Stihl MS341 MS361 Chainsaw Workshop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Online version - not for reprint

STIH)

STIHL MS 341, 361 2004-05

Online version - not for reprint

1 MS 341, MS 361, MS 361 C

q

© ANDREAS STIHL AG & Co. KG, 2004

Contents

1. Introduction 3

2. Safety Precautions 4

3. Specifications 5

3.1 Engine 5

3.2 Fuel System 5

3.3 Ignition System 5

3.4 Chain Lubrication 5

3.5 Tightening Torques 6

4. Troubleshooting

Chart 8

4.1 Clutch, Chain Drive,

Chain Brake,

Chain Tensioner 8

4.2 Rewind Starter 10

4.3 Chain Lubrication 11

4.4 Ignition System 12

4.5 Carburetor 13

4.6 Engine 16

5. Clutch, Chain Drive,

Chain Brake and

Chain Tensioner 17

5.1 Clutch Drum / Chain

Sprocket 17

5.2 Replacing the

Chain Catcher 18

5.3 Spiked Bumper 18

5.4 Clutch 19

5.5 Checking Operation

of Chain Brake 21

5.5.1 Removing and Installing

(without

QuickStop Super) 21

5.5.2 Removing and Installing

(with

QuickStop Super) 24

5.5.3 Brake Cable 28

5.5.4 Checking Play 28

5.5.5 Adjusting Play 29

5.5.6 Checking Operation of

Coasting Brake 30

5.6 Chain Tensioner 31

5.7 Bar Mounting Studs 32

6. Engine 32

6.1 Muffler/Spark

Arresting Screen 32

6.2 Shroud 33

6.3 Leakage Test 33

6.3.1 Preparations 34

6.3.2 Pressure Test 35

6.3.3 Vacuum Test 35

6.4 Oil Seals 36

6.5 Cylinder and Piston 37

6.5.1 Removing 37

6.5.2 Installing 39

6.6 Piston Rings 42

6.7 Crankcase/

Crankshaft 43

6.7.1 Removing 43

6.7.2 Installing 45

6.8 Decompression Valve 49

7. Ignition System 49

7.1 Ignition Module 49

7.1.1 Ignition Timing 50

7.1.2 Removing and

Installing 50

7.1.3 Testing the

Ignition Module 51

7.1.4 Ignition Lead /

Spark Plug Boot 52

7.1.5 Flywheel 53

7.2 Contact Spring 54

7.3 Testing Wiring

Harness 55

7.4 Ignition System

Troubleshooting 56

8. Rewind Starter 59

8.1 General 59

8.2 Removing and

Installing 59

8.3 Pawls 59

8.4 Rope Rotor 60

8.5 Starter Rope / Grip 60

8.6 Tensioning 61

8.7 Segment 62

8.8 Starter Rope Guide

Bushing 63

8.9 Replacing the

Rewind Spring 64

9. AV System 65

9.1 Repair 65

9.1.1 Spring between Front

Handle and Cylinder 65

9.1.2 Annular Buffer between

Tank Housing and

Crankcase 65

9.1.3 Spring, Annular Buffer

between Crankcase

and Tank Housing 66

9.1.4 Stop Buffer between

Crankcase and Tank

Housing 67

10. Master Control /

Handle System 67

10.1 Switch Shaft 67

10.2 Throttle Trigger /

Interlock Lever 68

10.2.1 Without

QuickStop Super 68

10.2.2 With

QuickStop Super 69

10.3 Front Handle 71

11. Chain Lubrication 71

11.1 Pickup Body /

Suction Hose 71

11.2 Valve 72

11.2.1 Cleaning 72

11.2.2 Replacing 73

11.3 Oil Pump 73

11.3.1 Removing and

Installing 73

11.3.2 Servicing 74

Online version - not for reprint

2 MS 341, MS 361, MS 361 C

Contents

12. Fuel System 74

12.1 Air Filter 74

12.2 Carburetor 75

12.2.1 Removing and

Installing 75

12.2.2 Leakage Test 76

12.3 Servicing

the Carburetor 77

12.3.1 Metering Diaphragm 77

12.3.2 Inlet Needle 78

12.3.3 Fixed Jet 79

12.3.4 Pump Diaphragm 79

12.3.5 Accelerator Pump 80

12.4 User Adjustment 82

12.5 Basic Setting 83

12.6 Tank Vent 84

12.7 Pickup Body 85

12.8 Fuel Hose 86

12.9 Separating Crankcase

and Tank Housing 86

12.10 Replacing the Tank

Housing 88

13. Carburetor Heating 88

13.1 Testing 88

13.2 Troubleshooting Chart 90

14. Handle Heating

System 91

14.1 Troubleshooting 91

14.2 Testing

Heating Element

in Rear Handle 92

14.3 Removing and

Installing 92

14.4 Testing

Heating Element

in Front Handle 93

14.5 Removing and

Installing 94

14.6 Heater Switch 95

14.7 Generator 96

14.7.1 Troubleshooting Chart 97

14.7.2 Test Connections

and Test Values 99

14.8 Wiring Harness 100

14.8.1 Without Handle and

Carburetor Heating 100

14.8.2 With Handle Heating

System 100

14.8.3 With Handle and

Carburetor

Heating System 101

15. Special Servicing

Tools 103

16. Servicing Aids 105

Online version - not for reprint

3 MS 341, MS 361, MS 361 C

This service manual contains

detailed descriptions of all the

typical repair and servicing

procedures for this power tool.

As the design concept of models

MS 341 and MS 361 is almost

identical, the descriptions and

servicing procedures in this manual

generally apply to both models.

Differences are described in detail.

You should make use of the

illustrated parts lists while carrying

out repair work. They show the

installed positions of the individual

components and assemblies.

Refer to the latest edition of the

relevant parts list to check the part

numbers of any replacement parts.

A fault on the machine may have

several causes. To help locate the

fault, consult the chapter on

"Troubleshooting" and the "STIHL

Service Training System".

Refer to the “Technical Information”

bulletins for engineering changes

which have been introduced since

publication of this service manual.

Technical information bulletins also

supplement the parts list until an

updated edition is issued.

The special tools mentioned in the

descriptions are listed in chapter

"Special Servicing Tools" of this

manual. Use the part numbers to

identify the tools in the "STIHL

Special Tools" manual which lists all

the special servicing tools currently

available from STIHL.

Symbols are included in the text and

pictures for greater clarity.

The meanings are as follows:

In the descriptions:

: = Action to be taken as

shown in the illustration

(above the text)

– = Action to be taken that is

not shown in the illustration

(above the text)

In the illustrations:

A Pointer

aDirection of movement

b 4.2

Reference to another chapter,

i.e. chapter 4.2 in this example.

Service manuals and technical

information bulletins are intended

exclusively for the use of properly

equipped repair shops. They must

not be passed to third parties.

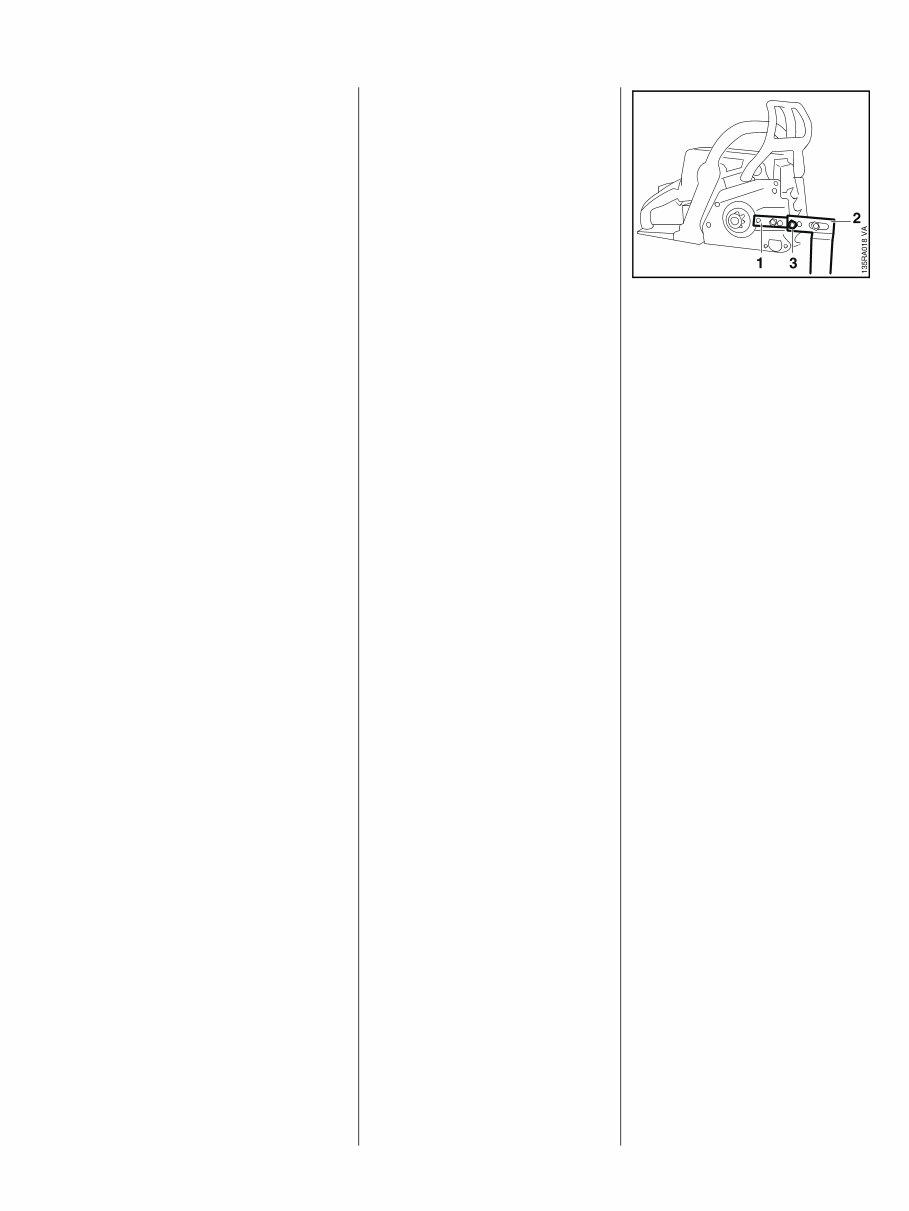

Servicing and repairs are made

considerably easier if the clamp (1)

5910 890 2000 is used to mount the

machine on assembly stand (2)

5910 890 3100 so that one clamp

screw engages the outer 10 mm

hole (3) in the assembly stand.

To service the underside of the

machine (e.g. remove the front

handle), turn it upside down and

mount it so that one clamp screw

engages the inner 10 mm hole in

the assembly stand.

Pull the hand guard back against

the front handle for this purpose.

Always use original STIHL

replacement parts.

They can be identified by the

STIHL part number,

the STIH) logo and the

STIHL parts symbol (

This symbol may appear alone on

small parts.

1. Introduction

Online version - not for reprint

4 MS 341, MS 361, MS 361 C

If the engine is started up in the

course of repairs or maintenance

work, observe all local and country-

specific safety regulations as well

as the safety precautions and

warnings in the instruction manual.

Gasoline is an extremely flammable

fuel and can be explosive in certain

conditions.

Improper handling may result in

burns or other serious injuries.

Warning!

Do not bring any fire, flame, spark or

other source of heat near the fuel.

All work with fuel must be performed

outdoors only. Spilled fuel must be

wiped away immediately.

2. Safety Precautions

Online version - not for reprint

5 MS 341, MS 361, MS 361 C

3. Specifications

3.1 Engine

MS 341 MS 361

Displacement: 59.0 cm

3

59.0 cm

3

Bore: 47 mm 47 mm

Stroke: 34 mm 34 mm

Engine power to ISO 7293: 3.1 kW (4.1 bhp)

at 9,500 rpm

3.4 kW (4.6 bhp)

at 9,500 rpm

Max. permissible engine speed

with bar and chain: 13,500 rpm 14,000 rpm

Idle speed: 2,800 rpm

Clutch: Centrifugal clutch without linings

Clutch engages at: 3,500 rpm

Crankcase leakage test

at gauge pressure: 0.5 bar

under vacuum: 0.5 bar

3.2 Fuel System

Carburetor leakage test

at gauge pressure: 0.8 bar

Operation of tank vent at

gauge pressure: 0.3 bar

Fuel: as specified in instruction

manual

3.3 Ignition System

Air gap between ignition

module and fanwheel: 0.15 – 0.3 mm

Spark plug (suppressed): Bosch WSR 6F

NGK BPMR 7 A

Electrode gap: 0.5 mm

3.4 Chain Lubrication

Fully automatic, speed-controlled oil pump with rotary piston

Oil delivery rate: 5.5 – 15 cm

3

at 10,000 rpm

Online version - not for reprint

6 MS 341, MS 361, MS 361 C

3.5 Tightening Torques

DG screws are used in polymer and light metal components. These screws form a permanent thread when they

are installed for the first time. They can be removed and installed as often as necessary without impairing the

strength of the screwed assembly, providing the specified tightening torque is observed.

For this reason it is essential to use a torque wrench.

Fastener Thread size For component Torque Remarks

Nm

Screw IS-M4x8 Chain tensioner cover plate/crankcase 3.0

Screw IS-M4x12 Brake band/crankcase 3.0 1)

Screw IS-P4x10 Brake cable retainer/tank housing 1.5 6)

Collar screw IS-M8x21.5 Collar screw for guide bar 23.0 1)

Screw IS-M4x12 Cover, chain brake/crankcase 3.0

IS-M10x1 Decompression valve 14.0

Screw IS-B4.2x9.5 Spark arresting screen/muffler 2.0

Screw IS-M4x12 Generator 3.0 1)5)

Screw IS-P5x16 Front handle/plug, AV spring 4.0

Screw IS-P6x19 Front handle/plug, AV spring 7.0 5)

Screw IS-P6x21.5 Front handle/tank housing, top right 7.0 3)

Screw IS-P6x32.5 Front handle/tank housing, top right 5.0 4)

Screw IS-P6x19 Front handle/tank housing, bottom 7.0 3)

Screw IS-P6x21.5 Front handle/tank housing, bottom 5.0 4)

Screw IS-M5x35 Handschutz/fan housing/crankcase 6.0

Nut M5 Shroud/stud, cylinder 3.0

Screw IS-P6x21.5 Chain catcher/crankcase/bearing plug 6.0

Screw IS-M5x16 Spiked bumper/crankcase 8.0

Screw IS-M5x12 Spiked bumper/crankcase/lock nut 8.0

Screw IS-M5x25 Crankcase, sprocket side/fan side 10.0

Screw IS-M5x16 Bearing plug/cylinder 10.0 2)

Screw IS-M5x20 Fan housing/crankcase 6.0

Carrier M12x1L Carrier/crankshaft 50.0

Remarks:

1) Loctite 243, medium strength

2) Loctite 270, high strength

3) aluminium

4) polymer

5) only version with handle heating

6) only version with QuickStop Super

Online version - not for reprint

7 MS 341, MS 361, MS 361 C

Fastener Thread size For component Torque Remarks

Nm

Screw IS-M4x16 Annular buffer/crankcase 3.5 1)

Collar screw IS-P6x27 Annular buffer/tank housing 6.0

Screw IS-M5x16 Muffler/crankcase 10.0 2)

Screw IS-M5x16 Muffler/cylinder 10.0

Nut M12x0.75 Switch/handle housing 5)

Nut M8x1 Flywheel/crankshaft 33.0

Screw IS-M4x8 Side plate/crankcase 3.0

Screw IS-M5x8.5 Stud/cylinder 1.4 2)

Collar nut M5 Carburetor/collar screw 3.5

Screw IS-M5x25 Cylinder/crankcase 10.0

M14x1.25 Spark plug 25.0

Screw IS-M5x20 Ignition module/crankcase 8.0

Screw IS-M4x12 Oil pump/crankcase 3.0

Remarks:

1) Loctite 243, medium strength

2) Loctite 270, high strength

5) Version with handle heating only

Use the following procedure when refitting a DG screw in an existing thread:

Place the screw in the hole and rotate it counterclockwise until it drops down slightly.

Tighten the screw clockwise to the specified torque.

This procedure ensures that the screw engages properly in the existing thread and does not form a new thread

and weaken the assembly.

Note:

Power screwdriver setting for polymer: DG screws max. 500 rpm

Online version - not for reprint

8 MS 341, MS 361, MS 361 C

4. Troubleshooting Chart

4.1 Clutch, Chain Drive, Chain Brake,

Chain Tensioner

Condition Cause Remedy

Saw chain stops under load at full

throttle

Clutch shoes badly worn Install new clutch

Clutch drum badly worn Install new clutch drum

Brake band stuck Check freedom of movement

and function of brake band.

Saw chain rotates at idle speed Engine idle speed too high Readjust with idle speed screw

(LA) (counterclockwise)

Clutch springs stretched or fatigued Replace the clutch springs or install

new clutch

Clutch spring hooks broken Replace the clutch springs

Loud noises Clutch springs stretched or fatigued Replace all clutch springs

Needle cage damaged Fit new needle cage

Clutch shoe retainer broken Fit new retainer

Clutch shoes and carrier worn Install new clutch

Chain sprocket wears rapidly Chain not properly tensioned Tension chain as specified

Wrong chain pitch Fit chain of correct pitch

Insufficient chain lubrication Check chain lubrication

Chain sprocket worn Fit new chain sprocket

Online version - not for reprint

9 MS 341, MS 361, MS 361 C

Condition Cause Remedy

Saw chain does not stop

immediately when brake is

activated

Brake spring stretched or broken Fit new brake spring

Brake band stretched. worn or

broken

Fit new brake band

Clutch drum worn Fit new clutch drum

Saw chain does not stop

immediately when coasting brake is

activated (only versions with

QuickStop Super)

Brake cable play incorrect Readjust brake cable play (free

travel)

Brake cable stretched or broken Fit new brake cable

Parts of activating mechanism stiff Clean or replace parts of activating

mechanism

Chain brake spring stretched or

broken

Fit new brake spring

Brake ban stretched, worn or

broken

Fit new brake band

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 38 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

The Stihl MS341 MS361 Chainsaw Workshop / Shop Manual provides comprehensive information for repairing and maintaining your chainsaw. Whether you are a professional mechanic or a DIY enthusiast, this manual covers all the essential details you need to know.