Kawasaki 1100 STX D.I. Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

1100 STX D.I.

JET SKI

®

Watercraft

Service Manual

Downloaded from www.Manualslib.com manuals search engine

is a trademark of Kawasaki Heavy Industries, Ltd. registered in U.S.A.,

Japan, Austria, Benelux, Sweden, Denmark, Switzerland, France, Canada, Finland,

Norway, Greece, Italy, U.K., Portugal,Thailand, and Taiwan.

KAWASAKI JET SKI is a trademark of Kawasaki Heavy Industries, Ltd. registered

in Australia.

Downloaded from www.Manualslib.com manuals search engine

Quick Reference Guide

General Information 1

Periodic Maintenance 2

Fuel System (DFI) 3

4 Engine Lubrication System

5 Exhaust System

Engine Top End 6

Engine Removal and Installation 7

Engine Bottom End 8

Cooling and Bilge Systems 9

10 Drive System

Pump and Impeller 11

Steering 12

Hull/Engine Hood 13

Electrical System 14

Storage 15

Appendix 16

This quick reference guide will assist you in

locating a desired topic or procedure.

• Bend the pages back to match the black tab

of the desired chapter number with the

black tab on the edge at each table of

contents page.

• Refer to the sectional table of contents for

the exact pages to locate the specific topic

required.

Downloaded from www.Manualslib.com manuals search engine

1100 STX D.I.

JET SKI Watercraft

Service Manual

All rights reserved. No parts of this publication may be reproduced, stored in a retrieval system, or transmitted in any

form or by any means, electronic mechanical photocopying, recording or otherwise, without the prior written permission of

Quality Assurance Department/Consumer Products & Machinery Company/Kawasaki Heavy Industries, Ltd., Japan.

No liability can be accepted for any inaccuracies or omissions in this publication, although every possible care has been

taken to make it as complete and accurate as possible.

The right is reserved to make changes at any time without prior notice and without incurring an obligation to make such

changes to products manufactured previously. See your "JET SKI" watercraft dealer for the latest information on product

improvements incorporated after this publication.

All information contained in this publication is based on the latest product information available at the time of publication.

Illustrations and photographs in this publication are intended for reference use only and may not depict actual model

component parts.

© 2002 Kawasaki Heavy Industries, Ltd. First Edition (1) :Jul. 3, 2002 (D)

Downloaded from www.Manualslib.com manuals search engine

LIST OF ABBREVIATIONS

A ampere(s) lb pound(s)

ABDC after bottom dead center m meter(s)

AC alternating current min minute(s)

ATDC after top dead center N newton(s)

BBDC before bottom dead center Pa pascal(s)

BDC bottom dead center PS horsepower

BTDC before top dead center psi pound(s) per square inch

C degree(s) Celsius r revolution

DC direct current rpm revolution(s) perminute

F farad(s) TDC top dead center

F degree(s) Fahrenheit TIR total indicator reading

ft foot,feet V volt(s)

g gram(s) W watt(s)

h hour(s) ohm(s)

L liter(s)

Read OWNER’S MANUAL before operating.

Downloaded from www.Manualslib.com manuals search engine

MAINTENANCE AND ADJUSTMENTS

Maintenance, replacement, or repair of the emission control devices and systems may be performed by any

marine Sl engine repair establishment or individual.

EMISSION CONTROL INFORMATION

Fuel Information

THIS ENGINE IS CERTIFIED TO OPERATE ON UNLEADED REGULAR GRADE GASOLINE ONLY.

A minimum of 87 octane of the antifknock index is recommended. The antiknock index is posted on service station

pumps.

Emission Control Information

To protect the environment in which we all live, Kawasaki has incorporated an exhaust emission control system in

compliance with applicable regulations of the United States Environmental Protection Agency.

Exhaust Emission Control System

This system reduces the amount of pollutants discharged into the atmosphere by the exhaust of this engine. The fuel,

ignition and exhaust systems of this engine have been carefully designed and constructed to ensure an efficient engine

with low exhaust pollutant levels.

Maintenance

Proper maintenance and repair are necessary to ensure that watercraft will continue to have low emission levels. This

Service Manual contains those maintenance and repair recommendations for this engine. Those items identified by the

Periodic Maintenance Chart are necessary to ensure compliance with the applicable standards.

Tampering with Emission Control System Prohibited

Federal law prohibits the following acts or the causing thereof: (1) the removal or rendering inoperative by any person

other than for purposes of maintenance, repair, or replacement, of any device or element of design incorporated into any

new engine for the purposes of emission control prior to its sale or delivery to the ultimate purchaser or while it is in use,

or (2) the use of the engine after such device or element of design has been removed or rendered inoperative by any

person.

Among those acts presumed to consitute tampering are the acts listed below:

Do not tamper with the original emission related parts.

* Engine Management Module (EMM)

* Fuel Pump

* Spark Plugs

* Fuel Injectors

Downloaded from www.Manualslib.com manuals search engine

Foreword

This manual is designed primarily for use by trained

mechanics in a properly equipped shop. However, it

contains enough detail and basic information to make

it useful to the owner who desires to perform his own

basic maintenance and repair work. A basic knowledge

of mechanics, the proper use of tools, and workshop

procedures must be understood in order to carry out

maintenance and repair satisfactorily. Whenever the

owner has insufficient experience or doubts his ability to

do the work, all adjustments, maintenance, and repair

should be carried out only by qualified mechanics.

In order to perform the work efficiently and to avoid

costly mistakes, read the text, thoroughly familiarize

yourself with the procedures before starting work, and

then do the work carefully in a clean area. Whenever

special tools or equipment are specified, do not use

makeshift tools or equipment. Precision measurements

can only be made if the proper instruments are used,

and the use of substitute tools may adversely affect safe

operation.

For the duration of the warranty period, we rec-

ommend that all repairs and scheduled maintenance be

performed in accordance with this service manual. Any

owner maintenance or repair procedure not performed in

accordance with this manual may void the warranty.

To get the longest life out of your "JET SKI" watercraft:

•

Follow the Periodic Maintenance Chart in the Service

Manual.

•

Be alert for problems and non-scheduled maintenance.

•

Use proper tools and genuine Kawasaki "JET SKI"

watercraft parts. Special tools, gauges, and testers

that are necessary when servicing Kawasaki "JET SKI"

watercraft are introduced by the Special Tool Manual.

Genuine parts provided as spare parts are listed in the

Parts Catalog.

•

Follow the procedures in this manual carefully. Don’t

take shortcuts.

•

Remember to keep complete records of maintenance

and repair with dates and any new parts installed.

How to Use This Manual

In this manual, the product is divided into its major sys-

tems and these systems make up the manual’s chapters.

The Quick Reference Guide shows you all of the

product’s system and assists in locating their chapters.

Each chapter in turn has its own comprehensive Table of

Contents.

For example, if you want spark plug information use

the Quick Reference Guide to locate the Electrical System

chapter. Then, use the Table of Contents on the first page

of the chapter to find the spark plug section.

Whenever you see these WARNING and CAUTION

symbols, heed their instructions! Always follow safe

operating and maintenance practices.

This warning symbol identifies special instruc-

tions or procedures which, if not correctly fol-

lowed, could result in personal injury, or loss of

life.

CAUTION

This caution symbol identifies special instruc-

tions or procedures which, if not strictly ob-

served, could result in damage to or destruction

of equipment.

This manual contains four more symbols (in addition to

WARNING and CAUTION) which will help you distinguish

different types of information.

NOTE

This note symbol indicates points of particular in-

terest for more efficient and convenient operation.

•

Indicates a procedural step or work to be done.

Indicates a procedural sub-step or how to do the work

of the procedural step it follows. It also precedes the

text of a NOTE.

Indicates a conditional step or what action to take based

on the results of the test or inspection in the procedural

step or sub-step it follows.

In most chapters an exploded view illustration of the

system components follows the Table of Contents. In

these illustrations you will find the instructions indicating

which parts require specified tightening torque, oil, grease

or a locking agent during assembly.

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 1-1

General Information

Table of Contents

1

Before Servicing................................................................................................................................................................ 1-2

Model Identification ........................................................................................................................................................... 1-5

General Specifications ...................................................................................................................................................... 1-6

Technical Information - Theory of Direct Fuel Injection.................................................................................................... 1-7

Technical Information – Kawasaki Smart Steering System............................................................................................ 1-19

Unit Conversion Table ..................................................................................................................................................... 1-22

Downloaded from www.Manualslib.com manuals search engine

1-2 GENERAL INFORMATION

Before Servicing

Before starting to service watercraft, careful reading of the applicable section is recommended to eliminate unnecessary

work. Photographs, diagrams, notes, cautions, warnings, and detailed descriptions have been included wherever

necessary. Nevertheless, even a detailed account has limitations, a certain amount of basic knowledge is also required

for successful work.

Especially note the following:

(1) Diagnostic Software “KADIAG”

The “KADIAG” is a useful tool to aid a technician in solving direct fuel injection service problems. To use this

“KADIAG” you should prepare the Communication Cable, a laptop computer, and the Software Manual.

(2) Adjustments

Adjustments shall be made in accordance with the Periodic Maintenance Chart or whenever troubleshooting or

presence of symptoms indicate that adjustments may be required. Whenever running of the engine is required during

maintenance it is best to have the watercraft in water.

CAUTION

Do not run the engine without cooling water supply for more than 15 seconds, especially in high revolutionary

speed or severe engine and exhaust system damage will occur.

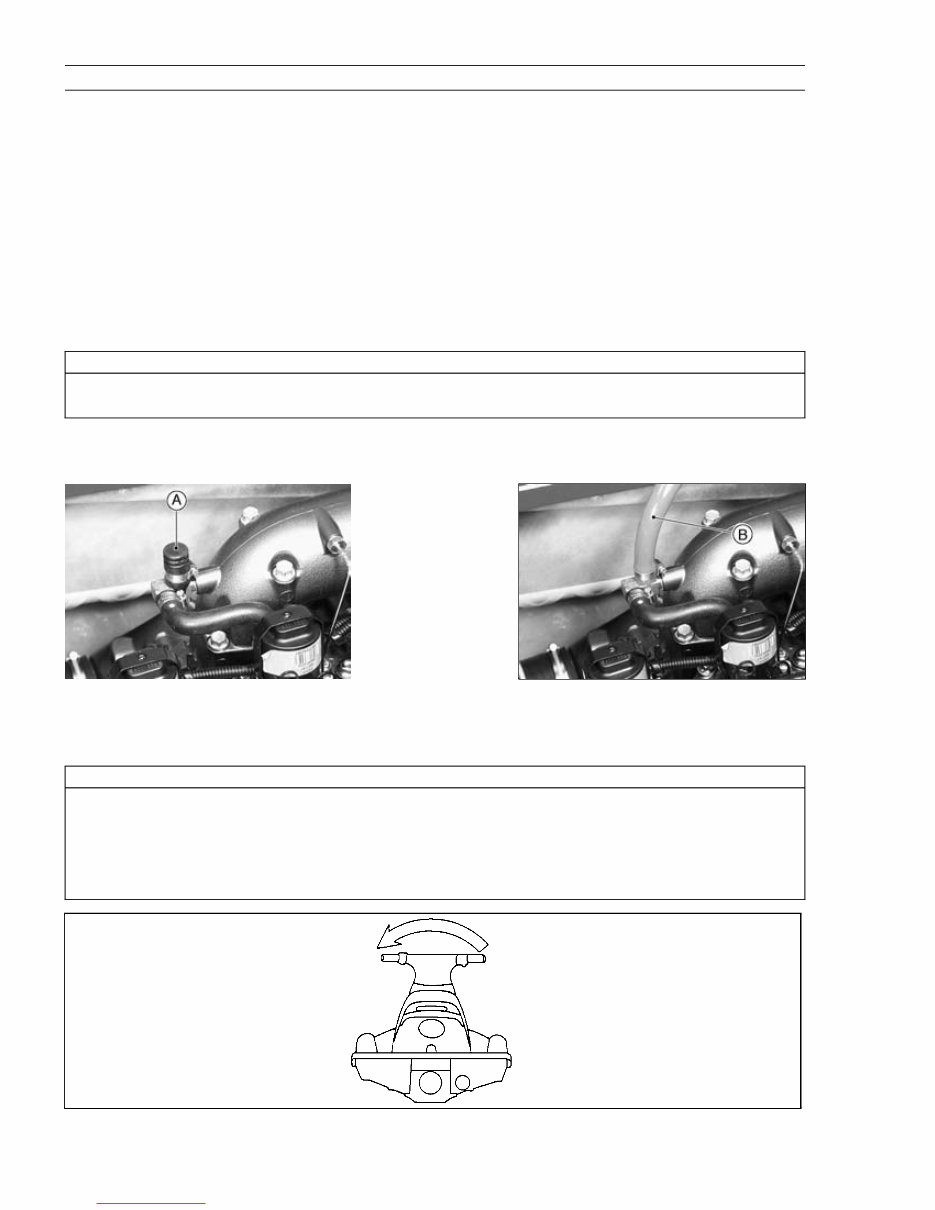

(3) Auxiliary Cooling

An auxiliary cooling supply may be used if the watercraft cannot be operated in water during adjustments. If possible,

always operate the watercraft in water rather than use an auxiliary cooling supply.

•

Loosen the clamp and remove the cap [A].

•

Connect the garden hose [B] to the hose fitting (see above).

•

Attach the garden hose to a faucet. Do not turn on the water until the engine is running and turn it off immediately when

the engine stops. The engine requires 2.4 L/min (2.5 qts/min) at 1800 rpm and 7.0 L/min (7.4 qts/min) at 6000 rpm.

CAUTION

Insufficient cooling supply will cause the engine and/or exhaust system to overheat and severe damage will

occur. Excessive cooling supply may kill the engine and flood the cylinders, causing hydraulic lock. Hydraulic

lock will cause severe damage to the engine. If the engine dies while using an auxiliary cooling supply, the

water must be shut off immediately.

Always turn the boat on its left side. Rolling to the right side can cause water in the exhaust system to run

into the engine, with possible engine damage.

Downloaded from www.Manualslib.com manuals search engine

GENERAL INFORMATION 1-3

Before Servicing

(4) Dirt

Before removal and disassembly, clean the "Jet Ski" watercraft. Any sand entering the engine, injector, or other

parts will work as an abrasive and shorten the life of the watercraft. For the same reason, before installing a new

part, clean off any dust or metal filings.

(5) Battery Ground

Remove the ground (–) lead from the battery before performing any disassembly operations on the watercraft. This

prevents:

(a) the possibility of accidentally turning the engine over while partially disassembled.

(b) sparks at electrical connections which will occur when they are disconnected.

(c) damage to electrical parts.

(6) Tightening Sequence

Generally, when installing a part with several bolts, nuts, or screws, they should all be started in their holes and

tightened to snug fit. Then tighten them evenly in a cross pattern. This is to avoid distortion of the part and/or causing

gas or oil leakage. Conversely when loosening the bolts, nuts, or screws, first loosen all of them by about a quarter

of turn and then remove them.

Where there is a tightening sequence indication in this Service Manual, the bolts, nuts, or screws must be tightened

in the order and method indicated.

(7) Torque

The torque values given in this Service Manual should always be adhered to. Either too little or too much torque

may lead to serious damage. Use a good quality, reliable torque wrench.

(8) Force

Common sense should dictate how much force is necessary in assembly and disassembly. If a part seems especially

difficult to remove or install, stop and examine what may be causing the problem. Whenever tapping is necessary, tap

lightly using a wooden or plastic faced mallet. Use an impact driver for screws (particularly for the removal of screws

held by a locking agent) in order to avoid damaging the screw heads.

(9) Edges

Watch for sharp edges, especially during major engine disassembly and assembly. Protect your hands with gloves

or a piece of thick cloth when lifting the engine or turning it over.

(10) High Flash-Point Solvent

A high flash-point solvent is recommended to reduce fire danger. A commercial solvent commonly available in North

America is Standard solvent (generic name). Always follow manufacturer and container directions regarding the use

of any solvent.

(11) Gasket, O-Ring

Do not reuse a gasket or O-ring once it has been in service. The mating surfaces around the gasket should be

free of foreign matter and perfectly smooth to avoid oil or compression leaks.

(12) Liquid Gasket, Non-Permanent Locking Agent

Follow manufacturer’s directions for cleaning and preparing surfaces where these compounds will be used. Apply

sparingly. Excessive amounts may block engine cooling passages and cause serious damage. An example of a

non-permanent locking agent commonly available in North America is Loctite Lock N’ Seal (Blue).

(13) Press

A part installed using a press or driver, such as a seal, should first be coated with oil on its outer or inner

circumference so that it will go into place smoothly.

(14) Ball Bearing

When installing a ball bearing, the bearing race which is affected by friction should be pushed by a suitable driver.

This prevents severe stress on the balls and races, and prevents races and balls from being dented. Press a ball

bearing until it stops at the stop in the hole or on the shaft.

(15) Oil Seal and Grease Seal

Replace any oil or grease seals that were removed with new ones, as removal generally damages seals. When

pressing in a seal which has manufacturer’s marks, press it in with the marks facing out. Seals should be pressed

into place using a suitable driver, which contacts evenly with the side of seal, until the face of the seal is even with

the end of the hole.

(16) Seal Guide

A seal guide is required for certain oil or grease seals during installation to avoid damage to the seal lips. Before a

shaft passes through a seal, apply a little lubricant, preferably high temperature grease on the lips to reduce rubber

to metal friction.

(17) Circlip, Retaining Ring

Replace any circlips and retaining rings that were removed with new ones, as removal weakens and deforms them.

When installing circlips and retaining rings, take care to compress or expand them only enough to install them and

no more.

(18) Cotter Pin

Replace any cotter pins that were removed with new ones, as removal deforms and breaks them.

Downloaded from www.Manualslib.com manuals search engine

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

Viewed 15 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

This Kawasaki 1100 STX D.I. Service Manual is an essential resource for owners and prospective owners of this jet ski model. It contains vital information on maintenance, troubleshooting, and repair.

The manual includes:

- Detailed instructions for proper usage and maintenance of the Kawasaki 1100 STX D.I.

- Comprehensive diagrams and illustrations for easy reference

- Step-by-step procedures for troubleshooting and maintenance

- Tips and tricks for optimizing the jet ski's performance

This manual is invaluable for both professional mechanics and DIY enthusiasts who own or plan to own a Kawasaki 1100 STX D.I. It offers detailed instructions and useful tips to maximize the jet ski's potential.

Secure your copy of the Kawasaki 1100 STX D.I. Service Manual today!