EF1000

Service Manual

7FL-28197-11

FOREWORD

This manual was written by the Yamaha Motor

Company primarily for use by Yamaha dealers and

their qualified mechanics. It is not possible to put

an entire mechanic's education into one manu-

al, so it is assumed that persons using this book

to perform maintenance and repairs on Yamaha

generator have a basic understanding of the

mechanical precepts and procedures inherent to

generator repair technology. Without such

knowledge, attempted repairs or service to this

model may render it unfit for use and/or unsafe.

Yamaha Motor Company Ltd. is continually striv-

ing to further improve all models manufactured

by Yamaha. Modifications and significant

changes in specifications or procedures will be for-

warded to all Authorized Yamaha dealers and will,

where applicable, appear in future editions of this

manual.

NOTE: --------------------------

This Service Manual contains information

regarding periodic maintenance to the emis-

sion control system. Please read this materi-

al carefully.

EF1000

SERVICE MANUAL

©1995 by Yamaha Motor Co., Ltd.

1st Edition, January 1995

All rights reserved. Any reprinting or

unauthorized use without the written

permission of Yamaha Motor Co., ltd.

is expressly prohibited.

Printed in Japan

HOW TO USE THIS MANUAL

PARTICULARLY IMPORTANT

INFORMATION

This material is distinguished by the following no-

tation.

&

The Safety Alert Symbol means ATTENTION!

BECOME ALERT! YOUR SAFETY IS INVOLVED!

A WARNING

Failure to follow WARNING instructions could

result in severe injury or death to the machine

operator, a bystander, or a person inspecting or

repairing the machine.

I"lllli•lz•·•••·••·•

A CAUTION indicates special precautions that

must be taken to avoid damage to the machine.

NOTE:

A NOTE provides key information to make proce-

dures easier or clearer.

MANUAL FORMAT

The procedures in this manual are organized

in a sequential, step-by-step format. The in-

formation has been compiled to provide the

mechanic with an easy to read, handy refer-

ence that contains comprehensive explana-

tions of all disassembly, repair, assembly,

and inspection operations.

In this revised format, the condition of a faulty

component will precede an arrow symbol and the

course of action required will follow the symbol,

e.g.,

• Bearings

Pitting/ Damage~ Replace.

EXPLODED DIAGRAM

Each chapter provides exploded diagrams before

each disassembly section for ease in identifying

correct disassembly and assembly procedures.

CD

GEN

....

,.

INFO

@

•llllull

ENG

1•1

@

I sPEc I g-1

®

~

@

l

@

~

©

[ij]

@

1

-

m

®

&

a

(2)

l~5~l§ll

@

IELEciUI

(j)

~

®

1~1

@

§

@

1

9

®

~

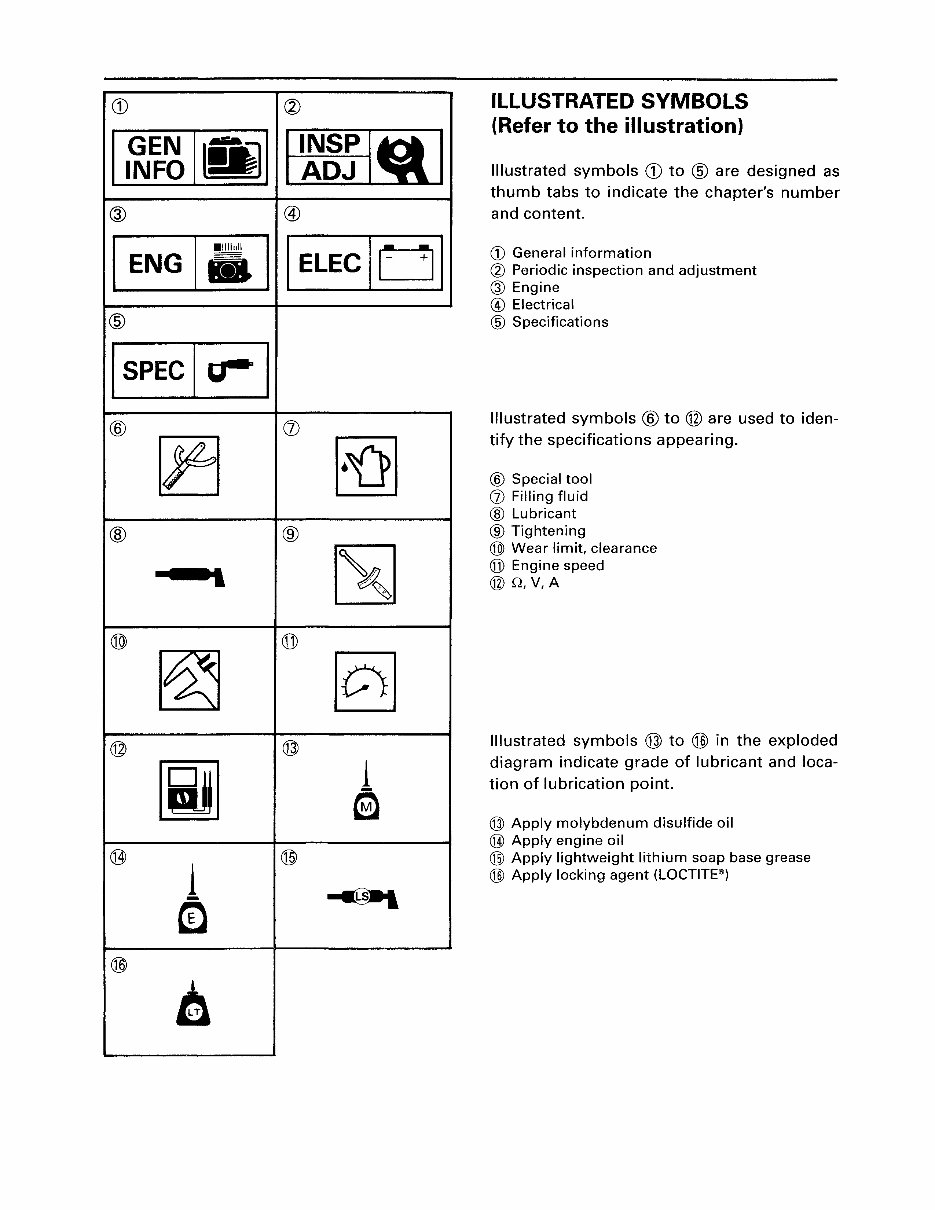

ILLUSTRATED SYMBOLS

(Refer to the illustration)

Illustrated symbols CD to @ are designed as

thumb tabs to indicate the chapter's number

and content.

<D General information

~ Periodic inspection and adjustment

®Engine

® Electrical

® Specifications

Illustrated symbols @to @ are used to iden-

tify the specifications appearing.

® Special tool

(]) Filling fluid

@ Lubricant

® Tightening

@ Wear limit, clearance

(j]) Engine speed

@Q,V,A

Illustrated symbols @ to @ in the exploded

diagram indicate grade of lubricant and loca-

tion of lubrication point.

@ Apply molybdenum disulfide oil

@ Apply engine oil

@ Apply lightweight lithium soap base grease

@ Apply locking agent (LOCTITE®)

INDEX

GENERAL INFORMATION

PERIODIC INSPECTIONS

AND ADJUSTMENTS

ENGINE

ELECTRICAL

SPECIFICATIONS

111

GEN

INFO

•II II nil

-

ENG

ELEC

CONTENTS

CHAPTER 1

GENERAL INFORMATION

MACHINE IDENTIFICATION ..................... 1-1

IMPORTANT INFORMATION ................... 1-2

SPECIAL TOOLS AND TESTERS ............. 1-5

CHAPTER 2

PERIODIC INSPECTIONS

AND ADJUSTMENTS

INTRODUCTION ....................................... 2-1

MAINTENANCE INTERVALS CHART ...... 2-1

PERIODIC MAINTENANCE/

LUBRICATION INTERVALS ...................... 2-1

BODY COVER/FUEL TANK ...................... 2-3

JOB INSTRUCTION CHART ................ 2-3

ENGINE ..................................................... 2-4

ENGINE OIL ......................................... 2-4

FUEL COCK .......................................... 2-5

START WIRE ADJUSTMENT .............. 2-6

FUEL LINE ............................................ 2-6

AIR FILTER ........................................... 2-7

MUFFLER ............................................. 2-7

VALVE CLEARANCE ADJUSTMENT .. 2-8

COMPRESSION PRESSURE

MEASUREMENT ................................. 2-9

ENGINE SPEED ADJUSTMENT ......... 2-10

GOVERNOR ADJUSTMENT ............... 2-10

SPARK PLUG ....................................... 2-11

CYLINDER HEAD ................................. 2-12

BREATHER HOSE INSPECTION ......... 2-12

CHAPTER3

ENGINE

AIR CARBURETOR, MUFFLER ................ 3-1

JOB INSTRUCTION CHART ................ 3-2

ENGINE ..................................................... 3-3

JOB INSTRUCTION CHART ................ 3-4

CYLINDER HEAD COVER, CYLINDER

HEAD, VALVE ........................................... 3-5

JOB INSTRUCTION CHART ................ 3-6

CYLINDER HAD INSPECTION ............ 3-7

VALVE REMOVAL ................................ 3-7

VALVE INSPECTION ............................ 3-7

VALVE SEAT INSPECTION .................. 3-8

PUSH ROD INSPECTION .................... 3-10

CYLINDER HEAD INSTALLATION ...... 3-10

PISTON,CAMSHAFT,CRANKCASE,

CRANKSHAFT ....................................... .. 3-11

JOB INSTRUCTION CHART ................ 3-12

CRANKSHAFT REMOVAL ................... 3-13

CAMSHAFT AND VALVE LIFTER

INSPECTION ........................................ 3-13

CRANKCASE INSPECTION ................. 3-14

PISTON,PISTON PIN AND

PISTON RING INSPECTION ............... 3-15

CRANKSHAFT INSPECTION .............. 3-16

FLYWEIGHT SHAFT (GOVERNOR)

GEAR INSPECTION ............................. 3-17

CRANKCASE COVER INSPECTION ... 3-18

PISTON RING AND PISTON

INSTALLATION .................................... 3-18

CONNECTING ROD INSTALLATION .. 3-19

CAMSHAFT INSTALLATION ............... 3-19

CRANKCASE COVER

INSTALLATION .................................... 3-19

RECOIL STARTER ................................... 3-20

JOB INSTRUCTION CHART ................ 3-20

RECOIL STARTER REMOVAL ............. 3-21

RECOIL STARTER INSPECTION ......... 3-21

RECOIL STARTER INSTALLATION ..... 3-22

FLYWHEEL ............................................... 3-23

JOB INSTRUCTION CHART ................ 3-23

FLYWHEEL REMOVAL . ........................ 3-24

GENERATOR ............................ .......... 3-25

JOB INSTRUCTION CHART ................. 3-25

ROTOR REMOVAL . .............................. 3-26

STATOR INSTALLATION ..................... 3-26

ROTOR INSTALLATION ...................... 3-26

REAR FRAME INSTALLATION ............ 3-26

GOVERNOR ............................................. 3-27

JOB INSTRUCTION CHART ................ 3-28

CARBURETOR ........................................ . 3-29

JOB INSTRUCTION CHART ................ 3-30

FLOAT HEIGHT INSPECTION ............. 3-31

FUEL PASSAGE INSPECTION ............ 3-31

VALVE SEAT INSPECTION .................. 3-31

CHAPTER 4

ELECTRICAL

ELECTRICAL COMPONENTS ................. .4-1

CIRCUIT DIAGRAM .................................. 4-2

IGNITION SYSTEM .................................. 4-3

TROUBLESHOOTING CHART ............ 4-3

GENERATOR SVSTEM ............................. 4-7

TROUBLESHOOTING CHART ............ 4-7

INSPECTION ........................................ 4-9

CHAPTER 5

SPECIFICATIONS

GENERAL SPECIFICATIONS .................... 5-1

MAINTENANCE SPECIFICATIONS .......... 5-2

TIGHTENING TORQUE ............................ 5-5

GENERAL TORQUE SPECIFICATIONS ... 5-6

DEFINITION OF UNITS ............................ 5-6

HOSE ROUTING ....................................... 5-7

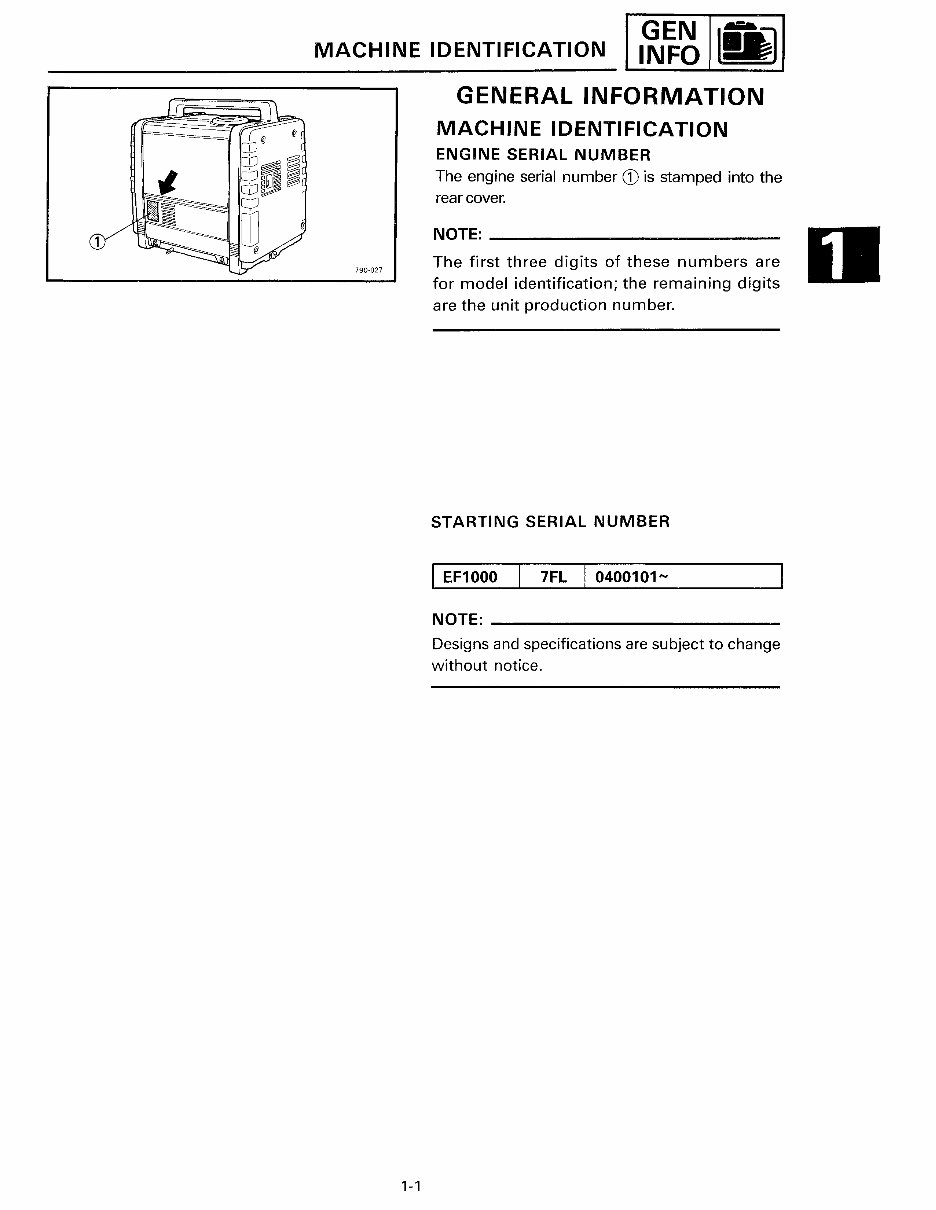

MACHINE IDENTIFICATION

~~~~.

790-027

1-1

GENERAL INFORMATION

MACHINE IDENTIFICATION

ENGINE SERIAL NUMBER

The engine serial number CD is stamped into the

rear cover.

NOTE: ________________________ ___

The first three digits of these numbers are

for model identification; the remaining digits

are the unit production number.

STARTING SERIAL NUMBER

I EF1000 7FL I 0400101-

NOTE: --------------------------

Designs and specifications are subject to change

without notice.

IMPORTANT INFORMATION

[ __ ]

1-2

IMPORTANT INFORMATION

PREPARATION FOR REMOVAL AND

DISASSEMBLY

NOTES ON SERVICE

1. Fire prevention

When servicing the engine, always keep away

from fire.

2. Right tools

Be sure to use the right special tool for the

job to guard against damage.

3. Oil, grease and sealers

Be sure to use genuine Yamaha oils, greases

and sealers, or the equivalents.

4. Expendable parts

Always replace gaskets, 0-rings, cotter pins,

and circlips with new parts when servicing

engine.

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual