STIHL 009/010/011 Chainsaw Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

STIHL 009, 010, 011

1

SERVICE MANUAL

STIHL 009, 010, 011

FOREWORD

This Service Manual covers model 010

chain saws up to machine number

7 900 000 as well as later machines

unless technical information bulletins

have been issued in the meantime

with updated repair procedures.

Models 009 and 011 have substantially

the same constructional features as

model 010 chain saws. This Service

Manual can therefore be used for the

009 and 011 chain saws as well.

In the event of faults it is quite possible

that a single fault may have several

causes. It is therefore advisable to

consult the "Troubleshooting Chart"

in each chapter when tracing faults.

We also recommend that you make

use of the exploded views in the

illustrated parts lists when carrying out

repair work.

This service manual and all technical

information bulletins are intended

exclusively for the use of STIHL

servicing dealers and staff and must not

be passed on to third parties.

SPECIAL TOOL MANUAL

Repair work is made considerably Our special tool manual illustrates

easier if the chain saw is mounted on and lists the part numbers of ail

assembly stand 5910 850 3100. The available machine-related tools as

saw is easily secured to the stand by well as general purpose tools for all

means of the bar mounting stud and machines.

collar nut.

The special tool manual is available

While on the assembly stand the chain in several languages and can be

saw can be swivelled into any required ordered by quoting the appropriate

position within a certain range to suit part number listed hereunder.

the repair in question. This not only

has the advantage of keeping the German 0455 901 0023

component in the most convenient English 0455 901 0123

position for the repair but also leaves French 0455 901 0223

both hands free for the work and thus Spanish 0455 901 0323

effects a considerable time saving. Yugoslav 0455 901 0423

Swedish 0455 901 0523

Italian 0455 901 0723

Portuguese 0455 901 1223

STIHl

Andreas Stihl

Postfach 1760

D-7050 Waiblingen

STIHL 009, 010, 011 2

CONTENTS

1. Specifications 4 3.7 Installation of 4.5.2 Adjusting Breaker-

Crankshaft Controlled Ignition 34

1.1 Engine 4 - Assembly of 4.6 Magneto Edge Gap

1.2 Fuel System 4 Crankcase 16 on Breaker-

1.3 Ignition System 5 3.8 Leakage Testing the Controlled Ignition 34

1.4 Tightening Torques 5 Crankcase 18

1.5 Cutting Attachment 6 3.8.1 Pressure Test 19

1.6 Weights 6 3.8.2 Vacuum Test 20

1.7 Special Accessories 6 3.8.3 Replacing the Oil 5. Rewind Starter 35

Seals 20

5.1 Construction and

Operation 35

2. Clutch, Chain Drive 5.2 Troubleshooting Chart 35

and Chain Brake 7 5.3 Disassembly 36

4. Ignition System 21 5.4 Replacing the

2.1 Construction and Operation 7 Starter Rope 36

2.1.1 Clutch and Chain 4.1 Construction 21 5.5 Replacing the

Sprocket 7 4.2 Description of Rewind Spring 37

2.1.2 Chain Brake 8 Operation 21 5.6 Tensioning the

2.2 Troubleshooting Chart 8 4.2.1 Breaker-Controlled Rewind Spring 37

2.3 Repair 9 Magneto Ignition 22 5.7 General Maintenance 37

2.3.1 Disassembly 4.3 Troubleshooting

and Assembly of Clutch 9 Chart 23

2.3.2 Disassembly of 4.4 Function and Repair

Chain Brake 10 of Components 24 6. AV Handle System 38

2.3.2.1 Assembly of Chain Brake 10 4.4.1 Spark Plug 24

4.4.2 Ignition Lead 25 6.1 Construction and

4.4.3 Ground Lead Contakt 26 Operation 38

4.4.4 Flywheel 27 6.2 Repair 38

3. Engine 11 4.4.5 Ignition Armature 28

4.4.5.1 Resistance Test on

3.1 Construction 11 Primary Winding 29 7. Chain Lubrication 39

3.2 Troubleshooting Chart 11 4.4.5.2 Resistance Test on

3.3 Exposing the Cylinder 12 Secondary Winding 29 7.1 Construction and

3.4 Disassembly of 4.4.5.3 Disassembly and Operation of

Cylinder and Piston 12 Assembly 29 Oil Pump 39

3.5 Assembly of Piston 4.4.6 Condenser 30 7.2 Troubleshooting Chart 40

and Cylinder 14 4.4.7 Contact Set 31 7.3 Oil Tank/Tank Vent 41

3.6 Disassembly of Crank- 4.5 Ignition Timing 32 7.4 Notes on Repair 41

case - Removal of 4.5.1 Checking Breaker- 7.5 Disassembly and Repair

Crankshaft 15 Controlled Ignition 33 of Pump Housing 42

STIHL 009, 010, 011 3

8. Fuel System 43

8.1 Construction and

Operation of Carburetor 43

8.1.1 Operation of Fuel Pump 43

8.1.2 Operation of Carburetor 43

8.2 Troubleshooting Chart 45

8.3 Leakage Test

(Pressure Test)

on Carburetor 47

8.4 Disassembly of

Carburetor 47

8.5 Repair of Carburetor 48

8.6 Carburetor Adjustment 50

8.6.1 Notes for Fine Adjust-

ment of Carburetor 50

8.7 Fuel Line 51

8.8 Tank Vent 51

8.9 Air Filter and

Choke Valve 52

STIHL 009, 010, 011 4

1. SPECIFICATIONS

1.1 Engine Single cylinder two-stroke engine with specially processed cylinder bore

Displacement 009, 010: 37 cm³ (2.26 cu. in)

Bore 009, 010: 36 mm (1.42 in)

Displacement 011: 41 cm³ (2.50 cu. in)

Bore 011: 38 mm (1.50 in)

Stroke: 36 mm (1.42 in)

Compression ratio: 9.8:1

Max. torque: 1.8 Nm (1.3 Ibf. ft)

at 4500 r.p.m.

Rated speed, off load with

bar and chain: 9500 - 9800 r.p.m.

Mean idle speed: 2200 - 2400 r.p.m.

Crankshaft: Drop forged

Crankshaft bearings: 2 needle sleeves

Crankpin: 13 mm (0.51 in) dia.

Big-end bearing: Cylindrical rollers without cage

Piston pin: 9 mm (0.35 in) dia.

Small-end bearing: Needle sleeve

Rewind starter: Pawl engagement with automatic

starter rope rewind mechanism

Starter rope: 3.5 mm (0.14 in) dia.,

960 mm (38 in) long

Clutch: Centrifugal clutch without

linings, 64 mm (2.5 in) dia.

Clutch engages at: 3200 - 3300 r.p.m.

Crankcase leakage test

with overpressure: 0.5 bar (7.1 Ibf/in²)

with vacuum: 0.5 bar (7.1 Ibf/in²)

1.2 Fuel System Carburetor: All-position diaphragm carburetor

with integral fuel pump

Adjustment:

High-speed adjustment screw H: Open 1 turn

Low-speed adjustment screw L: Open 1 turn

(basic setting starting with screws

lightly against their seats)

Carburetor leakage test

with overpressure: 0.4 bar (5.7 Ibf/in²)

Fuel capacity: 0.26 L (0.55 US pt)

STIHL 009, 010, 011 5

Fuel mixture: Regular grade gasoline and

branded two-cycle engine oil

Mix ratio 1:40 with STIHL

two-cycle engine oil: 1:25 with

other branded two-cycle

engine oils

Air filter: Large area felt mat

1.3 Ignition System Type: Breaker-controlled magneto

ignition

Magneto edge gap: 5 mm (0.2 in)

Ari gap: 0.2 mm (0.008 in)

Ignition timing: 1.8-2.1 mm before T D.C.

Ignition advance angle: 23°-24°

Breaker point gap: 0.3-0.4 mm (0.012-0.016 in)

Condenser: Capacitance 0.17 μF

Ignition armature: Coil winding resistance

Primary Secondary

0.8-1.3 Ω 7.2-8.8 kΩ

Spark plug (suppressed): Bosch WSR 6 F or

Champion RCJ 6 Y

Heat range 200

Electrode gap 0.5 mm (0.02 in)

Spark plug thread: M 14x1.25; 9.5 mm (0.37 in) long

1.4 Tightening Torques Crankshaft nut

(ignition side) M 8x1: 30 Nm (22.1 Ibf. ft)

Clutch (sprocket side): 30 Nm (22.1 Ibf. ft)

M 6 socket head screws: 10 Nm (74 Ibf. ft)

M 5 pan head screws: 5 Nm (3.7 Ibf. ft)

M 4 pan head screws: 2.5 Nm (1.8 Ibf. ft)

M 5 nuts: 5 Nm (3.7 lbf. ft)

Spark plug: 25 Nm (18.4 Ibf. ft)

STIHL 009, 010, 011 6

1.5 Cutting Attachment Guide bars: STIHL Standard guide bars

without stellite-tipped nose

STIHL Duromatic guide bars

with stellite-tipped nose

STIHL Rollomatic guide bars

with sprocket nose

All types with corrosion-resistant

finish and induction hardened rails

Bar lengths: Duromatic 30 and 35 cm (12 and 14 in)

Rollomatic 30, 35 and 40 cm

(12, 14 and 16 in)

Chain: 9.32 mm (3/8")-Oilomatic-Picco

Chain sprocket: 6-tooth for 3/8" Picco pitch

Chain speed: 13 m/s (42.6 ft/sec) at 7000 r.p.m.

Chain lubrication: Speed-controlled oil pump with

Diaphragm

Oil delivery rate: 6-12 cm

3

/min (0.37-0.74 cu. in/min)

at 7000 r.p.m.

Oil tank capacity: 0.28 L (0.59 US pt)

1.6 Weights Model: 009 010 AV 011 AV

Dry powerhead with

30 cm bar and chain: 4.3 kg 4.6 kg 4.7 kg

(9.51 b) (10.1lb) (10.4Ib)

1.7 Special Accessories STIHL repair kit 009, 010, 011 1120 900 5000

Set of gaskets 009, 010, 011 1120 007 1050

STIHL 009, 010, 011 7

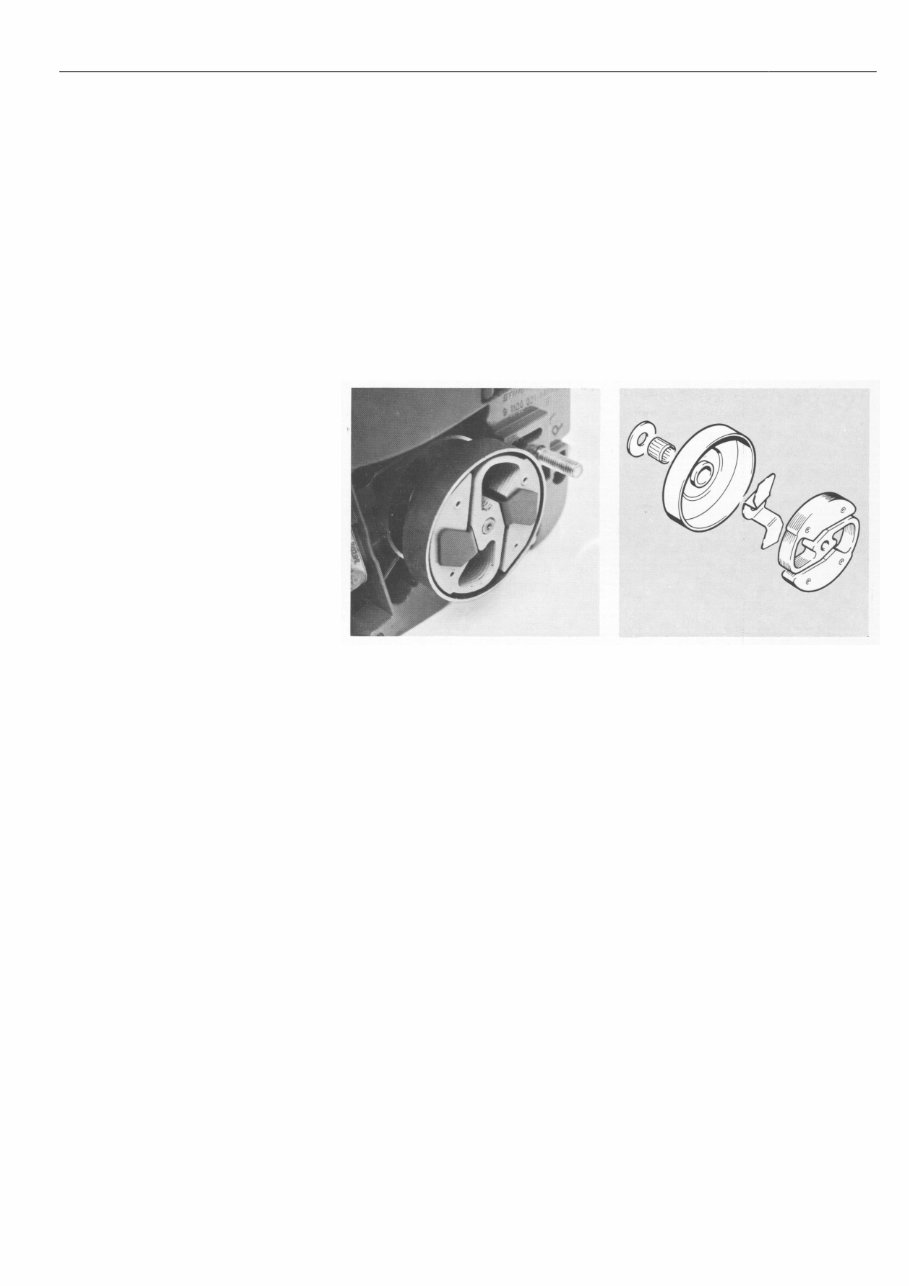

The construction of the clutch is

identical on both models of the saw

(with and without chain brake).

While the engine is running at idle

speed there is no change in the

shape of the clutch, i.e. its outside

diameter remains constant because

the rigidity of the laminate block's

smallest cross section is greater

than the centrifugal force applied.

As engine speed increases the outer

diameter of the clutch becomes

larger when the centrifugal force

overcomes the rigidity of the

laminate block. This causes the

clutch to be pressed against the

clutch drum and thus transmit engine

torque positively via the clutch drum

and the chain sprocket to the saw

chain.

The rigidity of the clutch is designed

so that the clutch begins to make

contact with the clutch drum at an

engine speed of approx. 3200 r.p.m.

The clutch engages fully above this

speed. It is therefore very important

to set the carburetor to the correct

idle speed in order to insure that

the clutch engagement speed

(3200 r.p.m.) is not reached when

the engine is idling.

The transmission of power from the

engine to the saw chain is effected

via a centrifugal clutch which has no

linings.

The clutch consists of a laminate block

made up of seven separate metal

sheets which are riveted together. The

laminate block is screwed to the

crankshaft. A cranked U-plate is fitted

between the laminate block and the

clutch drum and acts as a guard which

prevents parts of the clutch coming

adrift in the event of breakage.

Clutch with cranked U-plate in position Component parts of clutch

2. CLUTCH,

CHAIN DRIVE AND

CHAIN BRAKE

2.1 Construction

and Operation

2.1.1 Clutch and

Chain Sprocket

STIHL 009, 010, 011 8

2.1.2 Chain Brake

The chain brake is a spring-loaded The chain brake is disengaged by The chain brake is engaged by

band brake without any friction linings. pulling the hand guard back toward moving the hand guard toward the

Its main components are the brake the handlebar. This movement is bar nose. This movement unlatches

band, tension spring, hand guard and transmitted via a lever system which the locked brake lever and causes

the lever system. preloads the tension spring and re- the brake band to be clamped

leases the brake band. around the clutch drum by the force

The chain brake is actuated via the of the preloaded tension spring. The

hand guard which can be used to The actuating lever, which is attached cluch drum and saw chain are

disengage or engage the brake. to the hand guard, remains locked in brought to a standstill in a split

the idle position after the operator second.

releases the hand guard.

2.2 Troubleshooting Chart

Condition Cause Remedy

Saw chain turns at idle speed Engine idle speed too high Readjust at idle speed

adjusting screw

Clutch broken Fit new clutch

Excessive chain sprocket wear Incorrect chain tension Tension chain correctly

Saw chain does not stop Tension spring broken Fit new tension spring

immediately when chain brake is

actuated

STIHL 009, 010, 011 9

2.3 Repair

2.3.1 Disassembly and

Assembly of Clutch

First remove the chain sprocket cover Caution: The clutch has a lefthand

and the cutting attachment. On Quick- thread - unscrew it clockwise!

stop models it is necessary to dis-

engage the chain brake so that the After unscrewing the clutch, remove the

brake band releases the clutch drum. chain sprocket, needle cage and thrust

washer from the crankshaft. Examine

Take out the spark plug and fit the clutch for signs of cracks or breaks.

locking screw in its place. Use the If hairline cracks are found in the

special wrench to turn the clutch and sprung part of the clutch, fit a new

the crankshaft clockwise until the clutch. The cranked U-plate should

piston head butts against the locking also be inspected for hairline cracks.

screw. Now use wrench to unscrew If any are found, fit a new Cranked

the clutch. U-plate. Wash needle cage, thrust

washer and stub of crankshaft with

clean gasoline. Replace needle cage

if it is faulty.

Lubricate needle cage, thrust washer

and stub of crankshaft with

antifriction bearing grease before

assembly. When refitting the clutch

make sure that the side on which the

thread is counterbored to a depth of

about 2 mm (0.08 in) faces the

crankcase. Tighten down clutch

with the wrench to a torque load of

30 Nm (3.0 kpm).

Top: Top:

Locking screw 1107 191 1200 Wrench 1113 890 3600

Bottom: Bottom:

Locking screw in position Unscrewing the clutch Counterbored side of clutch

STIHL 009, 010, 011 10

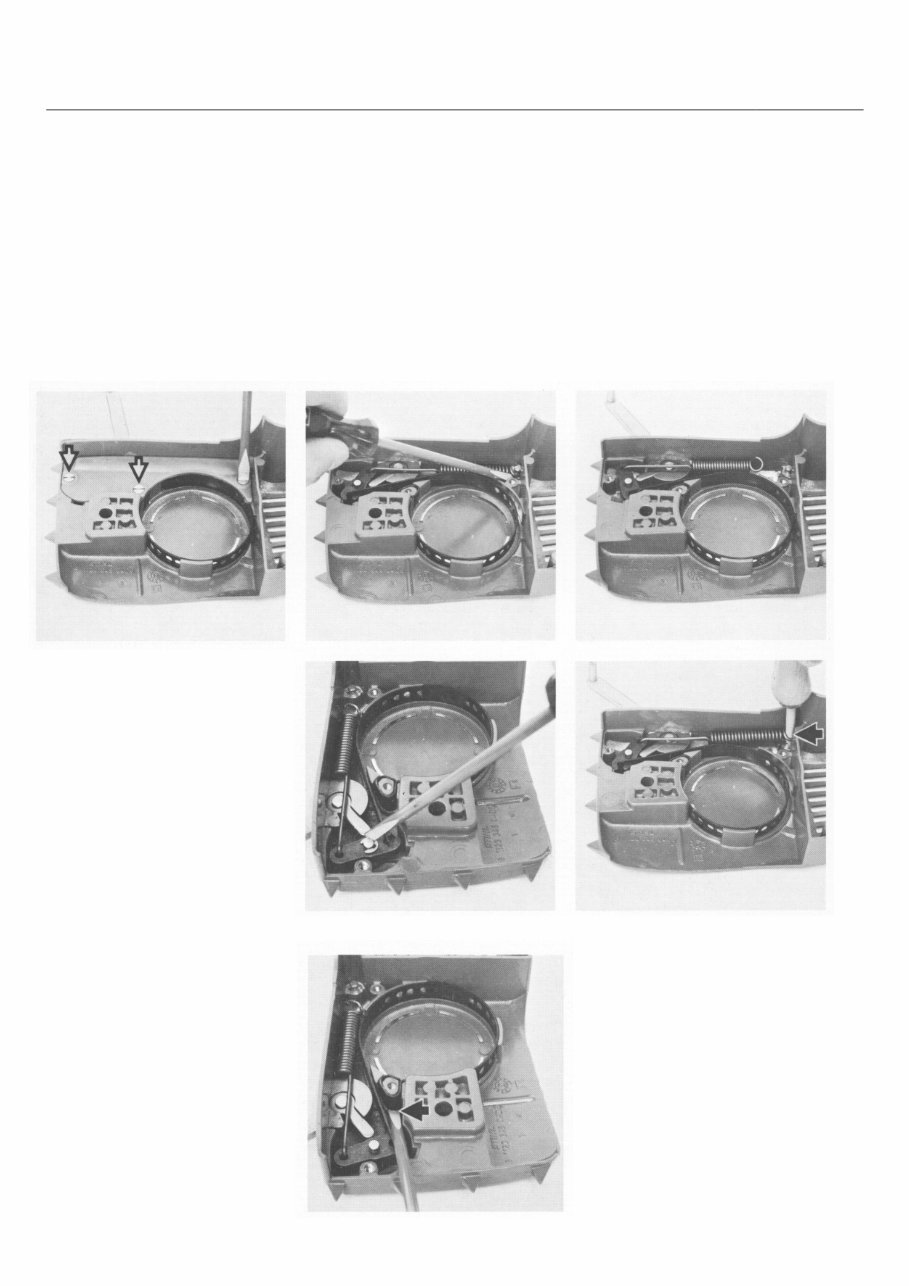

2.3.2 Disassembly of

Chain Brake

2.3.2.1 Disassembly of

Chain Brake

Top:

Detaching tension spring Top:

Brake band, brake lever and tension spring in

Center: position

Removing retaining washer

Bottom:

Bottom: Fitting tension spring with installing tool

Removing plastic cover Removing brake band 1117 890 0900

The chain brake components are inte-

grated in the chain sprocket cover. It

is therefore necessary to remove the

sprocket cover to gain access to the

brake components. After removing

the sprocket cover, engage the chain

brake, unscrew the plastic cover and

detach the tension spring from the pin

in the housing. Remove retaining

washer from brake lever pivot pin and

then prise brake lever together with

the brake band and the tension spring

out of their seats in the cover. The

relay lever and actuating lever cannot

be disassembled. If either one of

these levers is faulty the complete

chain sprocket cover (1120 640 1740)

must be replaced.

Check levers and brake band for

signs of wear. Renew damaged parts

and apply a little grease to the pivot

points before reassembly.

First engage brake band in the brake

lever. Then attach the tension spring

to the brake lever and install the pre-

assembled parts in the chain

sprocket cover.

Fit the retaining washer and use in-

stalling tool to attach tension spring

to the retaining pin. Finish off by

securing the plastic cover.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 44 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

This service and repair manual for the STIHL 009/010/011 Chainsaw is an indispensable guide for both professional mechanics and DIY enthusiasts. It provides a comprehensive Parts list, Owner's manual, and Repair manual designed specifically for the STIHL 009/010/011 range.

- Parts list

- Owner's manual

- Repair manual

The manual is packed with detailed technical information covering:

- Introduction

- Specifications

- Clutch, chain drive, chain brake, and chain tensioner

- Engine

- Ignition system

- Rewind starter

- AV handle system

- Master control/handle system

- Chain lubrication

- Fuel system

- Special servicing tools and aids

This manual is available in PDF format, fully compatible with all versions of Windows and Mac, and requires Adobe Reader for access. It is an essential resource for ensuring proper maintenance and repair of your STIHL 009/010/011 chainsaw.