Onan Marine MDL3 MDL4 MDL6 Service Manual 934-0500

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Caution: This document contains mixed page sizes (8.5 x 11 or 11 x

17), which may affect printing. Please adjust your printer settings

according to the size of each page you wish to print.

MDL3

MDL4

MDL6

.s

1

, ~-

I

934-0500

. 8-91

Printed in U.S.A.

Safety Precautions

Before operating the generator set, read the Operator’s

Manualandbecomefamiliarwith it andvourunit. Safeandeffl-

exhauster.

dent operatlon can be achleved onli if the unit is properly

operated and maintained. Manyaccidents are caused byfail-

ure to follow fundamental rules and precautions.

Throughout this manualyou will notice symbolswhich alert you

to potentiallydangerousconditionsto the operator, service per-

sonnel, or the equipment itself.

. D’ This symbol warns of immedlate haz-

ards which will result in severe personal Injury or

death.

1 - 1 Thissymbol refers to a hazard or unsafe

practlce which can result in severe personal injury or

death.

[A CAUTiON 1 Thls symbol mfers to a hazard or unsafe

practlce which can result in personal Injury or prod-

uct or properfy damage.

FUEL, ENGINE OIL, AND FUMES ARE FLAMMABLE AND

TOXIC. Fire, explosion, and personalinjurycan result from im-

proper practices.

Benzene and lead, found in some gasoline, have been

identifiedby some state and federal agencies as causing

cancer or reproductive toxicity. When checking, draining

or adding gasoline, take care not to ingest, breathe the

fumes, or contact gasoline.

Used engine oils have been identified by some state or

federal agencies as causingcancer or reproductive toxic-

ity. Whencheckingor changingengineoil, take care notto

ingest, breathe the fumes, or contact used oil.

Do not fill fueltankswith the engine running. Do notsmoke

around the generator set area. Wipe up any oil or gas

spills. Do not leaveoily rags in engine compartment or on

the generator set. Keep this and surrounding area clean.

lnspectfuel system beforeeachoperationand periodically

while running.

Equip the engine fuel supply with a positive fuel shutoff.

Always disconnectthe battery ground (-) leadfirst and re-

connect it last. Make sure you connect the battery cor-

rectly. A direct short across the battery terminals can

cause an explosion. Do not smoke while servicing batter-

ies. Hydrogen gas given off during charging is very explo-

sive.

0 Be sure propulsionand generator set engine exhaust sys-

tems are free of leaks. Performthorough, periodic inspec-

tions of the exhaust system and repair leaks immediately.

Exhaust gases are deadly.

0 Never sleep in the vessel with the generator set running

unless the vessel is equipped with an operating carbon

monoxide detector.

.

3

HOT COOLANT CAN CAUSE SEVERE PERSONAL

INJURY

0 Hot coolant is under pressure. Do not loosen the coolant

pressure cap while the engine is hot. Let the engine cool

before opening the pressure cap.

MOVING PARTS CAN CAUSE SEVERE PERSONAL

INJURY OR DEATH

Do not removeany belt guards or covers with the genera-

tor set running.

Keep hands and loose clothing away from moving parts.

Do notwearjewelry while servicingany part of the genera-

tor set.

Never step on the generator set (as when entering or leav-

ingthe engine compartment). It can stress and break unit

components, possible resulting in dangerous operating

conditions. . . from leaking fuel, leaking exhaust fumes,

etc.

Beforeperformingany maintenance on the generator set,

disconnect its batteries to prevent accidental starting. do

not disconnect or connect battery cables if fuel vapors are

present. Ventilate the generatorset compartment or bilge

thoroughly with the power exhauster.

ELECTRICAL SHOCK WILL CAUSE SEVERE

PERSONAL INJURY OR DEATH

Do not make adjustmentsinthe control panel or on engine

with unit running. High voltages are present. Work that

must be done while unit is runningshould be done only by

qualified service personnelstandingon dry surfacesto re-

duce shock hazard.

.

U

0 DO NOT CONNECT THE GENERATOR SET TO THE

PUBLIC UTILITY OR TO ANY OTHER ELECTRICAL

P

POWER SYSTEM. Electrocution or damage to property

can occur at a site remote from the boat where line or

equipment repairs are being made if the set is connected

to the power system. An approvedtransfer switch must be

used if more than one power source is to be made avail-

able to service the boat.

Keep a fire extinguisher available in or near the engine

compartment and in other areas throughout the vessel.

Use the correct extinguisher for the area. For most types

of fires, an extinguisher rated ABC by the NFPA is avail-

able and suitable for use on all types of fires except alco-

hol.

0 Do notworkon this equipment when mentallyor physically

fatigued, or after consuming any alcohol or drug that

makes the operation of equipmentunsafe. M8

EXHAUST GASES ARE DEADLY

Provideadequate ventilation. Equip the bilgewith a power

Copy and post these suggestions In potential hazard areas of the vessel.

Table of Contents

SECTION TITLE PAGE

SAFETY PRECAUTIONS ......................................................... ii

1 INTRODUCTION ............................................................. 1-1

About this Manual .......................................................... 1-1

Test Equipment ............................................................. 1-1

Safety Considerations ....................................................... 1-1

Generator Set Removal ..................................................... 1-2

GENERATOR AND VOLTAGE REGULATOR ..................................... 2-1

Generator Description ...................................................... 2-1

Generator Operation ........................................................ 2-2

Voltage Regulator ........................................................... 2-3

Generator Service .......................................................... 2-5

3 GENERATOWREGULATOR TROUBLESHOOTING .............................. 3-1

Preparation ................................................................ 3-1

Troubleshooting Procedures ................................................ 3-1

4 GENERATOWREGULATOR TESTS .............................................. 4-1

General ................................................................... 4-1

(A) Testing AC Residual Voltage ............................................. 4-1

(B) Testing Commutating Reactor ............................................. 4-1

(C) Testing Rectifier Bridge CR21 and Suppressor RV21 ........................ 4-1

(D) Flashing the Field ....................................................... 4-2

(E) Testing Reference Transformer ........................................... 4-2

(F) VR21 Replacement ....................................................... 4-2

(G) Testing Rotating Rectifiers ............................................... 4-3

(H) Testing Exciter Stator .................................................... 4-3

(J) Testing Exciter Rotor ..................................................... 4-4

(K) Testing Generator Stator ................................................. 4-4

(L) Testing Generator Rotor .................................................. 4-5

(M) Wiring Harness Check ................................................... 4-6

(N) Testing Regulating Transformer T21 ....................................... 4-6

. (P) Voltage Adjustment ...................................................... 4-7

(Q) Reconnection ........................................................... 4-7

General ................................................................... 5-1

MDL Control ............................................................... 5-1

ENGINE CONTROL ADJUSTMENTS/TESTS .................................... 6-1

General ................................................................... 6-1

(A) Battery Checkout ......................................................... 6-1

(B) Battery Cable Checkout .................................................. 6-1

(C) Battery Charging Checkout ............................................... 6-1

(D) Solenoid Checkout ...................................................... 6-1

(E) Relay Checkout ......................................................... 6-2

(F) Fuel Solenoid Checkout .................................................. 6-2

(G) Switch Checkout ........................................................ 6-2

(H) Solenoid Checkout ...................................................... 7-1

7 WIRING DIAGRAMS .......................................................... 7-1

2

5 ENGINE CONTROL ................................. ......................... 5-1 .

6

. iii

I

Section 1 Introduction

ABOUT THIS MANUAL

This manual covers troubleshooting and repair informa-

tion for the generator and control. Refer to a separate

engine service manual 934-0750 when servicing the

engine.

This manual has separate sections for the generator

and voltage regulator, engine control, and associated

wiring diagrams. While the wiring diagrams at the end of

the manual are included to help trace or isolate prob-

lems, it is suggested that service personnel use the

wiring diagrams shipped with the unit for trouble-

shooting.

Repair information for solid state printed circuit boards

is not extensive because they lend themselves more to

replacement than repair. Application of meters or hot

soldering irons to printed circuit boards by other than

qualified personnel can cause unnecessary and expen-

sive damage.

Repair of the printed circuit boards is not recommended

except by the factory. A return and exchange service

has been initiated whereby faulty printed circuit boards

can be returned to the Distributor and exchanged for

good units. For more information, contact your Onan

Distributor.

b

High voltage (Megger) testing or high

1 - 1 potential (high pot) testing oigenera-

tor windings can cause damage to solid state compo-

nents. Isolate these components before testing.

TEST EQUIPMENT

Most of the test procedures in this manual can be per-

formed'with an AC-DC multimeter such as a Simpson

Model 260 VOM or a digital VOM. Some other instru-

ments to have available are:

0 Megger or Insulation Resistance Meter

0 Onan Multitester

0 Wheatstone Bridge

0 Jumper Leads

0 Load Test Panel

0 Variac

0 AC Voltmeter

DC Voltmeter

Frequency Meter

Tachometer or Strobotach

See Tool Catalog 900-001 9.

Several troubleshooting guides are included in this

manual to help the serviceperson locate the cause of

various malfunctions. Note that some malfunctions

might have several possible'causes. For this reason,the

service person may haveto investigate several problem

areas in order to isolate the source of the malfunction.

Because of the complexity of the product, a trouble-

shooting chart cannot list every malfunction and cause.

In some situations, the serviceperson will haveto rely on

experience and a knowledge of the product to locate the

problem and service as required.

SAFETY CONSIDERATIONS

Always consider the safety aspects of any service

procedure. Generator sets present several hazards that

the serviceperson must be aware of to safely complete

the job. Read through the safety precautions listed on

the inside cover and familiarize yourself with the various

hazards shown in Table 1-1. Once the hazards are

known, approach the job with a safety conscious atti-

tude. Being safety conscious is the most effective way to

avoid injury to yourself or others. Reduce the chance

that an accident will occur by adopting the following

safeguards.

Safeguards to Avoid Hazards

0 Use Personal Protection - Protect your body by

wearing appropriate safety equipment. Protective

clothing includes safety shoes, gloves, safety

glasses, and hard hats. Leave rings and jewelry off

and do not wear loose clothing that might get

caught on equipment.

0 Work to Reduce the Hazard - The, workshop area

and all pieces of equipment used can contribute to

reducing the hazard potential. Keep guards and

shields in place on machinery and maintain equip-

ment in good working condition. Store flammable

liquids in approved containers, or other ignition

source. Keep the workshop clean and well-lighted,

and provide adequate ventilation. Keep fire extin-

guishers and safety equipment nearby and be pre-

pared to respond to an emergency.

1-1

TABLE 1-1

HAZARDS AND THEIR SOURCE

0 Fire and Explosions

-Leaking or spilled fuel

-Hydrogen gas from battery

-Oily rags improperly stored

-Flammable liquids improperly stored

0 Burns

-Hot exhaust pipes

-Hot engine and generator surfaces

-Electrical short in DC wiring system

-Carbon monoxide from faulty exhaust

pipes, joints, or hangers

-Operating generator set where

exhaust gases can accumulate

0 Poisonous Gases

0 Electrical Shock (AC)

-Improper generator set load connections

-Faulty vessel wiring

-Faulty electrical appliance

-Faulty generator set wiring

-Working in damp conditions

-Jewelry touching electrical components

0 Rotating Machinery

-Jewelry or loose clothing catching

in moving parts

0 Slippery Surfaces

-Leaking or spilled oil

0 Heavy Objects

-Removing generator set from vessel

-Removing heavy components

0 Develop Safe Work Habits - Unsafe actions are GENERATOR SET REMOVAL

identified as the cause of most accidents involving

the use of tools and machines. Be familiar with the

equipment and know how to use it safely. Use the

correct tool for the job and check its condition

before starting. Observe the warnings and cautions

in this manual and take special precautions when

working around electrical equipment. Do not work

alone if possible and do not take risks.

Be prepared if an accident does occur. Numerous

agencies such as the Red Cross and your local police

and fire departments offer basic courses in first aid,

mouth-to-mouth resuscitation, and fire control. Take

advantage of these offerings so you are ready to

respond when an accident happens. Learn to be safety

conscious and make safe practices a part of your work

routine. Do not work when tired or after consuming any

alcohol or drug that makes the operation of equipment

unsafe.

Service should be performed at location whenever pos-

sible due to the generator set size and weight. Some

service procedures may require removal from the ves-

sel. While there are many variations, the generator set is

usually located in the bilge, and sometimes with limited

service space.

Because of the variety of installations, it is not possible

to specify exact removal proceduresfor any one set. If a

satisfactory method cannot be determined, contact the

vessel manufacturer to obtain their recommendations.

Generator sets are heavy and can

l3!ZEEI result in severe personal injury or

death if dropped during removal. Use adequate lifting

devices to provide sufficient support. Keep hands, feet

and body clear while lifting.

IAWARNING I

INCORRECTSERVICE OR REPLACEMENTOF PARTSCANRESULTINSEVERE

PERSONAL INJURY AND/OR EQUIPMENT DAMAGE. SERVICE PERSONNEL

MUST BE QUALIFIED TO PERFORM ELECTRICAL AND/OR MECHANICAL

SERVICE.

P

..

Section 2. Generator/Voltage Regulator

GENERATOR DESCRIPTION

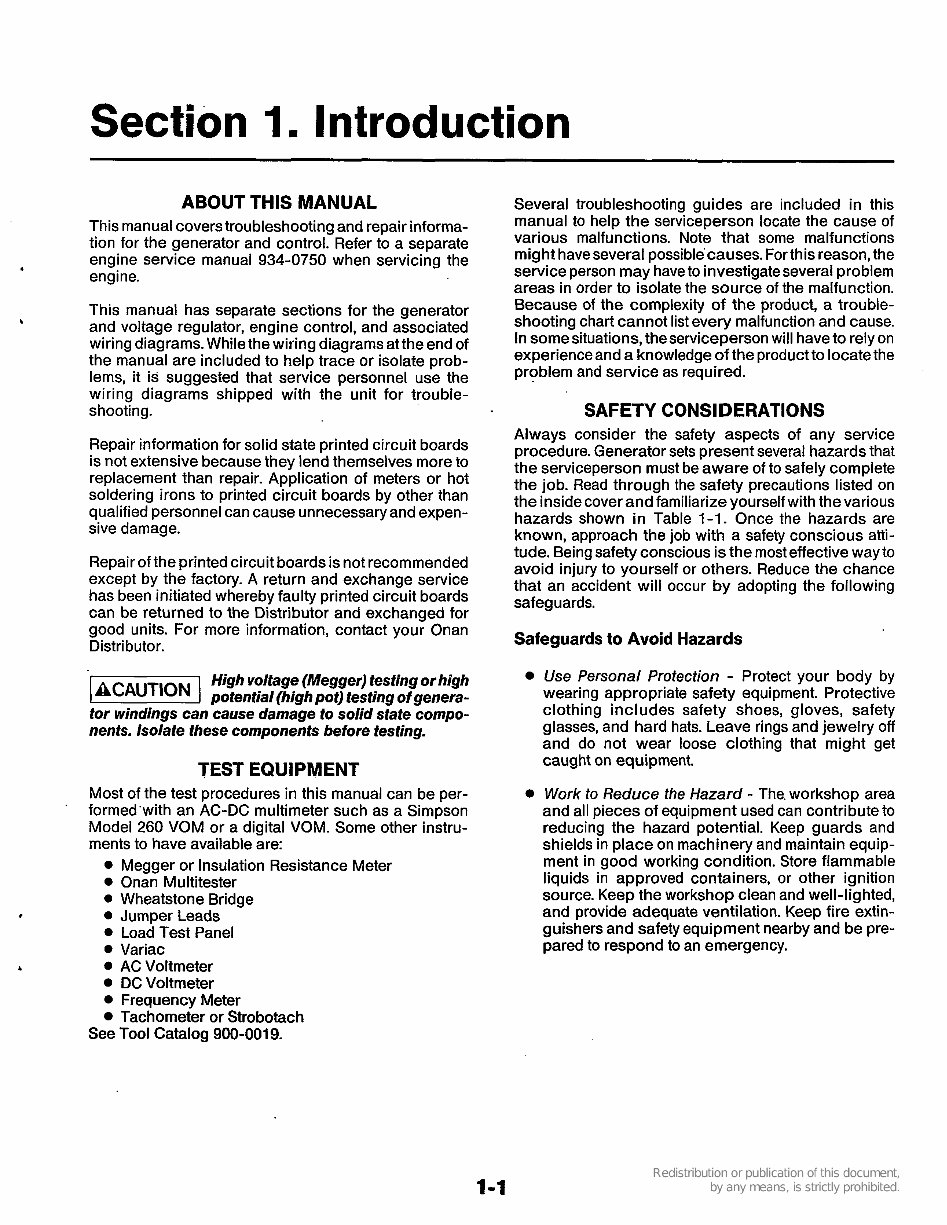

The YD generator (Figure 2-1) is a four-pole, revolving

field, brushless exciter design with drip-proof construc-

tion. Single and three phase generators are available for

both 50 and 60 hertz models. d

The generator rotor is directly coupled to the engine

flywheel with a flexible drive disc (engine speed

determines generator output voltage and frequency).

A centrifugal blower on the drive disc circulates

generator cooling air which is drawn in through the

end bell and discharged through an outlet in the

blower end.

.

DRIVE

DISC BLOWER

A ball bearing in the end bell supports the outer end

of the rotor shaft. The end bell is attached with four

studs that thread into the generator adapter casting.

The brushless exciter stator mounts in the end bell

while the exciter rotor and its rotating diode assem-

blies mount on the generator rotor shaft. Within the

end bell, leads F1 (+) and F2(-) from the exciter stator

winding are connected to the output terminals of the

voltage regulator.

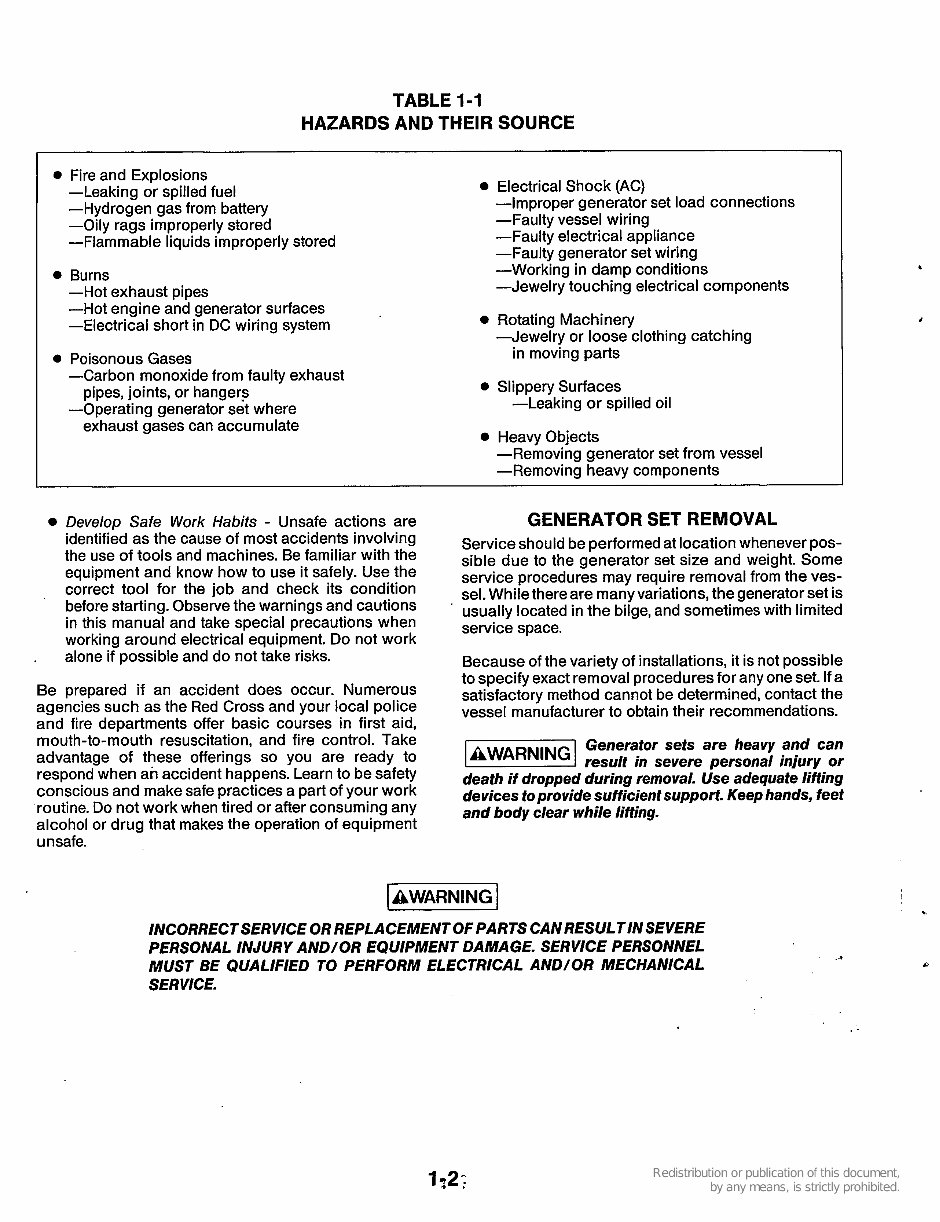

In addition to the AC output (load) leads, control wires.

exit ffom the generator housing. The number of wires

depends upon the model and options (see Figure 2-2).

END BELL

\

FIGURE 2-1. TYPICAL YD SERIES GENERATOR

2-1

CONTROL LEADS

THREE-PHASE

ll

CODE

3 8 53

SINGLE

PHASE

GENERATOR OPERATION

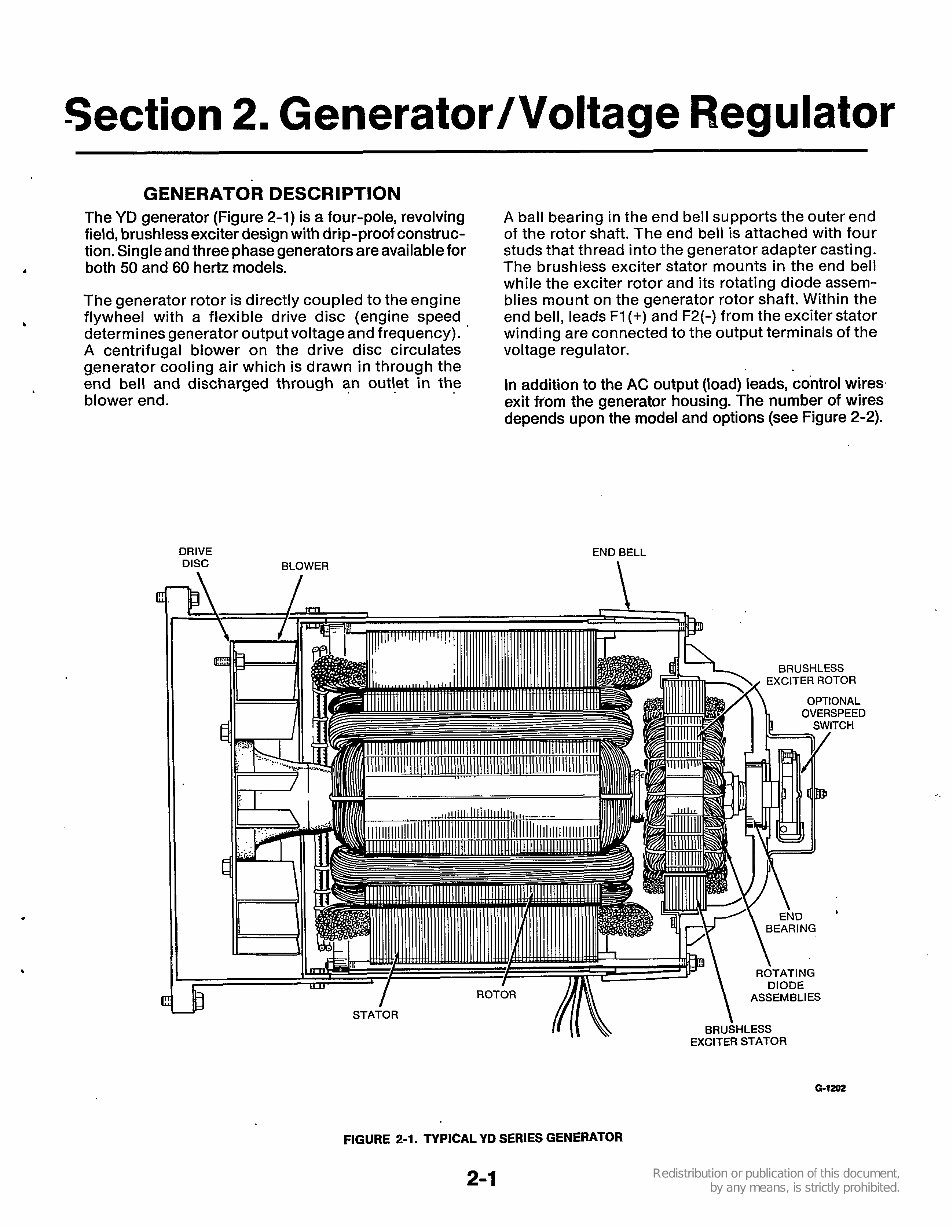

Operation of the generator involves the stator, voltage

regulator, exciter stator and rotor, rotating diode

assemblies, and the main rotor. See Figure 2-3. A per-

manent magnet embedded in one exciter field pole

begin the voltage build-up process as the generator set

starts. Single-phase AC voltage, taken from one of the

stator windings, is fed to the voltage regulator as a

reference for maintaining the generator output voltage.

DC voltage output from the voltage regulator is fed into

the brushless exciter stator.

b

The exciter rotor produces three-phase AC voltage

that is converted to DC by the rotating diode assem-

blies. The resultant DC voltage excites the main rotor

winding to produce the stator output voltage for the

AC load.

1

EXCITER

STATOR

ES1489

* - USED ONLY ON 12- AND 24-VOLT SYSTEMS

, FIGURE 2-2. SINGLE AND THREE PHASE GENERATOR

SCHEMATLC (COMPOSITE)

ROTOR

SHAFT

BRUSHLESS MAIN

EXCITER ROTOR ROTOR

- - . @+ -

ASSEMBLIES

W

?!

U

I

I

I'

EXCITER ' ' 1 : :

I I PERMANENT I MAGNETISM

MAGNETISM I I MA$~~c~sRTs

BRUSHLESS

EXCITER STATOR

I

STATOR

ASSY

VOLTAGE

I REGULATOR

1

ES1490

FIGURE '2-3. EXCITATION BLOCK DIAGRAM

2-2

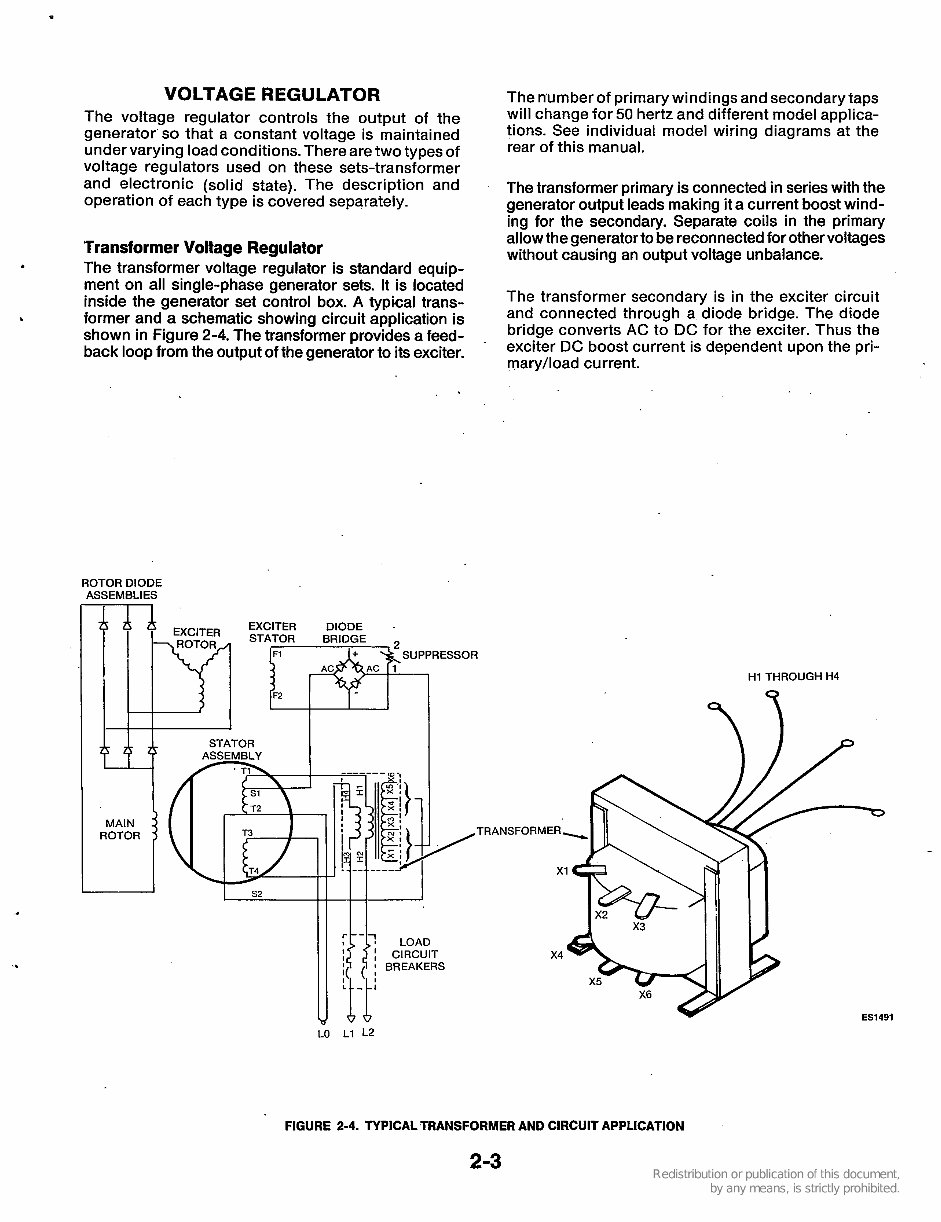

VOLTAGE REGULATOR

The voltage regulator controls the output of the

generator's0 that a constant voltage is maintained

under varying load conditions. There are two types of

voltage regulators used on these sets-transformer

and electronic (solid state). The description and

operation of each type is covered separately.

Transformer Voltage Regulator

The transformer voltage regulator is standard equip-

ment on all single-phase generator sets. It is located

inside the generator set control box. A typical trans-

shown in Figure 2-4. The transformer provides a feed-

back loop from the output of the generator to its exciter.

.

former and a schematic showing circuit application is

The number of primary windings and secondary taps

will change for 50 hertz and different model applica-

tions. See individual model wiring diagrams at the

rear of this manual.

The transformer primary is connected in series with the

generator output leads making it a current boost wind-

ing for the secondary. Separate coils in the primary

allow the generator to be reconnectedfor other voltages

without causing an output voltage unbalance.

The transformer secondary is in the exciter circuit

and connected through a diode bridge. The diode

bridge converts AC to DC for the exciter. Thus the

exciter DC boost current is dependent upon the pri-

mary/load current.

ROTOR DIODE

ASSEMBLIES

H1 THROUGH H4

ES1491

LO L1 L2

FIGURE 2-4. TYPICAL TRANSFORMER AND CIRCUIT APPLICATION

2-3

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 21 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Complete Factory Service Repair Workshop Manual is available for instant access on your computer, tablet, or smartphone. This Professional Manual covers all repairs, servicing, and troubleshooting procedures. It contains detailed pages with photos and diagrams, along with step-by-step instructions and highly detailed exploded diagrams and pictures. This manual is useful for both professional Mechanics and Technicians, as well as DIY enthusiasts. The files are easy to read, bookmarked, searchable, and can be viewed on almost any computer. You can print one page or the whole manual for your convenience.