Yamaha EF4000DFW EF5200DE EF6600DE Generator Full Service & Repair Manual

Have a question?Ask Us

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

EF4000DFW

EF4000DEFW

EF5200D

EF5200DE

EF6600D

EF6600DE

SERVICE MANUAL

7DA-F8197-10 LIT-19616-01-60

FOREWORD

This manual was written by the Yamaha Motor

Company primarily for use by Yamaha dealers

and their qualified mechanics. It is not possi-

ble to put an entire mechanic’s education into

one manual, so it is assumed that persons

using this book to perform maintenance and

repairs on Yamaha generators have a basic

understanding of the mechanical precepts and

procedures inherent to generator repair tech-

nology. Without such knowledge, attempted

repairs or service to this model may render it

unfit for use and/or unsafe.

Yamaha Motor Company Ltd. is continually

striving to further improve all models manufac-

tured by Yamaha. Modifications and significant

changes in specifications or procedures will

be forwarded to all Authorized Yamaha deal-

ers and will, where applicable, appear in

future editions of this manual.

TIP

This Service Manual contains information

regarding periodic maintenance to the

emission control system. Please read this

material carefully.

HOW TO USE THIS MANUAL

PARTICULARLY IMPORTANT

INFORMATION

Particularly important information is distin-

guished in this manual by the following nota-

tions.

This is the safety alert symbol. It is used to

alert you to potential personal injury haz-

ards. Obey all safety messages that follow

this symbol to avoid possible injury or

death.

WARNING

A WARNING indicates a hazardous situa-

tion which, if not avoided, could result in

death or serious injury.

NOTICE

A NOTICE indicates special precautions

that must be taken to avoid damage to the

machine or other property.

TIP

A TIP provides key information to make proce-

dures easier or clearer.

EF4000DFW/EF4000DEFW

EF5200D/EF5200DE

EF6600D/EF6600DE

SERVICE MANUAL

©2011 by Yamaha Motor

Corporation, U.S.A.

1st Edition, August 2011

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor

Corporation, U.S.A.

is expressly prohibited.

Printed in USA

LIT-19616-01-60

HOW TO USE THIS MANUAL

This manual is intended as a handy, easy-to-read reference book for the mechanic.

Comprehensive explanations of all installation, removal, disassembly, assembly, repair and check

procedures are laid out with the individual steps in sequential order.

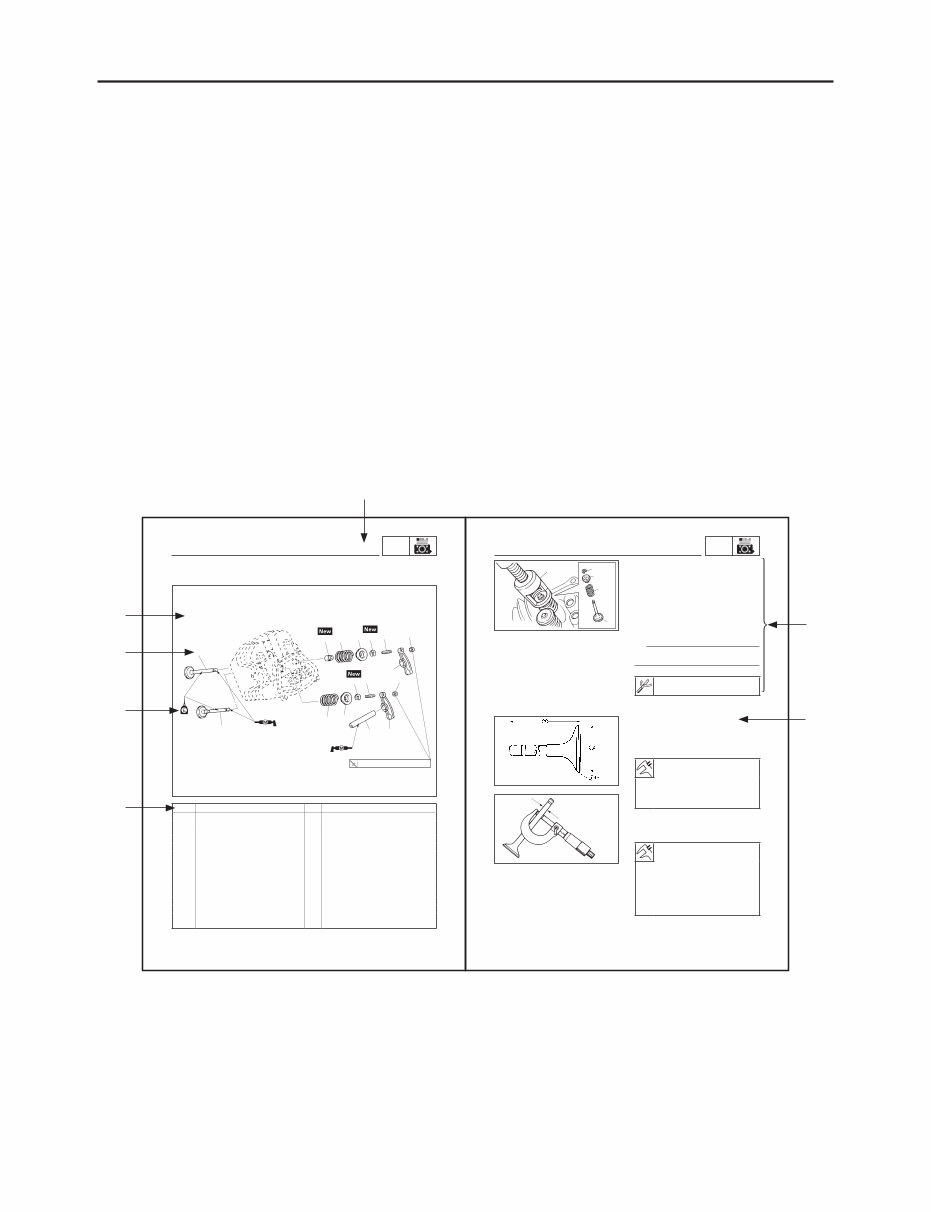

9 The manual is divided into chapters and each chapter is divided into sections. The current sec-

tion title is shown at the top of each page 1.

9 Sub-section titles appear in smaller print than the section title 2.

9 To help identify parts and clarify procedure steps, there are exploded diagrams at the start of

each removal and disassembly section 3.

9 Numbers are given in the order of the jobs in the exploded diagram. A number indicates a dis-

assembly step 4.

9 Symbols indicate parts to be lubricated or replaced 5.

Refer to “ILLUSTRATED SYMBOLS”.

9 A job instruction chart accompanies the exploded diagram, providing the order of jobs, names of

parts, notes in jobs, etc. 6.

9 Jobs requiring more information (such as special tools and technical data) are described

sequentially 7.

3-33

ENG VALVE

1

4

9

8

7 Nm (0.7 m · kgf, 5.1 ft · lbf)

2 5 6

7 10

1

3

2 5

6 7

4

Order Job/Parts to remove Q’ty Remarks

Removing the valve Remove the parts in the order listed.

Cylinder head Refer to “CYLINDER HEAD COVER,

CYLINDER HEAD” on 3-29.

1 Locknut 2

2 Adjuster 2

3 Rocker arm shaft 1

4 Rocker arm 2

5 Valve cotter 2

6 Valve spring retainer 2

7 Valve spring 2

8 Exhaust valve 1

9 Intake valve 1

10 Valve stem seal 1 Intake side only.

For installation, reverse the removal pro-

cedure.

VALVE

3-34

ENG VALVE

1

2

3

4

5

SCF3180

302-001

a

REMOVING THE VALVE AND VALVE

SPRING

1. Remove:

9 Valve cotters 1

9 Valve spring retainers 2

9 Valve springs 3

9 Valves 4

9 Valve stem seal (Intake side only)

Remove the parts using the valve

spring compressor 5.

TIP

Do not compress the spring more than neces-

sary.

Valve spring compressor:

YM-01253, 90890-01253

CHECKING THE VALVE AND VALVE

SPRING

1. Measure:

9 Valve stem length a

9 Valve head diameter b

Valve stem length:

Intake: 88.1 mm (3.47 in)

Exhaust: 87.9 mm (3.46 in)

Valve head diameter:

Intake: 32.0 mm (1.26 in)

Exhaust: 27.0 mm (1.06 in)

Out of specifications → Replace.

2. Measure:

9 Valve stem diameter a

Valve stem diameter:

Standard

Intake: 5.948–5.963 mm

(0.2342–0.2348 in)

Exhaust: 5.940–5.955 mm

(0.2339–0.2344 in)

Wear limit

Intake: 5.9 mm (0.23 in)

Exhaust: 5.9 mm (0.23 in)

Out of specifications → Replace.

1

3

4

5

6

7

2

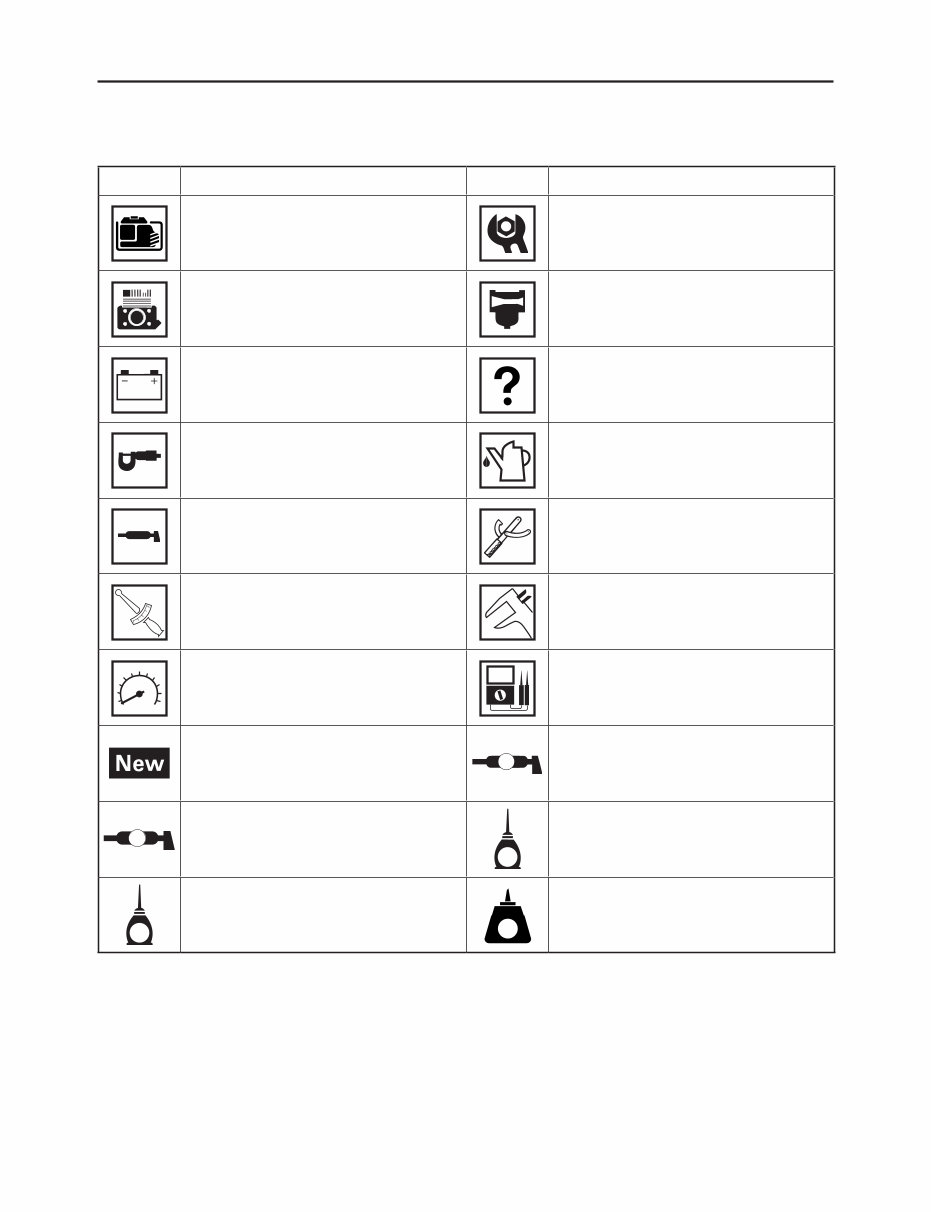

ILLUSTRATED SYMBOLS

(Refer to the illustration)

SYMBOL DEFINITION SYMBOL DEFINITION

General information

Periodic checks and

adjustments

Engine Carburetor

Electrical Troubleshooting

Specifications Filling fluid

Lubricant Special tool

T

R

.

.

Tightening torque Wear limit, clearance

Engine speed Electrical data

Replace the part with a new one.

LS

Lithium-soap base grease

M

Molybdenum disulfide grease

E

Engine oil

M

Molybdenum disulfide oil

LT

Apply locking agent (LOCTITE

®

)

INDEX

GENERAL INFORMATION

GEN

INFO

PERIODIC CHECKS

AND ADJUSTMENTS

CHK

ADJ

ENGINE

ENG

CARBURETOR

ELECTRICAL

TROUBLESHOOTING

CARB

ELEC

TRBL

SPECIFICATIONS

SPEC

1

2

3

4

5

6

7

CHAPTER 1.

GENERAL INFORMATION

MACHINE IDENTIFICATION .....................1-1

ENGINE SERIAL NUMBER..................1-1

STARTING SERIAL NUMBER ..............1-1

IMPORTANT INFORMATION ....................1-2

PREPARATION FOR REMOVAL AND

DISASSEMBLY .....................................1-2

CAUTION ON SERVICE .......................1-2

NOTES ON SERVICE...........................1-2

ALL REPLACEMENT PARTS ...............1-3

GASKETS, OIL SEALS,

AND O-RINGS ......................................1-3

BEARINGS AND OIL SEALS ...............1-3

BASIC SERVICE INFORMATION..............1-4

ELECTRICAL SYSTEM ........................1-4

SPECIAL TOOLS AND TESTERS .............1-7

CHAPTER 2.

PERIODIC CHECKS AND

ADJUSTMENTS

INTRODUCTION ........................................2-1

MAINTENANCE INTERVALS CHART ......2-1

PERIODIC MAINTENANCE/

LUBRICATION INTERVALS ......................2-1

PERIODIC MAINTENANCE ......................2-3

SPARK PLUG .......................................2-3

FUEL LEAKAGE ...................................2-5

ENGINE OIL LEAKAGE .......................2-5

ENGINE OIL LEVEL .............................2-5

REPLACING THE ENGINE OIL ...........2-6

AIR FILTER ELEMENT .........................2-7

MUFFLER .............................................2-8

FUEL TANK FILTER..............................2-9

FUEL COCK STRAINER ....................2-10

BATTERY (EF4000DEFW/

EF5200DE/EF6600DE).......................2-10

BREATHER HOSE..............................2-11

CYLINDER HEAD

DECARBONIZATION ..........................2-11

ADJUSTING THE VALVE

CLEARANCE ......................................2-11

ADJUSTING THE ENGINE SPEED ...2-14

RECOIL STARTER .............................2-15

FITTINGS AND FASTENERS ............2-15

CHAPTER 3.

ENGINE

ENGINE INSPECTION...............................3-1

MEASURING THE COMPRESSION

PRESSURE ..........................................3-1

CONTROL BOX .........................................3-3

AIR FILTER ................................................3-5

FUEL TANK, CANISTER ...........................3-6

CHECKING THE CANISTER................3-7

MUFFLER ..................................................3-8

INSTALLING THE EXHAUST PIPE

AND MUFFLER ....................................3-9

ENGINE ....................................................3-10

RECOIL STARTER ..................................3-11

REMOVING THE RECOIL

STARTER ............................................3-12

CHECKING THE RECOIL

STARTER ............................................3-13

INSTALLING THE RECOIL

STARTER ............................................3-13

FLYWHEEL ..............................................3-15

REMOVING THE FLYWHEEL ............3-16

INSTALLING THE FLYWHEEL ...........3-17

INSTALLING THE TCI UNIT ...............3-18

GENERATOR ...........................................3-19

REMOVING THE STATOR

ASSEMBLY AND ROTOR

ASSEMBLY .........................................3-21

INSTALLING THE STATOR

ASSEMBLY AND ROTOR

ASSEMBLY .........................................3-22

GOVERNOR .............................................3-24

REMOVING THE FLYWEIGHT

SHAFT ASSEMBLY AND

GOVERNOR SHAFT ..........................3-26

DISASSEMBLING THE FLYWEIGHT

SHAFT ASSEMBLY ............................3-26

CHECKING THE FLYWEIGHT

SHAFT ASSEMBLY AND

GOVERNOR SHAFT ..........................3-27

ASSEMBLING THE FLYWEIGHT

SHAFT ASSEMBLY ............................3-27

INSTALLING THE FLYWEIGHT

SHAFT ASSEMBLY AND

GOVERNOR SHAFT ..........................3-27

ADJUSTING THE GOVERNOR..........3-28

CYLINDER HEAD COVER,

CYLINDER HEAD ....................................3-29

CHECKING THE PUSH ROD .............3-31

CHECKING THE CYLINDER

HEAD ..................................................3-31

INSTALLING THE CYLINDER

HEAD ASSEMBLY ..............................3-32

VALVE ......................................................3-33

REMOVING THE VALVE AND

VALVE SPRING ..................................3-34

CHECKING THE VALVE AND

VALVE SPRING ..................................3-34

CHECKING THE ROCKER ARM .......3-36

CHECKING THE VALVE SEAT ...........3-36

VALVE LAPPING ................................3-38

INSTALLING THE VALVE AND

VALVE SPRING ..................................3-38

PISTON, CAMSHAFT,

CRANKCASE, AND CRANKSHAFT .......3-40

REMOVING THE BALANCER

SHAFT, CAMSHAFT, AND VALVE

LIFTER................................................3-42

CHECKING THE BALANCER

SHAFT ................................................3-42

CHECKING THE CAMSHAFT ............3-43

CHECKING THE VALVE LIFTER........3-44

INSTALLING THE VALVE LIFTER,

BALANCER SHAFT, AND

CAMSHAFT ........................................3-44

CHECKING THE CRANKCASE

COVER ...............................................3-44

INSTALLING THE CRANKCASE

COVER ...............................................3-45

CHECKING THE CYLINDER..............3-45

CHECKING THE CRANKCASE .........3-46

CHECKING THE PISTON AND

PISTON PIN........................................3-47

CHECKING THE PISTON RING ........3-48

CHECKING THE CRANKSHAFT .......3-49

CHECKING THE CONNECTING

ROD OIL CLEARANCE ......................3-51

INSTALLING THE PISTON AND

PISTON RING.....................................3-52

INSTALLING THE CRANKSHAFT ......3-53

CHAPTER 4.

CARBURETOR

REMOVING THE CARBURETOR ..............4-1

DISASSEMBLING THE CARBURETOR ...4-3

EF4000DFW/EF5200D/EF6600D .........4-3

EF4000DEFW/EF5200DE/

EF6600DE ............................................4-5

CHECKING THE CARBURETOR .........4-7

CHECKING THE AUTO CHOKE

(EF4000DEFW/EF5200DE/

EF6600DE) ...........................................4-8

CHECKING THE FUEL CUT

SOLENOID VALVE................................4-9

CHAPTER 5.

ELECTRICAL

ELECTRICAL COMPONENTS ..................5-1

CIRCUIT DIAGRAM ...................................5-2

EF4000DFW .........................................5-2

EF4000DEFW .......................................5-3

EF5200D/EF6600D...............................5-4

EF5200DE/EF6600DE ..........................5-5

CONTROL PANEL .....................................5-6

EF4000DFW/EF4000DEFW .................5-6

EF5200D/EF5200DE/EF6600D/

EF6600DE ............................................5-8

BATTERY

(EF4000DEFW/EF5200DE/EF6600DE) ...5-10

CHECKING THE BATTERY ................5-10

FUSE

(EF4000DEFW/EF5200DE/EF6600DE) ...5-12

CHECKING THE FUSE ......................5-12

SWITCHES...............................................5-14

CHECKING THE SWITCH

CONTINUITY .....................................5-14

IGNITION SYSTEM..................................5-15

TROUBLESHOOTING CHART...........5-15

ELECTRIC STARTING SYSTEM

(EF4000DEFW/EF5200DE/EF6600DE) ...5-21

TROUBLESHOOTING CHART...........5-21

REMOVING THE STARTER

MOTOR ...............................................5-23

DISASSEMBLING THE STARTER

MOTOR ...............................................5-24

CHECKING THE ARMATURE COIL...5-25

CHECKING THE BRUSH ...................5-26

CHECKING THE MAGNETIC

SWITCH ..............................................5-26

CHARGING SYSTEM

(EF4000DEFW/EF5200DE/EF6600DE) ...5-27

TROUBLESHOOTING CHART...........5-27

GENERATOR SYSTEM ...........................5-29

TROUBLESHOOTING CHART...........5-29

ECONOMY CONTROL SYSTEM ............5-40

ECONOMY CONTROL SYSTEM

DIAGRAM ...........................................5-40

TROUBLESHOOTING CHART...........5-41

CHAPTER 6.

TROUBLESHOOTING

ENGINE ......................................................6-1

CHAPTER 7.

SPECIFICATIONS

GENERAL SPECIFICATIONS ...................7-1

MAINTENANCE SPECIFICATIONS ..........7-4

ENGINE ................................................7-4

ELECTRICAL ........................................7-7

GENERATOR ........................................7-8

TIGHTENING TORQUES .........................7-10

GENERAL TORQUE

SPECIFICATIONS....................................7-12

LUBRICATION POINTS AND TYPE OF

LUBRICANTS ..........................................7-13

WIRE ROUTING DIAGRAM ....................7-14

CONTROL PANEL AND CONTROL

BOX (EF4000DFW) ............................7-14

CONTROL PANEL AND CONTROL

BOX (EF4000DEFW) ..........................7-16

CONTROL PANEL AND CONTROL

BOX (EF5200D/EF6600D) ..................7-18

CONTROL PANEL AND CONTROL

BOX (EF5200DE/EF6600DE) .............7-20

BACK SIDE AND LEFT SIDE VIEW...7-22

UPPER SIDE VIEW ............................7-23

ENGINE ..............................................7-25

GENERATOR ......................................7-26

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 22 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

- This is a complete factory service repair workshop manual for Yamaha EF4000DFW, EF5200DE, and EF6600DE generators.

- It is available for instant access on your computer, tablet, or smartphone.

- The manual covers all repairs, servicing, and troubleshooting procedures with detailed photos and diagrams.

- Professional mechanics and technicians use this type of manual, which contains step-by-step instructions and highly detailed exploded diagrams and pictures.

- You have the option to print out a single page or the entire manual.

- This manual can be used on multiple computers without any limitations or trial periods.

- There is no expiration date or renewal fee for this full manual, and it can be used for life.

- It is fully compatible with all Windows and MAC computers.

Thanks for considering this item. Please click on the button for more information.

We're currently collecting product reviews for this item. In the meantime, here are some reviews from our past customers sharing their overall shopping experience.

4.5

Out of 5.0

Overall Rating

89%

of customers that buyfrom this merchant give

them a 4 or 5-Star rating.

Verified Buyer

September 26, 2025 by Klaus U. (Alicante, ES)

“Perfect”

Verified Buyer

September 26, 2025 by Ian J. (US)

“It was fabulous”

Verified Buyer

September 26, 2025 by Loredano M. (Pordenone, IT)

“Very good experience!!”

Verified Buyer

September 26, 2025 by Trevor M. (County Antrim, GB)

“Not sure if I chose the correct manual. Can I change if incorrect.”

Verified Buyer

September 26, 2025 by Fidel M. (California, US)

“Easy quick and efficient .”

Verified Buyer

September 26, 2025 by Pastiu G. (DE)

“Excellence”

Verified Buyer

September 26, 2025 by Luis M. (US)

“Gnj”

Verified Buyer

September 25, 2025 by Calum C. (Western Australia, AU)

“Easy thanks”

Verified Buyer

September 25, 2025 by Gerald C. (US)

“doesn't only sell manuals, offers knowledgeable advice as well”

Verified Buyer

September 25, 2025 by Del M. (US)

“Easy to find what I was looking for, downloaded immediately.”