LG WM2010CW WASHING MACHINE Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

100

WASHING MACHINE

SERVICE MANUAL

READ THIS MANUAL CAREFULLY TO DIAGNOSE

PROBLEMS CORRECTLY BEFORE SERVICING THE UNIT.

MODEL: WM2010CW

CAUTION

Website: http: //www.LGEservice.com

E-mail: http: //www.LGEservice.com/techsup.html

!

101

APR. 2004 PRINTED IN KOREA P/No.:MFL30599115

2

CONTENTS

1. SPECIFICATIONS .........................................................................................................................3

2. FEATURES & TECHNICAL EXPLANATION ................................................................................ 4

3. PARTS IDENTIFICATION ............................................................................................................ 7

4. INSTALLATION & TEST ............................................................................................................... 8

5. OPERATION ................................................................................................................................11

6. WIRING DIAGRAM/PROGRAM CHART .....................................................................................14

7. TROUBLESHOOTING .................................................................................................................16

7-1. BEFORE PERFORMING SERVICE ...................................................................................16

7-2. QC TEST MODE .................................................................................................................16

7-3. HOW TO CHECK THE WATER LEVEL FREQUENCY ......................................................16

7-4. ERROR DISPLAY ...............................................................................................................17

8. ERROR DIAGNOSIS AND CHECK LIST ....................................................................................19

8-1. DIAGNOSIS AND SOLUTION FOR ABNORMAL OPERATION ........................................19

8-2. FAULT DIAGNOSIS AND TROUBLESHOOTING ..............................................................22

9. DISASSEMBLY INSTRUCTIONS ...............................................................................................31

10. EXPLODED VIEW .....................................................................................................................40

10-1. CABINET & CONTROL PANEL ASSEMBLY ....................................................................40

10-2. DRUM & TUB ASSEMBLY................................................................................................41

10-3. DISPENSER ASSEMBLY .................................................................................................42

3

4

7

8

11

12

13

13

13

13

14

16

16

19

26

34

34

35

36

3

1. SPECIFICATIONS

ITEM WM1812CW/WM1814CW WD-90286BD

COLOR BLUE WHITE TITANIUM

POWER SUPPLY AC 120 V, 60 Hz AC 127V, 60Hz

PRODUCT WEIGHT 173 lbs. (78.5 kg)

WASHING 280 W

DRAIN MOTOR 80 W

WASH HEATER

–

WASH 46 rpm

SPIN

0-900 rpm

CYCLES 5

WASH/RINSE TEMPERATURES 5

SPIN SPEEDS 5

OPTIONS Prewash, Quick Cycle, Extra Rinse, Rinse+Spin, Delay Wash

CUSTOM PROGRAM –

WATER CIRCULATION –

OPERATIONAL WATER PRESSURE 4.5-116 psi (800 kPa)

CONTROL TYPE Electronic

WASH CAPACITY 2.96 cu. ft (3.42 cu. ft. IEC)

DIMENSIONS 27” (W) X 30

1

/

32

” (D) X 38

11

/

16

” (H), 50

13

/

16

” (D, door open)

DELAY WASH up to 9 hours

DOOR SWITCH TYPE PTC + Solenoid

WATER LEVEL 9 steps (by sensor)

LAUNDRY LOAD SENSING Incorporated

ERROR DIAGNOSIS Incorporated

AUTO POWER OFF Incorporated

CHILD LOCK Incorporated

ELECTRIC POWER

CONSUMTION

REVOLUTION SPEED

4

2. FEATURES & TECHNICAL EXPLANATION

2-1. FEATURES

■

Direct Drive System

The advanced Brushless DC motor directly drives the drum without

belt and pulley.

■

Tilted Drum and Large Door Opening

Tilted drum and large opening make it possible to load

and unload clothing more easily.

■

Time-Released Dispenser

Detergent, fabric softener and bleach are dispensed separately at

the right time during wash cycle.

■

Automatic Wash Load Detection

Automatically detects the load and optimizes the washing time.

■

Child Lock

The Child lock prevents children from pressing any button to

change the settings during operation.

추가선택, 예약,

5

5

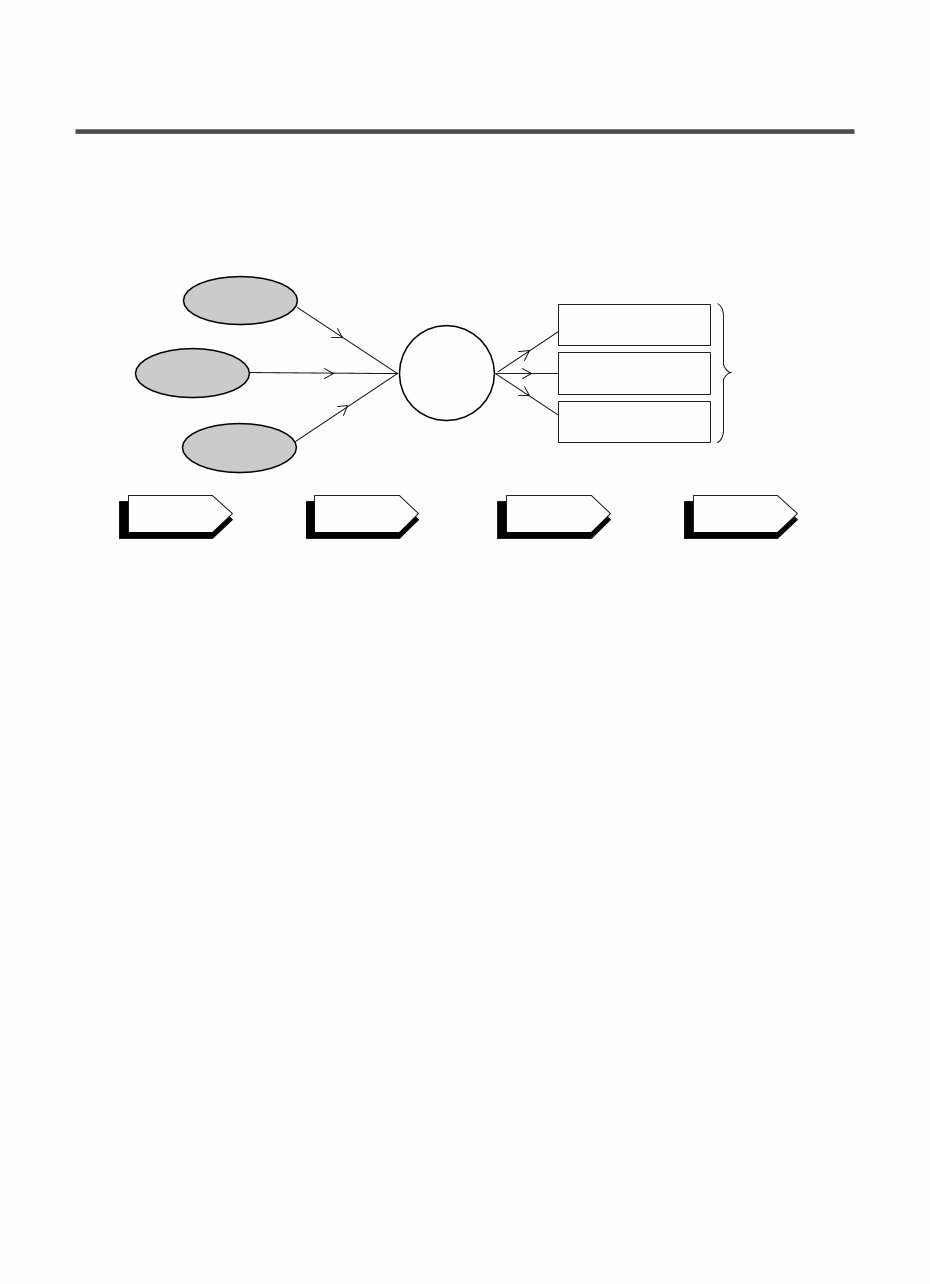

2-2. NEURO FUZZY WASHING TIME OPTIMIZATION

To get the best washing performance, optimal time is determined by the water temperature,

the selected washing temperature, and the size of the load.

2-3. WATER LEVEL CONTROL

● This model incorporates a pressure sensor which can sense the water level in the tub.

● The water supply is stopped when the water level reaches the preset level, the washing

program then proceeds.

● Spinning does not proceed until the water in the tub drains to a certain level.

2-4. DOOR CONTROL

● The door can be opened by pulling the door handle whenever washer is not in operation.

● When the cycle is completed, the DOOR LOCKED light will turn off.

● If a power failure has occurred while in operation, the door will unlock after 5 minutes.

● Clicking sounds can be heard when the door is locked/unlocked.

NEURO-

FUZZY

load

size

selected

washing

temperature

water

temperature

washing time

rinsing time

spin rhythm, time

the best

washing

performance

SENSING PROCESSING DETERMINATION EFFECT

6

2-5. THE DOOR CAN NOT BE OPENED

● While program is operating

● When a power failed and power plug is taken out in operation

● While Door Lock lights turn on.

● White the motor is in the process of intertial rotating, through the operation is paused.

2-6. DOOR LOCKED LAMP LIGHTS

● When the frequency of water level is lower than 22.9 kHz

(It can be canceled when the frequency is more than 23.8 kHz)

● When the temperature inside the tub is higher than 45 °C and water level is not 25.5 kHz

(It can be canceled when the water level is 25.5 kHz or the temperature inside the tub is lower than 40 °C)

2-7. CHILD LOCK

● Use this option to prevent unwanted use of the washer. Press and hold OPTION button for 3 seconds to

lock/unlock control.

● When Child lock is set, “ ” blinks and all buttons are disabled except the Power button. You can lock

the washer while it is operating.

7

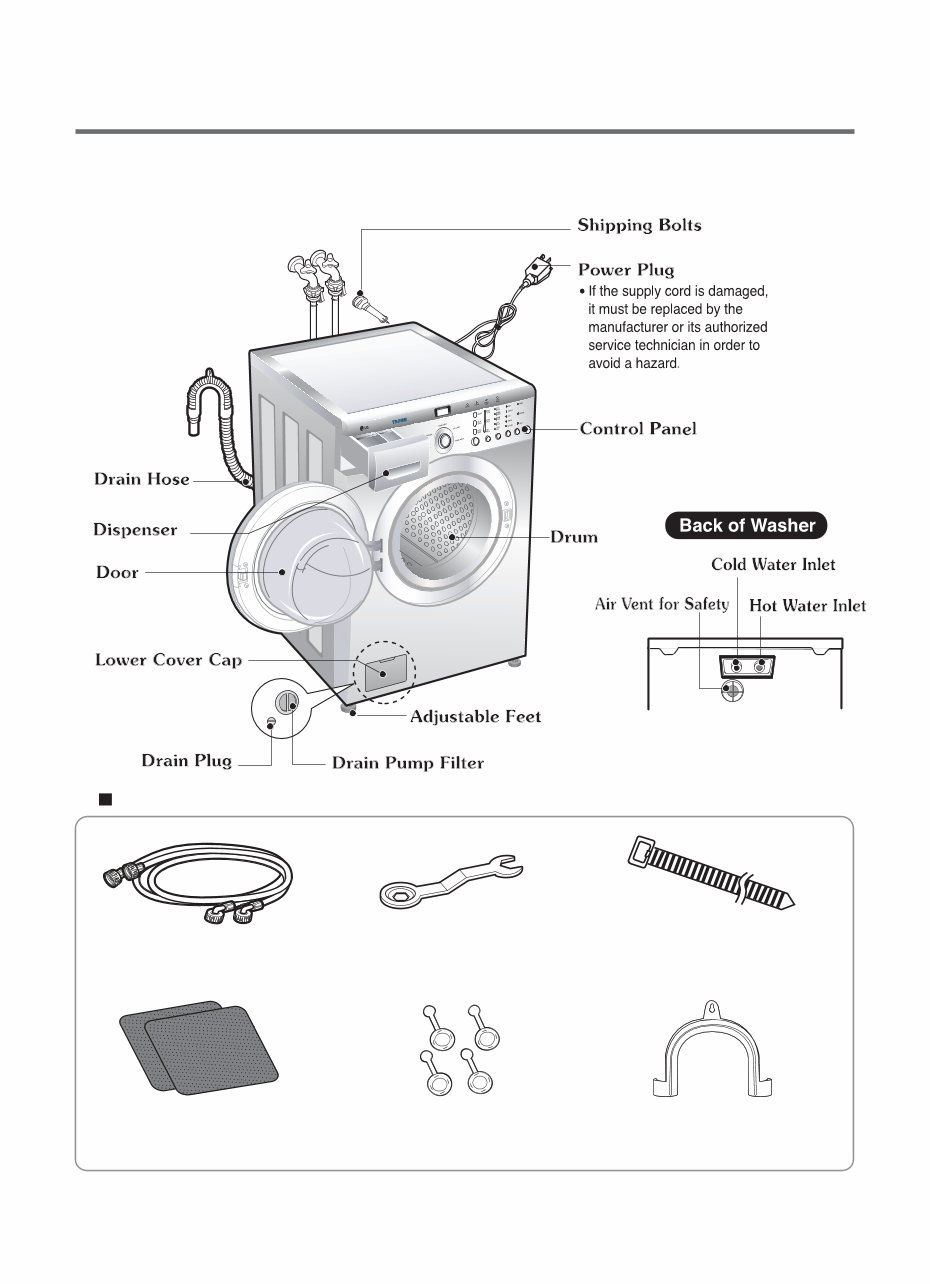

3. PARTS IDENTIFICATION

身

粁? 桁 ? 粁

ACCESSORIES

Wrench

Tie strap (Option)

to secure drain hose to standpipe,

inlet hose, or laundry tub

Hot/Cold (1 each)

Hose

Non-skid pads

Caps(4)

(for covering shipping

bolt holes)

Elbow Bracket

(for securing drain hose)

8

1 Before servicing, ask the customer what the trouble is.

2 Check the setup (power supply is 120 V AC, remove the transit bolts....).

3 Check with the troubleshooting guide.

4 Plan your service method by referring to the disassembly instructions.

5 Service the unit.

6 After servicing, operate the appliance to see whether it functions correctly.

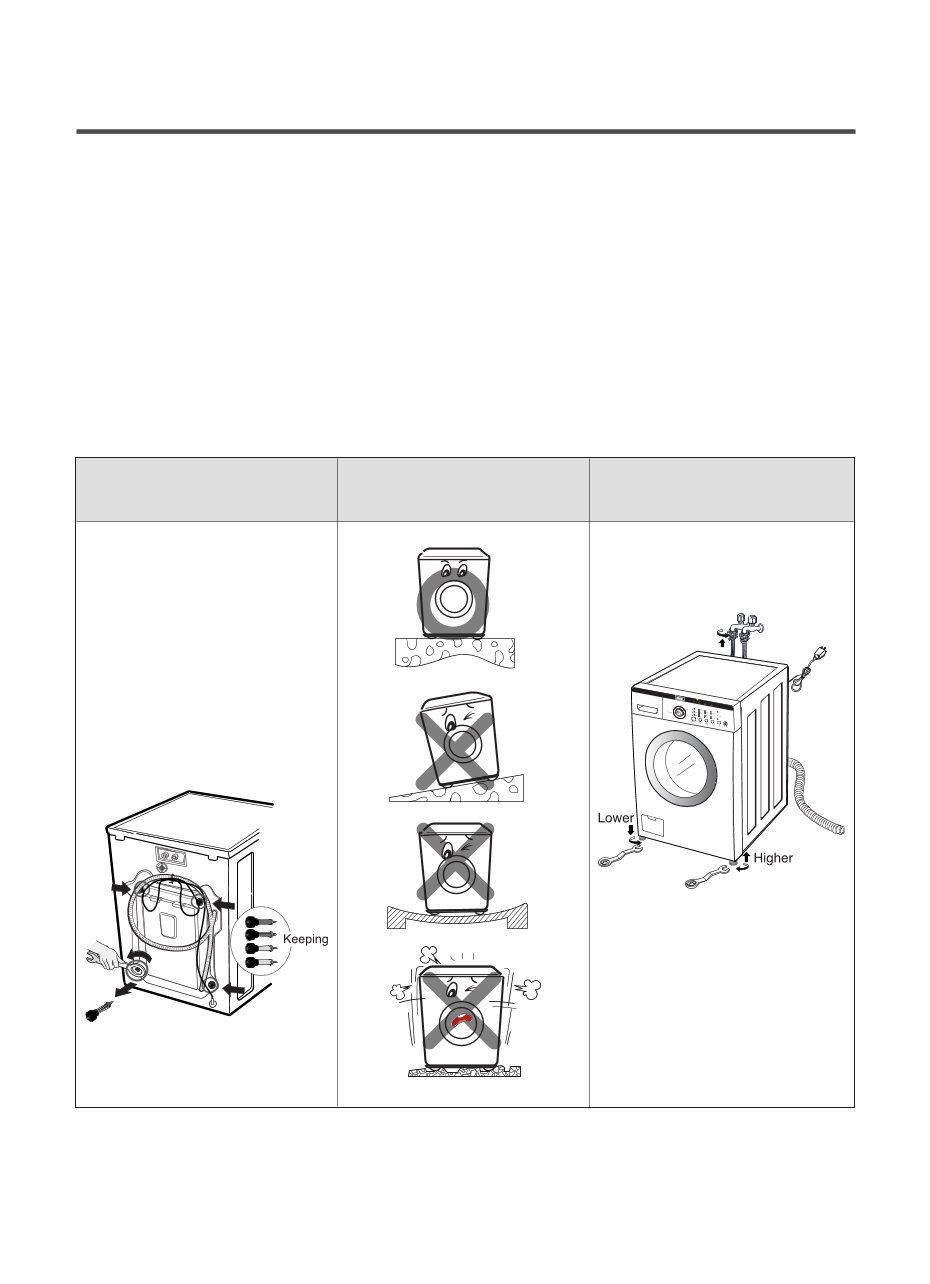

■ STANDARD INSTALLATION

The appliance should be installed as follows:

REMOVE THE SHIPPING INSTALL THE APPLIANCE ADJUST THE

BOLTS ON A FLAT AND FIRM SURFACE LEVELING

Remove the 4 shipping bolts Turn the leveling feet to adjust

with the supplied wrench. the appliance.

※ Do first lower side to remove easily.

Keep the shipping bolts and

spanner for future use.

Insert the 4 caps

(provided) into the hole.

Turn clockwise to raise;

counterclockwise to lower.

4. INSTALLATION & TEST

9

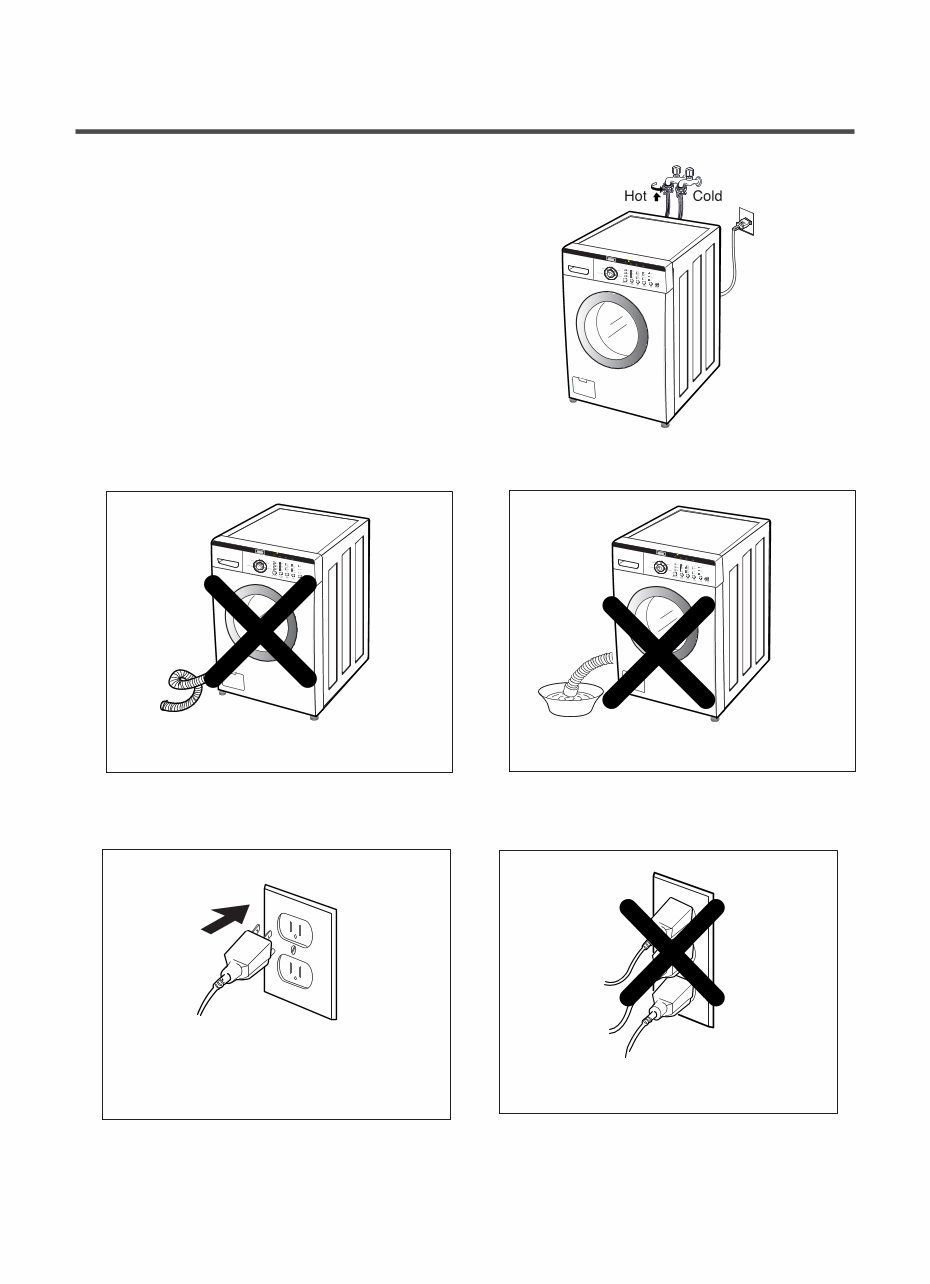

■ HOW TO CONNECT THE INLET HOSE

Verify that the rubber washer is inside of the

valve connector.

Tighten the inlet hose securely to prevent leaks.

■ CONNECT THE DRAIN HOSE

■ CONNECT POWER PLUG

※ The end of the drain hose should be placed less than 96 ” from the floor.

· Connect the power plug to the wall outlet.

· Avoid connecting several electric devices, as

doing so may cause a fire.

· Make sure that the hose is not twisted.

· Avoid submerging the end of the hose.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Viewed 24 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

The LG WM2010CW WASHING MACHINE Service Manual is a comprehensive guide that includes the following sections:

- SPECIFICATIONS

- FEATURES AND TECHNICAL EXPLANATION

- PARTS IDENTIFICATION

- INSTALLATION AND TEST

- OPERATION

- WIRING DIAGRAM

- TEST MODE

- TROUBLESHOOTING

- COMPONENT TESTING INFORMATION

- DISASSEMBLY INSTRUCTIONS

- EXPLODED VIEW

This manual is available in English and consists of 37 pages. It is compatible with both Windows and MAC platforms.