JONSERED CHAINSAW Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

CARBURETOR SERVICE CHAIN SAW

CARBURETOR SERVICE

GENERAL CARBURETOR SERVICE

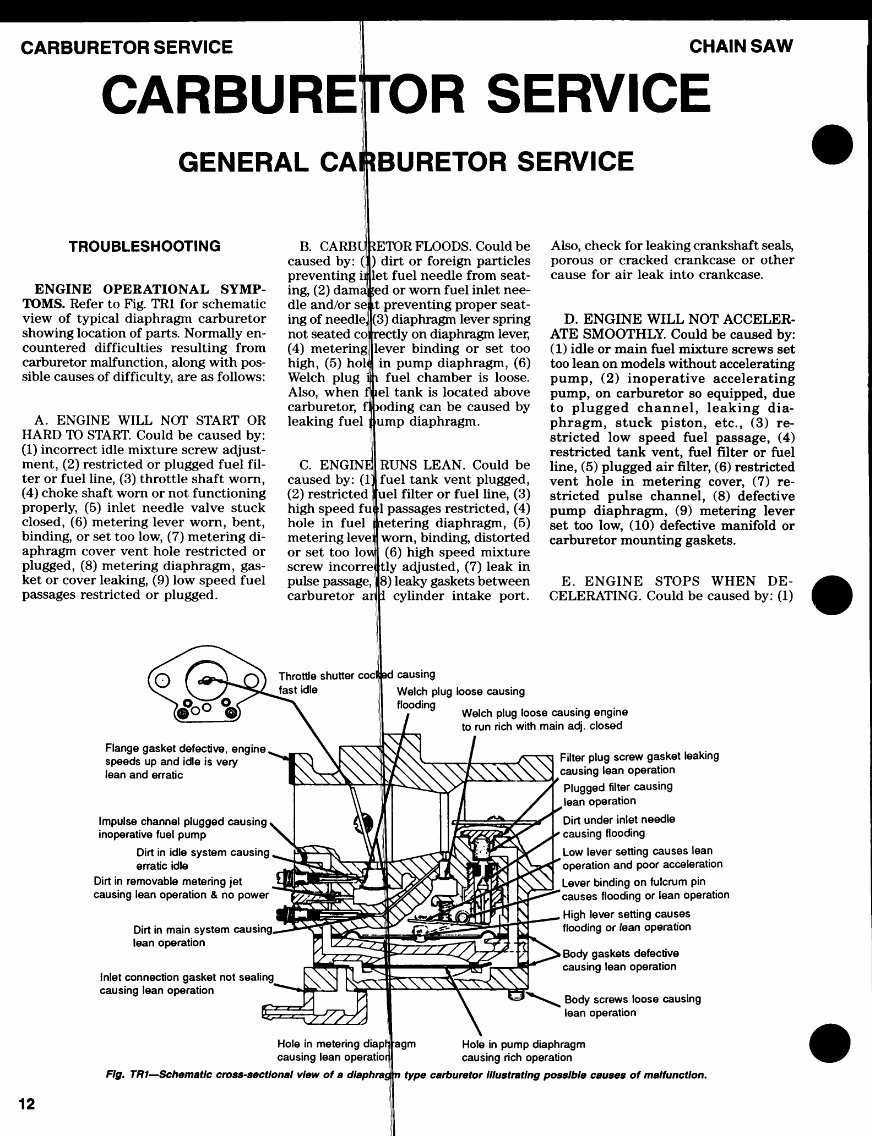

ENGINE OPERATIONAL SYMP-

TOMS. Refer to Fig. TR1 for schematic

view of typical diaphragm carburetor

showing location of parts. Normally en-

countered difficulties resulting from

carburetor malfunction, along with pos-

sible causes of difficulty, are as follows:

A. ENGINE WILL NOT START OR

HARD TO START. Could be caused by:

(1) incorrect idle mixture screw adjust-

ment, (2) restricted or plugged fuel fil-

ter or fuel line, (3) throttle shaft worn,

(4) choke shaft worn or not functioning

properly, (5) inlet needle valve stuck

closed, (6) metering lever worn, bent,

binding, or set too low, (7) metering di-

aphragm cover vent hole restricted or

plugged, (8) metering diaphragm, gas-

ket or cover leaking, (9) low speed fuel

passages restricted or plugged.

B. GARB

caused by: (

preventing i

ing, (2) dam

die and/or s

ing of needle,

not seated c

(4) metering

high, (5) hoi

Welch plug

Also, when

carburetor,

leaking fuel

:ETOR FLOODS. Could be

I) dirt or foreign particles

|let fuel needle from seat-

led or worn fuel inlet nee-

it preventing proper seat-

'3) diaphragm lever spring

;ly on diaphragm lever,

|lever binding or set too

in pump diaphragm, (6)

fuel chamber is loose,

icl tank is located above

•ding can be caused by

lump diaphragm.

C. ENGIN1

caused by: (1]

(2) restricted

high speed fuj

hole in fuel

metering level

or set too loi

screw incorrei

pulse passage,

carburetor ai

RUNS LEAN. Could be

fuel tank vent plugged,

[uel filter or fuel line, (3)

1 passages restricted, (4)

.etering diaphragm, (5)

worn, binding, distorted

(6) high speed mixture

ttly adjusted, (7) leak in

|8) leaky gaskets between

cylinder intake port.

Also, check for leaking crankshaft seals,

porous or cracked crankcase or other

cause for air leak into crankcase.

D. ENGINE WILL NOT ACCELER-

ATE SMOOTHLY. Could be caused by:

(1) idle or main fuel mixture screws set

too lean on models without accelerating

pump, (2) inoperative accelerating

pump, on carburetor so equipped, due

to plugged channel, leaking dia-

phragm, stuck piston, etc., (3) re-

stricted low speed fuel passage, (4)

restricted tank vent, fuel filter or fuel

line, (5) plugged air filter, (6) restricted

vent hole in metering cover, (7) re-

stricted pulse channel, (8) defective

pump diaphragm, (9) metering lever

set too low, (10) defective manifold or

carburetor mounting gaskets.

E. ENGINE STOPS WHEN DE-

CELERATING. Could be caused by: (1)

;o

Flange gasket defective, engine,

speeds up and idle is very

lean and erratic

Throttle shutter coclj

fast idle

! causing

Welch plug loose causing

flooding

Welch plug loose causing engine

to run rich with main adj. closed

Impulse channel plugged causing v

inoperative fuel pump >^

Dirt in idle system causing

erratic idle

Dirt in removable metering jet

causing lean operation & no power

Dirt in main system causing,

lean operation

Inlet connection gasket not sealing

causing lean operation

Filter plug screw gasket leaking

causing lean operation

Plugged filter causing

,lean operation

Dirt under inlet needle

causing flooding

Low lever setting causes lean

operation and poor acceleration

Lever binding on fulcrum pin

causes flooding or lean operation

High lever setting causes

flooding or (ean operation

> Body gaskets defective

causing lean operation

Body screws loose causing

lean operation

Hole in metering diaprj

causing lean operatior

Fig. TR1—Schematic cross-sectional view of a dlaphras

agm Hole in pump diaphragm

causing rich operation

type carburetor Illustrating possible causes of malfunction.

12

SERVICE MANUAL SAW CHAIN

tion in pitch which will contribute

to rapid wear of sprocket teeth.

6. A badly worn bar will contribute

to rapid wear of the chain which

will cause the sprocket to wear.

Rapid deterioration and wear on

chain drive lugs, side links and

cutters will result from installing a

new chain. Never install a new

chain on a worn sprocket or bar.

CLUTCH

CLUTCH BEARING. The clutch

drum and sprocket can rotate freely (or

stop) when the clutch is disengaged. A

caged needle roller bearing is located

between the clutch drum hub and the

shaft. The bearing on most models uses

the shaft as the inner race and the

clutch drum hub as the outer race and

can be removed by hand without any

special tools.

Clutch needle bearing failure is often

caused by storing the saw after oper-

ating under extremely wet conditions.

The water will penetrate the needle

bearing, form rust and cause the

needles to become locked. It is recom-

mended that the clutch drum be re-

moved periodically (depending on local

conditions) and the bearing repacked

with a good grade of water-resistant

grease (not water pump grease).

CLUTCH DRUM AND SHOES.

Rapid clutch drum wear, shoe glazing

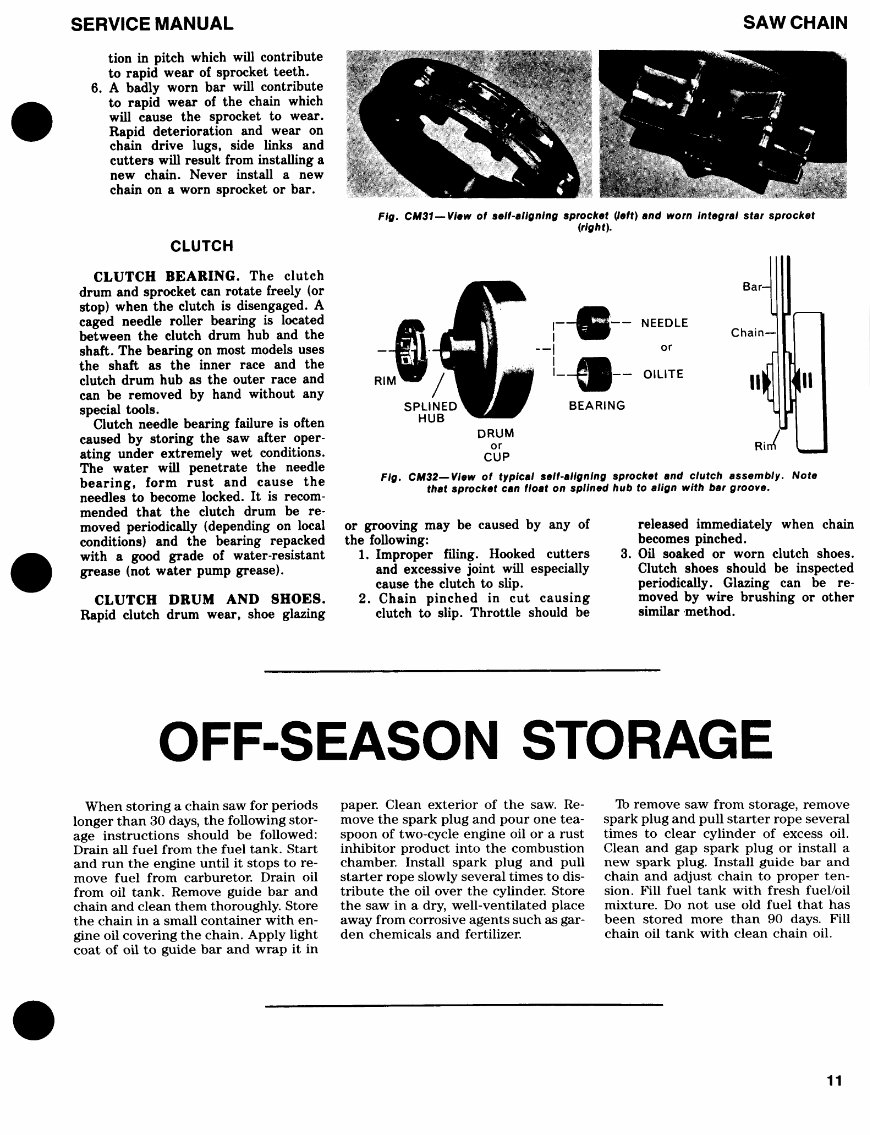

Fig. CM31—View of self-aligning sprocket (left) and worn integral star sprocket

(right).

Bar-

RIM

Chain—

II

lirrt

Fig. CM32—View of typical self-aligning sprocket and clutch assembly. Note

that sprocket can float on spllned hub to align with bar groove.

or grooving may be caused by any of

the following:

1. Improper filing. Hooked cutters

and excessive joint will especially

cause the clutch to slip.

2. Chain pinched in cut causing

clutch to slip. Throttle should be

released immediately when chain

becomes pinched.

3. Oil soaked or worn clutch shoes.

Clutch shoes should be inspected

periodically. Glazing can be re-

moved by wire brushing or other

similar method.

OFF-SEASON STORAGE

When storing a chain saw for periods

longer than 30 days, the following stor-

age instructions should be followed:

Drain all fuel from the fuel tank. Start

and run the engine until it stops to re-

move fuel from carburetor. Drain oil

from oil tank. Remove guide bar and

chain and clean them thoroughly. Store

the chain in a small container with en-

gine oil covering the chain. Apply light

coat of oil to guide bar and wrap it in

paper. Clean exterior of the saw. Re-

move the spark plug and pour one tea-

spoon of two-cycle engine oil or a rust

inhibitor product into the combustion

chamber. Install spark plug and pull

starter rope slowly several times to dis-

tribute the oil over the cylinder. Store

the saw in a dry, well-ventilated place

away from corrosive agents such as gar-

den chemicals and fertilizer.

Tb remove saw from storage, remove

spark plug and pull starter rope several

times to clear cylinder of excess oil.

Clean and gap spark plug or install a

new spark plug. Install guide bar and

chain and adjust chain to proper ten-

sion. Fill fuel tank with fresh fuel/oil

mixture. Do not use old fuel that has

been stored more than 90 days. Fill

chain oil tank with clean chain oil.

11

CARBURETOR SERVICE CHAIN SAW

CARBURETOR SERVICE

TROUBLESHOOTING

ENGINE OPERATIONAL SYMP-

TOMS. Refer to Fig. TR1 for schematic

view of typical diaphragm carburetor

showing location of parts. Normally en-

countered difficulties resulting from

carburetor malfunction, along with pos-

sible causes of difficulty, are as follows:

A. ENGINE WILL NOT START OR

HARD TO START. Could be caused by:

(1) incorrect idle mixture screw adjust-

ment, (2) restricted or plugged fuel fil-

ter or fuel line, (3) throttle shaft worn,

(4) choke shaft worn or not functioning

properly, (5) inlet needle valve stuck

closed, (6) metering lever worn, bent,

binding, or set too low, (7) metering di-

aphragm cover vent hole restricted or

plugged, (8) metering diaphragm, gas-

ket or cover leaking, (9) low speed fuel

passages restricted or plugged.

B. CARBUR]

caused by: (1)

preventing inl<

ing, (2) damag<

die and/or seal

ing of needle, (J

not seated coi

(4) metering H

high, (5) hole

Welch plug in

Also, when fu<

carburetor, floi

leaking fuel pi

!TOR FLOODS. Could be

irt or foreign particles

fuel needle from seat-

or worn fuel inlet nee-

ireventing proper seat-

diaphragm lever spring

Jctly on diaphragm lever,

jver binding or set too

pump diaphragm, (6)

Ifuel chamber is loose,

tank is located above

ding can be caused by

p diaphragm.

C. ENGINE

caused by: (1)

(2) restricted fit

high speed f

hole in fuel

metering lever

or set too low,

screw incorrect

pulse passage, (8

carburetor anc

:UNS LEAN. Could be

iel tank vent plugged,

il filter or fuel line, (3)

•assages restricted, (4)

stering diaphragm, (5)

n, binding, distorted

high speed mixture

[y adjusted, (7) leak in

leaky gaskets between

cylinder intake port.

Also, check for leaking crankshaft seals,

porous or cracked crankcase or other

cause for air leak into crankcase.

D. ENGINE WILL NOT ACCELER-

ATE SMOOTHLY. Could be caused by:

(1) idle or main fuel mixture screws set

too lean on models without accelerating

pump, (2) inoperative accelerating

pump, on carburetor so equipped, due

to plugged channel, leaking dia-

phragm, stuck piston, etc., (3) re-

stricted low speed fuel passage, (4)

restricted tank vent, fuel filter or fuel

line, (5) plugged air filter, (6) restricted

vent hole in metering cover, (7) re-

stricted pulse channel, (8) defective

pump diaphragm, (9) metering lever

set too low, (10) defective manifold or

carburetor mounting gaskets.

E. ENGINE STOPS WHEN DE-

CELERATING. Could be caused by: (1)

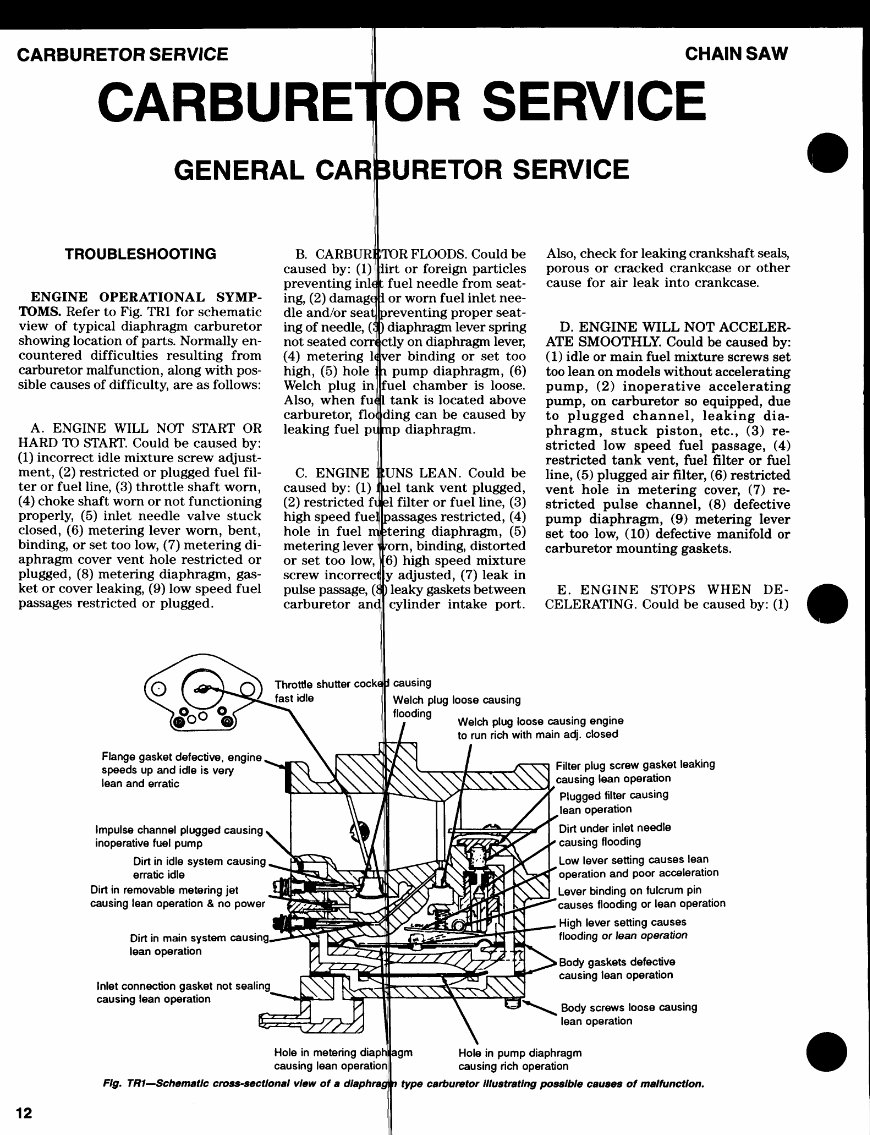

;o

Throttle shutter cocke

fast idle

! causing

Welch plug loose causing

flooding

Welch plug loose causing engine

to run rich with main adj. closed

Flange gasket defective, engine,

speeds up and idle is very

lean and erratic

Impulse channel plugged causing.

inoperative fuel pump

Dirt in idle system causing.

erratic idle

Dirt in removable metering jet

causing lean operation & no power

Dirt in main system causinc

lean operation

Inlet connection gasket not sealing

causing lean operation

Hole in metering diapti

causing lean operation|

Fig. TR1—Schematic cross-sectional view of a dlaphr

Filter plug screw gasket leaking

causing lean operation

Plugged filter causing

lean operation

Dirt under inlet needle

causing flooding

Low lever setting causes lean

operation and poor acceleration

Lever binding on fulcrum pin

causes flooding or lean operation

High lever setting causes

flooding or lean operation

Body gaskets defective

causing lean operation

Body screws loose causing

lean operation

igm Hole in pump diaphragm

causing rich operation

type carburetor Illustrating possible causes of malfunction.

12

SERVICE MANUAL CARBURETOR SERVICE

idle speed, idle mixture or high speed

mixture screws incorrectly adjusted, (2)

defective pump diaphragm, (3) pulse

passage leaking or restricted, (4) air

leaks between carburetor and crank-

case, (5) throttle shaft worn, (6) meter-

ing lever set too high, (7) fuel inlet nee-

dle binding.

F. ENGINE WILL NOT IDLE. Could

be caused by: (1) incorrect adjustment

of idle fuel and/or idle speed screws, (2)

idle discharge or air mixture ports

plugged, (3) fuel channel plugged, (4)

fuel tank vent, filter or fuel line re-

stricted, (5) leaky gaskets between car-

buretor and cylinder intake ports.

G. ENGINE IDLES WITH LOW

SPEED NEEDLE CLOSED. Could be

caused by: (1) metering lever set too

high or stuck, (2) fuel inlet needle not

seating due to wear or damage, (3)

Welch plug covering idle ports not seal-

ing properly.

H. ENGINE RUNS RICH. Could be

caused by: (1) plugged air filter, (2) low

speed or high speed mixture screws in-

correctly adjusted or damaged, (3)

metering lever worn, binding, distorted

or set too high, (4) fuel pump diaphragm

defective, (5) fuel inlet needle valve

leaking, (6) Welch plug leaking, (7)

faulty governor valve (if so equipped).

I. ENGINE HAS LOW POWER UN-

DER LOAD. Could be caused by: (1)

main mixture screw incorrectly ad-

justed, (2) plugged fuel tank vent, fil-

ter or fuel line, (3) pulse channel leak-

ing or restricted, (4) defective pump

diaphragm, (5) plugged air filter, (6) air

leaks between carburetor and crank-

case, (7) metering lever distorted or set

too low, (8) hole in metering diaphragm

or gasket leaking, (9) faulty nozzle check

valve.

PRESSURE TESTING

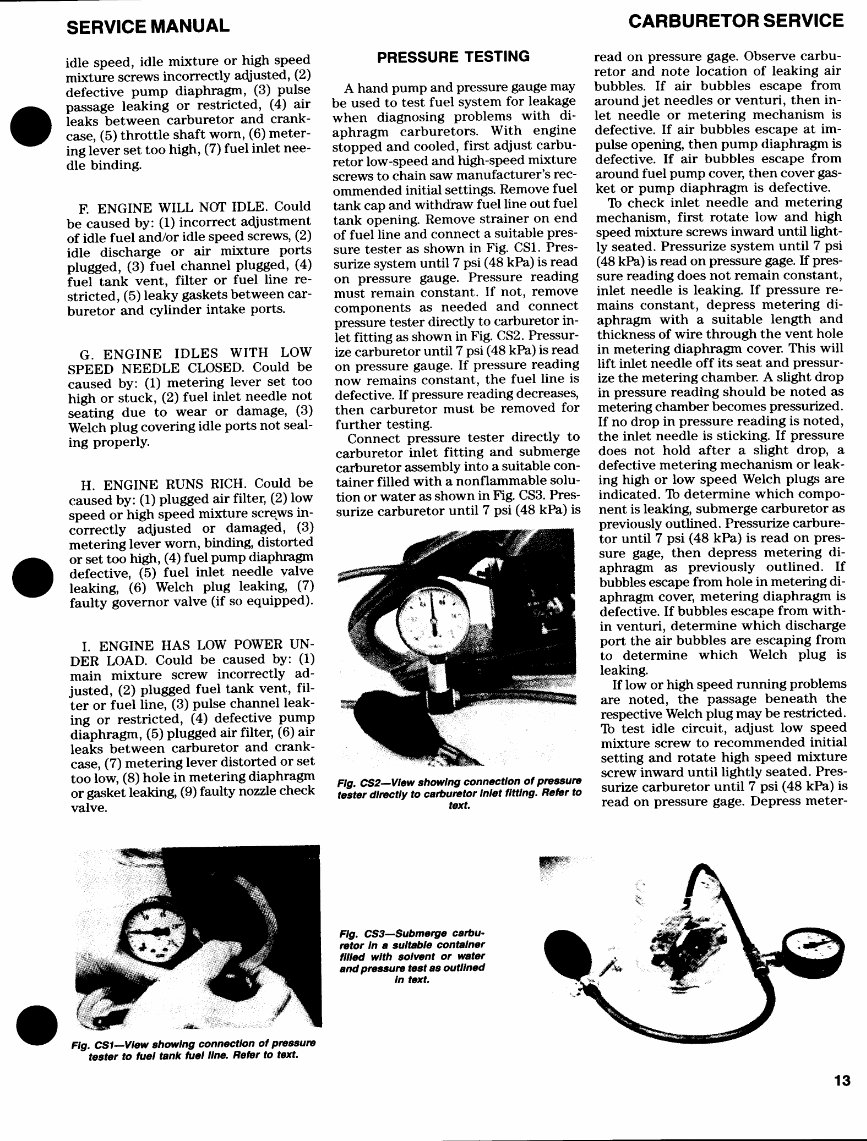

A hand pump and pressure gauge may

be used to test fuel system for leakage

when diagnosing problems with di-

aphragm carburetors. With engine

stopped and cooled, first adjust carbu-

retor low-speed and high-speed mixture

screws to chain saw manufacturer's rec-

ommended initial settings. Remove fuel

tank cap and withdraw fuel line out fuel

tank opening. Remove strainer on end

of fuel line and connect a suitable pres-

sure tester as shown in Fig. CS1. Pres-

surize system until 7 psi (48 kPa) is read

on pressure gauge. Pressure reading

must remain constant. If not, remove

components as needed and connect

pressure tester directly to carburetor in-

let fitting as shown in Fig. CS2. Pressur-

ize carburetor until 7 psi (48 kPa) is read

on pressure gauge. If pressure reading

now remains constant, the fuel line is

defective. If pressure reading decreases,

then carburetor must be removed for

further testing.

Connect pressure tester directly to

carburetor inlet fitting and submerge

carburetor assembly into a suitable con-

tainer filled with a nonflammable solu-

tion or water as shown in Fig. CS3. Pres-

surize carburetor until 7 psi (48 kPa) is

Fig. CS2—Vlew showing connection of pressure

tester directly to carburetor Inlet fitting. Refer to

text.

read on pressure gage. Observe carbu-

retor and note location of leaking air

bubbles. If air bubbles escape from

around jet needles or venturi, then in-

let needle or metering mechanism is

defective. If air bubbles escape at im-

pulse opening, then pump diaphragm is

defective. If air bubbles escape from

around fuel pump cover, then cover gas-

ket or pump diaphragm is defective.

To check inlet needle and metering

mechanism, first rotate low and high

speed mixture screws inward until light-

ly seated. Pressurize system until 7 psi

(48 kPa) is read on pressure gage. If pres-

sure reading does not remain constant,

inlet needle is leaking. If pressure re-

mains constant, depress metering di-

aphragm with a suitable length and

thickness of wire through the vent hole

in metering diaphragm cover. This will

lift inlet needle off its seat and pressur-

ize the metering chamber. A slight drop

in pressure reading should be noted as

metering chamber becomes pressurized.

If no drop in pressure reading is noted,

the inlet needle is sticking. If pressure

does not hold after a slight drop, a

defective metering mechanism or leak-

ing high or low speed Welch plugs are

indicated. To determine which compo-

nent is leaking, submerge carburetor as

previously outlined. Pressurize carbure-

tor until 7 psi (48 kPa) is read on pres-

sure gage, then depress metering di-

aphragm as previously outlined. If

bubbles escape from hole in metering di-

aphragm cover, metering diaphragm is

defective. If bubbles escape from with-

in venturi, determine which discharge

port the air bubbles are escaping from

to determine which Welch plug is

leaking.

If low or high speed running problems

are noted, the passage beneath the

respective Welch plug may be restricted.

To test idle circuit, adjust low speed

mixture screw to recommended initial

setting and rotate high speed mixture

screw inward until lightly seated. Pres-

surize carburetor until 7 psi (48 kPa) is

read on pressure gage. Depress meter-

Flg. CS3—Submerge carbu-

retor In a suitable container

filled with solvent or water

and pressure test as outlined

In text.

Fig. CS1—Vlew showing connection of pressure

tester to fuel tank fuel line. Refer to text.

13

CARBURETOR SERVICE

|^\^

r^^*^

^^X""

^^

4 -$^

^x?^.

6—^*b,"^^

f t v^Y/

s 6 ^ >fr

v u s. Jslx1^

^^-^&g)

1 £ ^r*^^i*~^^~2^

u^jfrlr1

^^^*\* s

15^>^

16 ^^=\5

x^"^

S^J_^

,

^^f^

I

>^

^3

/ /

^M /

\n

*n -j^ g

4^^&/

^^^w

18

'^19

K'!

r»

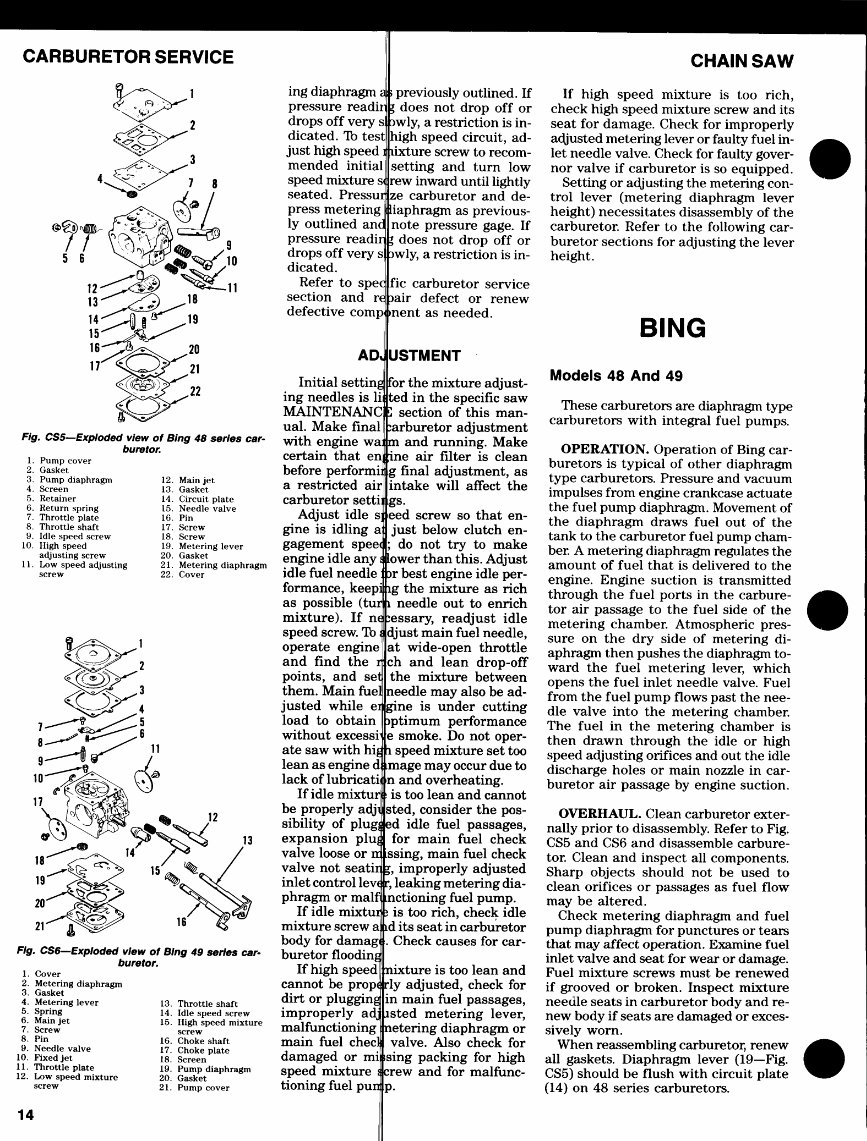

F/g. CSS— Exploded view of Bing 48 series car-

buretor.

1. Pump cover

2. Gasket

3. Pump diaphragm

4. Screen

5. Retainer

6. Return spring

7. Throttle plate

8. Throttle shaft

9. Idle speed screw

10. High speed

adjusting screw

11. Low speed adjusting

screw

fx^-^N^.1

< ^§=^^ < ^ 2

<C^'®^TV'^

XT^'TN^

7^-—^SS'^^5

^-X'^'^'^x' 6

8 ^-"Hfl c*^^ ^

9-^^J^» /

10 ^~^§S^\f

^ v^S^St-^v ^^

17 \i

Vv^j^^^t

«Tv3 ^^Jr^ ^^

•^^^'' 3 \4

18 ^^T' 3 ^^ 15

19 x^^C^

^^^o^

<£*r§^?Sv

21 ""jir^ll^^

*

12. Main jet

13. Gasket

14. Circuit plate

15. Needle valve

16. Pin

17. Screw

18. Screw

19. Metering lever

20. Gasket

21. Metering diaphragm

22. Cover

^<*!&^ / 2

Vo4 13

/« /

*% /

^w ^^C

^^v^^

/\X_^Sr

16 ^

F/g. CS6—Exploded view of Bing 49 series car-

buretor.

1 . Cover

2. Metering diaphragm

3. Gasket

4. Metering lever

5. Spring

6. Main jet

7. Screw

8. Pin

9. Needle valve

10. Fixed jet

11. Throttle plate

12. Low speed mixture

screw

14

13. Throttle shaft

14. Idle speed screw

15. High speed mixture

screw

16. Choke shaft

17. Choke plate

18. Screen

19. Pump diaphragm

20. Gasket

21. Pump cover

ing diaphragm a

pressure readir

drops off very s

dicated. To test

just high speed

mended initial

speed mixture s

seated. Pressur

press metering

ly outlined anc

pressure readir

drops off very s

dicated.

Refer to spec

section and re

defective comp

AD,

Initial setting

ing needles is li

MAINTENANC

ual. Make final

with engine wa:

certain that en

before perform!

a restricted air

carburetor setti

Adjust idle s

gine is idling a

gagement speet

engine idle any i

idle fuel needle

formance, keepi

as possible (tur

mixture). If ne

speed screw. To <

operate engine

and find the r

points, and set

them. Main fuel

justed while ei

load to obtain

without excessr

ate saw with hij

lean as engine d

lack of lubricatii

If idle mixtur

be properly adji

sibility of plugj

expansion plug

valve loose or rr

valve not seatir

inlet control lev<

phragm or malf

If idle mixtui

mixture screw a

body for damag

buretor flooding

If high speed

cannot be prop*

dirt or plugging

improperly ad:

malfunctioning

main fuel checl

damaged or mi

speed mixture i

tioning fuel pun

i previously outlined. If

I does not drop off or

awly, a restriction is in-

high speed circuit, ad-

lixture screw to recom-

setting and turn low

rew inward until lightly

ze carburetor and de-

liaphragm as previous-

note pressure gage. If

I does not drop off or

3wly, a restriction is in-

fic carburetor service

rair defect or renew

ment as needed.

USTMENT

for the mixture adjust-

ted in the specific saw

Z section of this man-

:arburetor adjustment

m and running. Make

ine air filter is clean

g final adjustment, as

intake will affect the

gs.

eed screw so that en-

just below clutch en-

; do not try to make

lower than this. Adjust

ar best engine idle per-

ig the mixture as rich

i needle out to enrich

:essary, readjust idle

djust main fuel needle,

at wide-open throttle

ch and lean drop-off

the mixture between

needle may also be ad-

gine is under cutting

>ptimum performance

e smoke. Do not oper-

i speed mixture set too

mage may occur due to

n and overheating.

is too lean and cannot

sted, consider the pos-

ed idle fuel passages,

for main fuel check

ssing, main fuel check

I, improperly adjusted

r, leaking metering dia-

nctioning fuel pump.

; is too rich, check idle

id its seat in carburetor

. Check causes for car-

nixture is too lean and

rly adjusted, check for

in main fuel passages,

isted metering lever,

netering diaphragm or

valve. Also check for

ising packing for high

crew and for malfunc-

P-

CHAIN SAW

If high speed mixture is too rich,

check high speed mixture screw and its

seat for damage. Check for improperly

adjusted metering lever or faulty fuel in-

let needle valve. Check for faulty gover-

nor valve if carburetor is so equipped.

Setting or adjusting the metering con-

trol lever (metering diaphragm lever

height) necessitates disassembly of the

carburetor. Refer to the following car-

buretor sections for adjusting the lever

height.

BING

Models 48 And 49

These carburetors are diaphragm type

carburetors with integral fuel pumps.

OPERATION. Operation of Bing car-

buretors is typical of other diaphragm

type carburetors. Pressure and vacuum

impulses from engine crankcase actuate

the fuel pump diaphragm. Movement of

the diaphragm draws fuel out of the

tank to the carburetor fuel pump cham-

ber. A metering diaphragm regulates the

amount of fuel that is delivered to the

engine. Engine suction is transmitted

through the fuel ports in the carbure-

tor air passage to the fuel side of the

metering chamber. Atmospheric pres-

sure on the dry side of metering di-

aphragm then pushes the diaphragm to-

ward the fuel metering lever, which

opens the fuel inlet needle valve. Fuel

from the fuel pump flows past the nee-

dle valve into the metering chamber.

The fuel in the metering chamber is

then drawn through the idle or high

speed adjusting orifices and out the idle

discharge holes or main nozzle in car-

buretor air passage by engine suction.

OVERHAUL. Clean carburetor exter-

nally prior to disassembly. Refer to Fig.

CSS and CS6 and disassemble carbure-

tor. Clean and inspect all components.

Sharp objects should not be used to

clean orifices or passages as fuel flow

may be altered.

Check metering diaphragm and fuel

pump diaphragm for punctures or tears

that may affect operation. Examine fuel

inlet valve and seat for wear or damage.

Fuel mixture screws must be renewed

if grooved or broken. Inspect mixture

needle seats in carburetor body and re-

new body if seats are damaged or exces-

sively worn.

When reassembling carburetor, renew

all gaskets. Diaphragm lever (19—Fig.

CSS) should be flush with circuit plate

(14) on 48 series carburetors.

SERVICE MANUAL CARBURETOR SERVICE

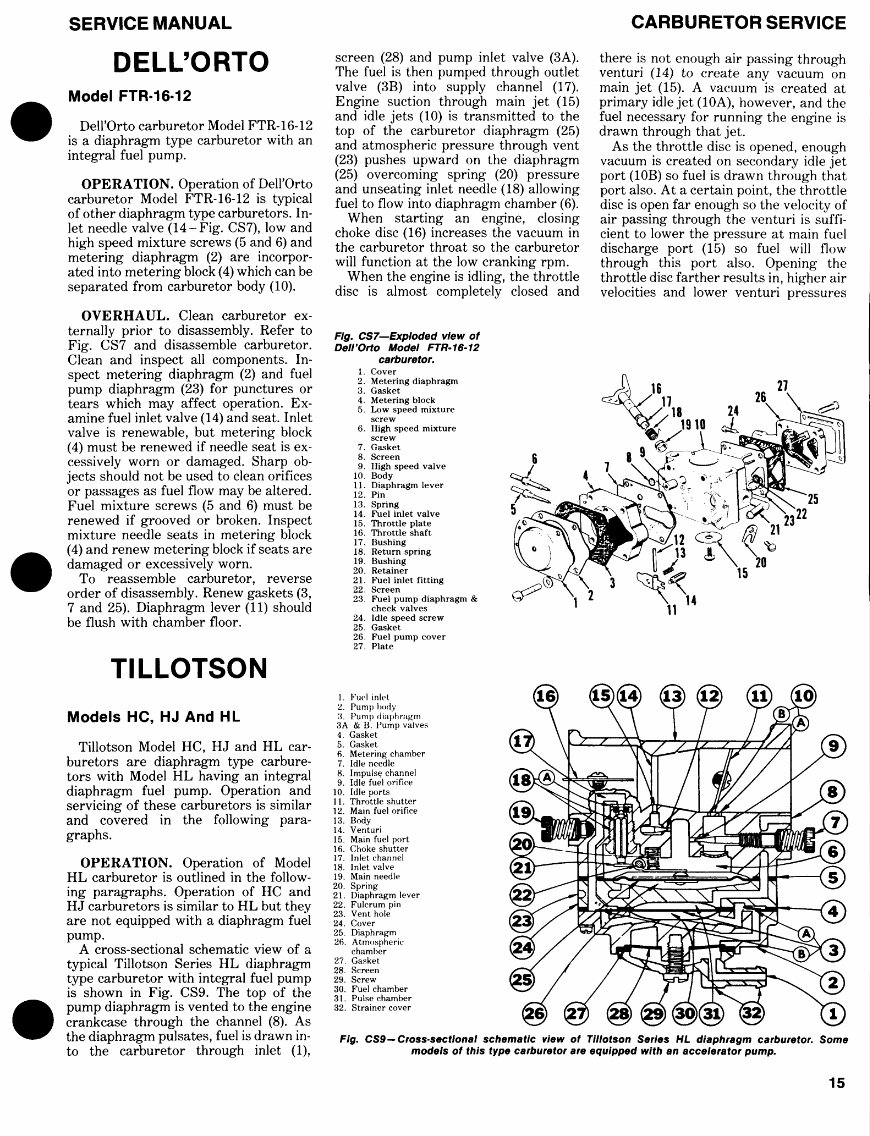

DELL'ORTO

Model FTR-16-12

Dell'Orto carburetor Model FTR-16-12

is a diaphragm type carburetor with an

integral fuel pump.

OPERATION. Operation of Dell'Orto

carburetor Model FTR-16-12 is typical

of other diaphragm type carburetors. In-

let needle valve (14-Fig. CS7), low and

high speed mixture screws (5 and 6) and

metering diaphragm (2) are incorpor-

ated into metering block (4) which can be

separated from carburetor body (10).

OVERHAUL. Clean carburetor ex-

ternally prior to disassembly. Refer to

Fig. CS7 and disassemble carburetor.

Clean and inspect all components. In-

spect metering diaphragm (2) and fuel

pump diaphragm (23) for punctures or

tears which may affect operation. Ex-

amine fuel inlet valve (14) and seat. Inlet

valve is renewable, but metering block

(4) must be renewed if needle seat is ex-

cessively worn or damaged. Sharp ob-

jects should not be used to clean orifices

or passages as fuel flow may be altered.

Fuel mixture screws (5 and 6) must be

renewed if grooved or broken. Inspect

mixture needle seats in metering block

(4) and renew metering block if seats are

damaged or excessively worn.

To reassemble carburetor, reverse

order of disassembly. Renew gaskets (3,

7 and 25). Diaphragm lever (11) should

be flush with chamber floor.

TILLOTSON

Models HC, HJ And HL

Tillotson Model HC, HJ and HL car-

buretors are diaphragm type carbure-

tors with Model HL having an integral

diaphragm fuel pump. Operation and

servicing of these carburetors is similar

and covered in the following para-

graphs.

OPERATION. Operation of Model

HL carburetor is outlined in the follow-

ing paragraphs. Operation of HC and

HJ carburetors is similar to HL but they

are not equipped with a diaphragm fuel

pump.

A cross-sectional schematic view of a

typical Tillotson Series HL diaphragm

type carburetor with integral fuel pump

is shown in Fig. CS9. The top of the

pump diaphragm is vented to the engine

crankcase through the channel (8). As

the diaphragm pulsates, fuel is drawn in-

to the carburetor through inlet (1),

there is not enough air passing through

venturi (14) to create any vacuum on

main jet (15). A vacuum is created at

primary idle jet (10A), however, and the

fuel necessary for running the engine is

drawn through that jet.

As the throttle disc is opened, enough

vacuum is created on secondary idle jet

port (10B) so fuel is drawn through that

port also. At a certain point, the throttle

disc is open far enough so the velocity of

air passing through the venturi is suffi-

cient to lower the pressure at main fuel

discharge port (15) so fuel will flow

through this port also. Opening the

throttle disc farther results in, higher air

velocities and lower venturi pressures

27

screen (28) and pump inlet valve (3A).

The fuel is then pumped through outlet

valve (3B) into supply channel (17).

Engine suction through main jet (15)

and idle jets (10) is transmitted to the

top of the carburetor diaphragm (25)

and atmospheric pressure through vent

(23) pushes upward on the diaphragm

(25) overcoming spring (20) pressure

and unseating inlet needle (18) allowing

fuel to flow into diaphragm chamber (6).

When starting an engine, closing

choke disc (16) increases the vacuum in

the carburetor throat so the carburetor

will function at the low cranking rpm.

When the engine is idling, the throttle

disc is almost completely closed and

Fig. CS7—Exploded view of

Dell'Orto Model FTR-16-12

carburetor.

1. Cover

2. Metering diaphragm

3. Gasket

4. Metering block

5. Low speed mixture

screw

6. High speed mixture

screw

7. Gasket

8. Screen

9. High speed valve

10. Body

11. Diaphragm lever

12. Pin

13. Spring

14. Fuel inlet valve

15. Throttle plate

16. Throttle shaft

17. Bushing

18. Return spring

19. Bushing

20. Retainer

21. Fuel inlet fitting

22. Screen

23. Fuel pump diaphragm &

check valves

24. Idle speed screw

25. Gasket

26. Fuel pump cover

27. Plate

1. Fuel inlet

2. Pump body

3. Pump diaphragm

3A & B. Pump valves

4. Gasket

5. Gasket

6. Metering chamber

7. Idle needle

8. Impulse channel

9. Idle fuel orifice

10. Idle ports

11. Throttle shutter

12. Main fuel orifice

13. Body

14. Venturi

15. Main fuel port

16. Choke shutter

17. Inlet channel

18. Inlet valve

19. Main needle

20. Spring

21. Diaphragm lever

22. Fulcrum pin

23. Vent hole

24. Cover

25. Diaphragm

26. Atmospheric

chamber

27. Gasket

28. Screen

29. Screw

30. Fuel chamber

31. Pulse chamber

32. Strainer cover

Fig. CS9—Cross-sectional schematic view of Tillotson Series HL diaphragm carburetor. Some

models of this type carburetor are equipped with an accelerator pump.

_^r\ ^*c

^ \ V 14

15

CARBURETOR SERVICE

1 2 3

F/'g. CS10-Exploded view of Tillotson Model

HC carburetor. Model HJ is similar.

1. Throttle plate

2. Lever pin

3. Body

4. Return spring

5. Throttle shaft

6. Choke shaft

7. Choke plate

8. Idle mixture screw

9. High speed mixture

screw

10. Choke friction pin

11. Fuel inlet valve assy.

12. Spring

13. Diaphragm lever

14. Idle speed screw

15. Gasket

16. Metering diaphragm

17. Cover

Fig. CS11 - Exploded view of Tillotson Model HL

carburetor. On some HL carburetors, pump dia-

phragm (19) and valves (20) are one-piece. Gover-

nor valve (25) is not used on all carburetors.

1. Throttle plate 13. Idle speed screw

2. Lever pin 14. Choke plate

3. Body 15. Gasket

4. Throttle return 16. Metering diaphragm

spring 17. Diaphragm cover

5. Idle mixture screw 18. Gasket

6. Drain plug 19. Fuel pump diaphragm

7. High speed mixture 20. Fuel pump valves

screw 21. Pump body

8. Choke detent 22. Screen

9. Gasket 23. Gasket

10. Fuel inlet valve assy. 24. Fuel inlet

11. Spring 25. Governor valve

12. Diaphragm lever 26. Diaphragm lever pin

that increase;! the flow of fuel out of the

discharge

Any vacuuih created at idle discharge

ports (10) on main fuel discharge port

(15) is transferred through metering

chamber (6) to diaphragm (25). Air

pressure entering through atmospheric

vent hole (fe) pushes against the

diaphragm because of the vacuum and

overcomes pnessure applied by spring

(20) through control lever (21). This

releases inlel needle valve (18) and

allows fuel to enter the metering

chamber in a direct relationship to the

vacuum creaned at the fuel discharge

ports. The Higher the vacuum, the

greater the movement of the diaphragm

and the largen the opening of the needle

valve. Thus, reel is metered into the car-

buretor to meet the needs of the engine.

Some HL carburetors are equipped

with governd| valve (25-Fig. CS11)

which enricheis the fuel mixture at the

governed speld and prevents engine

overspeeding. Original governor assem-

bly is tuned for each engine and cannot

be renewed. M disc may be installed in

place of governor assembly.

OVERHAU)

carburetor is

buretor, overt

Model HL will

Models HC an]

carburetor wit|

pump. Refer td

Since the Model HL

ie most widely used car-

[aul procedures for the

be covered. Overhaul of

HJ is similar to the HL

the exception of the fuel

Figs. CS10 and CS11.

DISASSEMBLY. Clean carburetor

and inspect for signs of external

damage. Remove idle speed screw and

inspect screw, [washer and spring. In-

spect threads in carburetor body for

damage and repair with a Heli-Coil in-

sert, if necessaf

Remove the ffter cover, cover gasket,

and filter screen. Clean filter screen by

flushing with sdlvent and dry with com-

pressed air. The cover gasket should be

renewed whenever filter screen is serv-

iced. Clean all ||dirt from plastic cover

before assembly

Remove the llsix body screws, fuel

pump cover casting, fuel pump dia-

phragm and gaiket. Diaphragm should

be flat and free from holes. The gasket

\.

ill 1111

Fig. CS12—Diaphragm lever should be flush

with diaphragm chamber floor.

CHAIN SAW

should be renewed if there are holes or

creases in the sealing surface.

Remove the diaphragm cover casting,

metering diaphragm and diaphragm

gasket. Inspect the diaphragm for holes,

tears and other imperfections.

Remove the fulcrum pin, inlet control

lever and inlet tension spring. Care must

be used while removing parts due to

spring pressure on inlet control lever.

The spring must be handled carefully to

prevent stretching or compressing. Any

alteration to the spring will cause im-

proper carburetor operation. If in doubt

as to its condition, renew it.

Remove inlet needle. Remove inlet

seat assembly using a 5/16 inch thin wall

socket. Remove the inlet seat gasket.

Inlet needles and seats are in matched

sets and should not be interchanged.

Needle and seat assembly must be clean

for proper performance. Use a new

gasket when installing the insert cage.

Do not force cage as threads may be

stripped or the cage distorted. Use a tor-

que wrench and tighten cage to 25-30

in.-lbs. (2.8-3.4 N-m).

Remove both high speed and idle mix-

ture screws and inspect points. Notice

the idle mixture screw point has the step

design to minimize point and casting

damage. The mixture screws may be

damaged from being forced into the

casting seat or possibly broken off in the

casting. They may be bent. If damage is

present be sure to inspect condition of

casting. If adjustment seats are dam-

aged, a new body casting is required.

ASSEMBLY. Install the main nozzle

ball check valve if this part was found to

be defective. Do not overtighten as dis-

tortion will result. Install new Welch

plugs if they were removed. Place the

new Welch plugs into the casting

counterbore with convex side up and

flatten it to a tight fit using a 5/16 inch

flat end punch. If the installed Welch

plug is concave, it may be loose and

cause an uncontrolled fuel leak. The cor-

rectly installed Welch plug is flat.

Install inlet seat and tighten to 25-30

in.-lbs. (2.8-3.4 N-m). Install inlet needle.

Install inlet tension spring, inlet control

lever, fulcrum pin and fulcrum pin retain-

ing screw. The inlet control lever must

rotate freely on the fulcrum pin. Adjust

inlet control lever so the center of the

lever that contacts the metering dia-

phragm is flush to the metering chamber

floor as shown in Fig. CS12.

Place metering diaphragm gasket on

the body casting. Install metering dia-

phragm next to gasket. Reinstall dia-

phragm cover casting over metering dia-

phragm and gasket. Install pump gasket

on diaphragm cover first, then the fuel

pump diaphragm should be assembled

next to the gasket and the flap valve

16

SERVICE MANUAL CARBURETOR SERVICE

member next to the fuel pump dia-

phragm so that the flap valves will seat

against the fuel pump cover. Reinstall

fuel pump cover and attach with six

body screws. The above parts must be

assembled in the proper order or the

carburetor will not function properly.

Install filter screen on fuel pump

cover. Install gasket on filter screen and

replace filter cover over filter screen

and gasket and attach with center

screw.

Install high speed and idle mixture

screws in their respective holes being

careful not to damage points.

Welch plugs seal the idle bypass ports

and main nozzle ball check valve from

the metering chamber. Removal of these

plugs is seldom necessary because of

lack of wear in these sections and any

dirt that may accumulate can usually be

blown out with compressed air through

the mixture screw holes. If removal of

the Welch plugs is necessary, drill

through the Welch plug using a V8-inch

drill bit. Allow the drill bit to just break

through the Welch plug. If the drill bit

travels too deep into the cavity, the cast-

ing may be ruined. Pry the Welch plug

out of its seat using a small punch.

Inspect the idle bypass holes to ensure

they are not plugged. Do not push drill

bits or wires into the metering holes.

This may damage the flow characteris-

tics of the holes and upset carburetor

performance. Blow out plugged holes

with compressed air. Remove main noz-

zle ball check assembly with a screw-

driver of correct blade width. If ball

check is defective, engine idling will be

hampered unless high speed mixture

screw is shut off or there will be poor

high speed performance with high

speed mixture screw adjusted at 1V4

turns open. Replace the ball check if de-

fective.

Removing choke and throttle plates

before cleaning the body is not neces-

sary if there is no evidence of wear. In-

dication of wear will require the removal

of plates to check the casting. To remove

the plates, first mark the position of the

plates on their respective shafts to

assure correct reassembly. The plates

are tapered for exact fit in the carbure-

tor bore. Remove two screws and pull

the plate out of the carburetor body.

Remove the throttle shaft clip and pull

the shaft out of the casting. Examine

both the shaft and body bearing areas

for wear. Should either part show wear

then either the shaft or the body or both

will have to be renewed. Remove the

choke shaft from the body carefully so

the friction ball and spring will not fly

out of the casting. Inspect the shaft and

bushings for wear.

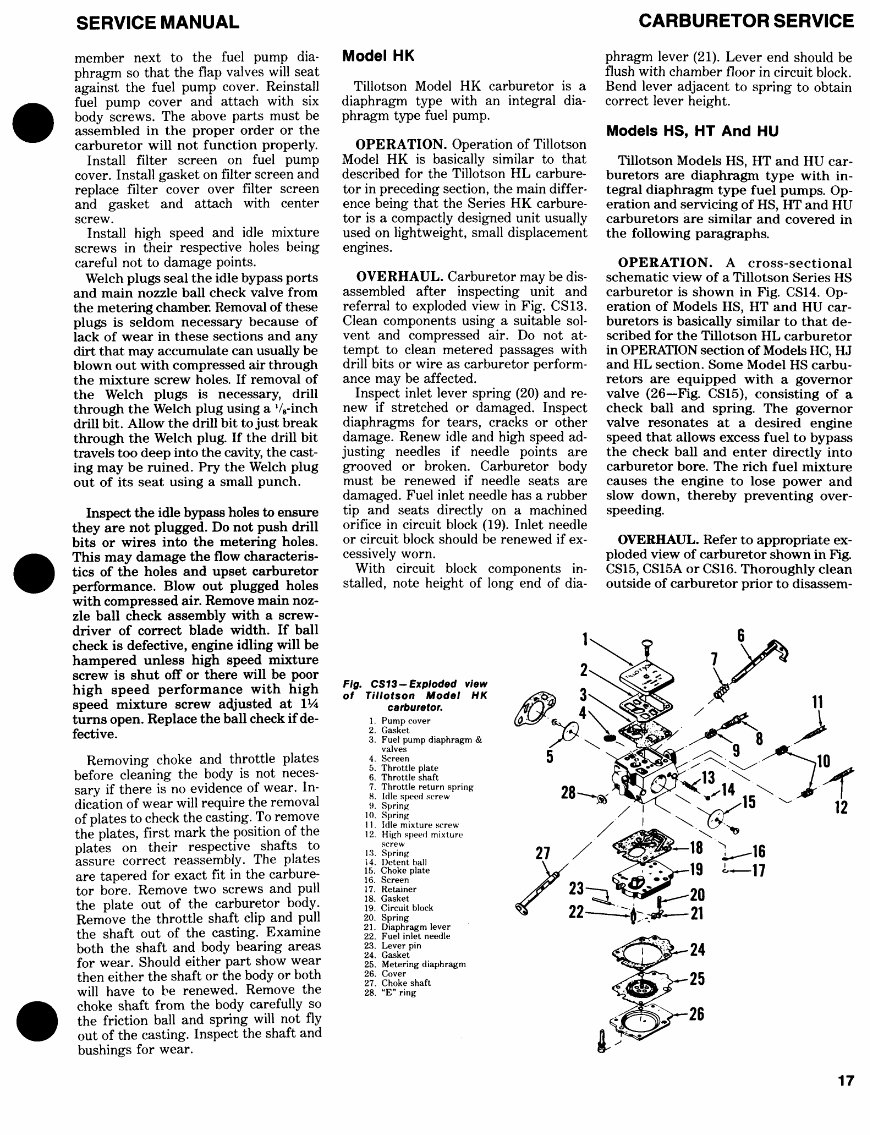

Model HK

Tillotson Model HK carburetor is a

diaphragm type with an integral dia-

phragm type fuel pump.

OPERATION. Operation of Tillotson

Model HK is basically similar to that

described for the Tillotson HL carbure-

tor in preceding section, the main differ-

ence being that the Series HK carbure-

tor is a compactly designed unit usually

used on lightweight, small displacement

engines.

OVERHAUL. Carburetor may be dis-

assembled after inspecting unit and

referral to exploded view in Fig. CS13.

Clean components using a suitable sol-

vent and compressed air. Do not at-

tempt to clean metered passages with

drill bits or wire as carburetor perform-

ance may be affected.

Inspect inlet lever spring (20) and re-

new if stretched or damaged. Inspect

diaphragms for tears, cracks or other

damage. Renew idle and high speed ad-

justing needles if needle points are

grooved or broken. Carburetor body

must be renewed if needle seats are

damaged. Fuel inlet needle has a rubber

tip and seats directly on a machined

orifice in circuit block (19). Inlet needle

or circuit block should be renewed if ex-

cessively worn.

With circuit block components in-

stalled, note height of long end of dia-

phragm lever (21). Lever end should be

flush with chamber floor in circuit block.

Bend lever adjacent to spring to obtain

correct lever height.

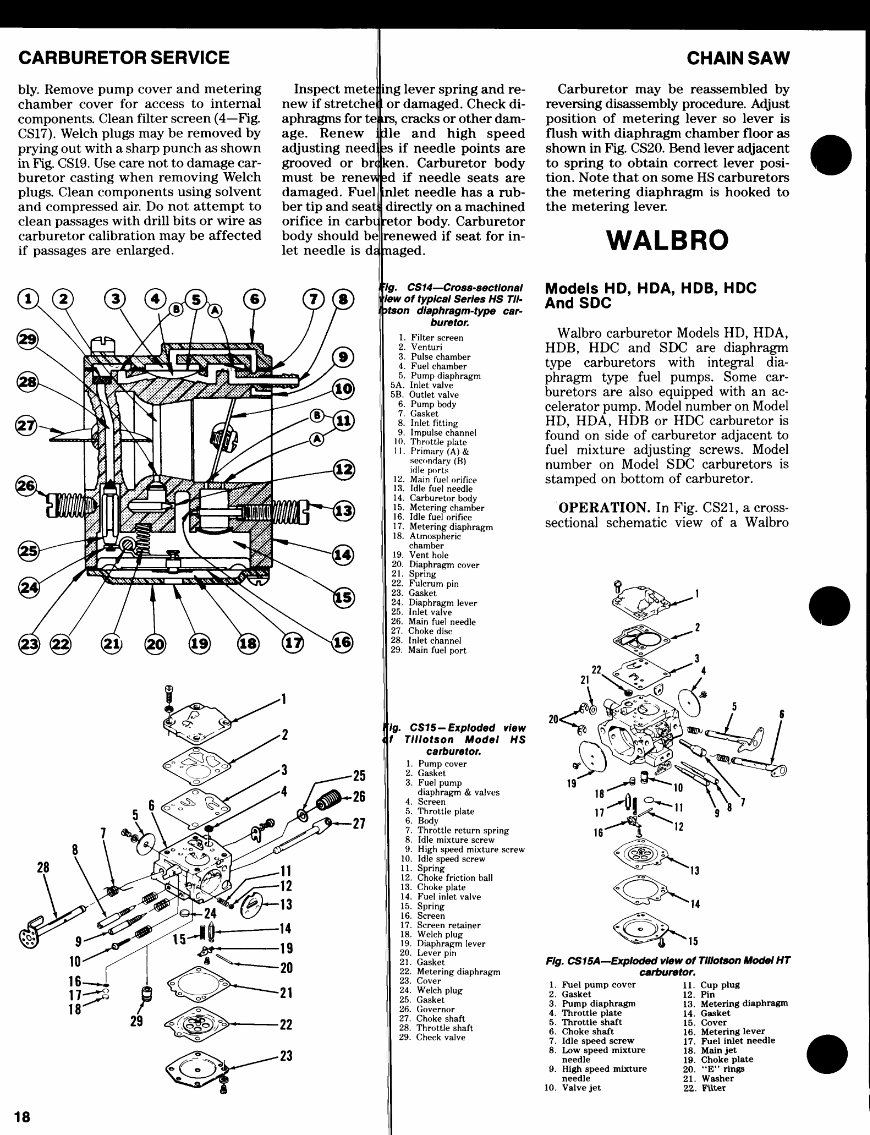

Models HS, HT And HU

Tillotson Models HS, HT and HU car-

buretors are diaphragm type with in-

tegral diaphragm type fuel pumps. Op-

eration and servicing of HS, HT and HU

carburetors are similar and covered in

the following paragraphs.

OPERATION. A cross-sectional

schematic view of a Tillotson Series HS

carburetor is shown in Fig. CS14. Op-

eration of Models HS, HT and HU car-

buretors is basically similar to that de-

scribed for the Tillotson HL carburetor

in OPERATION section of Models HC, HJ

and HL section. Some Model HS carbu-

retors are equipped with a governor

valve (26—Fig. CS15), consisting of a

check ball and spring. The governor

valve resonates at a desired engine

speed that allows excess fuel to bypass

the check ball and enter directly into

carburetor bore. The rich fuel mixture

causes the engine to lose power and

slow down, thereby preventing over-

speeding.

OVERHAUL. Refer to appropriate ex-

ploded view of carburetor shown in Fig.

CS15, CS15A or CS16. Thoroughly clean

outside of carburetor prior to disassem-

Fig. CS13-Exploded view

of Tillotson Model HK

carburetor.

1. Pump cover

2. Gasket

3. Fuel pump diaphragm &

valves

4. Screen

5. Throttle plate

6. Throttle shaft

7. Throttle return spring

8. Idle speed screw

9. Spring

10. Spring

11. Idle mixture screw

12. High speed mixture

screw

13. Spring

14. Detent hall

15. Choke plate

16. Screen

17. Retainer

18. Gasket

19. Circuit block

20. Spring

21. Diaphragm lever

22. Fuel inlet needle

23. Lever pin

24. Gasket

25. Metering diaphragm

26. Cover

27. Choke shaft

28. "E" ring

17

CARBURETOR SERVICE CHAIN SAW

bly. Remove pump cover and metering Inspect mete]

chamber cover for access to internal new if stretchel

components. Clean filter screen (4—Fig. aphragms for t(

CS17). Welch plugs may be removed by age. Renew

prying out with a sharp punch as shown adjusting need]

in Fig. CS19. Use care not to damage car- grooved or bn

buretor casting when removing Welch must be rene^

plugs. Clean components using solvent damaged. Fuel

and compressed air. Do not attempt to ber tip and seat!)

clean passages with drill bits or wire as orifice in carbi

carburetor calibration may be affected body should b<

if passages are enlarged. let needle is d;

ing lever spring and re-

or damaged. Check di-

cracks or other dam-

le and high speed

s if needle points are

en. Carburetor body

d if needle seats are

nlet needle has a rub-

directly on a machined

tor body. Carburetor

renewed if seat for in-

aged.

Carburetor may be reassembled by

reversing disassembly procedure. Adjust

position of metering lever so lever is

flush with diaphragm chamber floor as

shown in Fig. CS20. Bend lever adjacent

to spring to obtain correct lever posi-

tion. Note that on some HS carburetors

the metering diaphragm is hooked to

the metering lever.

WALBRO

28

fig. CS14—Cross-sectional

\lew of typical Series HS Til-

jtson diaphragm-type car-

buretor.

1. Filter screen

2. Venturi

3. Pulse chamber

4. Fuel chamber

5. Pump diaphragm

5A. Inlet valve

5B. Outlet valve

6. Pump body

7. Gasket

8. Inlet fitting

9. Impulse channel

10. Throttle plate

11. Primary (A) &

secondary (B)

idle ports

12. Main fuel orifice

13. Idle fuel needle

14. Carburetor body

15. Metering chamber

16. Idle fuel orifice

17. Metering diaphragm

18. Atmospheric

chamber

19. Vent hole

20. Diaphragm cover

21. Spring

22. Fulcrum pin

23. Gasket

24. Diaphragm lever

25. Inlet valve

26. Main fuel needle

27. Choke disc

28. Inlet channel

29. Main fuel port

\ig. CS15-Exploded view

\t Tillotson Model HS

carburetor.

1. Pump cover

2. Gasket

3. Fuel pump

diaphragm & valves

4. Screen

5. Throttle plate

6. Body

7. Throttle return spring

8. Idle mixture screw

9. High speed mixture screw

10. Idle speed screw

11. Spring

12. Choke friction ball

13. Choke plate

14. Fuel inlet valve

15. Spring

16. Screen

17. Screen retainer

18. Welch plug

19. Diaphragm lever

20. Lever pin

21. Gasket

22. Metering diaphragm

23. Cover

24. Welch plug

25. Gasket

26. Governor

27. Choke shaft

28. Throttle shaft

29. Check valve

Models HD, HDA, HDB, HOC

And SDC

Walbro carburetor Models HD, HDA,

HDB, HOC and SDC are diaphragm

type carburetors with integral dia-

phragm type fuel pumps. Some car-

buretors are also equipped with an ac-

celerator pump. Model number on Model

HD, HDA, HDB or HOC carburetor is

found on side of carburetor adjacent to

fuel mixture adjusting screws. Model

number on Model SDC carburetors is

stamped on bottom of carburetor.

OPERATION. In Fig. CS21, a cross-

sectional schematic view of a Walbro

15

Fig. CS15A—Exploded view of Tillotson Model HT

carburetor.

1. Fuel pump cover

2. Gasket

3. Pump diaphragm

4. Throttle plate

5. Throttle shaft

6. Choke shaft

7. Idle speed screw

8. Low speed mixture

needle

9. High speed mixture

needle

10. Valve jet

11. Cup plug

12. Pin

13. Metering diaphragm

14. Gasket

15. Cover

16. Metering lever

17. Fuel inlet needle

18. Main jet

19. Choke plate

20. "E" rings

21. Washer

22. Filter

18

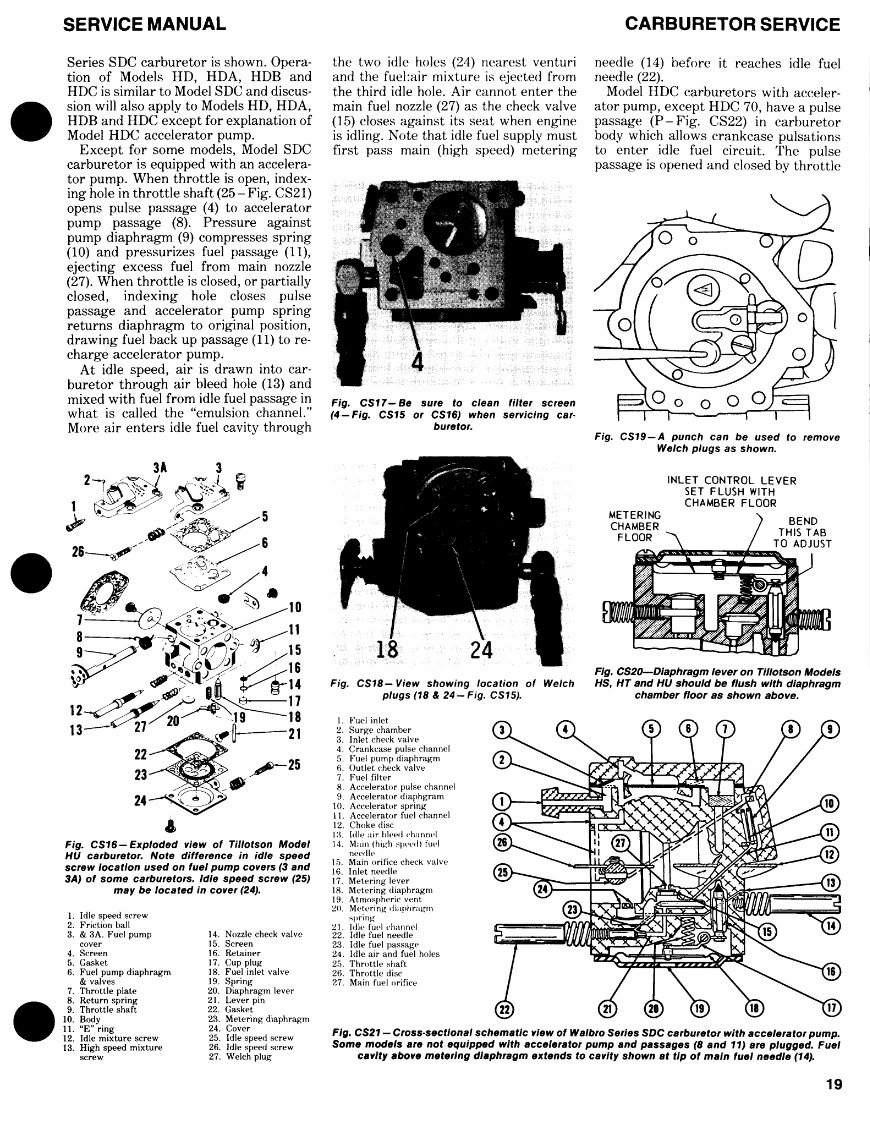

SERVICE MANUAL CARBURETOR SERVICE

Series SDC carburetor is shown. Opera-

tion of Models HD, HDA, HDB and

HDC is similar to Model SDC and discus-

sion will also apply to Models HD, HDA,

HDB and HDC except for explanation of

Model HDC accelerator pump.

Except for some models, Model SDC

carburetor is equipped with an accelera-

tor pump. When throttle is open, index-

ing hole in throttle shaft (25-Fig. CS21)

opens pulse passage (4) to accelerator

pump passage (8). Pressure against

pump diaphragm (9) compresses spring

(10) and pressurizes fuel passage (11),

ejecting excess fuel from main nozzle

(27). When throttle is closed, or partially

closed, indexing hole closes pulse

passage and accelerator pump spring

returns diaphragm to original position,

drawing fuel back up passage (11) to re-

charge accelerator pump.

At idle speed, air is drawn into car-

buretor through air bleed hole (13) and

mixed with fuel from idle fuel passage in

what is called the "emulsion channel."

More air enters idle fuel cavity through

Fig. CS16—Exploded view of Tillotson Model

HU carburetor. Note difference in idle speed

screw location used on fuel pump covers (3 and

3A) of some carburetors. Idle speed screw (25)

may be located in cover (24).

1. Idle speed screw

2. Friction ball

3. & 3A. Fuel pump

cover

4. Screen

5. Gasket

6. Fuel pump diaphragm

& valves

7. Throttle plate

8. Return spring

9. Throttle shaft

10. Body

11. "E" ring

12. Idle mixture screw

13. High speed mixture

screw

14. Nozzle check valve

15. Screen

16. Retainer

17. Cup plug

18. Fuel inlet valve

19. Spring

20. Diaphragm lever

21. Lever pin

22. Gasket

23. Metering diaphragm

24. Cover

25. Idle speed screw

26. Idle speed screw

27. Welch plug

the two idle holes (24) nearest venturi

and the fuehair mixture is ejected from

the third idle hole. Air cannot enter the

main fuel nozzle (27) as the check valve

(15) closes against its seat when engine

is idling. Note that idle fuel supply must

first pass main (high speed) metering

needle (14) before it reaches idle fuel

needle (22).

Model HDC carburetors with acceler-

ator pump, except HDC 70, have a pulse

passage (P-Fig. CS22) in carburetor

body which allows crankcase pulsations

to enter idle fuel circuit. The pulse

passage is opened and closed by throttle

Fig. CS17—Be sure to clean filter screen

(4 —Fig. CS15 or CS16) when servicing car-

buretor.

Fig. CS19 —A punch can be used to remove

Welch plugs as shown.

INLET CONTROL LEVER

SET FLUSH WITH

CHAMBER FLOOR

METERING

CHAMBER

FLOOR

18

Fig. CS20—Diaphragm lever on Tillotson Models

HS, HT and HU should be flush with diaphragm

chamber floor as shown above.

Fig. CS18—View showing location of Welch

plugs (18 & 24-Fig. CS15).

1. Fuel inlet

2. Surge chamber

3. Inlet check valve

4. Crankcase pulse channel

5. Fuel pump diaphragm

6. Outlet check valve

7. Fuel filter

8. Accelerator pulse channel

9. Accelerator diaphgram

10. Accelerator spring

11. Accelerator fuel channel

12. Choke disc

13. Idle air bleed channel

14. Main (high speed) fuel

needle

15. Main orifice check valve

16. Inlet needle

17. Metering lever

18. Metering diaphragm

19. Atmospheric vent

20. Metering diaphragm

spring

21. Idle fuel channel

22. Idle fuel needle

23. Idle fuel passage

24. Idle air and fuel holes

25. Throttle shaft

26. Throttle disc

27. Main fuel orifice

Fig. CS21 —Cross-sectional schematic view of Walbro Series SDC carburetor with accelerator pump.

Some models are not equipped with accelerator pump and passages (8 and 11) are plugged. Fuel

cavity above metering diaphragm extends to cavity shown at tip of main fuel needle (14).

19

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 26 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

JONSERED CHAINSAW REPAIR MANUAL

- JONSERED 111

- JONSERED 111 S

- JONSERED 361

- JONSERED 361 AV

- JONSERED 365

- JONSERED 370

- JONSERED 451E

- JONSERED 451EV

- JONSERED 455

- JONSERED 49SP

- JONSERED 50

- JONSERED 51

- JONSERED 510 SP

- JONSERED 520 SP

- JONSERED 521 EV

- JONSERED 52E

- JONSERED 535

- JONSERED 60

- JONSERED 601

- JONSERED 62

- JONSERED 621

- JONSERED 625

- JONSERED 625 II

- JONSERED 630

- JONSERED 630 SUPER

- JONSERED 670

- JONSERED 670 CHAMP

- JONSERED 670 SUPER

- JONSERED 670 SUPER II

- JONSERED 70E

- JONSERED 75

- JONSERED 751

- JONSERED 801

- JONSERED 820

- JONSERED 830

- JONSERED 830 DLX

- JONSERED 9

- JONSERED 910 D

- JONSERED 910 E

- JONSERED 910 EV

- JONSERED 920

FACTORY REPAIR MANUAL

COVERS ALL ASPECTS OF YOUR CHAINSAW.

- ENGINE REPAIR

- CARB REPAIR

- CHANGE BLADE

- SHARPEN BLADE

- MORE

PAY WITH OUR SECURE SERVER USING YOUR CREDIT CARD OR PAYPAL.