BETA Marine OPERATOR Maintenance Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

CALIFORNIA – Proposition 65 Warning: Diesel engine exhaust and some of its constituents are known

to the state of California to cause cancer, birth defects and other reproductive harm.

Operator’s

Maintenance

Manual

Heat Exchanger Cooled

Mid Diesel Engine Range

Beta 43, Beta 50 & Beta 60

Operator’s

Maintenance

Manual

Heat Exchanger Cooled

Mid Diesel Engine Range

Beta 43, Beta 50 & Beta 60

Downloaded from www.Manualslib.com manuals search engine

Engine Details

IMPORTANT - Please fill in details at moment of purchase - it really will

help you! (and it will really help us specify the correct spare parts for you).

Engine Type: Power: bhp Speed: rpm

BETA WOC NO:

K

Gearbox Type:

Purchased From:

Invoice No.:

Date Commissioned:

Specification / Special Details:

Downloaded from www.Manualslib.com manuals search engine

1

My engine details (to be completed now) Inside front cover

Introduction

Engine identification 2

Initial receipt of the engine 2

Engine storage 2

Safety precautions 3

Technical specifications 4

Section 1: Installation guidelines

Engine mounting 5

Engine alignment - drives, flanges, flexible couplings 6

Exhausts and mounting exhausts 7

Fuel supply and "leak off" 8

Cooling - sea water inlet system 9

Calorifier connections (if fitted) 9

Electrical Installation 10

Section 2: Guidelines for operation of the engine

Important checks prior to initial use 11

Initial start-up and bleeding the fuel system 11

Starting and stopping 13

Section 3: Maintenance & Service guidelines

Maintenance schedule 14

Lubrication - checking and changing oil 16

Fuel system - fuel/water separator, fuel lift pump, fuel filter 18

Cooling - fresh water system, heat exchanger 19

Sea water pump, heat exchanger 20

Belt tensioning adjustment 21

Air filter inspection / replacement 22

Electrical maintenance 22

Laying up - winterising 23

Troubleshooting 24

Torque settings 34

Wiring diagrams and general arrangement drawings index 35

Exhaust Emission - Declaration of Conformity 61

Exhaust Emission - Durability 62

Fast Moving Parts Listing 63

Maintenance record Inside back cover

Contents

Downloaded from www.Manualslib.com manuals search engine

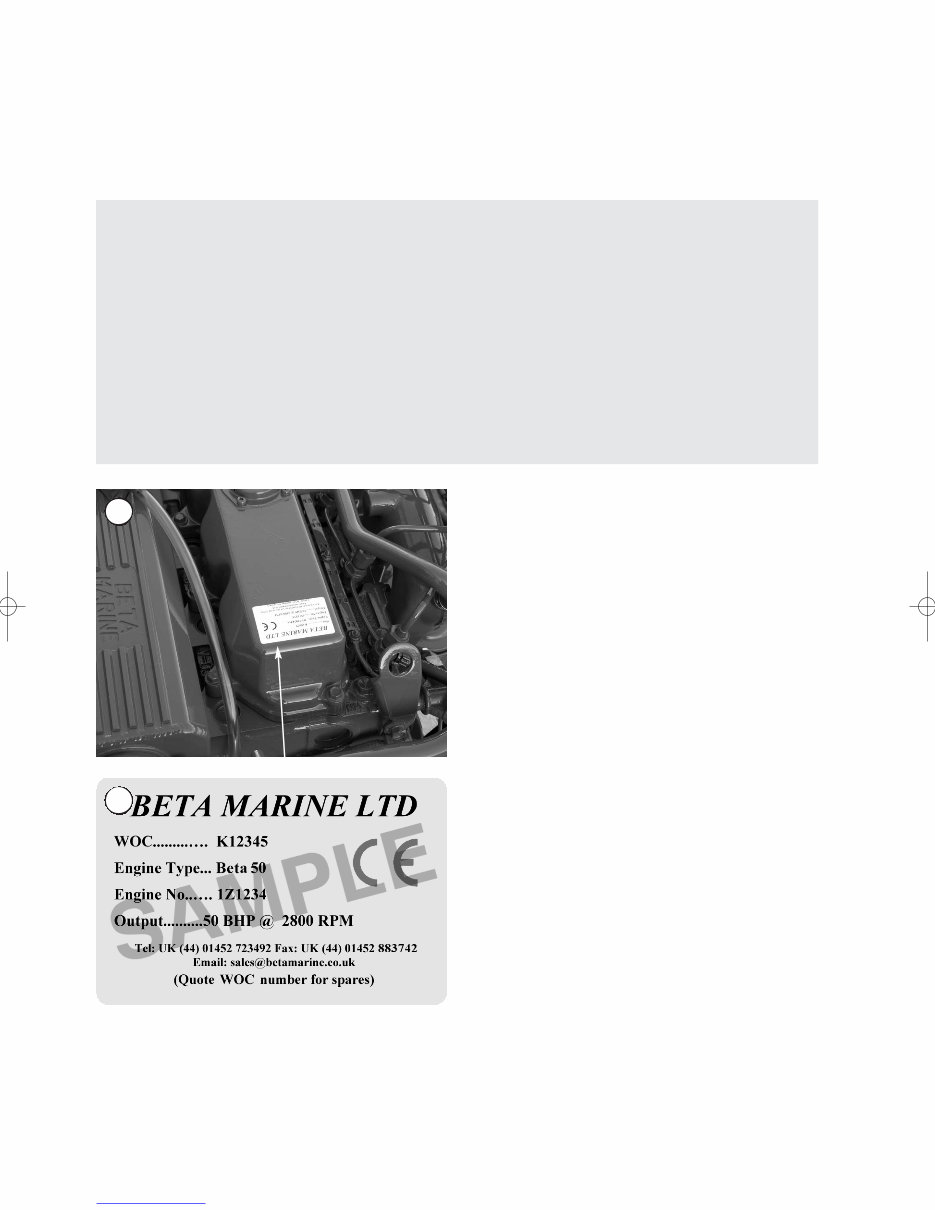

Engine Identification

NOTE: In all communications with the

distributor or Beta Marine, the W.O.C.

and engine number must be quoted.

Beta 43, Beta 50 and Beta 60

The engine serial number is stamped above starter motor on

the port side of the engine, and is shown on the rocker cover

label.

Initial Receipt of the Engine

A full inspection of the engine must be made immediately

on delivery to confirm that there is no damage. If there is

any damage then write this clearly on the delivery note and

inform your dealer or Beta Marine within 24 hours. A

photograph would always help.

Engine Storage

The engine must be stored in a dry, frost free area and this is

best done in its packing case. If storage is to be more than

six months then the engine must be inhibited (contact your

dealer or Beta Marine). Failure to inhibit the engine may

result in the formation of rust in the injection system and the

engine bores, this could invalidate the warranty.

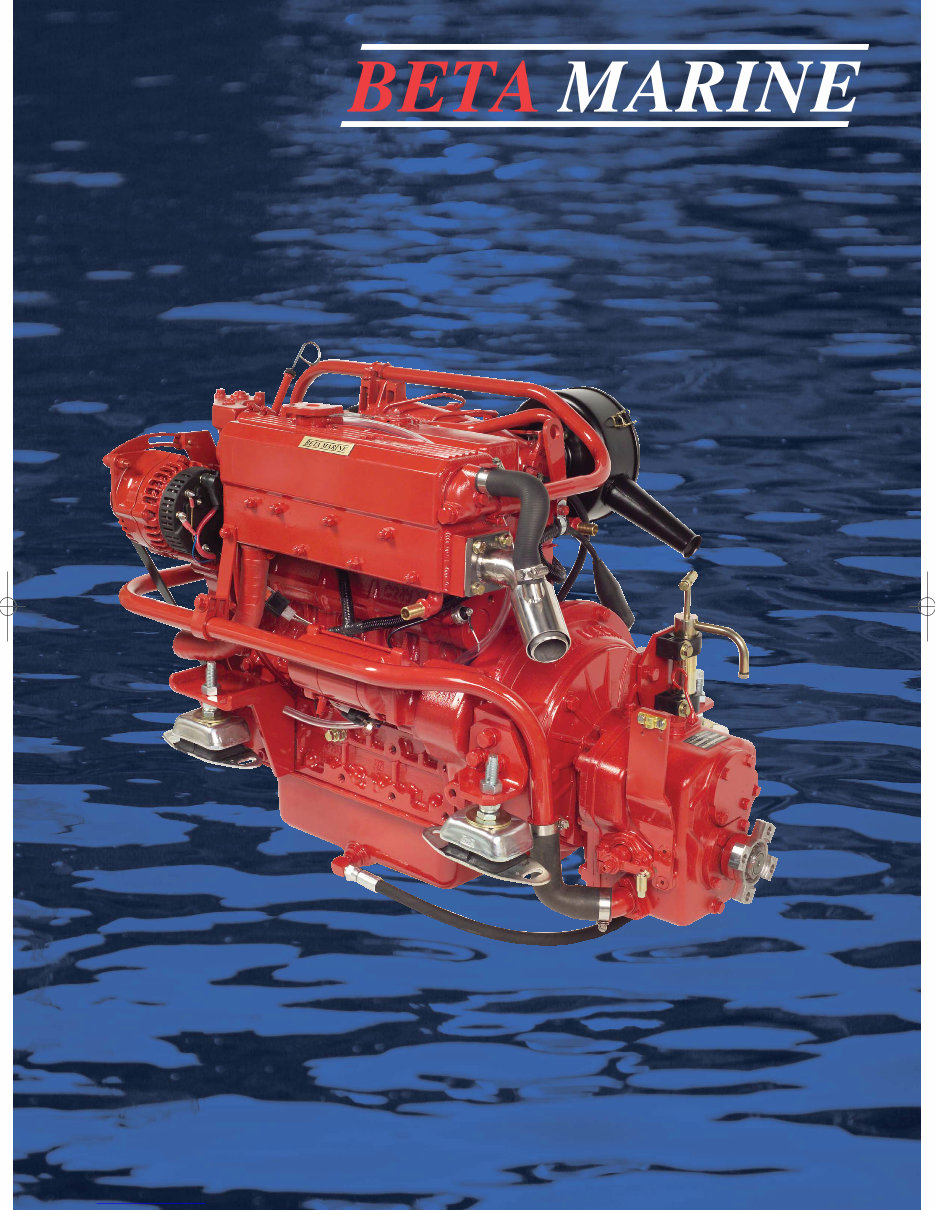

OPERATION AND MAINTENANCE MANUAL FOR THE FOLLOWING

BETA MARINE ENGINES BASED ON KUBOTA SERIES

Beta 43, Beta 50 & Beta 60

2

1

2

This manual has been compiled to provide the user with important information and recommendations to ensure trouble free

and economical operation of the engine.

As manufacturers we have obviously written this “Operators Maintenance Manual’ from our ‘involved technical viewpoint’

assuming a certain amount of understanding of marine engineering. We wish to help you, so if you do not fully understand

any phrase or terminology or require any explanations please contact Beta Marine Limited or its distributors and we will be

pleased to provide further advice or technical assistance.

All information and recommendations given in this publication are based on the latest information available at the time of

publication, and are subject to alteration at any time.

The information given is subject to the company’s current conditions of Tender and Sale, is for the assistance of users, and

is based upon results obtained from tests carried out at the place of manufacture and in vessels used for development

purposes. We do not guarantee the same results will be obtained elsewhere under different conditions.

Downloaded from www.Manualslib.com manuals search engine

3

A Keep the engine, gearbox and surrounding area clean,

including the area immediately below the engine

B Drives - Power Take Off Areas

i) Gearbox Output Flange

The purpose of a marine diesel propulsion engine is to

provide motive power to propel a vessel. Accordingly the

gearbox output shaft rotates at between 280 and 2400

rev/min. This flange is designed to be coupled to a

propeller shaft by the installer and steps must be taken to

ensure adequate guarding.

ii) Forward End Drive

Engines are supplied with unguarded belt drives to power

the fresh water pump and battery charging alternator.

The installer must ensure that it is not possible for injury

to occur by allowing access to this area of the engine.

The three pulleys run at high speed and can cause injury

if personnel or clothing come in contact with the belts or

pulleys, when the engine is running.

iii) Power Take Off Shaft (Engine Mounted Option)

Shaft extensions are available as an option and rotate at

between 850 and 3600 rev/min. If contact is made with

this shaft when the engine is running, injury can occur.

C Exhaust Outlet

Diesel marine propulsion engines emit exhaust gases at

very high temperatures - around 400 - 500°C. Engines

are supplied with either wet exhaust outlet (water

injection bend) or dry outlet (dry exhaust stub) - see

option list. At the outlet next to the heat exchanger /

header tank, the exhaust outlet can become very hot and

if touched, can injure. This must be lagged or avoided by

ensuring adequate guarding. It is the responsibility of the

installer to lag the exhaust system if a dry system is used.

Exhaust gases are harmful if ingested, the installer must

therefore ensure that exhaust lines are led overboard and

that leakage in the vessel does not occur.

D Fuel

i) Fuel Lines

Diesel engines are equipped with high pressure fuel

injection pumps, if leakages occur, or if pipes fracture,

fuel at a high pressure can harm personnel. Skin must be

thoroughly cleaned in the event of contact with diesel

fuel.

ii) Fuel Supply Connections

Engines are supplied with 8mm compression fittings. The

installer must ensure that when connections are made,

they are clean and free of leaks.

E Oil

The Beta propulsion unit is supplied with 2 dipsticks, one

for the engine and one for the gearbox. Ensure dipsticks

are returned and secure after checking, if not oil leaks can

cause infection when touched. All oil must be removed

from the skin to prevent infection.

F Scalding

An engine running under load will have a closed circuit

fresh water temperature of 85° to 95°C. The pressure

cap on the top of the heat exchanger must not be

removed when the engine is running. It can only be

removed when the engine is stopped and has cooled

down.

G Transportation / Lifting

Engines are supplied on transportable pallets. Lifting eyes

on engines are used for lifting engine and gearbox

assembly only, not the pallet and associated kit.

GENERAL DECLARATION

This machinery is not intended to be put into service until it

has been incorporated into or with other machinery. It is the

responsibility of the purchaser / installer / owner, to ensure

that the machinery is properly guarded and that all necessary

health and safety requirements, in accordance with the laws

of the relevant country, are met before it is put into service.

Signed:

J A Growcoot, C.E.O,

Beta Marine Limited

NOTE: Recreational Craft

Where applicable, the purchaser / installer / owner and

operator must be responsible for making sure that the

Recreational Craft Directive 94/25/EC is complied with.

Safety Precautions!

Downloaded from www.Manualslib.com manuals search engine

Maximum Angle of Installation: Trim 15°; Roll 25° (intermittent) or 20° continuous, see page 6.

Rotation: Anti-clockwise on flywheel, clockwise on output gearbox flange for use with right hand propeller in ahead, on

mechanical gearboxes. Hydraulic gearboxes can be left or right handed. Diesel fuel must conform to BS2869-1970 class A1

or A2. The fuel must be a distillate and not a residual oil or blend.

Lubricant:

Engine - engine oil must meet API Classification CF (CD or CE), See section 2 for details

Gearbox - see gearbox operator’s manual for the gearbox oil type and capacity

Oil pressure - minimum (tickover) 0.5 bar

Power outputs: These comply with BS EN ISO 8665:1996 crankshaft power

Note: Declared Powers to ISO8665:1996

1. The declared powers are at the same engine speed as the ISO 3046 figures. This speed is the speed related to the

outputs / powers shown.

2. Declared powers are at the gearbox coupling (coupling to the propeller shaft) as per clause 3.2.1 with standard

specifications as per our current price lists. Additional accessories or alternative gearboxes may affect the declared powers.

3. Operation at parameters outside the test parameters may affect the outputs / powers which in any case are subject to the

ISO tolerance bands.

Standard Engines Beta 43 Beta 50 Beta 60

Cylinder 4 4 4

Bore (mm) 83 87 87

Stroke (mm) 92.4 92.4 102.4

Displacement (cc) 1999 2197 2434

Combustion 3 Vortex 3 Vortex 3 Vortex

Cooling Water Water Water

Starter voltage (V) 12 12 12

Starter output (kW) 1.4 1.4 2.0

Starter alternator output (Amps) 65 (standard) 65 (standard) 65 (standard)

Glow plug resistance (each) 1Ω 1Ω 1Ω

Engine speed (RPM) 2,800 2,800 2,700

Power output to ISO3046 (BHP) 43.0 50.0 56.0

Declared power ISO8665 (kW) 31.0 36.1 40.6

Compression Ratio 23.0:1 23.0:1 23.0:1

Fuel timing BTDC 18° 18° 18°

Capacity of standard sump approx. (litres) 9.5 9.5 9.5

Capacity of shallow sump approx. (litres) 7.0 7.0 7.0

Nett dry weight with gearbox (kg) 270 300 310

Fuel Diesel fuel oil No.2D

Coolant 33%-50% maximum antifreeze:water

Coolant capacity approx.. (H/E litres) 7.4 7.4 7.4

Min. recommended battery capacity 12V, 120Ah (600 CCA Min)

4

Technical Specifications

Downloaded from www.Manualslib.com manuals search engine

5

Installation Recommendations

The installation details are basic guidelines to assist installation, however due to the great diversity of marine craft it is

impossible to give definitive instructions. Therefore Beta Marine can accept no responsibility for any damage or injury incurred

during the installation of a Beta Marine Engine whilst following these guidelines.

Engine Mounting

To ensure vibration free operation, the engine must be

installed and correctly aligned on substantial beds, extending

as far forward and aft as possible, well braced and securely

fastened to form an integral part of the hull.

The engine must be installed as low as possible on the

flexible mount pillar stud. This will limit vibration and extend

the life of the flexible mount. To assist with engine

replacement we offer ‘Special Engine Feet’ manufactured to

your dimensions, as an optional extra to suit your existing

engine bearers and shaft alignment/installation.

Warning

(1) Do not set the engine feet high up the flexible mount

pillar stud. This will cause excessive engine movement

and vibration. Pack under the flexible mount with steel

shims securely bolted into the engine bearer.

(2) The pillar stud on the flexible mount is secured into

position by the lower locknut, do not forget to tighten

this. Also ensure that the stud is not screwed too far

through the mounting body so that it can touch the

bearer. This will cause vibration and knocking noises

which are very hard to find!

Section 1

Flexible Output Couplings

A flexible coupling should be mounted on the gearbox output

flange and is strongly recommended in almost every case.

Flexible couplings do not accommodate bad alignment, they

are designed to absorb torsional vibrations from the propeller

(transmitted along the propeller shaft).

3

• All engines shall be placed within an enclosure separated

from living quarters and installed so as to minimise the

risk of fires or spread of fires as well as hazards from toxic

fumes, heat, noise or vibrations in the living quarters.

• Unless the engine is protected by a cover or its own

enclosure, exposed moving or hot parts of the engine that

could cause personal injury shall be effectively shielded.

• Engine parts and accessories that require frequent

inspection and / or servicing must be readily accessible.

• The insulating materials inside engine spaces shall be

non-combustible.

• Adequate ventilation must be included with every engine

installation. It is very important that the engine

compartment is ventilated, as the engine will produce

radiated heat - approximately equal to

1

/

3

of the engine

output power. Also the 65 and/or 100 amp battery

charging alternator/s create lots of heat. In yachts we

recommend forced ventilation using an extraction fan to

draw out the hot air and limit the maximum engine

compartment /room temperature to 60°C. This can be

checked with a thermometer on a hot day - the cooler the

engine compartment the better. A symptom of overheating

problems is black belt dust. It is normally best with two

ventilation holes; an inlet of at least 300 cm

2

allowing

colder air to enter near to the alternator and drive belts

and a second outlet (a third bigger than the inlet) for the

hot air to rise and ventilate out from the top of the engine

compartment using the cooling fan.

Downloaded from www.Manualslib.com manuals search engine

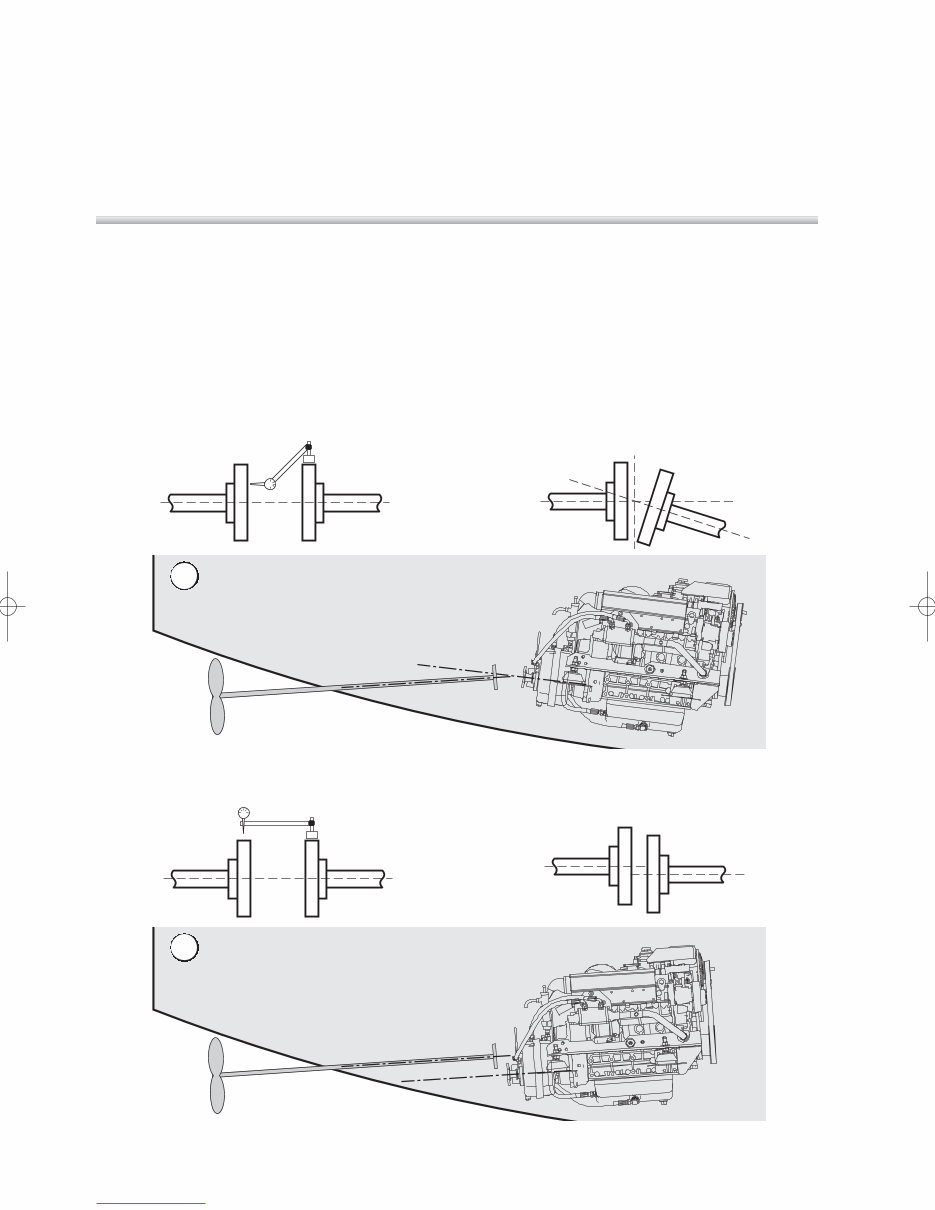

4 Angular Mis-alignment

Angular Mis-alignment

Engine / gearbox

flange

Propeller

shaft

Alignment

To obtain accurate alignment the flexible mountings must be

adjusted until alignment is attained, and the mountings must

be locked in position.

The engine/gearbox unit has to be aligned with the propeller

shaft in two ways. The traditional engine alignment method

involves measuring with either feeler gauges or a DTI (Dial

Test Indicator) mounted on a magnetic foot so that they are

aligned within 0.125mm (0.005”).

The engine mountings and the couplings must now be tightened in position and the alignment re-checked.

6

Engine Installation at an Angle

Beta Marine propulsion engines can be installed at angles up

to a maximum of 15° flywheel up or flywheel down when

static, or can be run at up to 25° when heeling. When our

engines are installed at varying angles of inclination the

normal markings on the dipstick should be disregarded.

It is probably better to totally drain the lubricating oil from the

sump, replacing the oil filter with a new one; then add the

recommended amount of lubricating oil – noting its position

on the dipstick – and then marking the dipstick. If in doubt

ask Beta Marine.

Angular Alignment

5 Parallel Mis-alignment

Parallel Mis-alignment

Engine / gearbox

flange

Propeller

shaft

Parallel Alignment

Downloaded from www.Manualslib.com manuals search engine

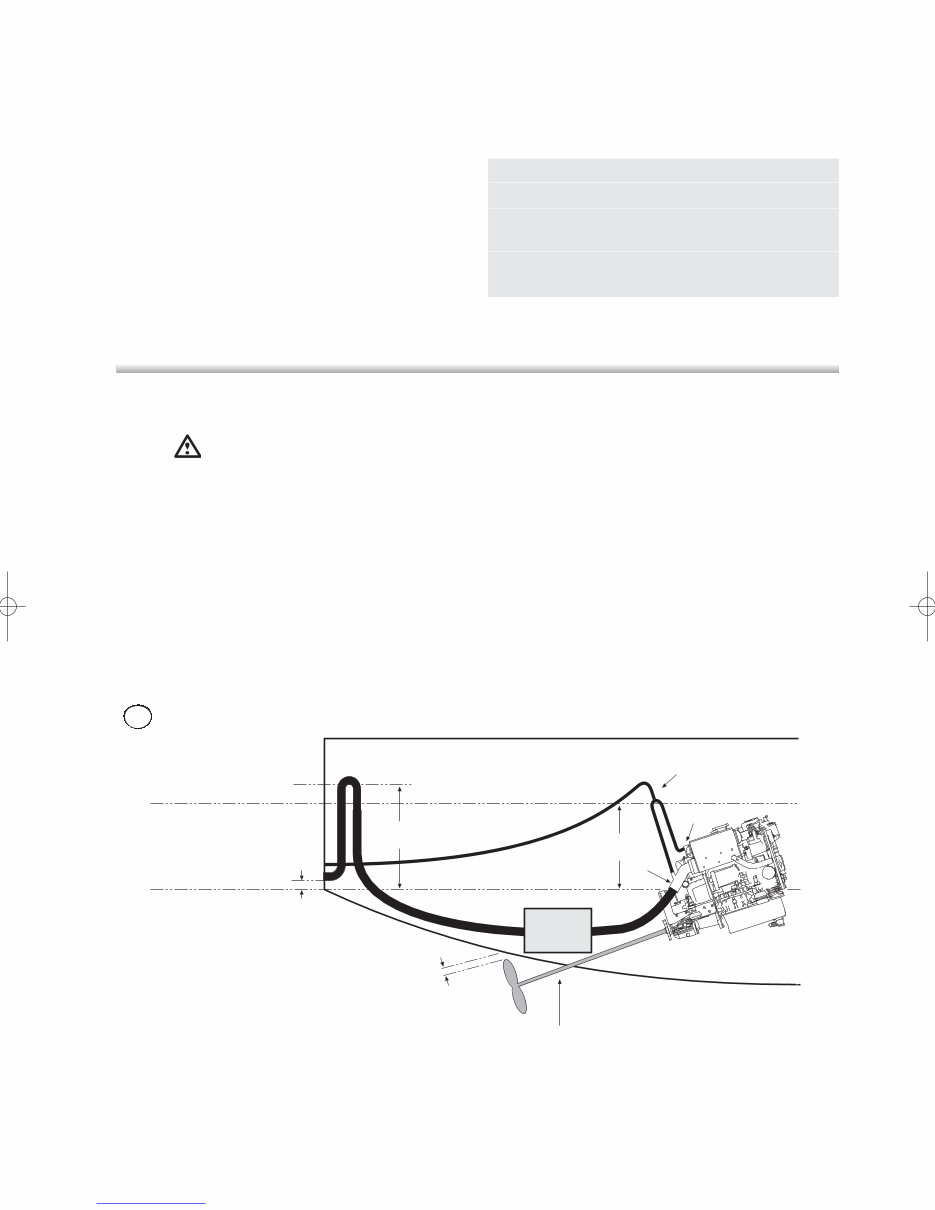

Typical Yacht Exhaust Installation

Warning

(1) One of the most common problems with engine

installations (and possibly expensive), is water entering

the engine exhaust manifold from the exhaust system by

syphoning when the engine is switched off. This can

occur when the point of water injection "X" on the engine

is close to or below the water line. Water entering the

pistons can cause bent con rods, emulsified engine oil

and a wrecked fuel pump! It’s best avoided!

(2) This diagram shows a typical exhaust installation.

The rubber hose connecting the heat exchanger to the

injection bend must be replaced by a hose (a) of

sufficient length, connecting to a "T" piece or anti-syphon

valve that is above the maximum seawater level when

heeled (at least 30 cms / 12 inches above the water line)

on the centre line of the boat. The pipe then returns to

the injection bend and the seawater is pumped down the

exhaust pipe.

(3) The exhaust back pressure should NOT exceed

62 mm Hg (2.4 inches Hg).

Exhausts

(a) An engine correctly installed in accordance with this

handbook will meet the emission requirements of the

RCD (see page 64).

(b) Keep dry exhaust systems to a minimum length and have

swept bends (NOT right angle elbows). Exhaust back

pressure is increased by longer exhaust length and sharp

bends. Back pressure should be measured; with the

complete exhaust system connected and the engine

running at full speed; and should NOT exceed 62 mm

Hg (2.4 inches Hg). The correct measuring point is before

the injection bend (at the manifold flange).

Wet Exhaust hose should be matched to the injection

bend sizes detailed below.

7

Exhaust Beta 43 Beta 50 Beta 60

Standard 50 mm 50 mm 50 mm

High rise water 50 mm 50 mm 50 mm

injection bend SS

Cross over water 50 mm 50 mm 50 mm

injection bend SS

Normal Seawater Level

Anti syphon valve or

T piece fitted here

Propeller Clearance:

between tip of propeller blade and underside

of hull should be at least 10 percent of the

propeller blade diameter

If a rope cutter is fitted, allow approximately 1/2”

for movement of engine, see manufacturer’s literature

30 cm

minimum

Maximum Seawater level

when heeled (measured on

the centre line of the boat)

40 cm

minimum

a

X

5 cm

minimum Waterlock

Silencer

6

Downloaded from www.Manualslib.com manuals search engine

8

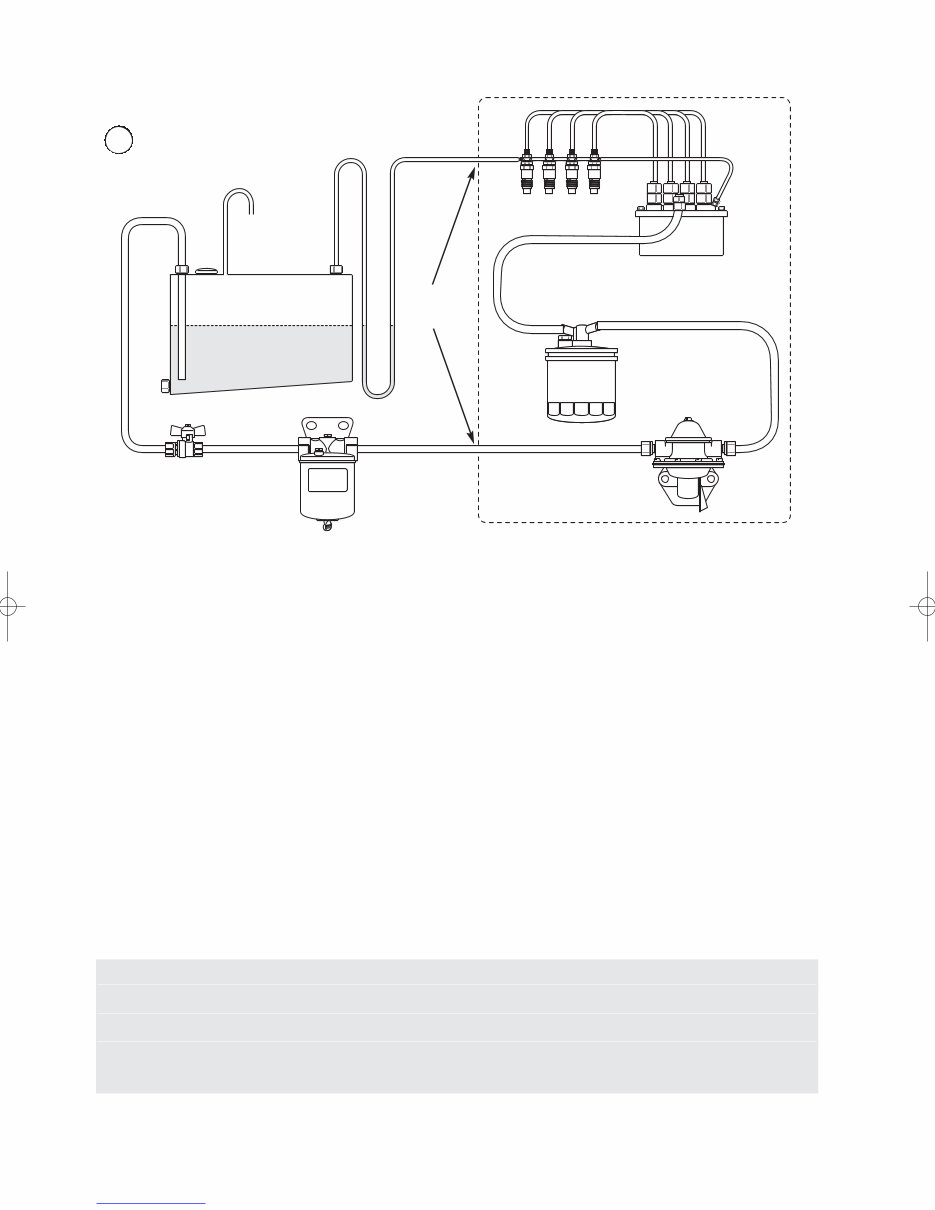

Fuel supply & leak off

Fuel tank

Stop tap/valve

Fuel/water

separator

Fuel filter

Fuel lift pump

Fuel injection

pump

Engine (All Fuel Connections Supplied)

Flexible Fuel

Connections

to be used

Fuel injectors

7

Notes:

1) A fuel/water separator must be installed.

2) The mechanical fuel lift pump is fitted to all engines as

standard, but if a suction head of 0.25m or more is

required, then an electric fuel lift pump must be fitted

(ask your dealer or Beta Marine).

3) It is very important that the excess fuel from the injectors

is fed back to the fuel tank and not back to any point in

the supply line. This will help prevent air getting into the

system.

4) The fuel return (leak off) pipe must loop down to be level

with the bottom of the tank before it enters the top of the

tank – see drawing. This prevents fuel ‘drain down’.

5) Fuel lines and hoses connecting the fuel tank to the

engine, must be secured, separated and protected from

any source of significant heat. The filling, storage,

venting, fuel supply arrangements and installation must

be designed and installed so as to minimise the risk of

fire. When connecting the engine to the fuel supply and

return lines, flexible fuel hoses must be used (next to the

engine) and must meet the requirements set in standard

ISO7840:1995/A1:2000 and/or as required by your

surveyor / authority.

6) Any fuel leaks in the system when static are likely to

cause poor starting and erratic running and must be

corrected immediately. These leaks will allow air to be

sucked in when the engine is running.

Engine Connections

Actual Connector: Required Pipe Size:

Fuel supply and fuel leaf-off connections are 8 mm conex with olives 8 mm O.D piping for both with flexible section

Seawater cooling pump connections are 28 mm OD Engine Inlet = 28 mm I.D hose

Water injected exhaust elbow outlet 50 mm OD Flexible exhaust rubber pipe to correct quality

- 50 mm OD

Vent

Downloaded from www.Manualslib.com manuals search engine

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$28.99

Viewed 87 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$28.99

Get the comprehensive operator maintenance manual for Beta Marine engines based on the Kubota Mini Series. This manual covers the following models:

- Beta 10

- BZ482

- Beta 16 (BZ602)

- BD722

- Beta 25 (BD902)

These manuals are invaluable resources for both professional mechanics and DIY enthusiasts.