KOHLER Generator Service Workshop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Residential/Commercial Generator Sets

Models:

14RES/RESL

20RES/RESL

Controllers:

RDC Residential Digital Control

DC Digital Control

TP-6735 9/10

Service

Table of Contents

TP-6735 9/10 Table of Contents

Safety Precautions and Instructions 7 ........................................................

Introduction 11 ...............................................................................

List of Related Materials 11 .....................................................

Service Assistance 12 ........................................................................

Section 1 Specifications 13 ...................................................................

1.1 Introduction 13 ..........................................................

1.2 Controller Specifications 13 ...............................................

1.3 Engine Service 13 .......................................................

1.4 Engine Specifications 13 ..................................................

1.5 Alternator Specifications 14 ...............................................

1.6 Torque Specifications 14 ..................................................

1.7 Service View 15 .........................................................

Section 2 Scheduled Maintenance 17 ..........................................................

2.1 Service Schedule 17 .....................................................

2.2 Lubrication System 19 ....................................................

2.2.1 Low Oil Pressure Shutdown 19 ....................................

2.2.2 Oil Check 19 ....................................................

2.2.3 Engine Oil Recommendation 19 ....................................

2.2.4 Oil Change Procedure 19 .........................................

2.2.5 Oil Cooler, 14RES/RESL 20 .......................................

2.2.6 Oil Cooler, 20RES/RESL 21 .......................................

2.3 Spark Plugs 21 ..........................................................

2.4 Air Cleaner Service 22 ....................................................

2.4.1 Air Cleaner, 14RES/RESL Models 22 ...............................

2.4.2 Air Cleaner, 20RES/RESL Models 23 ...............................

2.5 Cooling System 23 .......................................................

2.6 Stepper Motor Coupling 24 ................................................

2.7 Exhaust System 24 ......................................................

2.8 Battery 24 ...............................................................

2.9 Battery Charger 25 .......................................................

2.10 Storage Procedure 26 ....................................................

2.10.1 Lubricating System 26 ............................................

2.10.2 Fuel System 26 ..................................................

2.10.3 Cylinder Lubrication 26 ...........................................

2.10.4 Exterior Preparation 26 ...........................................

2.10.5 Battery 26 .......................................................

Section 3 Troubleshooting 27 .................................................................

3.1 Introduction 27 ..........................................................

3.2 Initial Checks 27 .........................................................

3.3 Controller Service Access 27 ..............................................

3.4 Troubleshooting Chart 27 .................................................

3.5 Controller Troubleshooting 36 .............................................

Section 4 Controller 37 .......................................................................

4.1 Introduction 37 ..........................................................

4.2 RDC and DC Generator Set/ Transfer Switch Controllers 37 ...................

4.3 Controller Power 37 ......................................................

4.4 Controls and Indicators 38 ................................................

4.4.1 LED Display 39 ..................................................

4.4.2 Controller Keypad 39 .............................................

4.4.3 LED Indicators 40 ................................................

Table of Contents, continued

TP-6735 9/10 Table of Contents

4.5 Generator Set Operation 41 ...............................................

4.5.1 Engine Start Crank Cycle 41 .......................................

4.5.2 Local Starting and Stopping 41 ....................................

4.5.3 Automatic Operation with Model RRT Transfer Switch 41 ..............

4.5.4 Automatic Operation with Model RDT or RSB Transfer Switches 41 .....

4.6 Exercise 42 .............................................................

4.6.1 Unloaded Exercise with Diagnostic Test 42 ..........................

4.6.2 Low-Speed Diagnostics 42 ........................................

4.6.3 Loaded Exercise 42 ..............................................

4.6.4 Exerciser Reset and Disable 43 ....................................

4.6.5 Power Failure During Exercise Cycle 43 .............................

4.7 Test 43 .................................................................

4.7.1 Unloaded Test 43 ................................................

4.7.2 Loaded Test 44 ..................................................

4.7.3 Power Failure During Test Cycle 44 .................................

4.8 Faults 45 ...............................................................

4.8.1 Warnings 45 .....................................................

4.8.2 Shutdowns 45 ...................................................

4.8.3 ATS Communication Errors 45 .....................................

4.8.4 Resetting the Controller after a Fault Shutdown 45 ....................

4.9 Event History 48 .........................................................

4.10 Model RRT Transfer Switch Operation 49 ...................................

4.10.1 Source Availability 49 .............................................

4.10.2 ATS Control Sequence of Operation 49 .............................

4.10.3 Time Delays 49 ..................................................

4.10.4 Engine and Transfer Time Delays 50 ...............................

4.10.5 Load Control Time Delay 50 .......................................

4.10.6 Model RRT ATS Connection 50 ....................................

4.11 Controller Configuration and Adjustment 51 .................................

4.11.1 SiteTech Software 51 .............................................

4.11.2 Controller Configuration 51 ........................................

4.11.3 Controller Time Out 51 ............................................

4.11.4 Controller Firmware Version Number 51 .............................

4.11.5 Voltage and Frequency Adjustments 52 .............................

4.12 Calibration 52 ...........................................................

4.12.1 Calibrate Function 52 .............................................

4.12.2 Calibration Factor 52 .............................................

4.13 Controller Circuit Board 54 ................................................

4.13.1 Relays and LEDs 54 ..............................................

4.13.2 Controller Fuse F2 54 ............................................

4.14 Controller Replacement 55 ................................................

Section 5 Component Testing and Adjustment 57 ..............................................

5.1 Theory of Operation 57 ...................................................

5.2 Separate Excitation 57 ....................................................

5.3 Stator 59 ................................................................

5.4 Main Field (Rotor) 61 .....................................................

5.4.1 Rotor Continuity and Resistance Tests 61 ...........................

5.5 Slip Rings 62 ............................................................

5.6 Brushes 62 ..............................................................

5.7 Voltage Connections 63 ...................................................

5.7.1 Voltage Connections, Single-Phase Models 63 .......................

5.7.2 Voltage Regulation 63 ............................................

Table of Contents, continued

TP-6735 9/10 Table of Contents

5.8 Voltage Adjustment 63 ....................................................

5.8.1 Voltage Adjustment Procedure 64 ..................................

5.8.2 Volts per Hertz (Hz) Adjustments (Droop) 64 .........................

5.9 Governor System 66 .....................................................

5.9.1 Operation 66 ....................................................

5.9.2 Initial Checks 66 .................................................

5.9.3 Hunting/Surging 66 ...............................................

5.9.4 Governor System/Magnetic Pickup Operation Test 67 .................

5.9.5 Frequency Adjustment 70 .........................................

5.10 Fault Shutdown Tests 71 ..................................................

5.10.1 Controller Fault Shutdown Functions 71 .............................

5.10.2 Fault Shutdown Switches 72 .......................................

5.11 Fuel Systems 74 .........................................................

5.11.1 Fuel Solenoid Valve 74 ...........................................

5.11.2 Digital Spark Advance Ignition (DSAI) Timing 75 .....................

5.11.3 Fuel Regulators 75 ...............................................

5.11.4 Fuel Conversion, 20RES/RESL 76 .................................

5.11.5 Fuel Conversion, 14RES/RESL 77 .................................

5.11.6 Fuel Metering Valve Adjustment, 14RES/RESL Only 78 ...............

5.12 Starter Relay 80 .........................................................

5.13 Continuity Checks 81 .....................................................

5.14 Circuit Protection 82 ......................................................

5.14.1 Line Circuit Breaker 82 ...........................................

5.14.2 Fuses and Mini-Breaker 82 ........................................

Section 6 Disassembly/Reassembly 83 ........................................................

6.1 Initial Steps 83 ...........................................................

6.2 Disassembly 84 ..........................................................

6.3 Reassembly 90 ..........................................................

Section 7 Wiring Diagrams 95 ................................................................

Appendix A Abbreviations 99 ..................................................................

Appendix B Common Hardware Application Guidelines 101 ........................................

Appendix C General Torque Specifications 102 ...................................................

Appendix D Common Hardware Identification 103 .................................................

Appendix E Common Hardware List 104 .........................................................

Appendix F Controller Parameters (SiteTech) 107 .................................................

TP-6735 9/10 6

TP-6735 9/10 7 Safety Precautions and Instructions

Safety Precautions and Instructions

IMPORTANT SAFETY INSTRUCTIONS.

Electromechanical equipment,

including generator sets, transfer

switches, switchgear, and accessories,

can cause bodily harm and pose

life-threatening danger when

improperly installed, operated, or

maintained. To prevent accidents be

aware of potential dangers and act

safely. Read and follow all safety

precautions and instructions. SAVE

THESE INSTRUCTIONS.

This manual has several types of safety

precautions and instructions: Danger,

Warning, Caution, and Notice.

DANGER

Danger indicates the presence of a

hazard that will cause severe

personal injury, death, or

substantial property damage.

WARNING

Warning indicates the presence of a

hazard that can cause severe

personal injury, death, or

substantial property damage.

CAUTION

Caution indicates the presence of a

hazard that will or can cause minor

personal injury or property damage.

NOTICE

Notice communicates installation,

operation, or maintenance information

that is safety related but not hazard

related.

Safety decals affixed to the equipment

in prominent places alert the operator

or service technician to potential

hazards and explain how to act safely.

The decals are shown throughout this

publication to improve operator

recognition. Replace missing or

damaged decals.

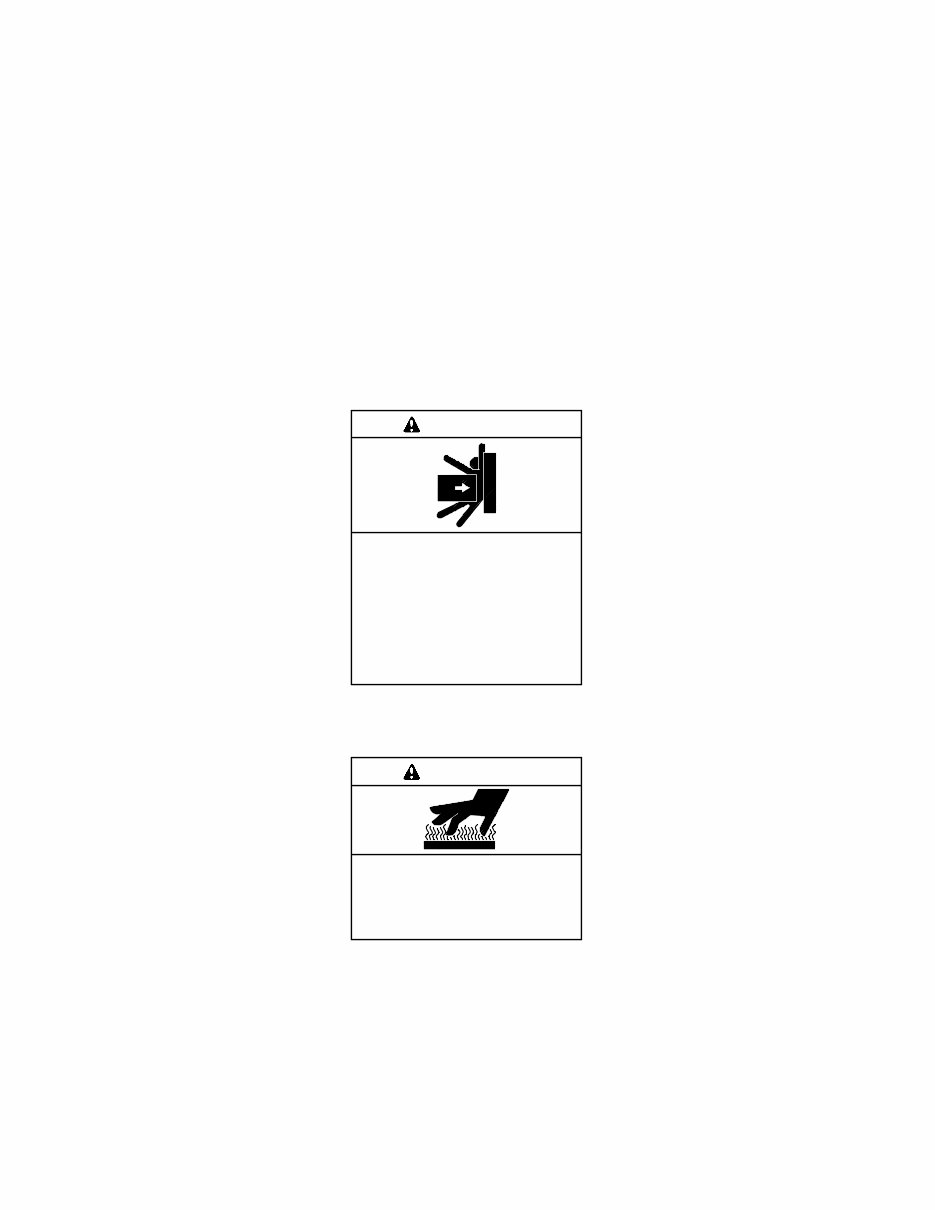

Accidental Starting

Accidental starting.

Can cause severe injury or death.

Disconnect the battery cables before

working on the generator set.

Remove the negative (--) lead first

when disconnecting the battery.

Reconnect the negative (--) lead last

when reconnecting the battery.

WARNING

Disabling the generator set.

Accidental starting can cause

severe injury or death. Before

working on the generator set or

connected equipment, disable the

generator set as follows: (1) Move the

generator set master switch to the OFF

position. (2) Disconnect the power to

the battery charger. (3) Remove the

battery cables, negative (--) lead first.

Reconnect the negative (--) lead last

when reconnecting the battery. Follow

these precautions to prevent starting of

the generator set by an automatic

transfer switch, remote start/stop

switch, or engine start command from a

remote computer.

Battery

Sulfuric acid in batteries.

Can cause severe injury or death.

Wear protective goggles and

clothing. Battery acid may cause

blindness and burn skin.

WARNING

Explosion.

Can cause severe injury or death.

Relays in the battery charger

cause arcs or sparks.

Locate the battery in a well-ventilated

area. Isolate the battery charger from

explosive fumes.

WARNING

Battery electrolyte is a diluted

sulfuric acid. Battery acid can cause

severe injury or death. Battery acid

can cause blindness and burn skin.

Always wear splashproof safety

goggles, rubber gloves, and boots

when servicing the battery. Do not

open a sealed battery or mutilate the

battery case. If battery acid splashes in

the eyes or on the skin, immediately

flush the affected area for 15 minutes

with large quantities of clean water.

Seek immediate medical aid in the case

of eye contact. Never add acid to a

battery after placing the battery in

service, as this may result in hazardous

spattering of battery acid.

Battery acid cleanup. Battery acid

can cause severe injury or death.

Battery acid is electrically conductive

and corrosive. Add 500 g (1 lb.) of

bicarbonate of soda (baking soda) to a

container with 4 L (1 gal.) of water and

mix the neutralizing solution. Pour the

neutralizing solution on the spilled

battery acid and continue to add the

neutralizing solution to the spilled

battery acid until all evidence of a

chemical reaction (foaming) has

ceased. Flush the resulting liquid with

water and dry the area.

Battery gases. Explosion can cause

severe injury or death. Battery gases

can cause an explosion. Do not smoke

or permit flames or sparks to occur near

a battery at any time, particularly when

it is charging. Do not dispose of a

battery in a fire. To prevent burns and

sparks that could cause an explosion,

avoid touching the battery terminals

with tools or other metal objects.

TP-6735 9/10 8 Safety Precautions and Instructions

Remove all jewelry before servicing the

equipment. Discharge static electricity

from your body before touching

batteries by first touching a grounded

metal surface away from the battery. To

avoid sparks, do not disturb the battery

charger connections while the battery

is charging. Always turn the battery

charger off before disconnecting the

battery connections. Ventilate the

compartments containing batteries to

prevent accumulation of explosive

gases.

Battery short circuits. Explosion

can cause severe injury or death.

Short circuits can cause bodily injury

and/or equipment damage.

Disconnect the battery before

generator set installation or

maintenance. Remove all jewelry

before servicing the equipment. Use

tools with insulated handles. Remove

the negative (--) lead first when

disconnecting the battery. Reconnect

the negative (--) lead last when

reconnecting the battery. Never

connect the negative (--) battery cable

to the positive (+) connection terminal

of the starter solenoid. Do not test the

battery condition by shorting the

terminals together.

Engine Backfire/Flash

Fire

Fire.

Can cause severe injury or death.

Do not smoke or permit flames or

sparks near fuels or the fuel system.

WARNING

Servicing the fuel system. A flash

fire can cause severe injury or death.

Do not smoke or permit flames or

sparks near the carburetor, fuel line,

fuel filter, fuel pump, or other potential

sources of spilled fuels or fuel vapors.

Catch fuels in an approved container

when removing the fuel line or

carburetor.

Servicing the air cleaner. A sudden

backfire can cause severe injury or

death. Do not operate the generator

set with the air cleaner removed.

Combustible materials. A fire can

cause severe injury or death.

Generator set engine fuels and fuel

vapors are flammable and explosive.

Handle these materials carefully to

minimize the risk of fire or explosion.

Equip the compartment or nearby area

with a fully charged fire extinguisher.

Select a fire extinguisher rated ABC or

BC for electrical fires or as

recommended by the local fire code or

an authorized agency. Train all

personnel on fire extinguisher

operation and fire prevention

procedures.

Exhaust System

Carbon monoxide.

Can cause severe nausea,

fainting, or death.

The exhaust system must be

leakproof and routinely inspected.

WARNING

Generator set operation. Carbon

monoxide can cause severe nausea,

fainting, or death. Carbon monoxide

is an odorless, colorless, tasteless,

nonirritating gas that can cause death if

inhaled for even a short time. Avoid

breathing exhaust fumes when working

on or near the generator set. Never

operate the generator set inside a

building unless the exhaust gas is

piped safely outside. Never operate

the generator set where exhaust gas

could accumulate and seep back inside

a potentially occupied building.

Carbon monoxide detectors.

Carbon monoxide can cause severe

nausea, fainting, or death. Install

carbon monoxide detectors on each

level of any building adjacent to the

generator set. Locate the detectors to

adequately warn the building’s

occupants of the presence of carbon

monoxide. Keep the detectors

operational at all times. Periodically

test and replace the carbon monoxide

detectors according to the

manufacturer’s instructions.

Carbon monoxide symptoms.

Carbon monoxide can cause severe

nausea, fainting, or death. Carbon

monoxide is a poisonous gas present in

exhaust gases. Carbon monoxide is an

odorless, colorless, tasteless,

nonirritating gas that can cause death if

inhaled for even a short time. Carbon

monoxide poisoning symptoms include

but are not limited to the following:

D Light-headedness, dizziness

D Physical fatigue, weakness in

joints and muscles

D Sleepiness, mental fatigue,

inability to concentrate

or speak clearly, blurred vision

D Stomachache, vomiting, nausea

If experiencing any of these symptoms

and carbon monoxide poisoning is

possible, seek fresh air immediately

and remain active. Do not sit, lie down,

or fall asleep. Alert others to the

possibility of carbon monoxide

poisoning. Seek medical attention if

the condition of affected persons does

not improve within minutes of breathing

fresh air.

Fuel System

Explosive fuel vapors.

Can cause severe injury or death.

Use extreme care when handling,

storing, and using fuels.

WARNING

TP-6735 9/10 9 Safety Precautions and Instructions

The fuel system. Explosive fuel

vapors can cause severe injury or

death. Vaporized fuels are highly

explosive. Use extreme care when

handling and storing fuels. Store fuels

in a well-ventilated area away from

spark-producing equipment and out of

the reach of children. Never add fuel to

the tank while the engine is running

because spilled fuel may ignite on

contact with hot parts or from sparks.

Do not smoke or permit flames or

sparks to occur near sources of spilled

fuel or fuel vapors. Keep the fuel lines

and connections tight and in good

condition. Do not replace flexible fuel

lines with rigid lines. Use flexible

sections to avoid fuel line breakage

caused by vibration. Do not operate the

generator set in the presence of fuel

leaks, fuel accumulation, or sparks.

Repair fuel systems before resuming

generator set operation.

Gas fuel leaks. Explosive fuel

vapors can cause severe injury or

death. Fuel leakage can cause an

explosion. Check the LP vapor gas or

natural gas fuel system for leakage by

using a soap and water solution with

the fuel system test pressurized to

6--8 ounces per square inch

(10--14 inches water column). Do not

use a soap solution containing either

ammonia or chlorine because both

prevent bubble formation. A successful

test depends on the ability of the

solution to bubble.

LP liquid withdrawal fuel leaks.

Explosive fuel vapors can cause

severe injury or death. Fuel leakage

can cause an explosion. Check the LP

liquid withdrawal gas fuel system for

leakage by using a soap and water

solution with the fuel system test

pressurized to at least 90 psi

(621 kPa). Do not use a soap solution

containing either ammonia or chlorine

because both prevent bubble

formation. A successful test depends

on the ability of the solution to bubble.

Hazardous Noise

Hazardous noise.

Can cause hearing loss.

Never operate the generator set

without a muffler or with a faulty

exhaust system.

CAUTION

Hazardous Voltage/

Moving Parts

Hazardous voltage.

Will cause severe injury or death.

Disconnect all power sources before

opening the enclosure.

DANGER

Hazardous voltage.

Can cause severe injury or death.

Operate the generator set only when

all guards and electrical enclosures

are in place.

Moving parts.

WARNING

Hazardous voltage.

Backfeed to the utility system can

cause property damage, severe

injury, or death.

If the generator set is used for

standby power, install an automatic

transfer switch to prevent inadvertent

interconnection of standby and

normal sources of supply.

WARNING

Welding the generator set.

Can cause severe electrical

equipment damage.

Never weld components of the

generator set without first

disconnecting the battery, controller

wiring harness, and engine electronic

control module (ECM).

CAUTION

Grounding electrical equipment.

Hazardous voltage can cause

severe injury or death. Electrocution

is possible whenever electricity is

present. Ensure you comply with all

applicable codes and standards.

Electrically ground the generator set,

transfer switch, and related equipment

and electrical circuits. Turn off the main

circuit breakers of all power sources

before servicing the equipment. Never

contact electrical leads or appliances

when standing in water or on wet

ground because these conditions

increase the risk of electrocution.

TP-6735 9/10 10 Safety Precautions and Instructions

Welding on the generator set. Can

cause severe electrical equipment

damage. Before welding on the

generator set perform the following

steps: (1) Remove the battery cables,

negative (--) lead first. (2) Disconnect

all engine electronic control module

(ECM) connectors. (3) Disconnect all

generator set controller and voltage

regulator circuit board connectors.

(4) Disconnect the engine battery-

charging alternator connections.

(5) Attach the weld ground connection

close to the weld location.

High voltage test. Hazardous

voltage can cause severe injury or

death. Follow the instructions of the

test equipment manufacturer when

performing high-voltage tests on the

rotor or stator. An improper test

procedure can damage equipment or

lead to generator set failure.

Connecting the battery and the

battery charger. Hazardous voltage

can cause severe injury or death.

Reconnect the battery correctly,

positive to positive and negative to

negative, to avoid electrical shock and

damage to the battery charger and

battery(ies). Have a qualified

electrician install the battery(ies).

Short circuits. Hazardous

voltage/current can cause severe

injury or death. Short circuits can

cause bodily injury and/or equipment

damage. Do not contact electrical

connections with tools or jewelry while

making adjustments or repairs.

Remove all jewelry before servicing the

equipment.

Electrical backfeed to the utility.

Hazardous backfeed voltage can

cause severe injury or death. Install

a transfer switch in standby power

installations to prevent the connection

of standby and other sources of power.

Electrical backfeed into a utility

electrical system can cause severe

injury or death to utility personnel

working on power lines.

Testing live electrical circuits.

Hazardous voltage or current can

cause severe injury or death. Have

trained and qualified personnel take

diagnostic measurements of live

circuits. Use adequately rated test

equipment with electrically insulated

probes and follow the instructions of the

test equipment manufacturer when

performing voltage tests. Observe the

following precautions when performing

voltage tests: (1) Remove all jewelry.

(2) Stand on a dry, approved electrically

insulated mat. (3) Do not touch the

enclosure or components inside the

enclosure. (4) Be prepared for the

system to operate automatically.

(600 volts and under)

Heavy Equipment

Unbalanced weight.

Improper lifting can cause severe

injury or death and equipment

damage.

Do not use lifting eyes.

Lift the generator set using lifting bars

inserted through the lifting holes on

the skid.

WARNING

Hot Parts

Hot engine and exhaust system.

Can cause severe injury or death.

Do not work on the generator set until

it cools.

WARNING

Servicing the alternator. Hot parts

can cause severe injury or death.

Avoid touching the alternator field or

exciter armature. When shorted, the

alternator field and exciter armature

become hot enough to cause severe

burns.

Servicing the exhaust system. Hot

parts can cause severe injury or

death. Do not touch hot engine parts.

The engine and exhaust system

components become extremely hot

during operation.

Servicing the engine heater. Hot

parts can cause minor personal

injury or property damage. Install the

heater before connecting it to power.

Operating the heater before installation

can cause burns and component

damage. Disconnect power to the

heater and allow it to cool before

servicing the heater or nearby parts.

Notice

NOTICE

Canadian installations only . For

standby service connect the output of

the generator set to a suitably rated

transfer switch in accordance with

Canadian Electrical Code, Part 1.

NOTICE

Electrostatic discharge damage.

Electrostatic discharge (ESD)

damages electronic circuit boards.

Prevent electrostatic discharge

damage by wearing an approved

grounding wrist strap when handling

electronic circuit boards or integrated

circuits. An approved grounding wrist

strap provides a high resistance (about

1 megohm), not a direct short, to

ground.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 76 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Our digital manuals in PDF format cover a range of residential and commercial generator sets, including models such as 14RES/RESL and 20RES/RESL. These manuals are valuable resources for professional mechanics and DIY enthusiasts alike. They provide detailed information on various aspects of the generator sets, including controllers like RDC Residential Control and DC Control.