14. Dip stick for gear oil

15. Coupling flange for propeller shaft

16. Reversible engine mountings

17. Lubricating oil filter

18. Dipstick for engine oil

19. Fuel pump

20. Control lever

21. Cock

22. Reverse-reduction gear

23. Cooling water circulating pump

24. Exhaust pipe connection

25. Cooling water temperature transmitter

26. Thermostat housing

27. Water drain plug for exhaust manifold

28. Identification label

29. Cooling water filling plug

30. Cooling water expansion tank

31. Water cooled exhaust manifold

32. Zinc anode

33. Alternator

34. Tension device for V-belt

35. Flywheel

36. Bracket for reversing cable

37. Reversing lever for gear

38. Outlet to keelcooler

39. Lubricating oil cooler

40. Oil pan

41. Inlet from keel cooler

42. Electric starter

OPERATING MANUAL FOR BUKH DV36RME LIFEBOAT ENGINES

009W4326-R08

- 4 -

INTRODUCTION

BASIC ENGINE CONFIGURATION:

The BUKH Lifeboat engine is a four-stroke marine diesel engine with direct fuel injection and the following basic equipment:

Crankcase with oil pan, one-piece cylinder head with 2 valves per cylinder, forged crankshaft with counterweights, balance

weights, cast iron connecting rods, light metal pistons, water-cooled exhaust manifold; all necessary pipework for exhaust,

coolant, fuel and lubricating oil are fitted on engine.

A reverse/reduction gearbox with integrated thrust bearing is fitted on the engine.

All BUKH Diesel Lifeboat Engines are tested in the factory, and a test certificate according to SOLAS and ISO regulations is

issued.

If a problem with the engine should arise, we ask you to apply to one of our distributors, who will always be ready to

help you, having skilled personnel, necessary tools etc., and at the same time you will be sure that only original BUKH spare

parts are used.

Do always use original BUKH spare parts.

When ordering spare parts from the distributor please state: Engine type and serial number, description and number of

parts.

BUKH A/S

Powering Marine Safety

As BUKH A/S is always endeavouring to improve the engines, the specifications mentioned are subject to alterations

without previous notice.

Read this instruction book thoroughly before starting your new BUKH Diesel Engine.

STANDARD EQUIPMENT for DV36RME

Reverse-reduction gear

Wet sump lubrication oil system

Full-flow lubrication oil filter

Automatic injection timing

Centrifugal governor

Keel cooling with thermostat

Watercooled exhaust manifold

Air inlet filter and silencer

Fuel lift pump

Electric start

Charging alternator

Operating remote panel with:

a) Charging light

b) Lub. oil pressure warning light

c) Cooling water temp. warning light

d) Push button for start

e) Electric stop or mechanical stop

f) Audible warning

Fittings for remote control

Standard set of tools

Drain pump for lub. oil (built on engine)

Following documentation is delivered with the engine:

1. Operating manual with sparepart katalog

2. Test certificate

3. Declaration of conformity according to SOLAS and

IMO regulations.

Flex. engine mounts (optional)

Stern gear (optional)

Raised hand start (optional)

Spring start (optional)

2 El-start (optional)

Hydro start (optional)

OPERATING MANUAL

Before the engine is put into use you are recommended to get familiar with the placing of the following components of

engine and gear:

Fuel oil filter, lub oil filter and air intake filter, fuel lift pump with handle, zincrod in the crankcase and water-separator in the

fuel pipe (if mounted).

Where is lub oil poured into engine and gear and where are the dipsticks placed? Where is fuel oil filled into the fuel tank

and where is the drain plug placed? Where is the main switch?

OPERATING MANUAL FOR BUKH DV36RME LIFEBOAT ENGINES

009W4326-R08 - 5 -

Preparation before first start

1. Pour lubricating oil through filling hole on top of valve cover.

Check that oil level is between the marks on the dipstick, placed at

the port side of the engine.

Check oil level as mentioned below:

a) remove and wipe dipstick

b) reinsert dipstick in the pipe

c) withdraw dipstick, check oil level.

2. Pour lubricating oil through dipstick hole on the top of reverse- and

reduction gear and check oil level as described in pos 1.

3. Flexible sterntube: Lubricate the stuffing box with sterntube oil

(outboard).

Unscrew the filler plug and pour in oil until the bearing is full.

Important:The stuffing box shall under no circumstances be force-

lubricated.

These instructions are only valid for propeller equipment supplied by

BUKH.

If other equipment is mounted, we refer to the instructions given

for this.

4. We always recommend checking of oil level before start.

5. Fill the fuel tank.

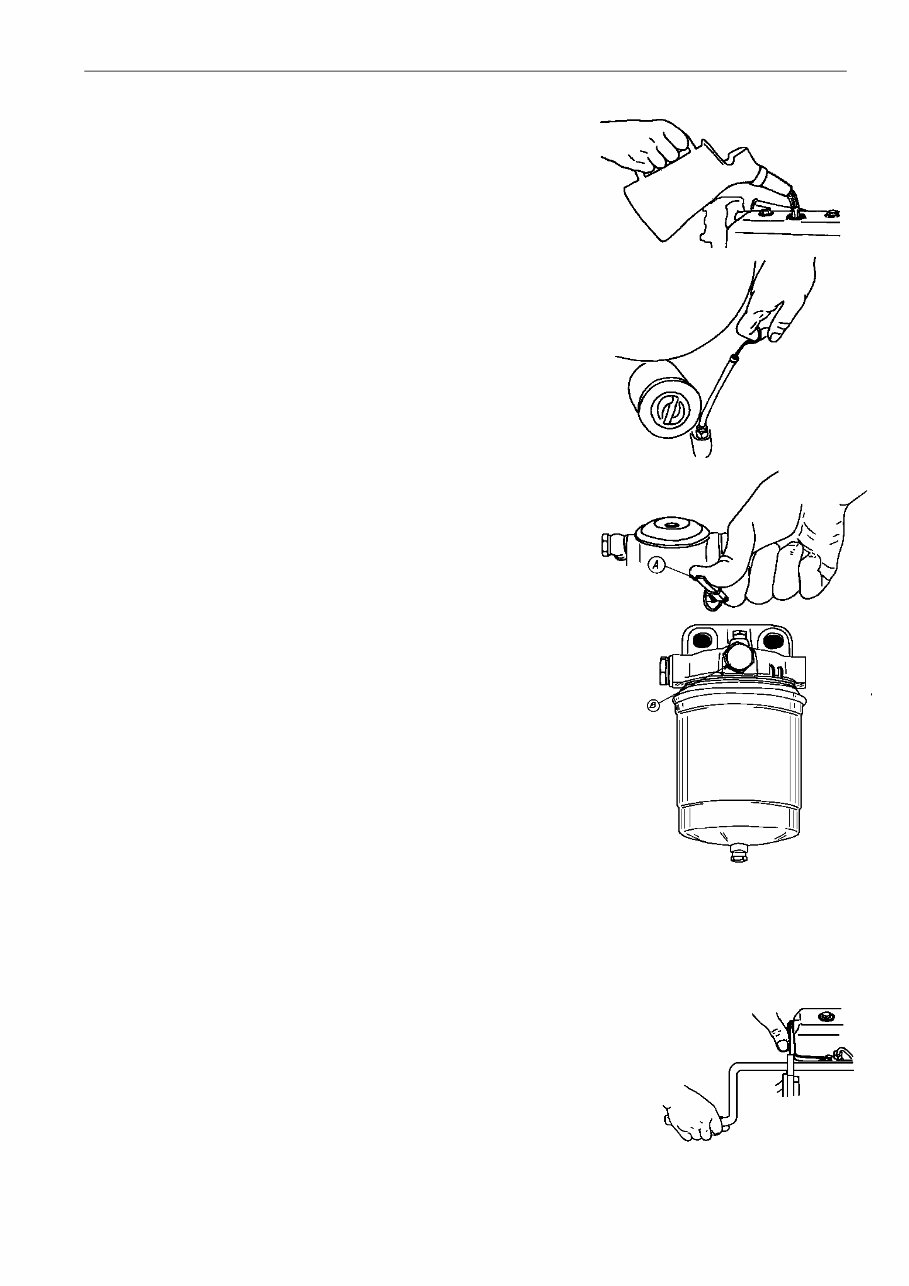

6. Bleed the fuel system in the following way:

a) Loosen the slotted screw B on the fuel filter and pump with the handle

A on the fuel lift pump until the fuel is free from air bubbles and runs

out at the slotted screw.

b) Tighten the slotted screw B and continue pumping with the handle A

until fuel, free from bubbles, runs through the transperent hose from

fuel pump to tank.

You must lock the pumping handle in the upper position when you

have finished pumping.

c) Loosen the fuel pressure pipes at their connection on the fuel valves

and turn the engine by the starter motor until fuel, free from bubbles,

runs out from the fuel pressure pipes. Finally tighten the pipes and the

engine fuel system is ready for use. This procedure must also be

followed, if the fuel tank by mischance runs out of fuel, after change of

filter and after repairs to the fuel system.

AFTER THE ENGINE HAS BEEN TAKEN INTO USE

Before start

1. The oil level of the engine should be checked every 14 days or every 25

hours of running as described in ”Preparation before first start”. It is not

necessary to refill oil if the level is between the two marks on the dipstick.

2. The oil level of the reduction gear should be checked every 14 days or every

25 hours of running as described in ”Preparation before first start”.

3. The sterntube stuffing box should be lubricated every 14 days or every 25

hours of running.

4. Check the quantity of fuel in the tank.

Electric start with remote control and instrument panel

1. Switch on the main switch.

2. Put the marine gear in neutral position by means of the control handle.

3. The engine is started by putting the switch into ”RUN” position.

4. Push the ”START” button until the engine starts. The starter should not work for more than 10-15 secs. continuously.

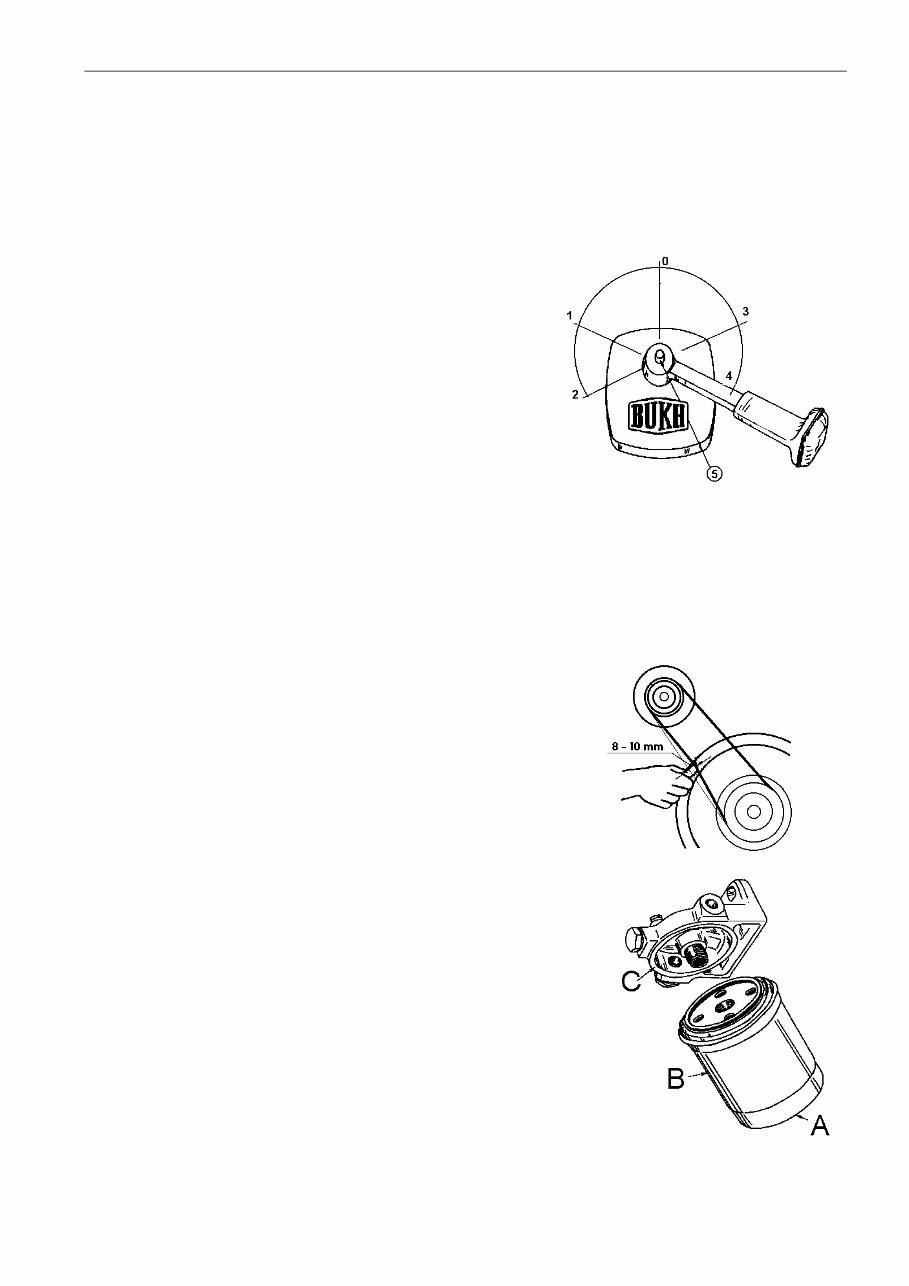

Hand start (optional)

1. Put the gear lever in neutral position.

2. Turn decompression lever on valve cover anti-clockwise as far as possible.

3. Engage starting handle and crank engine as quickly as possible. Release decom-

pression lever quickly by turning lever clockwise while cranking and engine will start.

4. By hand start in cold weather you may achieve an easier start after having cranked

the engine with activated decompression lever before the starting procedure.

Never accelerate a cold engine. Let it get warm first.

OPERATING MANUAL FOR BUKH DV36RME LIFEBOAT ENGINES

009W4326-R08 - 6 -

After Start

1. When the engine has started, the RPM should be 900-1000 RPM when idling.

2. Check the oil pressure. Normally this should be 2-4.5 bar. With cold engine the RPM should be kept down so that the oil

pressure does not exceed 4.5 bar. When idling at warm engine the oil pressure must not be below 1 bar.

3. Immediately after start the oil pressure warning lamp should go out. During normal operation the lamp should stay off.

4. Make sure that the charging control lamp goes out after the engine has started.

5. Check the cooling water temperature frequently. The temperature should be in the area of 70 – 95

o

C when engine is

warm.

Manoeuvering

1. With the control lever in central position the engine is idling, and the

marine gear is in neutral (pos. 0). When the lever is moved forward in

range 1, the marine gear is engaged to "Ahead” first, and then in range

2 the engine R.P.M. is increased. When the lever is moved from the

central position to range 3, the marine gear is engaged to "Astern”

first, and then in range 4 the engine R.P.M. is increased.

2. Only engage "Ahead” or "Astern” when the engine is idling.

3. To accelerate engine without engaging gear, operate gear release

button 5 and move control handle in either direction.

4. Increase the load gradually from idling in the course of the first 15-20

minutes shortly after the start of the engine.

Stopping the engine

1. Reduce the load gradually in the course of 15-20 minutes before stop.

2. Reduce the engine to idling and put the gear in neutral position.

3. Push the ”Stop” button (or pull the mechanical stop handle) until engine stops.

4. Move the ”Off/Run” switch to the ”Off” position.

5. Turn off the battery main switch.

Running in

To secure long life and maximum power it is recommended to run the engine for the first 25 hours at not more than 80 pct. of

the maximum output (about 3200 r.p.m.)

You should avoid slow hauling as for instance towage. After the first 25 hours it is recommended to change engine and gear

oil and to tighten up the cylinder head and to check or to possibly adjust the tension of the V-belt. Besides, it is

recommended to let an authorized service dealer go over engine and installation.

MAINTENANCE

Belt for alternator

To be adjusted every 150 hours by turning the alternator round the centres of

suspension. Tensioning should be so as to allow 8 - 10 mm deflection of the belt

under firm thumb pressure.

Air inlet filter

This is a wire gauze filter to be rinsed in petrol and cleaned by a blast of

compressed air after 300 hours' operating.

Fuel filter

A fuel filter is fitted between the fuel lift pump and the H.P. fuel pump. The filter is

a disposable one which cannot be cleaned. It should be changed every 300

operating hours or if water contamination is suspected.

Change the filter as follows:

1. Drain off the fuel from the filter by slackening drain screw A in the bottom of the

filter casing B.

2. Remove by hand or by means of a pair of tongs the filter casing and discard it.

3. Clean the sealing surface of the filter holder C if necessary.

4. Fill the new filter casing with clean fuel through the holes at the top of same.

5. Screw on the filter casing and tighten it by hand about half a turn after the

gasket fits tightly.

6. After changing the filter, bleed the fuel system as stated under ”Preparation for

first start”

OPERATING MANUAL FOR BUKH DV36RME LIFEBOAT ENGINES

009W4326-R08 - 7 -

Fuel lift pump

The fuel lift pump is a cam shaft driven sealed type diaphragm pump, which cannot be

dismantled for repair or cleaning. It is recommended to install a water/dirt accumulating

filter in the suction line to the pump.

After repairs the fuel system must be bled as described under ”Preparation for the first

start” if necessary.

Lubricating Oil System

The engine is pressure lubricated and the oil system has a built-in relief valve for

controlling the oil pressure. A lubricating oil cooler is also fitted.

The oil level is checked as mentioned before.

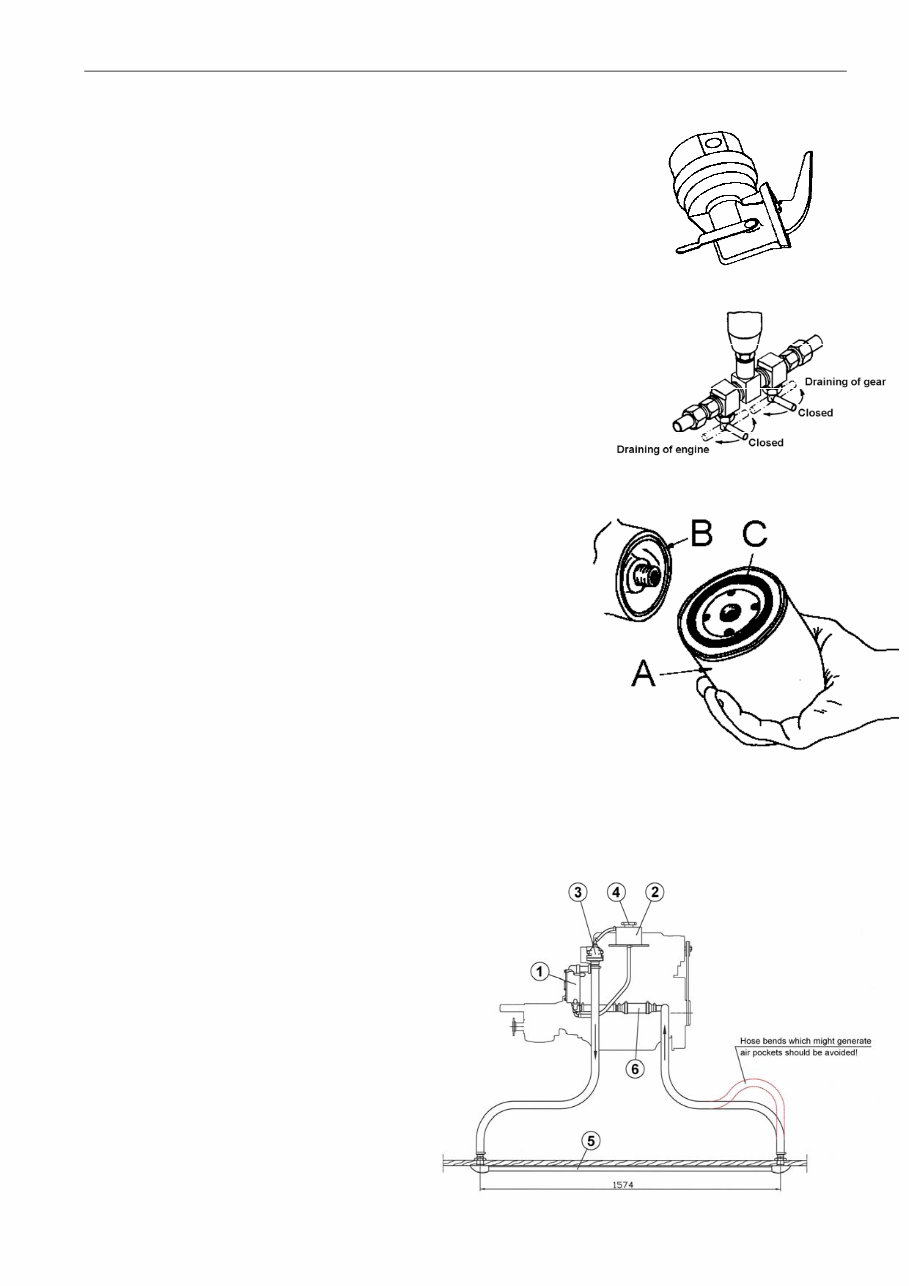

Change of Oil

Lubricating oil should be changed for the first time after 25 hours of running,

later for every 150 hours or at least once a year. It is recommended to chan-

ge the oil when engine is warm, and the procedure is as follows:

1. Turn the left cock below oil bilge pump 90°.

2. Pump up the oil from the sump by means of the bilge pump.

3. When the sump is empty pour fresh oil.

4. Check oil level on dipstick.

Recommended Lubricating Oil

Modern diesel engines demand heavy-duty oils with additives securing best

operation conditions and longest life time of the engine under various conditions.

Therefore use a first class HD-oil from a recognized oil company.

Oil specifications as mentioned in ”LUBRICATION OIL CHART”.

When operating under difficult conditions, i.e. frequent cold starting, short

operation periods, greatly varying loads, use quality ”Service CD” and also

use quality "Service CD" in case the sulphur content of fuel is higher than 1

%.

Change of Lubricating Oil Filter

Lubricating oil filter cannot be cleaned, but should be changed every 150

hours or once a year. To change the filter proceed as follows :

1. Unscrew filter A and discard it.

2. Clean the sealing surface of the engine B, and remove old gasket C if

any from old filter

3. Mount new filter at once under clean conditions.

4. Screw on filter until gasket fits tightly, tighten a further half turn.

5. Fill with oil until normal level is reached.

6. Start the engine and check that the filter is tight.

Cooling system (Keel cooling)

A pump circulates the freshwater in a closed system.This circulation pump is fitted on the rear end of the engine.

The freshwater circulates through the cooling jackets of the engine and through the keel cooler, fitted on the bottom of the boat.

Too high cooling temperature will cause the blue lamp in the control panel to light up and the acoustic alarm to function.

1. Cirkulating pump

2. Expansion tank

3. Thermostat 75

o

C

4. Pressure cap

5. Keel cooling pipe 2 x ø22/ø19 copper pipe

6. Oil cooler

OPERATING MANUAL FOR BUKH DV36RME LIFEBOAT ENGINES

009W4326-R08 - 8 -

Frost precautions

As protection against corrosion and to secure the cooling water freezing temperature to min. minus 15° Celsius as per

IMO/SOLAS requirement or lower if required from climate conditions, It is recommended to use a mixture of min. 30%

antifreeze liquid and 70% water and max. 50% antifreeze and 50% water.

However please also note when doing service on lifeboats that the mix of water and antifreeze can get aggressive and

start corrosion. If corrosion is found in the cooling system it can be caused by one of two conditions:

1. The anti corrosion additives in the anti freezing liquid are exhausted and have evaporated.

2. Oxidation due to incoming air causing an acid which is lowering the PH value.

Therefore and also to keep the anti freezing properties it is recommended to change the cooling water and antifreeze

every 3 years min. Please also note the details provided by your supplier of antifreeze liquid normally stated on the can.

Electrical System

The engine is equipped with a 12 volt electrical system consisting of a starter motor and an alternator, the max. charging

current of which is 50 Amp.

Electrical wiring diagram for the engine with control and instrument panels is shown later in this instruction.

The battery must never be isolated from the alternator, when the engine is running.

Warning! It is not allowed to connect additional equipment to the wiring system on the engine. Possible additional

equipment has to be connected directly to the terminals of the battery.

NOTE!

The starter must not be operated for more than 10 sec. If further operation is necessary, a pause of at least half a minute

before starting attempt is repeated.

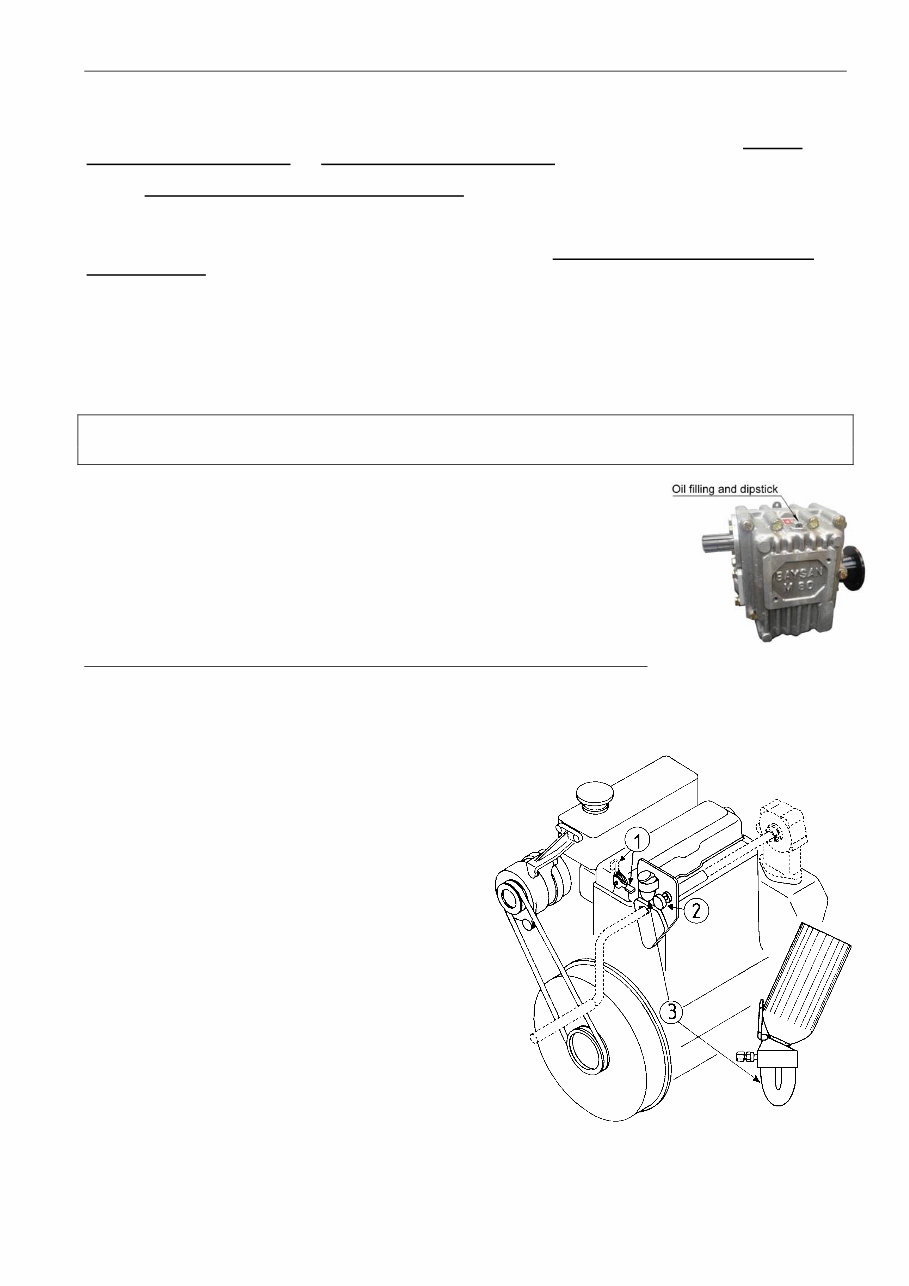

Marine Gear

The engine is equipped with a reverse-reduction gear. The standard reduction is 2.94:1 for

AHEAD and 1.95:1 for REVERSE (but also available as 2.63:1 for special purposes).

The marine gear will need no other attendance than regular change of oil. This to be carried

out after 25 hours of operation, and then every 250 hours or once a year.

Oil quality: "Automatic Transmission Fluid” (ATF).

The oil change is carried out by means of the lubricating oil bilge pump fitted on the engine.

The oil should be warm when draining.

Refill new oil to the quantity of 0.5 liters through the dipstick hole.

Check oil level on the dipstick.

Don’t forget to close the cock before starting up.

Starting instructions for BUKH Diesel Engine type DV36RME

Electric start:

1. Switch on the main switch.

2. Put the gear in neutral position

3. Put the switch into ”RUN” position

4. Push the ”START” button until the engine starts

Cold Start (below minus 15

o

C if mounted):

Start pilot: Pull and push the pump (2) 2-3 times.

Stopping the engine: Push the ”STOP” button until the

engine stops.

After the engine has stopped:Put the switch in ”OFF”

position.

Filling the pressure tank (3) (if mounted):

1. Open the cover.

2. Put the gas cylinder on top of the valve and fill up the

tank to max. marking.

Hand Start: (If mounted):

Put gear into neutral position.

Put handle into crank claw.

Lift decompression lever (1).

Cold start with hand start (below 0

o

C).

Start pilot: Pos 1 – 2 - 3

Pull and push the pump (2) 2-3 times.

Turn the start handle as quickly as possible (clockwise), release the decompression lever, but keep on turning until the

engine starts.

OPERATING MANUAL FOR BUKH DV36RME LIFEBOAT ENGINES

009W4326-R08 - 9 -

WINTER STORAGE OF THE ENGINE

1. Carry out the following whilst the boat is still in the water:

1. Run the engine until normal workingtemperature is reached.

2. Drain off engine and gear oil with the oil bilge pump.

3. Fill the engine and gearbox with preservative lubricating oil of a recognized make up to the upper mark on the dipstick.

4. Fill the fuel tank with fuel preservative oil in the rate of mixture prescribed by the oil manufacturer.

5. Start the engine and let it run for about 10 minutes to be sure that the fuel mixed with preservative oil has been flushed

through the fuel system of the engine.

6. Fill the fuel tank completely with fuel. Pay no special attention to the preservative oil previously added to the fuel as this

is consumed normally and properly when service is resumed in spring.

2. On land the following procedure has to be carried out:

1. Remove the engine cooling water drain plugs, drain off the sea water from the engine and refit plugs.

2. For direct sea water cooled engines: Remove the suction hose from the cooling water pump at the bottom cock and put

the hose into a bucket with freshwater containing preservative oil in the rate of mixture prescribed by the oil

manufacturer

3. The outlet hose for the cooling water which goes into the exhaust elbow may be removed and returned to the bucket via

a length of hose so that the freshwater is able to circulate.Start the engine and the freshwater containing preservative oil

will be flushed through the engine.

4. Stop the engine after 5 - 10 minutes and drain off the water. Ensure that after removing the drain plug (1 plug is placed

in the block, see page 3, pos. 6; and 1 plug in the exhaust manifold) all the water is drained off. This is done by cleaning

the drain holes with a nail,a steel wire or the like, so that any remaining water may drain out. Remove the impeller from

the cooling water pump, which will allow water in pump and pipes to be drained off. Keep the impeller separately in a

dry place during the winter.

4A. For freshwater-cooled engines: Drain the freshwater from the engine by removing the plugs as indicated for seawater

cooled engines.It is not necessary to flush this system with freshwater containing preservative oil. If the engine is to be

used in period of frost, it must be protected against frost burst with a mixture of anti-freeze solution in the freshwater

system - irrespective of the protection to the freshwater system against the risk of frost - by removing the cover of the

impeller pump and turning the engine manually or with the starter motor.

5. Remove the battery and store it separately during the winther in a dry and frost-free place. Fill up and charge the battery

before storing.

6. Remove the air filter and turn the engine manually until each inlet valve opens alternately, during which about 50 mL of

preservative oil is injected into each piston head. Turn the engine backwards and forwards manually in order to spread

the preservative oil.

7. Insert a clean, oil moistened rag (not cotton waste) into the inlet manifold.

8. Insert another clean, oil moisted rag into the exhaustelbow aperture.

9. Treat electrical connections with grease free from acid. Fill the multiple plugs with grease from the wire side.

The engine is now preserved for winther storage and can be futher protected by covering of polythen sheeting, under

which a bucket of silicagel should be placed.

3. Preparation of engine before launching.

1. Remove the oil moisted rags from the inlet manifold and the aperture of the exhaust elbow.

2. Fit the cooling water pump impeller.

3. Fit cooling water drain plugs.

4. Drain the preservative lubricating oil from both engine and gearbox and fill up with fresh oil to the upper mark of the

dipstick.

5. Change the lubricating oil filter.

6. Make sure - before starting up - that the oil on the piston heads is drained off. This is checked by turning the engine

manually without operating the decompression lever.

7. Examine the stern tube stuffing box and fill up with stern tube oil.

8. Fit the battery after re-charging.

9. Lubricate all moveable parts with oil.

10. Check the anode.

11. Check that there is electrical contact at the sterntube at the internal connection to thegearbox.

OPERATING MANUAL FOR BUKH DV36RME LIFEBOAT ENGINES

009W4326-R08 - 10 -

RME-ENGINES MOUNTED WITH HYDRO- OR SPRING STARTER EQUIPMENT (service info 9201)

The above mentioned type of starting method has proved to start the lifeboat engines in a very short period of time. In cold

climates a standard multigrade lubrication oil may not be sufficient for a rapid build-up of lub. oil pressure. We recommend

the following methods to prevent problems:

1. Full synthetic low friction lub. oil with a viscosity of 5W/40 or 10W/30 (e.g. Mobil No. 1 or Castrol Syntruck).

2. Cooling water jacket heater.

3. Oil sump heater.

In view of starting time the above points also increase the electrical start performance.

LUBRICATION OIL QUANTITIES FOR DV36RME AND DV48RME (service info 0202)

When the engine is dry, you are recommended to fill up with 4.9 litres of lubricating oil (min. 4.3 litres - max. 5.5 litres).

A dip stick with standard indications of minimum (63 mm) and maximum (75 mm) oil levels for checking of the oil quantity is

located on the side of the engine.

THESE INDICATIONS APPLY WHEN THE ENGINE IS IN HORIZONTAL POSITION!

When mounted in a lifeboat, the engine is rarely in a horizontal position. Usually, it has an aft inclination of max. 15

o

, which

will change the oil level on the dip stick.

The following values are intended as a guide:

Oil level when 4.9 litres of oil have been added to the engine:

Horizontal engine: Oil level on dipstick= 69 mm

Engine inclination 15

o

aft: Oil level on dipstick= 61 mm

Engine inclination 30

o

forward: Oil level on dipstick= 60 mm

Irrespective of the inclination, engine running will be troublefree if the above oil quantity has been added. If more oil than

advised is added, the crank will be running submerged in oil. Consequently, the oil will get too warm and foam, and bleeding

will be inadequate.

Oil vapour will condense and in extreme cases run out of the suction filter.

Do NOT fill the engine with more oil than indicated above.

It will not be necessary to adjust the oil quantity of freefall boats, in which the engine will

be started while the boat is still in the chute at an inclination of approx 30°.

INSTRUCTION FOR MARINE DIESEL FUEL IN COLD CLIMATES

COLD FILTER PLUGGING POINT (CFPP) (service info 0502)

To ensure proper operation of the lifeboat engines in very cold climates, it is essential to ensure that the diesel fuel in the

fuel tank of the lifeboat is suitable to the lowest temperature possible in the area of operation of the ship. The temperature

where the fuel is no more filterable is called "CFPP" in the specifications for the particular fuel

To improve the CFPP-point, a dilution with kerosene is recommended. A max. dilution of 40% kerosene is possible. If 50%

or more are necessary, 2-stroke lubricating oil must be added to protect the fuel injection pump and nozzles from seizure.

If no information is available onboard the ship about the particular fuel to be diluted, it is recommended to use 2-stroke

lubricating oil in ratio 0.3 ltrs. to 100 ltrs. of fuel. This is necessary due to the fact that the diesel oil might be winter-type and

already diluted from the oil company.

The reason for the necessity of 2-stroke lub. oil is that it is self-mixing with the fuel.

Note: In ship storage tanks a max. of 25% dilution is the limit, in order to ensure that min. flame point of fuel = 55°C.

For operation below -28°C use specific Arctic fuel.

EXAMPLE:

Diesel Oil without Dilution CFPP/-18

o

C

90 litres diesel + 10 litres kerosene

80 litres diesel + 20 litres kerosene

70 litres diesel + 30 litres kerosene

60 litres diesel + 40 litres kerosene

50 litres diesel + 50 litres kerosene

-20°C

-22°C

-24°C

-26°C

-28°C

Specific Arctic fuel -40°C

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

Viewed 84 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

The Bukh Marine Diesel Lifeboat Engine type DV36 RME Owner's Handbook & Maintenance Manual is a comprehensive guide available in digital format. It contains all the necessary information for engine maintenance, making it useful for both professional mechanics and DIY enthusiasts. Whether you're looking to maximize engine performance or ensure smooth operation, this manual has you covered.