1990 Maytag Washer Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

16023083

© 1996 Maytag Corporation

INTRODUCTION

The information presented in this manual is printed in a loose format and is divided into

sections relating to a general group of components and/or service procedures. Each

section is further subdivided to describe a particular component or service procedure.

Anything of a unique nature concerning these models has been detailed and labeled as

such in the manual.

The subdividing of the subject matter, plus the loose leaf form will facilitate the updat-

ing of the manual as new or revised components are added or new models are intro-

duced.

Each page of the manual will be identified in the lower right-hand corner, and as new or

revised pages are published, the manual can easily be updated by following the file

instructions on the cover letter of the supplement.

The service manual is a valuable tool and care should be taken to keep it up to date by

prompt and proper filing of subsequent pages as they are used.

MODELS COVERED IN THIS MANUAL

PAV1000AW*

PAV2000AW*

INTRODUCTION i

DLW231*

PAV2300*

PAV3300*

PAV5000*

PAV5157*

PAV5158*

PAVT344*

HAV2460*

PAVT244*

PAVT234*

HAV2360*

MAV2200*

HAV2557*

HAV2558*

HAV3460*

PAVT444*

HAV4657*

16023083

© 1996 Maytag Corporation

INTRODUCTION ii

16023083

© 1996 Maytag Corporation

CONTENTS iii

SECTION 1. INSTALLATION ............................................................... 1-1

PRE-INSTALLATION REQUIREMENT .......................................................................... 1-1

Water Supply Requirements .................................................................................. 1-1

Drain Requirements ................................................................................................ 1-1

Electrical Requirements .......................................................................................... 1-2

INSTALLATION PROCEDURE ...................................................................................... 1-2

SECTION 2. OUTLINE OF MECHANICAL OPERATION ................... 2-1

CLUTCH ASSEMBLY ................................................................................................... 2-1

AGITATION .................................................................................................................. 2-2

SPIN ............................................................................................................................. 2-2

SECTION 3. CABINET ASSEMBLY COMPONENTS ......................... 3-1

CABINET BODY ASSEMBLY ...................................................................................... 3-1

Front Panel ............................................................................................................. 3-1

Rear Access Panel ................................................................................................. 3-2

TOP ASSEMBLY .......................................................................................................... 3-3

DOOR ASSEMBLY ...................................................................................................... 3-4

CONTROL PANEL ASSEMBLY (PAV1000AWW, PAV2000AWW) ............................ 3-4

Disassembly ........................................................................................................... 3-4

CONTROL PANEL ASSEMBLY (PAV2200, 3200, 4200) ............................................. 3-6

Disassembly ........................................................................................................... 3-6

BASE ASSEMBLY ....................................................................................................... 3-8

STABILIZER ASSEMBLY ............................................................................................. 3-9

SECTION 4. WATER RELATED COMPONENTS ................................ 4-1

WATER MIXING VALVE .............................................................................................. 4-2

WATER INLET FLUME .................................................................................................. 4-3

AIR BELL ...................................................................................................................... 4-3

HOSES ......................................................................................................................... 4-3

TUB TOP ...................................................................................................................... 4-4

AGITATOR (PAV1000AWW, PAV2000AWW) ............................................................ 4-4

AGITATOR (PAV2200, 3200, 4200) ............................................................................. 4-5

SPIN BASKET .............................................................................................................. 4-5

OUTER TUB ASSEMBLY ............................................................................................. 4-6

PUMP ASSEMBLY ....................................................................................................... 4-7

SECTION 5. SUSPENSION SYSTEM (PAV1000AWW, PAV2000AWW) ... 5-1

SUSPENSION SYSTEM (PAV2200, 3200, 4200) ........................................................ 5-2

SUSPENSION HOUSING ............................................................................................. 5-3

TUB BRACES ............................................................................................................... 5-3

SUSPENSION SPRINGS .............................................................................................. 5-3

CONTENTS

16023083

© 1996 Maytag Corporation CONTENTS iv

SECTION 6. TRANSMISSION AND RELATED COMPONENTS ........ 6-1

CENTER POST ASSEMBLY ........................................................................................ 6-2

BEARING AND SEAL HOUSING .................................................................................. 6-2

TUB SEAL .................................................................................................................... 6-3

SPIN BEARING ............................................................................................................. 6-4

DRIVE PULLEY AND CAMS ........................................................................................ 6-5

BRAKE ASSEMBLY ..................................................................................................... 6-8

TRANSMISSION HOUSING ASSEMBLY ..................................................................... 6-10

Oil Seal Replacement ............................................................................................ 6-11

LOWER BEARING ASSEMBLY .................................................................................. 6-11

DIAGNOSING TRANSMISSION PROBLEMS ............................................................. 6-13

SECTION 7. ELECTRICAL COMPONENTS AND TESTING .............. 7-1

TIMER ........................................................................................................................... 7-1

TIMER SEQUENCE CHART ......................................................................................... 7-2

MOTOR ........................................................................................................................ 7-3

MOTOR SWITCH ........................................................................................................ 7-3

MOTOR MOUNTING .................................................................................................... 7-6

MOTOR CIRCUIT TESTING ......................................................................................... 7-7

Overload Protector ................................................................................................ 7-7

Motor Switch ........................................................................................................... 7-8

Motor ...................................................................................................................... 7-8

WATER MIXING VALVE .............................................................................................. 7-8

WATER LEVEL SWITCH .............................................................................................. 7-9

SELECTOR SWITCHES ............................................................................................. 7-11

SAFETY SPIN SWITCH ............................................................................................. 7-11

SECTION 8. SCHEMATIC DIAGRAM ................................................... 8-1

SECTION 9. TROUBLESHOOTING ...................................................... 9-1

16023083

© 1996 Maytag Corporation

SAFETY NOTES

PRECAUTIONS TO BE OBSERVED BEFORE AND DURING SERVICING TO AVOID

POSSIBLE EXPOSURE TO EXCESSIVE DANGER AND ELECTRICAL SHOCK:

1. Disconnect electrical supply before servicing machine.

2. If electricity is required for a test:

(A) First, disconnect electrical supply;

(B) Second, make any connections or adjustments required for the test;

(C) Third, connect electrical supply;

(D) Fourth, perform the test. If service is required, disconnect electrical

supply before servicing machine.

3. Please use caution when servicing the machine with the front panel

removed because there is danger of injury due to potential contact

with spinning transmission.

4. Please use caution when servicing the machine with the front panel

removed because there is danger of injury due to contact with a

potential "pinch point" between the turned up edge of the transmission

cover and the tub support flange.

SAFETY NOTES v

16023083

© 1996 Maytag Corporation

SAFETY NOTES vi

16023083

© 1996 Maytag Corporation

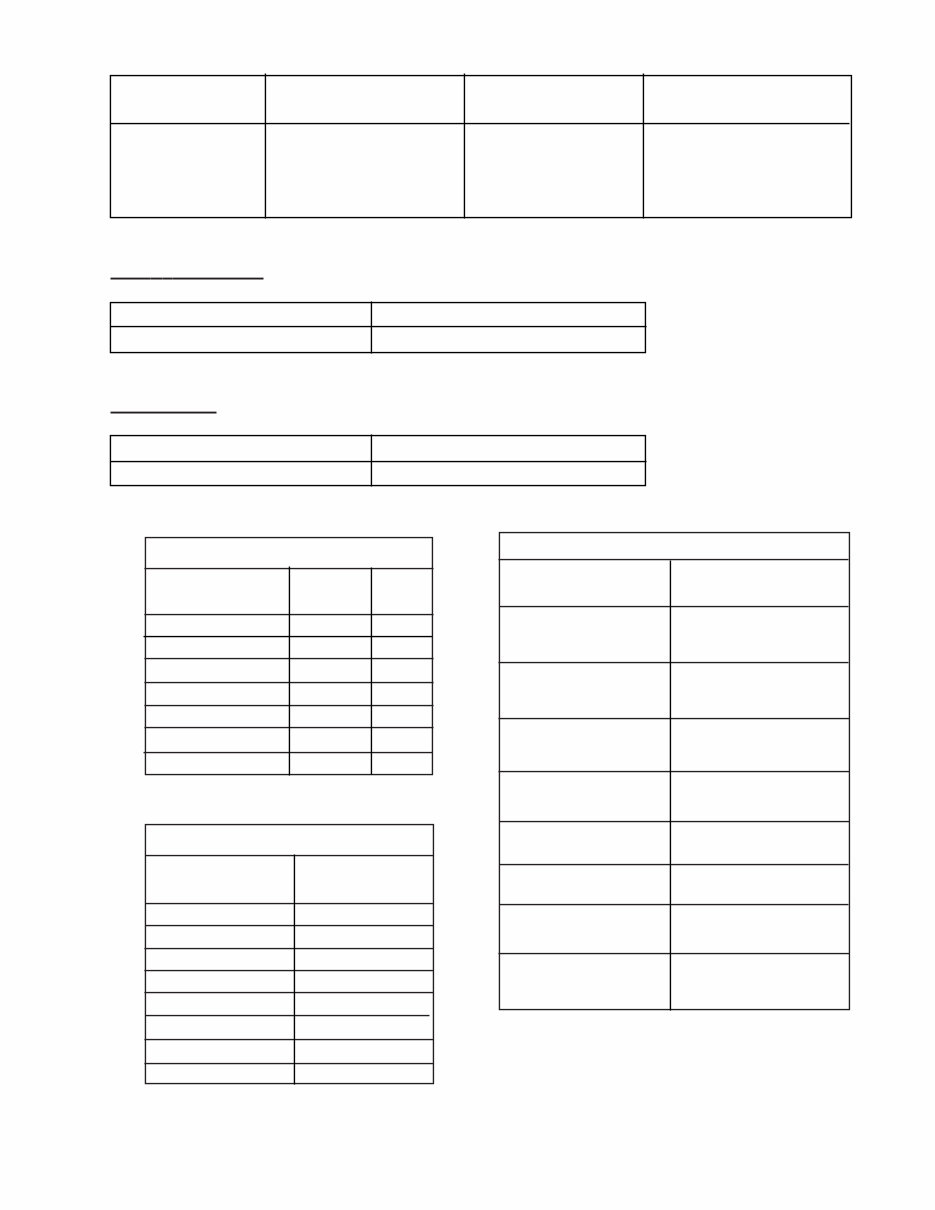

WASHER WEIGHT

Shipping - 185 pounds approximately

Operating - 160 pounds approximately

DIMENSIONS

Width 27"

Depth 27"

Height to top of cabinet 35 3/4"

Height to top of control panel 44"

Height with door open 53 1/2"

FINISH

Cabinet Top - powdered paint

Clothes Door - powdered paint

Outer Tub - constructed entirely of polypropylene

Basket - polypropylene

Cabinet - baked enamel

Base and other finished parts - baked primer

DRAIN HEIGHT

32 inch minimum

60 inch minimum

MOTOR

3/4 H.P., reversible, 115 volt, 60 cycle A.C.

TRANSMISSION

Rack and pinion type, incorporating reduction gears

SPECIFICATIONS

SPECIFICATIONS Vii

16023083

© 1996 Maytag Corporation

WATER

CYCLE LEVEL *AMPS

Agitate-Regular Full Tub 10.4

Agitate-Slow Full Tub 7.6

Agitate-Regular Dry Tub 7.5

Spin-Regular Dry Tub 10.2

Spin-Slow Dry Tub 7.6

Pump Out-Regular Full Tub 10.8

Pump Out-Slow Full Tub 8.0

Setting Gallons *Depth *Basket

Inches Perforations

Mini 10.5 6" 3 1/2"

Medium 14.1 8 1/2" 5"

High 19.5 11" 7"

Super 23.3 13 1/2" 9 1/4"

*Allowable variations are plus or minus 1/2 inch.

AGIT A T OR SPEED

Regular Cycle 90 Oscillations per minute

Slow (Delicate) Cycle 60 Oscillations per minute

SPIN SPEED

Regular Cycle 625 R.P.M.

Slow (Fine Wash) Cycle 416 R.P.M.

SPECIFICATIONS viii

*WATTAGE

CYCLE RANGE

Agitate-Regular

Full Tub 610-640 / 670 (MAX.)

Agitate-Slow

Full Tub 370-400 / 420 (MAX.)

Agitate-Regular

Dry Tub 460-470 / 480 (MAX.)

Agitate-Slow

Dry Tub 350-360 / 370 (MAX.)

Pump Out-Regular 760

Pump Out-Slow 510

Spin-Regular

Full Tub 460

Spin-Slow

Full Tub 340

* These will vary with washer load and line voltage.

TABLE 0-1. AMPERAGE CHART

TABLE 0-2. RESISTANCE CHART

TABLE 0-2. RESISTANCE CHART

*RESISTANCE

COMPONENTS (OHMS)

Timer Motor 2360

Mixing Valve

Cold Solenoid 853

Hot Solenoid 867

Drive Motor

High Speed 1.3

Low Speed 2.3

Start 3.1

* These values can vary slightly.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$28.99

Viewed 74 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$28.99

The Factory Repair Manual is the perfect resource for both professional mechanics and DIY enthusiasts. This comprehensive manual covers everything you need to fix your Maytag washer model 1990. Whether you're using a Windows or Mac computer, this manual is compatible with both platforms. With this manual, you can print out any pages you need to assist you in repairing your washer. Say goodbye to expensive repair costs and take control of the repair process yourself. Securely purchase the manual using PayPal or your credit card.