Husqvarna 455 Rancher Chainsaw parts manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Workshop manual

English

455 Rancher 460

2 – English

Workshop manual

Husqvarna 455 Rancher and 460

Contents

Introduction ........................................................... 3

Safety regulations ................................................ 4

General instructions ........................................... 4

Special instructions ............................................ 4

Special tools ......................................................... 5

Technical data ....................................................... 7

Carburettor ............................................................ 9

Carburettor ........................................................ 9

Carburettor - pressure testing .......................... 14

Carburettor - adjustment .................................. 15

Troubleshooting ................................................. 17

Repair instructions ............................................. 19

Chain brake ...................................................... 19

Silencer ............................................................ 21

Chain catcher ................................................... 21

Stop switch ....................................................... 22

Stop switch – resistance measurement............ 22

Choke control ................................................... 23

Throttle trigger .................................................. 24

Starter assembly .............................................. 25

Starter cord....................................................... 25

Recoil spring..................................................... 26

Ignition module – testing .................................. 27

Ignition module and flywheel ............................ 27

Centrifugal clutch.............................................. 29

Oil pump ........................................................... 30

Air intake system ............................................. 32

Fuel filter........................................................... 33

Fuel hose.......................................................... 33

Fuel tank........................................................... 34

Piston and cylinder ........................................... 34

Decompression valve – pressure testing ......... 35

Cylinder – pressure testing............................... 37

Crankshaft complete ........................................ 37

Crankshaft bearings ......................................... 38

Thread insert .................................................... 39

Guide bar bolts ................................................. 39

English – 3

Arrangement of the manual

This workshop manual can be used in two different

ways.

• To repair a specific sub-assembly on a chainsaw.

• To dismantle and reassemble a complete chain-

saw.

Repairing a specific sub-assembly

If a specific sub-assembly on the chainsaw needs

to be repaired:

1. Look up the page referring to the relevant sub-

assembly.

2. Follow the instructions under the headings:

• Removal/Dismantling

• Cleaning and inspection

• Refitting/Reassembly

Dismantling and reassembling the entire chainsaw

If the entire chainsaw is to be dismantled, follow

the instructions under the heading “Removal/Dis-

mantling”.

Work through the manual and follow the instruc-

tions given in each section under the heading

“Removal/Dismantling”.

Then follow all the “Cleaning and inspection” ins-

tructions in each section.

Working from the back of the manual, follow all the

instructions under the headings “Refitting/Reas-

sembly” in reverse order.

Each of the sections covering removal/dismantling

and refitting/reassembly include the relevant lubri-

cation instructions and bolt torques for each stage

of repair.

Construction and function

This chapter gives a simple description of the

chainsaw carburettor and its various parts.

Introduction

Troubleshooting

These pages describe the most common faults that

affect a chainsaw. They are divided into four dif-

ferent groups with the most likely faults described

first.

Repair instructions

The section that describes how to repair the chain-

saw consists of detailed, step-by-step instructions.

It explains in detail the special tools, lubricants

and bolt torques that are needed when working on

each component.

This workshop manual covers the following

chainsaw models: 455 Rancher

460

4 – English

General instructions

This workshop manual gives detailed instructions

on how to troubleshoot, repair and test a chain-

saw. This section also describes the various safety

precautions that should be taken when carrying out

repairs.

The workshop manual has been written for person-

nel who are assumed to have general experience

of repairing and servicing chainsaws.

Workshops where chainsaws are repaired must be

equipped with safety equipment that meets local

regulations.

No-one should carry out repairs on a chainsaw

until they have read and understood the contents

of this workshop manual.

Chainsaws are type-approved to meet the rele-

vant safety legislation, but this only applies when

the saw is fitted with the cutting equipment speci-

fied in the user’s manual. The fitting of any other

equipment, or of accessories or parts that are not

approved by Jonsered, could mean that the saw

no longer meets these safety requirements and

the person who carried out the work may be held

responsible for its non-conformance.

In this workshop manual the following boxes indi-

cate where caution should be taken.

Special instructions

The fuel that is used in a chainsaw poses the fol-

lowing hazards:

• The fuel and its fumes are toxic.

• May cause irritation to skin or eyes.

• May cause breathing difficulties.

• Highly flammable.

When using compressed air the air jet should

never be pointed at the body. Air can be forced into

the bloodstream and cause fatal injury.

Wear ear protection when testing saws.

After testing a saw do not touch the silencer until

it has cooled down. The silencer gets very hot and

you may burn yourself. Wear protective gloves

when working on the silencer.

The guide bar, chain and clutch cover (chain

brake) must be fitted before the saw is started. If

not, the clutch may come loose and cause injury.

Poor chain lubrication can result in failure of the

chain, which could cause serious or fatal injury.

Take care to ensure that the spring inside the

starter assembly does not fly out and cause injury.

Wear eye protection. If the spring is under

compression when the pulley is removed it could

fly out and cause injury.

Before removing the tensioning spring from the

chain brake, ensure that the brake is in the on

position, otherwise the spring may fly out and

cause injury.

After completing the repair the chain brake must be

tested, see “Chain brake – reassembly \ Operating

test”.

Always consider the fire risk. A chainsaw can

produce sparks that could start a fire.

Inspect the chain catcher and replace it if it is

damaged.

WARNING!

The warning text warns of the risk

of personal injury if the instruc-

tions are not followed.

NOTE!

The warning text warns of the risk of ma-

terial damage if the instructions are not

followed.

Safety regulations

Safety regulations

English – 5

10

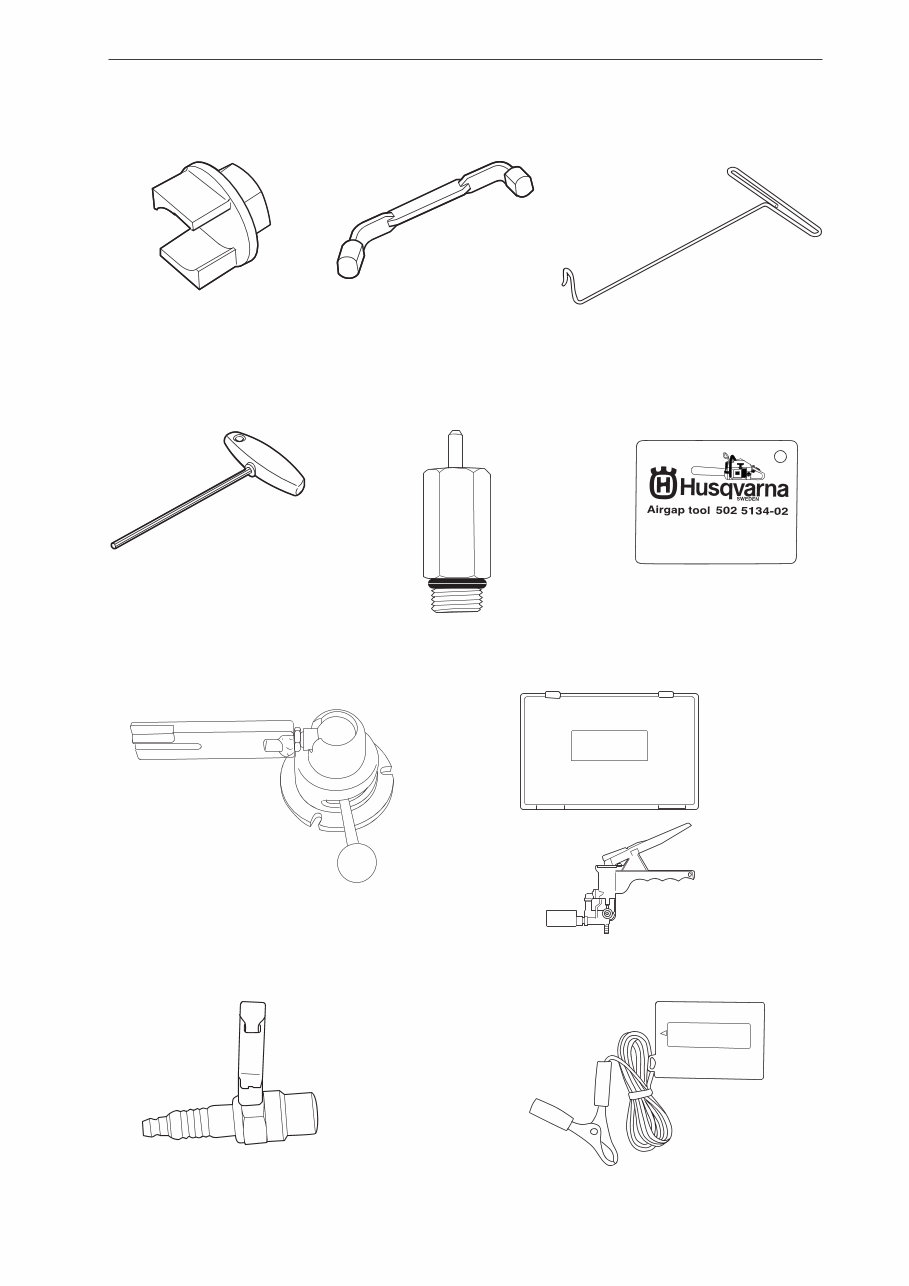

Special tools

4

5

8

1

2

3

6

7

9

Special tools

6 – English

Item Description Used for Order no.

1 Clutch tool Centrifugal clutch 502 54 16-01

2 Piston stop Locking the crankshaft 504 91 06-05

3 Fuel filter hook Withdrawing the fuel filter 502 50 83-01

4 Allen key For M5 bolts 502 50 18-01

5 Pressure tester Pressure testing cylinder 503 84 40-02

6 Feeler gauge Adjusting ignition module 502 51 34-02

7 Assembly fixture Assembling chain saw 502 51 02-01

8 Pressure gauge Pressurisation during testing 531 03 06-23

9 Test spark plug Checking the ignition module 502 71 13-01

10 Rev counter Adjusting carburettor 502 71 14-01

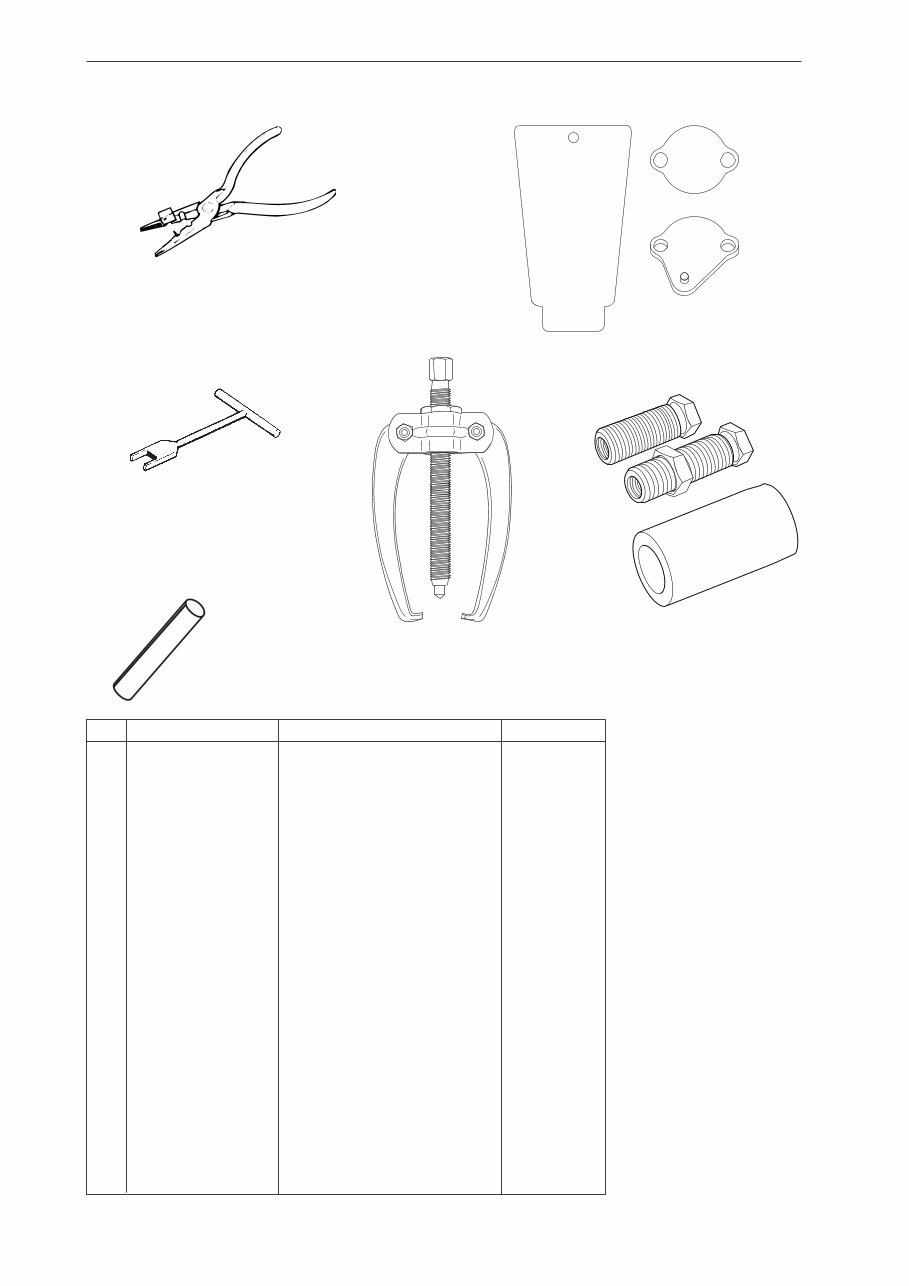

11 Assembly pliers Fitting spark plug guard 502 50 06-01

12a Cover plate, exhaust Sealing the exhaust port 502 54 11-02

12b Cover plates, inlet Sealing the intake manifold 502 52 48-02

13 Assembly tool Assembling spring, chain brake 502 50 67-01

14 Puller Pulling bearing of crankshaft 504 90 90-01

15a Sleeve Fitting crankshaft 502 50 30-18

15b Shaft extension Flywheel side 502 50 30-18

15c Shaft extension Cluch side 502 50 30-18

16 Punch Dismantling the flywheel 502 51 94-01

11

12a

13

14

12b

15a

15c

15b

16

Special tools

English – 7

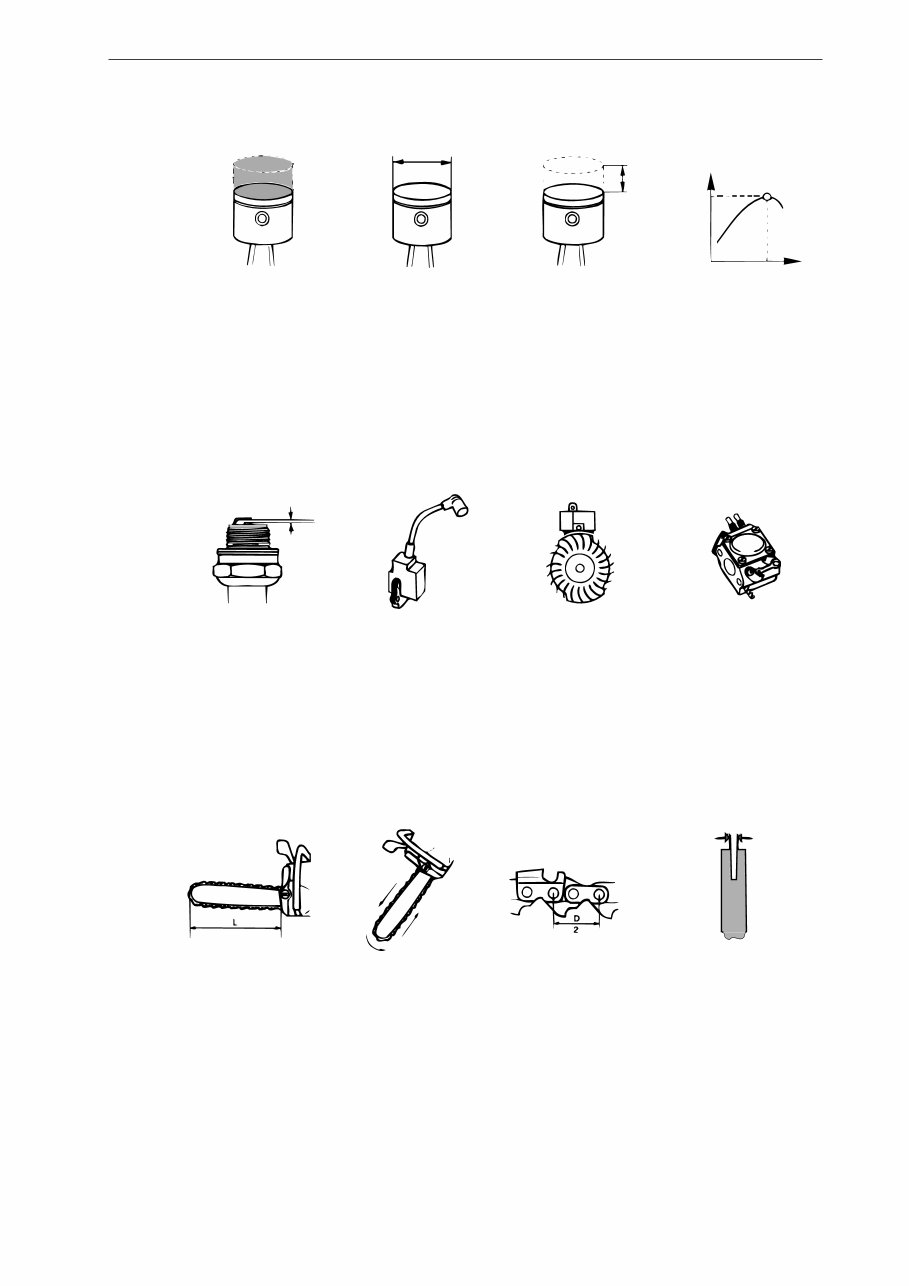

Displacement Cylinder bore Stroke Max power/speed

cm

3

/cubic inches Ø mm/Ø inches mm/inches kW/hp/rpm

455: 55,5 / 3,38 47 / 1,85 32 / 1,28 2,6 / 3,5 / 9 000

460: 60,3 / 3,68 49 / 1,93 32 / 1,28 2,7 / 3,7 / 9 000

Spark plug gap Ignition system Air gap Carburettor type

mm/inches mm/inches

455: 0,5 / 0,02 SEM CD 0,3 / 0,012 Walbro WTA 29

460: 0,5 / 0,02 SEM CD 0,3 / 0,012 Walbro WTA 29

Effective cutting length Chain speed at Chain pitch Drive link

cm/inches max power – revs mm/inches mm/inches

m/s – rpm

455: 31-50 / 13-20 20,0 / 9 000 9,52 / 3/8 1,3 / 0,050 - 1,5 / 0,058

460: 31-50 / 13-20 20,0 / 9 000 8,25 / 0,325 1,3 / 0,050 - 1,5 / 0,058

Technical data

Technical data

8 – English

Idling speed Engagement speed Spark plug

rpm rpm

455: 2 700 3 800 NGK BPMR 7A

Champion RCJ 7Y

460: 2 700 3 800 NGK BPMR 7A,

Champion RCJ 7Y

Fuel tank capacity Oil pump capacity at Oil tank capacity Automatic oil pump

Litres/US pints 8,500 rpm, Litres/US pints

ml/min

455: 0,44 / 0,93 9 0,32 / 0,68 Yes

460: 0,44 / 0,93 9 0,32 / 0,68 Yes

Weight without Weight with

bar and chain bar and chain

kg / lbs kg / lbs

455: 5,8 / 12,8 6,2 / 13,6

460: 5,8 / 12,8 6,2 / 13,6

rpm

GAS

OIL

Technical data

English – 9

Carburettor

WARNING!

The fuel used in the chainsaw has

the following hazardous properties:

1. The fluid and its fumes are

poisonous.

2. Can cause skin irritation.

3. Is highly inflammable.

Carburettor

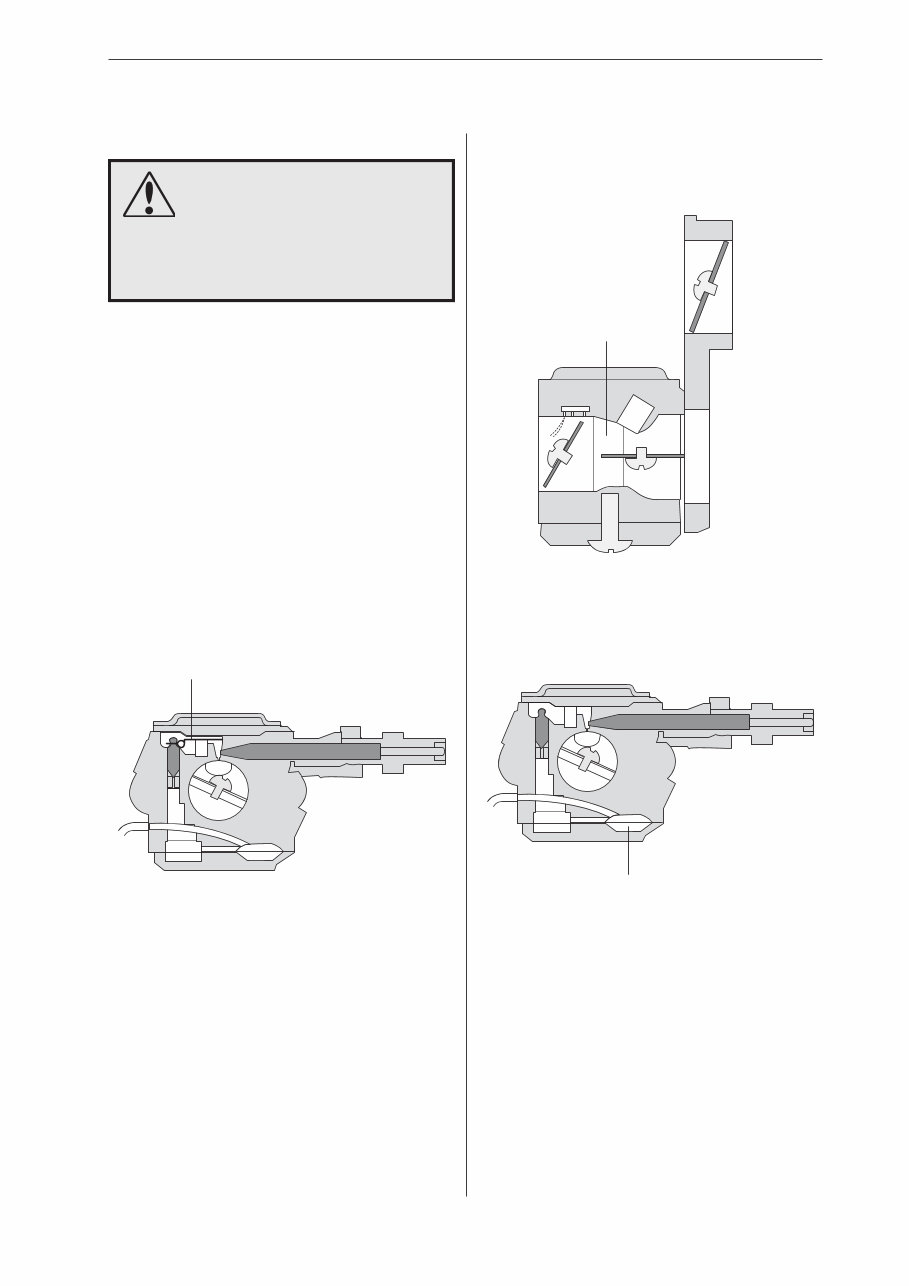

Description

The drawings accompanying this description do

not correspond with the carburettor on the chain-

saw. They only show the principle for the design

and function.

Design

The carburettor is based on three sub-systems:

• The metering unit, A.

• The mixing venturi, B.

• The pump unit, C.

The jets and the fuel’s control functions are located

in the metering unit (A). Here the correct quantity

of fuel is adjusted for the actual speed and power

output.

A

B

C

The mixing venturi (B) houses the choke, throttle

valve and diffuser jets. Here air is mixed with the

fuel to give a fuel/air mixture that can be ignited by

the ignition spark.

In the pump unit (C), fuel is pumped from the fuel

tank to the metering unit. One side of the pump di-

aphragm is connected to the crankcase and pulses

in time with the pressure changes in the crankcase.

The other side of the diaphragm pumps the fuel.

Carburettor

10 – English

Function

The carburettor operates differently in the following

modes:

• Cold start mode

• Idling mode

• Part throttle mode

• Full throttle mode

In the cold start mode (see figure below) the choke

valve (H) is fully closed. This increases the vacuum

in the carburettor so that fuel is sucked more easily

from all the diffuser jets (D, E and F). The throttle

valve (I) is partly open. Extra air inlet (J) is closed.

I

H

G

D

F

E

J

In the idling mode (see figure below) the throttle

valve (I and J) is closed and the choke valve (H) is

open.

Air is sucked in through an aperture in the throttle

valve and a small amount of fuel is supplied th-

rough the diffuser jet (D).

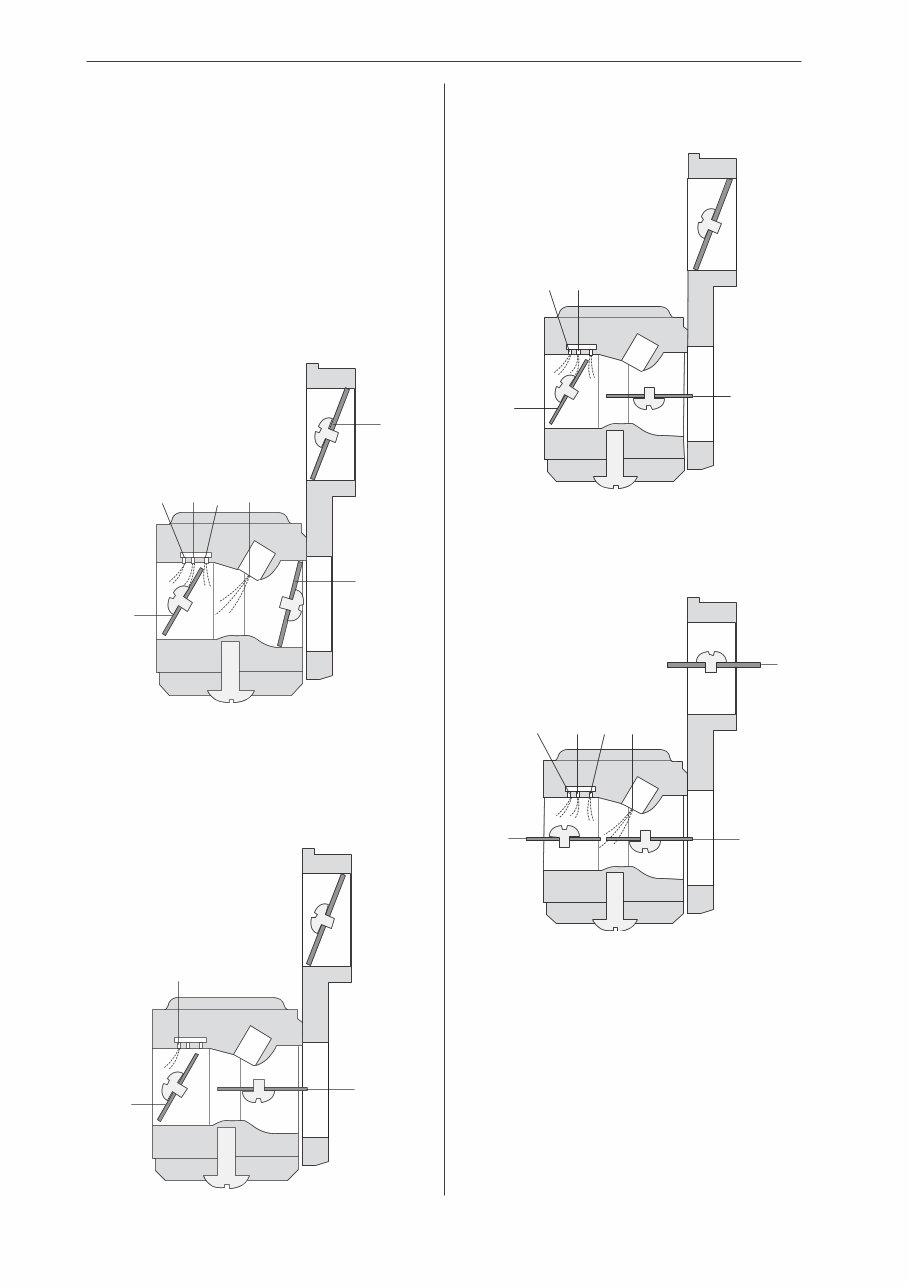

In the part throttle mode (see figure below) the th-

rottle valve (I) is partially open and the choke valve

(H) is open. Fuel is supplied through the diffuser

jets (D and E).

In full throttle mode (se figure below) all valves

are open and fuel is supplied through all diffuser

jets (D, E, F and G). Extra air inlet (J) is also fully

opened.

I

D

H

E

I

H

D

G D F

E

H

I

J

Carburettor

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 63 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Get the official Husqvarna parts manual for the 455 Chainsaw. This manual is fully indexed and available in PDF format. It provides detailed exploded views and part numbers, making it an essential resource for professional mechanics and DIY enthusiasts alike.