McCulloch Chainsaws Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Two-Stroke

Engine Repair

& Maintenance

This page intentionally left blank

1

Fundamentals

There comes a time when work stops and the mechanic becomes abstracted, dis-

tant from the task at hand. Something about the machine does not conform to the

picture in the mechanic’s mind. Images flash by until he or she finds one that most

closely conforms to actual conditions. Once that is done, repairs can begin.

Constructing visual images is what mechanics do; the other stuff is mere

wrench-twisting.

This chapter provides grist for these mental images. Because the material

must be conveyed in words, it tends to be abstract. But once you can picture

how these engines work, you will have made the first step in the journey to

becoming a real mechanic.

Spark-ignition engines operate in a cycle consisting of four events: intake,

compression, expansion (or power), and exhaust. A fresh charge of air and

fuel is inducted into the cylinder, which then is compressed by the piston

and ignited by the spark plug. The pressure created by combustion reacts

against the piston to generate torque on the crankshaft. The spent gases

then exhaust into the atmosphere.

Four-stroke-cycle engines require four up and down strokes of the piston, or two

full crankshaft revolutions, to complete the cycle. Two-stroke-cycle engines tele-

scope events into two strokes or one crankshaft revolution. For convenience we

abbreviate the terms to four-cycle or four-stroke, and two-cycle or two-stroke.

Two-cycle operation

Focus on the piston. The double-acting piston works in both directions to

compress the air-fuel mixture in the cylinder above it and in the crankcase

below it. The piston and connecting rod convert a portion of the heat and

1

energy released by combustion into mechanical motion that turns the crank-

shaft. Were that not enough, the piston also acts as a slide valve to open and

close exhaust, transfer and (in some applications) intake ports. Because it

works so hard, the piston is the first mechanical part to fail on two-cycle

engines.

Third-port engines

Third- or piston-ported engines have three ports cast or milled into their

cylinder liners. The inlet port admits fuel to the crankcase, the transfer port

conveys fuel from the crankcase into the combustion chamber, and the

exhaust port opens to the atmosphere.

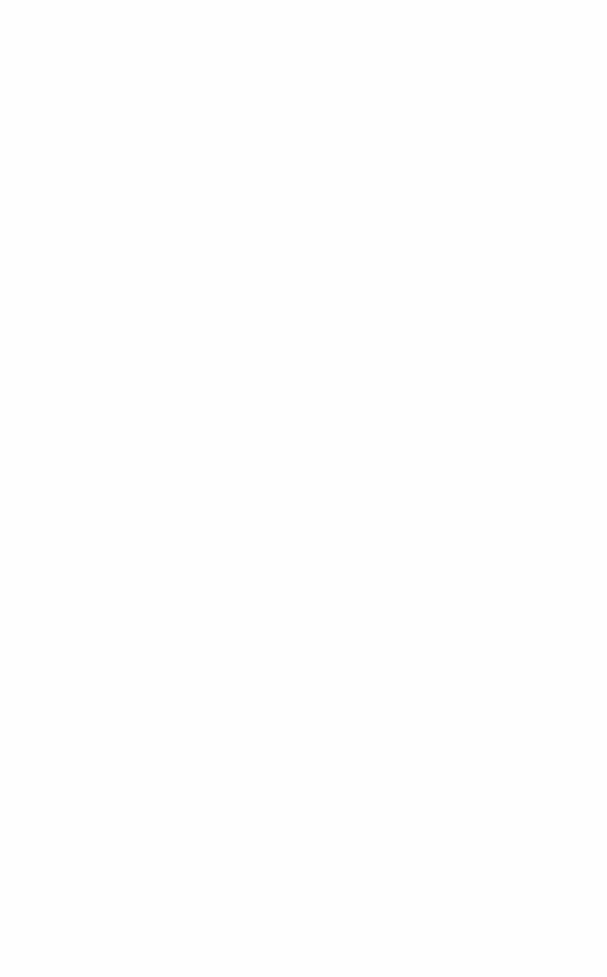

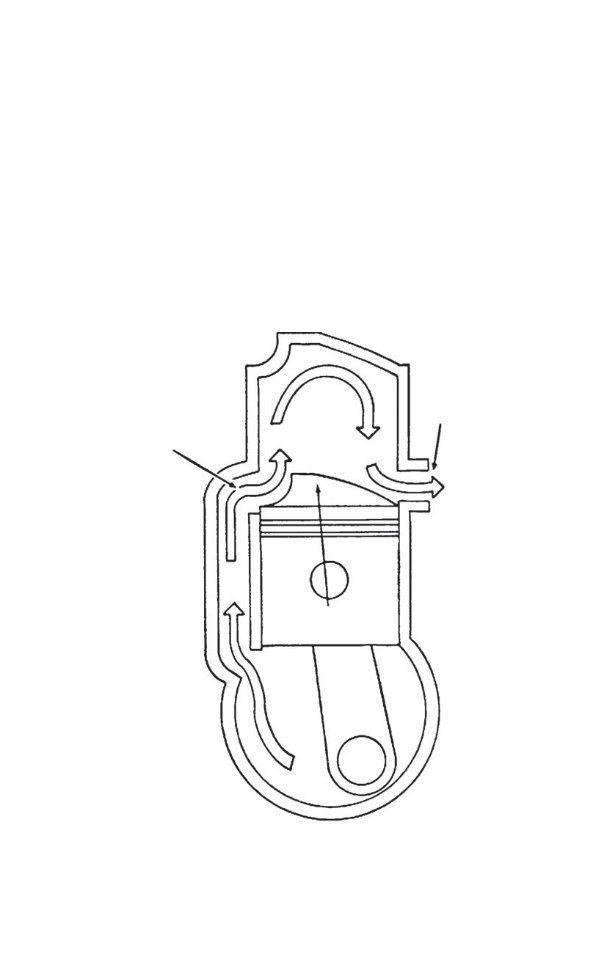

First, let’s look at events above the piston during a full turn of the crank-

shaft. In Fig. 1-1A the piston approaches the upper limit of travel, or top

dead center (TDC), and has compressed the air-fuel mixture above it. The

piston has also uncovered the inlet port to admit fuel and air from the car-

buretor to the crankcase. Figure 1-1B illustrates the beginning of the power

stroke under the impetus of expanding combustion gases. As the piston

falls, it first uncovers the exhaust port (Fig. 1-1C) and, a few degrees of

crankshaft rotation later, the transfer port (Fig.1-1D). Fuel and air pass

through the transfer port and into the cylinder bore.

Meanwhile, much is happening in the crankcase. As the piston falls on

the power stroke, it partially fills the crankcase, reducing its volume, as

shown in Fig. 1-1C. Since the piston now covers the inlet port, the pressure

of the air-fuel mixture trapped in the case rises.

Near bottom dead center (BDC) the piston uncovers the transfer port and

the pressurized fuel mixture passes through this port to the upper cylinder

(Fig. 1-1D). The piston then rounds BDC and begins to climb, an action that

simultaneously compresses the mixture above the piston and creates a par-

tial vacuum under it. Once the inlet port opens, atmospheric pressure forces

fuel and air from the carburetor into the crankcase.

A problem with third-port engines is fuel reversion. At low speeds the

crankcase fills to overflowing. When the piston reverses at the top of the

stroke, some of the charge can flow back through the inlet port to the car-

buretor. A fog of oily fuel hovers around the air cleaner, dirtying the engine

and playing havoc with carburetor metering.

Reed-valve engines

Although third-port engines are still encountered, many manufacturers prefer to

control crankcase filling with a reed valve installed between the carburetor and

crankcase. The valve, similar to the reed on musical instruments, opens and

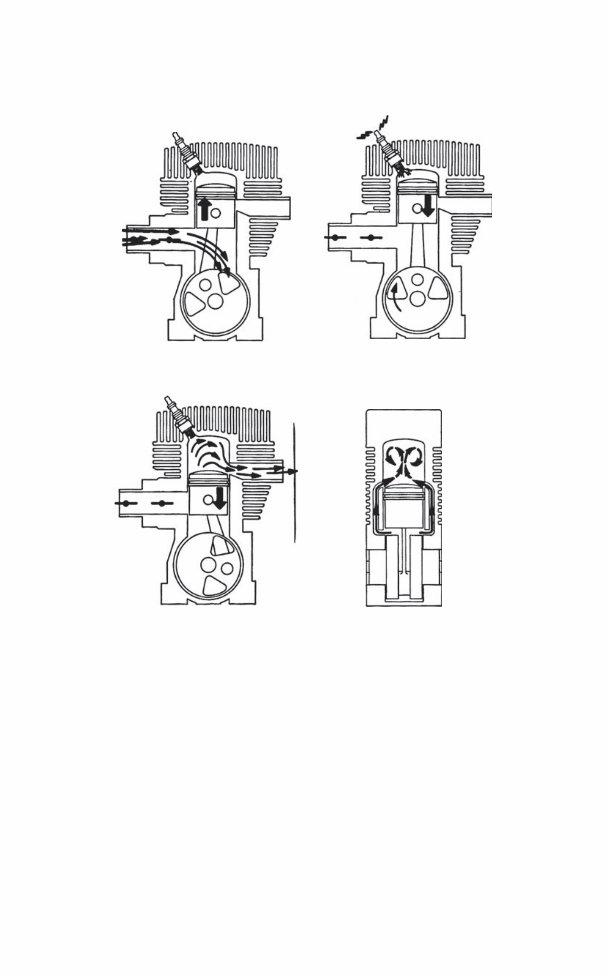

closes in response to crankcase pressure (Fig. 1-2). Utility engines make do with

a single reed, or pedal, athwart the intake port (Fig. 1-3). High-performance

2 Fundamentals

Two-cycle operation 3

Transfer

D

Intake

A

Power stroke

B

C

Exhaust

FIG. 1-1. Operating sequence of a third-port, loop-scavenged engine. Walbro

engines employ a tent-like valve block with multiple reeds. This arrangement

provides a large valve area for better crankcase filling (Fig. 1-4).

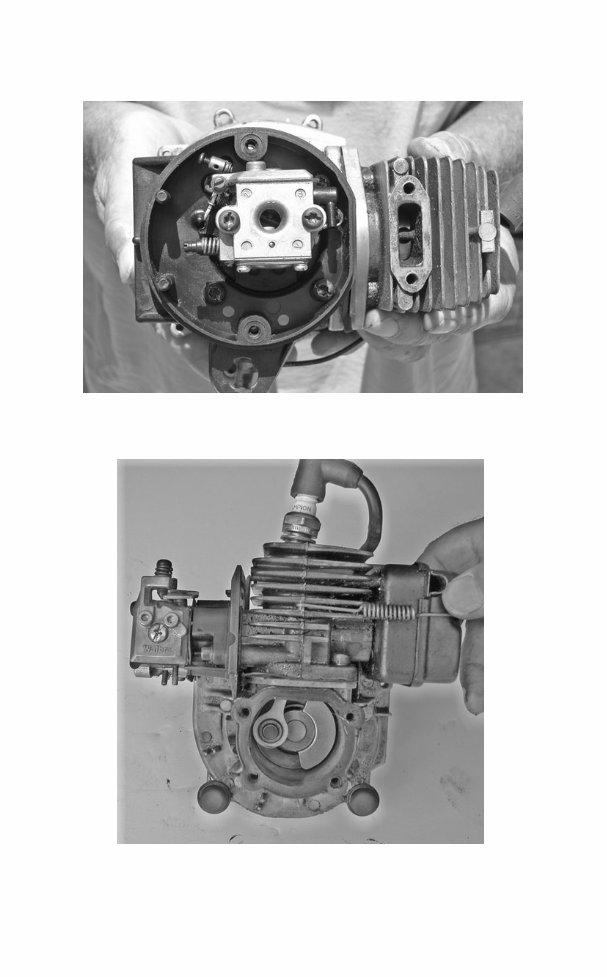

For mini-two-strokes, the position of the carburetor indicates the type of

inlet valve: when a reed is present, the carburetor mounts on the crankcase

(Fig. 1-5). Third-port engines mount their carburetors on the cylinder barrel

in line with the inlet port, as shown in Fig. 1-6. Being able to recognize the

presence of a reed valve without disassembling the engine is useful, since the

reed can malfunction. Should the pedal split or fail to seal, the engine will

not start.

But the rule about the carburetor location does not necessarily apply to

larger engines. Some European motorcycles had crankcase-mounted carbu-

retors that fed through a rotary valve in the form of a partially cutaway disk,

keyed to crankshaft. Model airplane engines and a few vintage outboards

use a slotted crankshaft to the same effect.

Motorcycle engines often combine a third port with an integral reed valve.

The port controls timing and the reed prevents backflow through the carbu-

retor. Although the reeds impose a pressure drop, midrange torque benefits.

4 Fundamentals

A

C D

B

FIG. 1-2. Operating sequence of a reed-valve engine that in the example shown

employs loop scavenging. The small tube on the lower left of the drawing transfers

crankcase pressure pulses to the fuel pump. Deere and Company

5

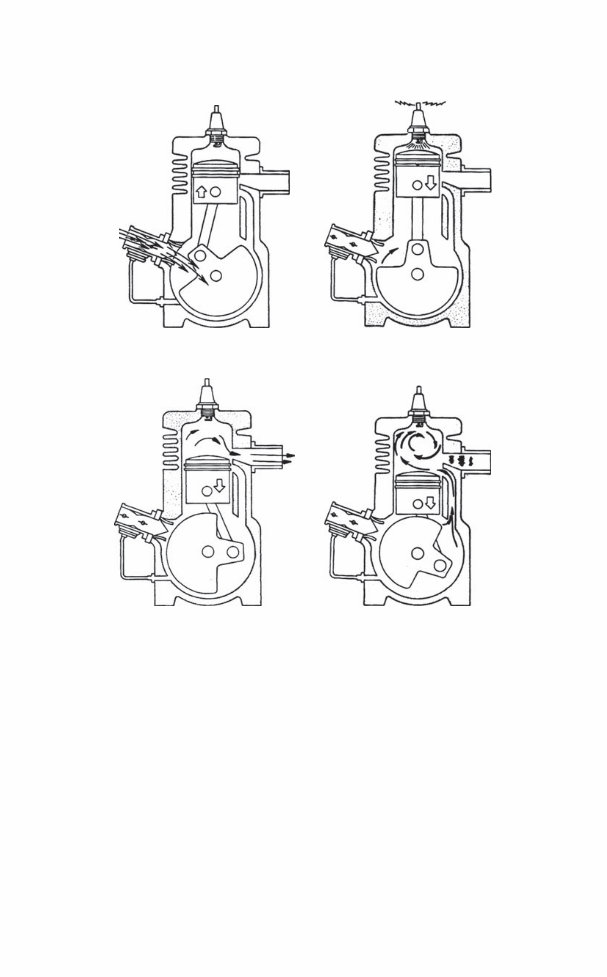

FIG. 1-3. Reed valves for handheld engines generally have a single pedal backed by

a guard plate to limit deflection. Robert Shelby

FIG. 1-4. Multiple pedals are standard on high-performance engines. While there

has been considerable experimentation with fiberglass, carbon fiber, and other

high-tech materials, spring-steel pedals appear to work as well as any. Tecumseh

Products Co.

6 Fundamentals

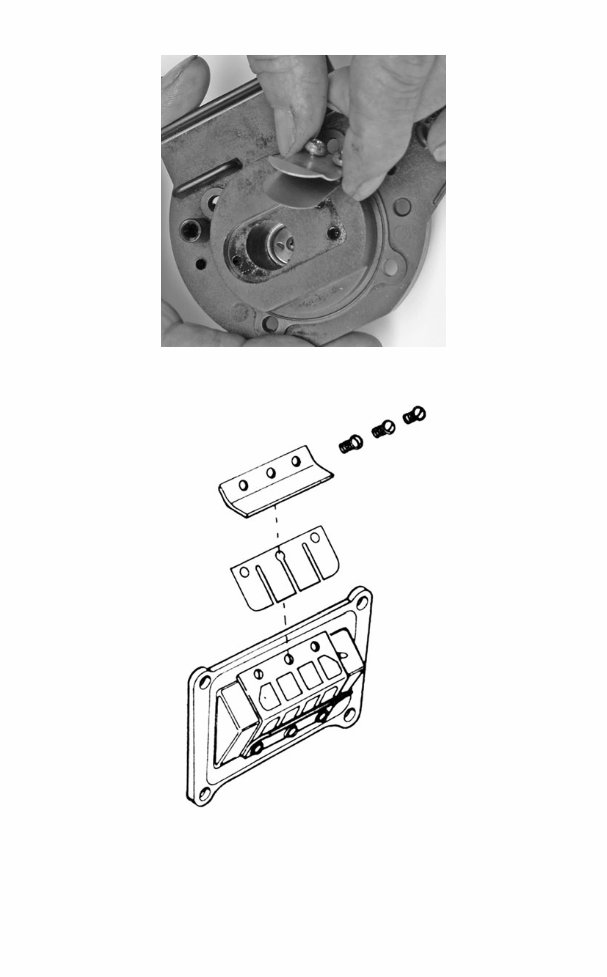

FIG. 1-5. Reed-valve engines mount their carburetors low on the crankcase. Robert

Shelby

FIG. 1-6. Carburetors for third-port engines attach to the cylinder. Some of these

engines incorporate a reed valve in the third port. Robert Shelby

Scavenging

Scavenging is the term for purging the cylinder of exhaust gases. Unlike a four-

cycle engine, which devotes a full stroke of the piston to clear the cylinder, a

two-stroke must scavenge during the 100° or so of crankshaft rotation that the

exhaust port remains open.

Blowdown As the piston falls, it first uncovers the exhaust port and then,

5° or 10° of crankshaft rotation later, the transfer port. Blowdown occurs dur-

ing this brief period that, at wide-open throttle, occupies no more than one

or two thousandths of a second. In spite of its brevity, the blowdown phase

is the primary mechanism for evacuating the cylinder.

The rapid opening of a port releases a high-pressure slug of exhaust gas that

trails a low-pressure zone or wave in its wake. Cylinder pressure momentarily

drops below atmospheric pressure. Responding to the pressure differential, the

fresh charge moves through the transfer port to fill the cylinder. At part throttle,

crankcase pressure is less than cylinder pressure. Were it not for the drop in cylin-

der pressure that accompanies blowdown, two-cycle engines would not run.

The need to accelerate exhaust gases quickly explains why exhaust ports for

high-performance engines are rectangular rather than round. It also explains

why we must keep these ports and mufflers free of carbon accumulations.

Exhaust tuning When a high-pressure wave encounters a solid obstacle

or an abrupt change in direction in the exhaust plumbing, it rebounds back

to the exhaust port. These waves oscillate at the speed of sound and at a

frequency determined by engine rpm. Where space permits, the length of

the exhaust system can be tuned to reflect a high-pressure wave back to the

exhaust port just as the cylinder fills to overflowing. The wave rams any fuel

that spills out of the port back into the cylinder where it belongs. Of course,

this works only over a narrow rpm range; at other speeds the wave can

arrive early to the detriment of cylinder filling. In a similar manner, the

intake tract can be tuned to maximize crankcase filling.

Spatial constraints make tuned exhaust and intake systems impractical for

handheld equipment. About all that can be done is to arrange for a small boost

from third- or fourth-order wave harmonics.

Charge scavenging What exhaust gas remains in the cylinder after blow-

down must be scavenged by the fuel charge, which enters the cylinder at

velocities as high as 65 m/s. Charge scavenging takes two forms, neither of

which can entirely eliminate short-circuiting.

Short-circuiting Short-circuiting is the term for the way incoming fuel

escapes out the exhaust, as if one were trying to fill a leaky bucket. Most of

the leak can be laid to symmetrical timing.

Because piston motion controls port timing, the timing is symmetrical

around BDC. For example, an exhaust port that opens 60 crankshaft degrees

Two-cycle operation 7

before bottom dead center must remain open for 60° after BDC. The exhaust

port opens a few degrees before the transfer port. Otherwise, the cylinder

would not blow down and very little fuel would be delivered. But opening the

exhaust port early means that it stays open throughout the entire fuel transfer

process.

The open exhaust port acts as an escape hatch for incoming fuel. How

much fuel escapes combustion varies with port geometry, rpm, and throttle

position. An idling motorcycle short-circuits as much as 70% of its fuel out

the exhaust. On average, two-stroke engines waste between 25% and 35%

of their fuel in this manner.

Cross scavenging Readers with long memories may recall the deflec-

tor pistons that were once standard ware on these engines (Fig. 1-7).

8 Fundamentals

Intake port

Exhaust port

Deflector

FIG. 1-7. Cross-scavenged engines have the intake port 180° opposite the exhaust

port. Incoming gases rebound upward off the deflector on the piston crown to give

some protection against short-circuiting.

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 55 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get your hands on the McCulloch Chainsaws Service & Repair Manual, covering a wide range of models including 10-10 AUTO, 7-10 AUTO, DOUBLE EAGLE 80, EAGER BEAVER 2.1, and more. This comprehensive .pdf manual is printable and available in English. It is compatible with various electronic devices such as PC & Mac computers, Android and Apple smartphones & tablets, and more. All you need is the free Adobe Reader to access this valuable resource.

- 10-10 AUTO

- 7-10 AUTO

- DOUBLE EAGLE 80

- EAGER BEAVER 2.1

- MINI-MAC 25

- MINI-MAC 30

- MINI-MAC 35

- PM10-10S

- PM310

- PM320

- PM330

- PM340

- PM355

- PM365

- PM375

- PM510

- PM515

- PM55

- PM555

- PM60

- PM700

- PM800

- PM805

- PM850

- POWER MAC 6

- SP40

- SP60

- SP80

- SP81

- W