YANMAR INDUSTRIAL Diesel Engine TNE Series 4TNE82 4TNE84 4TNE88 3TNE84T 4TNE84T Full Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SERVISE MANU

INDUSTRIAL DIES

MODEL TNE s

FOREWORD

This Service Manual describes the procedure of maintenance and service of the Yanmar industrial

TNE series engine (Special swirl precombustion chamber (hereinafter "Indirect injection system")

and Direct injection systems}.

Before starting service and maintenance of TNE engine, you are requested to read this Service

Manual carefully to your full understanding and to take careful note that the standard TNE engine

may differ in the structure and applicable specification from that loaded on each of individual driven

machines (such as the generator, pump, compressor, and combine, etc.).

For further information, carefully read the Service Manual issued for each driven machine.

This Service Manual in subject to changes, with or without notice, with respect to the structure and

the content of maintenance for the purpose of improving engine quality.

Setup before work

To perform work efficiently, the following setup (preparation) is necessary.

1. Customer ledger check

(1) Previous date of service

(2) Check on which month (and at what time) the last service was performed, what

problem occurred, and what the history of the customer (engine) is.

2. Stock control of parts

(1) Stock check for consumable parts, periodic replacement parts, etc., that are

required for service.

(2) Provision of check list, parts list and parts card.

3. Provision of service record

(1) Work (process) time table

(2) Check sheet (including used parts list)

~)~.uffimentd~~p~1 . .

(4) Operation data and quality (for maintenance of performance and quality)

4. Disassembly and reassembly tools

(1) Tools

(2) Measuring devices

(3) Other instruments and equipment necessary for service

FM23056 JQA-0099

ISO 9001 Certified

This product has been developed, designed and produced in

accordance with the Standards for Quality System of ISO 9001

(International Organization for Standardization) under the

following authorized institutions: JMI (Japan Machinery and

Metals Inspection Institute), SSI (British Standards Institution)

Institution) and EQNET (The European Network tor Quality

System Assessment and Certification).

Certified under the following standards:

ISO 9001 - 19871 BS 5750: Part 1 : 19871

EN 29001 - 19871 JIS Z9901 -1991

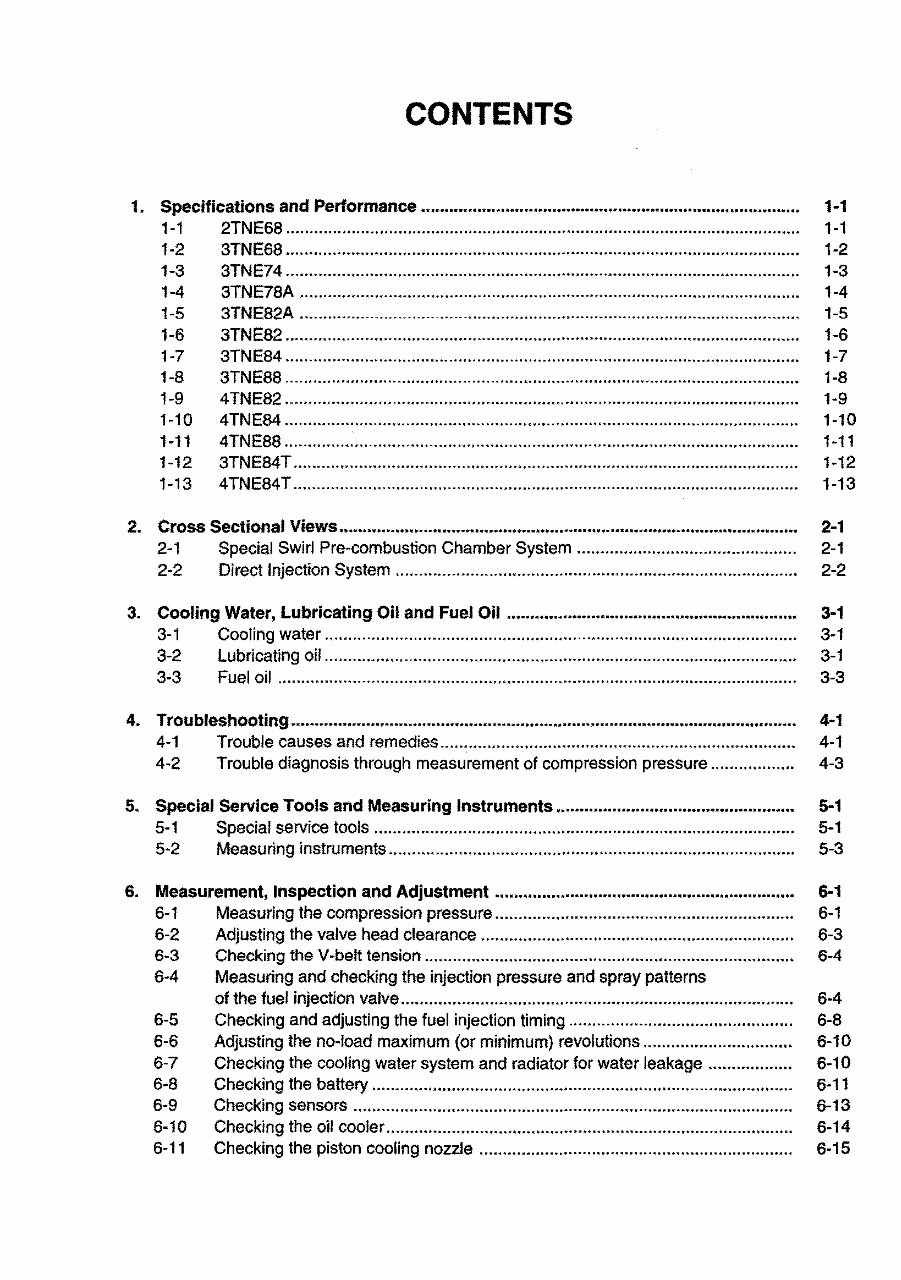

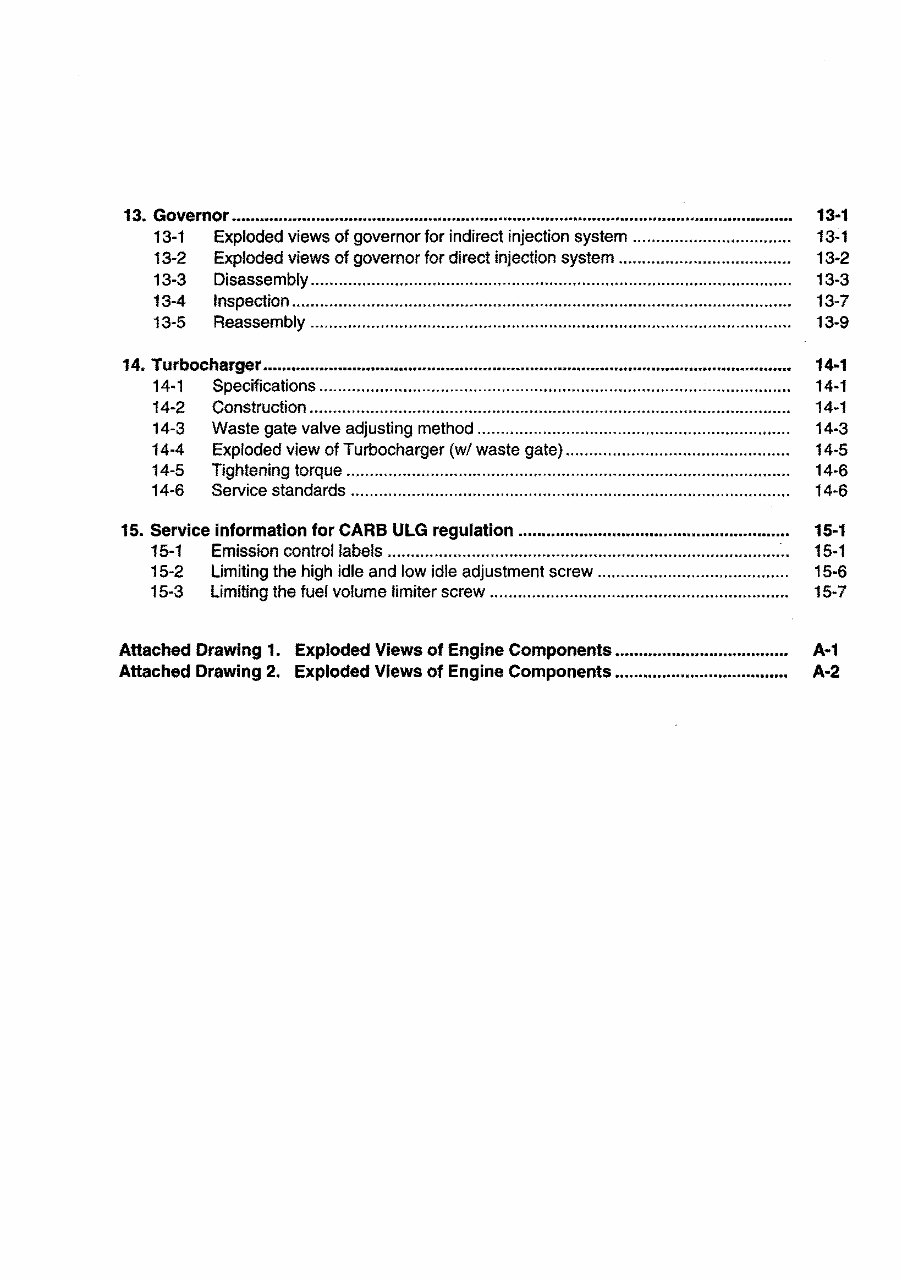

CONTENTS

1. Specifications and Performance •..• ................... •.•...•.• ..... •••• .... •••.•.• ........... • ....... •.•...•.•. 1-1

1-1 2TNE68.............................................................................................................. 1-1

1-2 3TNE68 .... .... ....................... ...................... ......................................................... 1-2

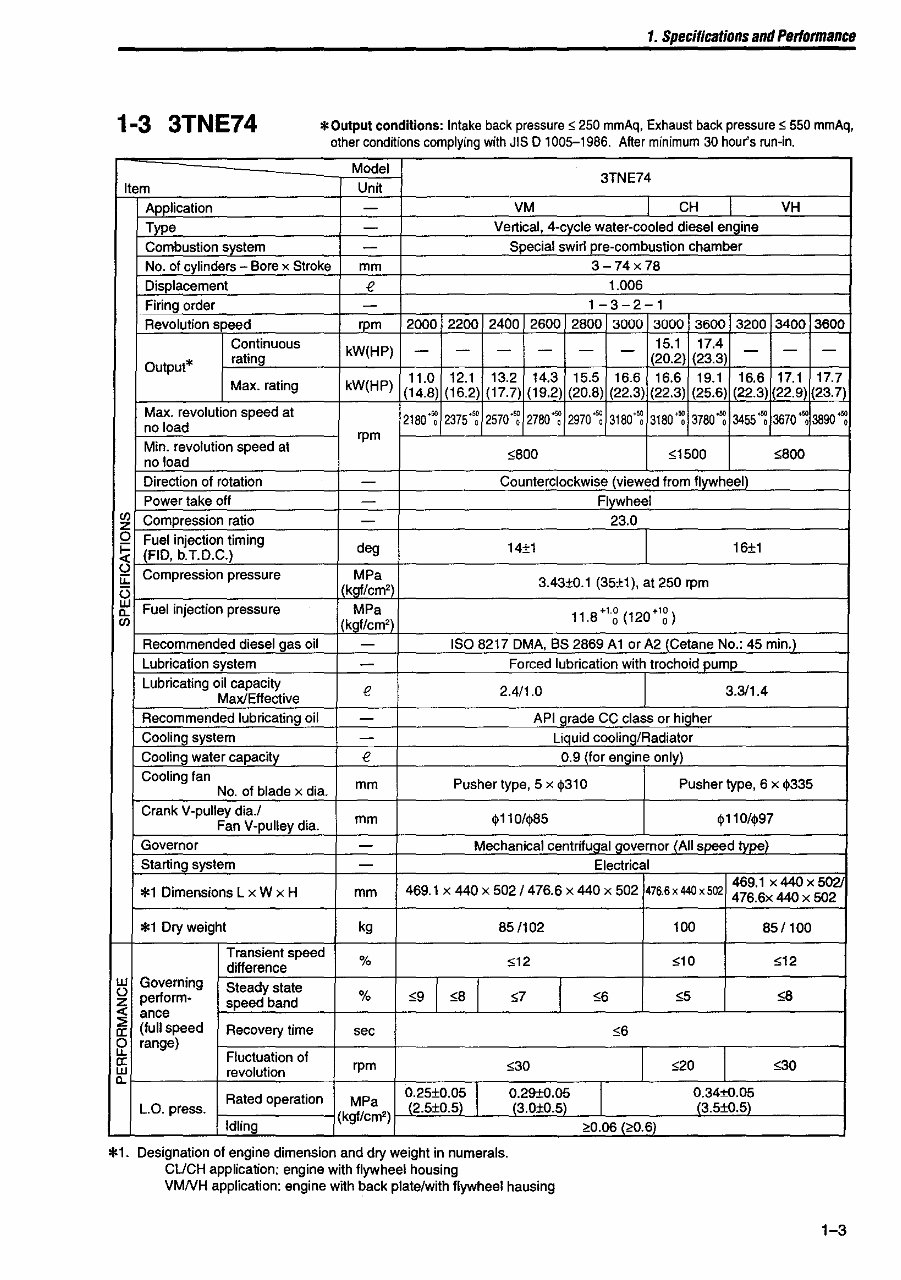

1-3 3TNE74 .............................................................................................................. 1-3

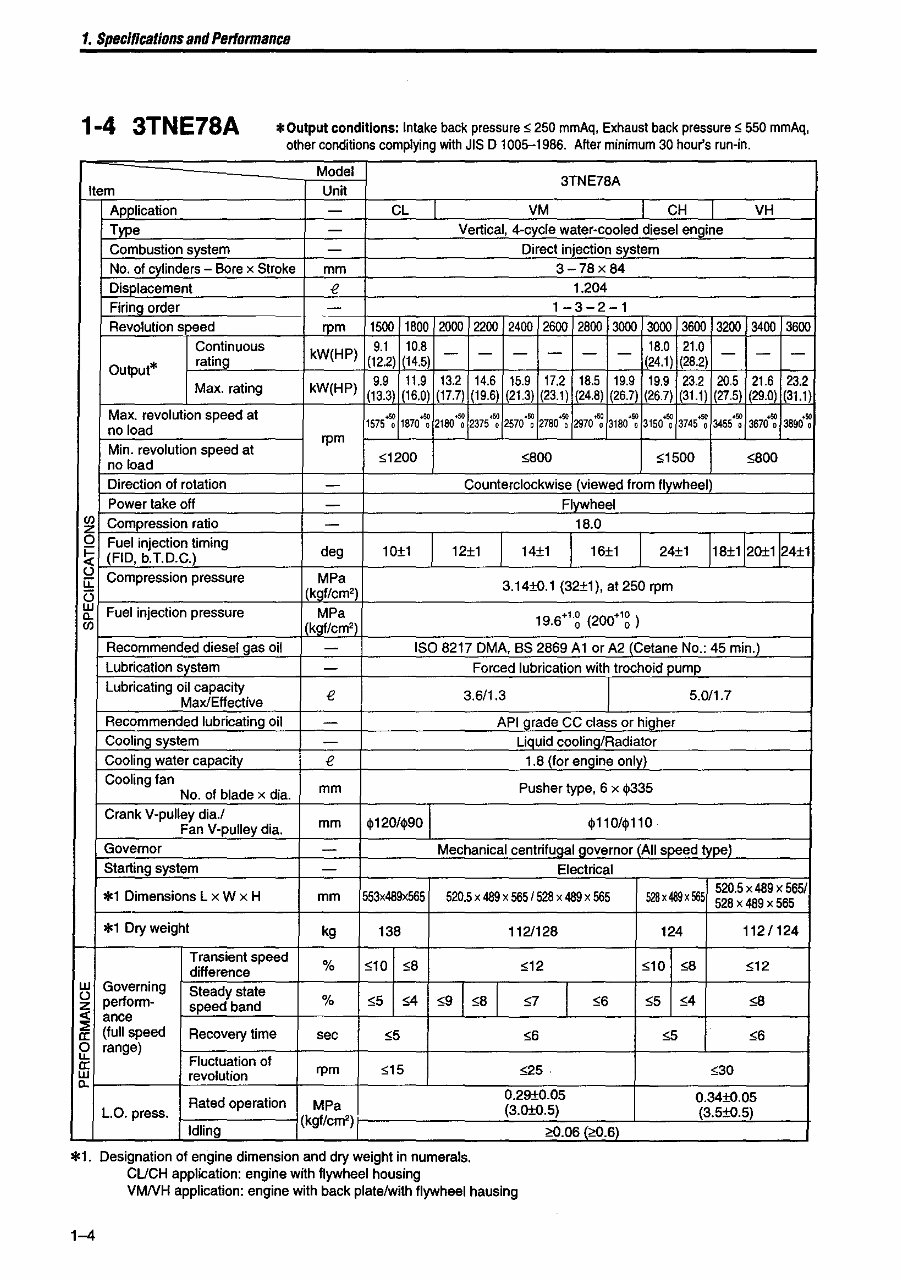

1-4 3TNE78A .. ................................. ........ ............ .......................... ........ .......... ........ 1-4

1-5 3TNE82A ........................................................................................................... 1-5

1-6 3TNE82 .............................................................................................................. 1-6

1-7 3TNE84.............................................................................................................. 1-7

1-8 3TNE88 .............................................................................................................. 1-8

1-9 4TNE82.............................................................................................................. 1-9

1-10 4TNE84.............................................................................................................. 1-10

1-11 4TNE88.............................................................................................................. 1-11

1-12 3TNE84T............................................................................................................ 1-12

1-13 4TNE84T............................................................................................................ 1-13

2. Cross Sectional Views ................. • ......... ••.•..•••.•••...• ........... • ....... •...••••• .... •...•...• ..... • ..... •. 2-1

2-1 Special Swirl Pre-combustion Chamber System ............................................... 2-1

2-2 Direct Injection System.......... ................................ ...... ........ .............................. 2-2

3. Cooling Water, Lubricating Oil and Fuel Oil .............................................................. 3-1

3-1 Cooling water ..................................................................................................... 3-1

3-2 lubricating oil........................................ ............................................................. 3-1

3-3 Fuel oil .................... ............. .............. .............. .............. ..... ............................... 3-3

4. Troubleshooting ............................................................................................................ 4-1

4-1 Trouble causes and remedies............................................................................ 4-1

4-2 Trouble diagnosis through measurement of compression pressure .................. 4-3

5. Special Service Tools and Measuring Instruments ................................................... 5-1

5-1 Special service tools.......... ...................... ..................... .................... ............ ..... 5-1

5-2 Measuring instruments ....................................................................................... 5-3

6. Measurement, Inspection and Adjustment ................................................................ 6-1

6-1 Measuring the compression pressure ......... ................. ................ .......... ............ 6-1

6-2 Adjusting the valve head clearance .................. ................................................. 6-3

6-3 Checking the V -belt tension ...... ............................. ................ ............................ 6-4

6-4 Measuring and checking the injection pressure and spray patterns

of the fuel injection valve ........................................... ........................... .............. 6-4

6-5 Checking and adjusting the fuel injection timing ................................................ 6-8

6-6 Adjusting the no-load maximum (or minimum) revolutions ................................ 6-10

6-7 Checking the COOling water system and radiator for water leakage .................. 6-10

6-8 Checking the battery ............................. ............................................................. 6-11

6-9 Checking sensors .............................................................................................. 6-13

6-10 Checking the oil cooler ....................................................................................... 6-14

6-11 Checking the piston cooling nozzle ................................................................... 6-15

7. Measuring Procedures, Service Data and Corrective Action ................................... 7-1

7-1 Cylinder head ... ...... ........•......... ...... ...................... ........ ........ ... ........... ........ ........ 7-1

7-2 Cylinder block .................................................................................................... 7-7

7-3 Valve rocker arm..... ........ ...... .......... ...... .............. ............................................... 7-10

7-4 Piston and piston ring ...... ...................... .......................................... .................. 7-12

7·5 Connecting rod................ ............ .......... ............. ............. ................................... 7-17

7-6 Camshaft............................................................................................................ 7-20

7-7 Crankshaft.......................................................................................................... 7-22

7-8

7-9

Gears .................................................................................................................

Trochoid pump ................................................................................................. ..

8. Disassembly and Reassembly .....................................................................................

8-1 Disassembly .......................................................................................................

8-2 Precautions before and during reassembly ..................................................... ..

9. Service Data ................................................................................................................. .

9-1 Cylinder head ................................................................................................... ..

9-2 Cylinder block ....................................................................................................

9-3 Valve rocker arm ................................................................................................

9-4 Piston ................................................................................................................ .

9-5 Piston ring ........................................................................................................ ..

9-6 Connecting rod ................................................................................................. ..

9-7 Camshaft ............................................................................................................

9-8 Crankshaft ........................................................................................................ ..

7·25

7-27

8-1

8-1

8-6

9-1

9·1

9-2

9·2

9-3

9-4

9-5

9-5

9-5

9-9 Side gap and backlash ....................................................................................... 9-6

9-1 0 Others ................................................................................................................ 9-6

10. Tightening Torque ........................................................................................................ 10-1

10-1 Main bolVnut ...................................................................................................... 10-1

10-2 Standard bolt and nut.. .................. ...... ..................... .......................................... 10-1

11. Fuel Injection Pump for Indirect Injection System .................................................... 11-1

11·1 Exploded views (YPFR type) .. ........ ........ ................ ..... ............ ........ ..... ... ...... .•.. 11-1

11-2 Disassembly ....................................................................................................... 11-2

11·3 Inspection......... .................................................................................................. 11-3

11-4 Reassembly .............................. ................... ................. ........... ............. ............. 11-5

12. Fuel Injection Pump for Direct Injection System ....................................................... 12-1

12-1 Exploded Views (YPES type)............................................................................. 12·1

12-2 Special service tools for disassembly and reassembly.... .................................. 12·2

12-3 Disassembly.......................... ........ ..................................................................... 12-3

12-4 Inspection........................................................................................................... 12-7

12-5 Reassembly .......................................................... ......................... ........ ...... ...... 12·9

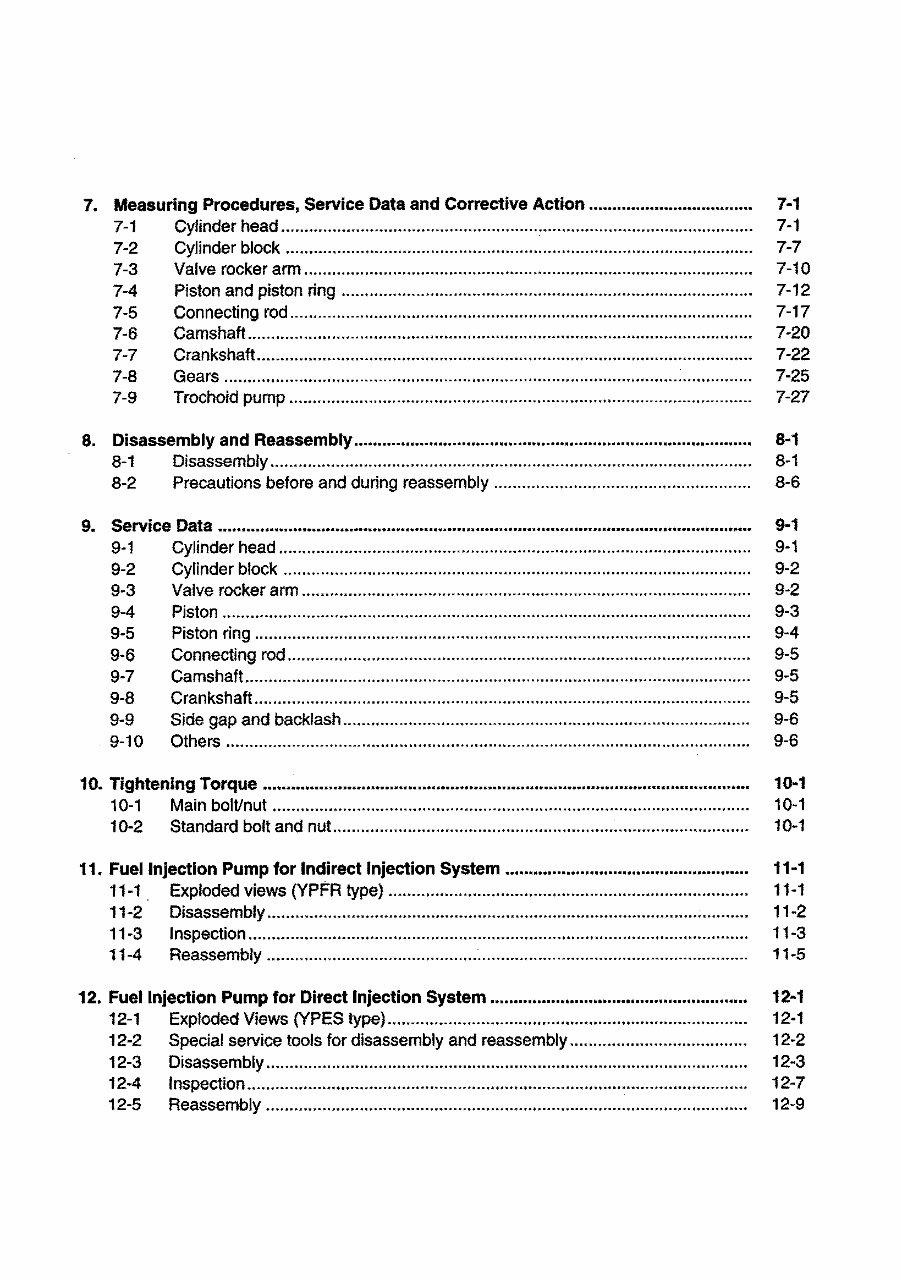

13. Governor ................................................................................................. ....................... 13·1

13-1 Exploded views of governorfor indirect injection system ... ............................... 13-1

13-2 Exploded views of governor for direct injection system ..................................... 13-2

13-3 Disassembly................ ............................. ..... .... .......................... ..... ........... ....... 13-3

13-4 Inspection........................................................................................................... 13-7

13-5 Reassembly.... ....... ...... ...... .................... ........ ........... ................. ................ .... .... 13-9

14. Turbocharger ................................................................................................................. 14·1

14-1 Specifications ..................................................................................................... 14·1

14-2 Construction ....................................................................................................... 14-1

14-3 Waste gate valve adjusting method .... .... .... ........ ...... .... ................ ..... ......... ....... 14-3

14·4 Exploded view of Turbocharger (wI waste gate) .. ... ........ .... .... ............ .......... ..... 14-5

14-5 Tightening torque ............................. ................ ........... ............ ........................... 14-6

14-6 Service standards .............................................................................................. 14-6

15. Service Information for CARS ULG regulation .......................................................... 15·1

15-1 Emission control labels ................................................................................... :.. 15-1

15-2 Limiting the high idle and low idle adjustment screw......................................... 15-6

15-3 Limiting the fuel volume limiter screw.... ............................................................ 15-7

Attached Drawing 1. Exploded Views of Engine Components ..................................... A·1

Attached Drawing 2. Exploded Views of Engine Components ..................................... A·2

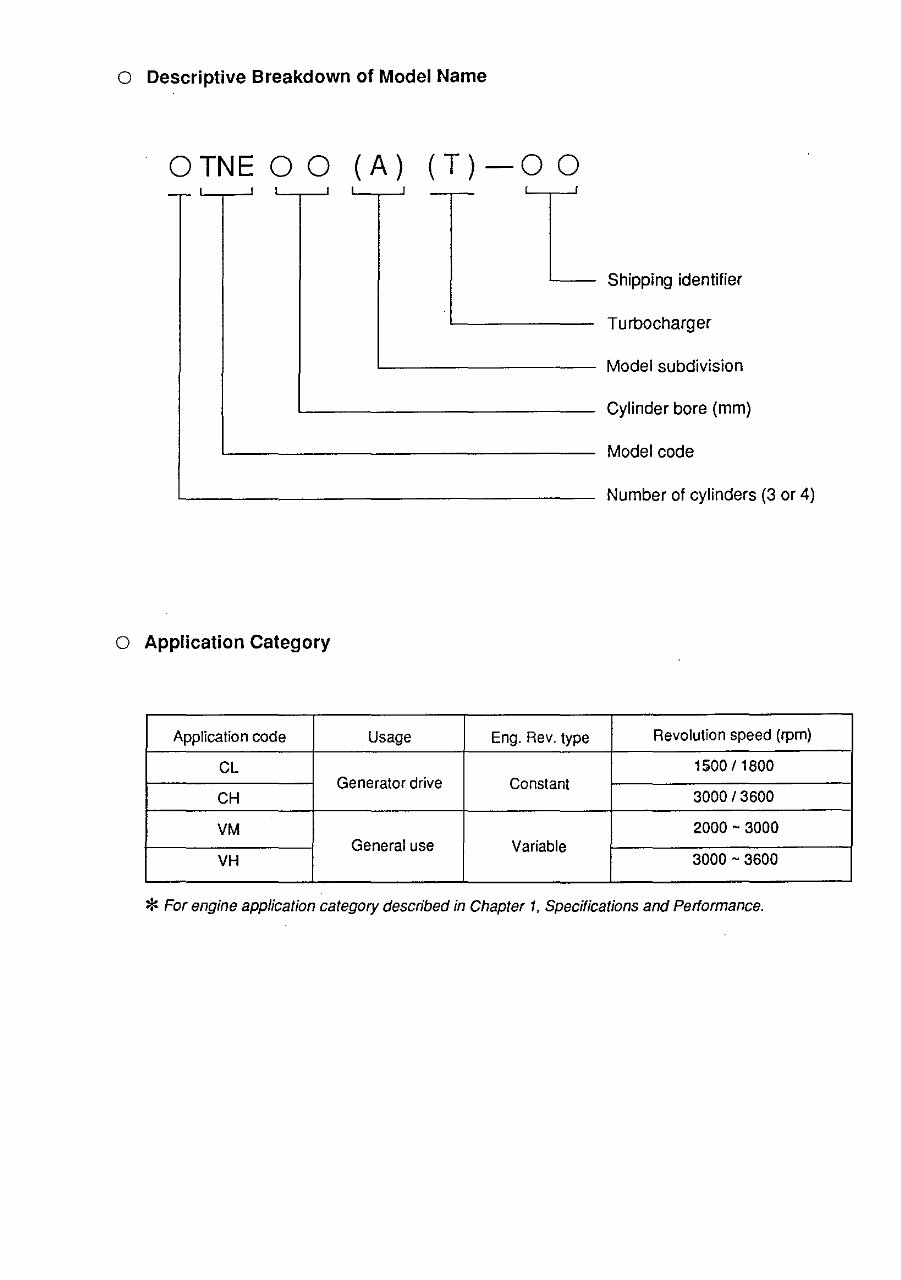

o Descriptive Breakdown of Model Name

o TN E 0 0 (A) (T) - 0 0

-,-

'------. Shipping identifier

Turbocharger

L-_________ Model subdivision

Cylinder bore (mm)

Model code

Number of cylinders (3 or 4)

o Application Category

Application code Usage Eng. Rev. type

Revolution speed (rpm)

CL

1500/1800

Generator drive Constant

CH

3000/3600

VM

2000 ~ 3000

General use Variable

VH

3000 ~ 3600

* For engine application category described in Chapter 1. Specifications and Performance.

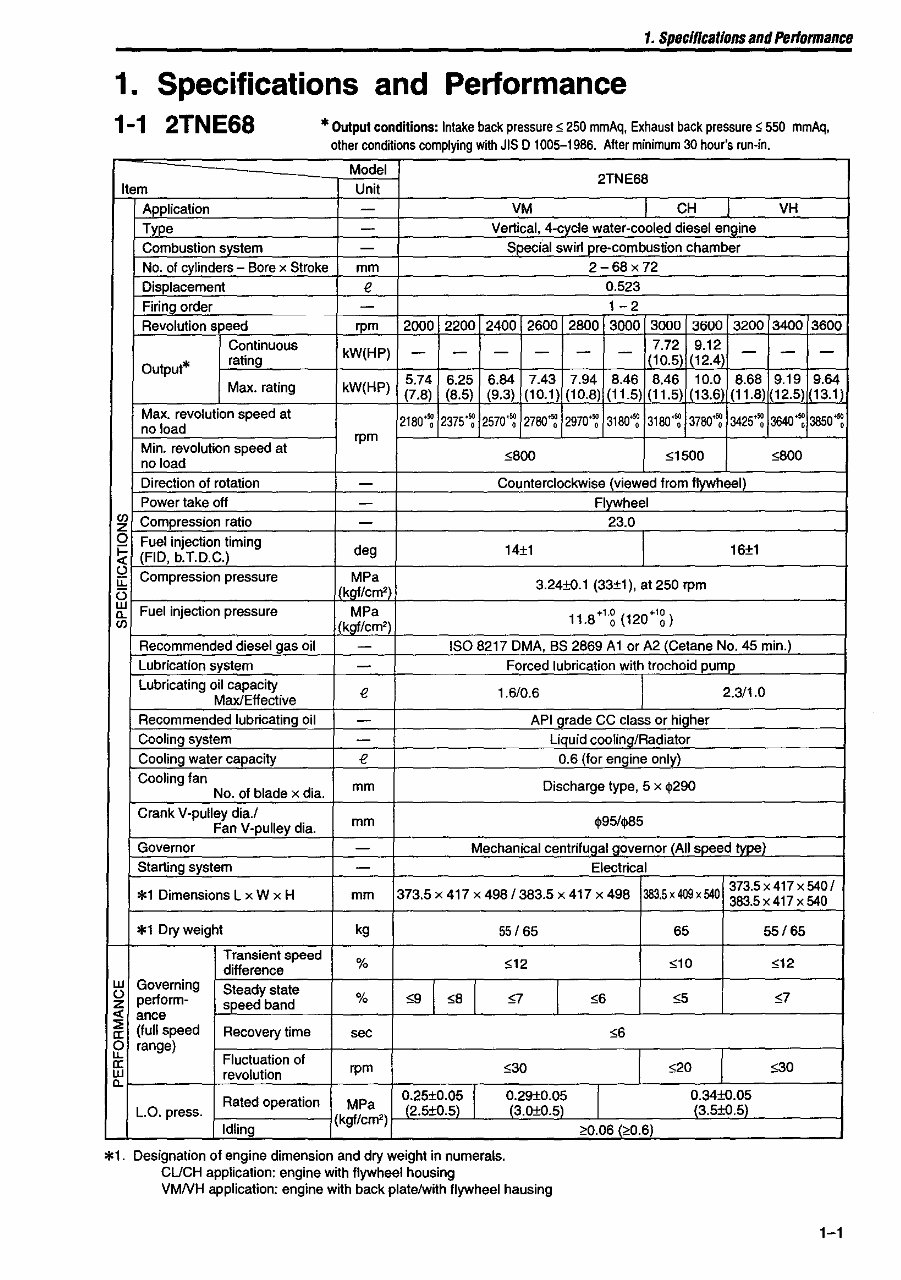

1. Specifications and Performance

1. Specifications and Performance

1-1 2TNE68 * Output conditions: Intake back pressure $ 250 mmAq, Exhaust back pressure $ 550 mmAq,

other conditions complying with JIS 0 1005-1986. After minimum 30 hour's run·in.

Model

2TNE68

Item Unit

Application - VM

I

CH VH

Type

-

Vertical, 4·cycle water·cooled diesel engine

Combustion system - Special swirl pre·combustion chamber

No. of cylinders - Bore x Stroke mm 2-68x72

Displacement e

0.523

Firing_order - 1-2

Revolution speed rpm 2000 2200 2400 2600 2800 3000 3000 3600 3200 3400 3600

Continuous

kW(HP) - -

- - - -

7.72 9.12

- -

-

Output*

rating (10.5) (12.4)

5.74 6.25 6.84 7.43 7.94 8.46 8,46 10.0 8.68 9.19 9.64

Max. rating kW(HP)

(7.8) (8.5) (9.3) (10.1 ) (10.8) (11.5) (11.5) (13.6) (11.8) (12.5) (13.1 )

Max. revolution speed at

2180'~ 2375'~ 2570'~ 2780+~ 2970'~ 3180+~ 3180'~ 3780+~ 3425'~ 3640~

3850+~

no load

Min. revolution speed at

rpm

no load

5800 51500 5800

Direction of rotation - Counterclockwise (viewed from flywheel)

Power take off - Flywheel

en

Compression ratio

z

- 23.0

0

Fuel injection timing

~

(FlO, b.T.D.C.)

deg 14±1 16±1

C,)

Compression pressure MPa

u::

3.24±O.1 (33±1), at 250 rpm

i3

IlkQficm"

w

Fuel injection pressure MPa

11.8·'g (120·'g)

0..

en

.Ikgf/cm')

Recommended diesel gas oil - ISO 8217 DMA, BS 2869 AI or A2 (Cetane No. 45 min.)

Lubrication system

-

Forced lubrication with trochoid pump

Lubricating oil capacity

e 1.6/0.6 2.311.0

Max/Effective

Recommended lubricating oil

- API grade CC class or higher

Cooling system - Liquid coolinglRadiator

Cooling water capacity e 0.6 (for engine only)

Cooling fan

mm Discharge type, 5 x $290

No. of blade x dia.

Crank V·pulley dia.l

mm $95/$85

Fan V·pulley dia.

Governor - Mechanical centrifugal governor (All speed ty~

Starting system - Electrical

*1 DimenSions L x W x H 373.5 x 417 x 498/383.5 x 417 x 498 383.5 x 409 x 540

373.5 x 417 x 540 I

mm

383.5x417 x 540

*1 Dry weight kg

55/65 65 55/65

Transient speed

% $12 510 512

difference

w

Governing

Steady state

59 I 58

I

C,)

perform·

% 57 56 $5 $7

z speed band

<{

ance

~

(full speed

Recovery time 56

a:

sec

0 range)

u.

Fluctuation of

a:

rpm 530 520 530

w

revolution

0..

I

Rated operation

MPa

0.25±0.05 0.29±0.05

O.34±O·~r

L.a. press.

(2.5±O.5) (3.0±0.5) (3.5±O.5

Idling

(kgf/cm')

,,0.06 (;>0.6)

*1. Designation of engine dimension and dry weight in numerals.

CUCH application: engine with flywheel housing

VMNH application: engine with back plateiwith flywheel hausing

1-1

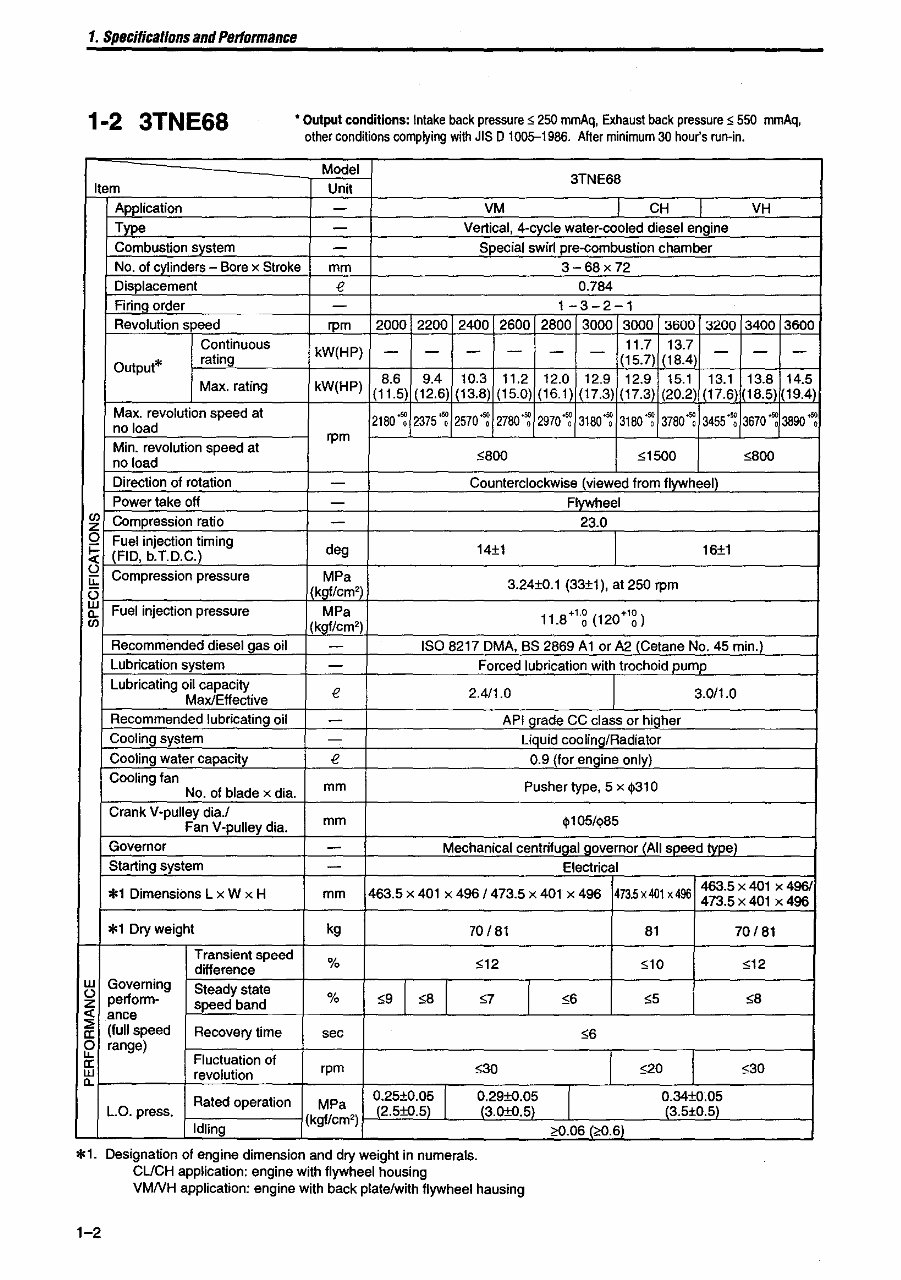

1. Specificallons and Performance

1-2 3TNE68

• Output conditions: Intake back pressure ~ 250 mmAq, Exhaust back pressure ~ 550 mmAq,

other conditions complying with JIS D 1005-1986. After minimum 30 hour's run-in.

Model

3TNE68

Item Unit

Application - VM CH

T

VH

Type

-

Vertical, 4-cvcle water-cooled diesel en!line

Combustion svstem

-

Special swirl pre-combustion chamber

No. of cvlinders - Bore x Stroke mm 3-68x72

Displacement € 0.784

Firing order - 1-3-2-1

Revolution speed rpm 2000 2200 2400 2600 2800 3000 3000 3600 3200 3400 3600

Continuous

kW(HP) - - -

- - -

11.7 13.7

- - -

Output*

rating (15.7) (18.4)

Max. rating kW(HP)

8.6 9.4 10.3 11.2 12.0 12.9 12.9 15.1 13.1 13.8 14.5

(11.5) (12.6) (13.8) (15.0) (16.1) (17.3) (17.3) (20.2 (17.6) (18.5) (19.4)

Max. revolution speed at

2180": 2375 ": 2570": 2780 ": 2970": 3180": 3180'~ 3780'~ 3455'~ 3670 ": 3890 ":

no load

Min. revolution speed at

rpm

no load

$800 $1500 $800

Direction of rotation - Counterclockwise (viewed from flywheel)

Power take off - Flywheel

Ul

Compression ratio

-

23.0

z

0

Fuel injection timing

~

(FlO, b.T.D.C.)

deg 14±1 16±1

u

Compression pressure MPa

u:

3.24±0.1 (33±1), at 250 rpm

5

(kaf/cm')

w

Fuel injection pressure MPa

11.8+'~ (120+'g)

Il.

Ul

(kaf/cm')

Recommended diesel gas oil

- ISO 8217 DMA, BS 2869 AI or A2 (Cetane No. 45 min.)

Lubrication system - Forced lubrication with trochoid pump

Lubricating oil capacity

€ 2.4/1.0 3.0/1.0

Max/Effective

Recommended lubricating oil

-

API !lrade CC class or higher

Cooling system -

Liquid coolinglRadiator

Cooling water capacity € 0.9 (for engine only)

Coolingfan

mm Pusher type, 5 x $310

No. of blade x dia.

Crank V-pulley dia.!

mm $105/$85

Fan V-pulley dia.

Governor

-

Mechanical centrifugal governor (All speed type)

Starting system

- Electrical

*1 Dimensions Lx W x H 463.5 x 401 x 496 I 473.5 x 401 x 496 473.5x401 x 496

463.5 x 401 x 4961

mm

473.5 x 401 x 496

*1 Dry weight kg

70/81 81 70/81

Transient speed

% $12 SID s12

difference

w

Governing

Steady state

$9 I $8 I

I

u

perform- % 57 $6 $5 $8

z

sDeed band

« ance

::;;

(full speed

Recovery time $6 a: sec

0 range)

"-

Fluctuation of

a:

rpm :>30 :>20 $30

w

revolution

Il.

Rated operation

MPa

~.25±0.~~ I

~:29±O.~~

I

~:34±0.~~

L.O. press. 2.5±O.5 3.0±0.5 3.5±O.5

Idling

(kgf/em')

>0.06 (?0.6)-

*1. Designation of engine dimension and dry weight in numerals.

CUCH application: engine with flywheel housing

VMNH application: engine with back platelwith flywheel hausing

1-2

1. Specifications and Performance

1-3 3TNE74

*Output conditions: Intake back pressure ~ 250 mmAq, Exhaust back pressure ~ 550 mmAq,

other conditions complying with JIS 0 1005-1986. After minimum 30 hour's run·in.

Model

3TNE74

Item Unit

Application - VM CH

~

VH

Type -

Vertical, 4·cycle water·cooled diesel engine

Combustion system

-

Special swirl pre·combustion chamber

No. of cylinders - Bore x Stroke mm 3-74x78

Displacement

f!

1.006

Firing order

-

1-3-2-1

Revolution speed rpm 2000 2200 2400 2600 2800 3000 3000 3600 3200 3400 3600

Continuous

kW(HP) - - - -

-

-

15.1 17.4

- - -

Output*

rating (20.2) (23.3)

11.0 12.1 13.2 14.3 15.5 16.6 16.6 19.1 16.6 17.1 17.7

Max. rating kW(HP)

(14.8) (16.2) (17.7) (19.2) (20.8) (22.3) (22.3) (25.6) (22.3) 22.9 (23.7)

Max. revolution speed at

2180+~ 2375'~ 2570'~ 2780": 2970'~ 3180": 3180'~ 3780": 3455~ 3670": 3890~

no load

Min. revolution speed at

rpm

no load

~800 ~1500 ~800

Direction of rotation - Counterclockwise (viewed from flywheel)

Power take off - Flywheel

(/)

Compression ratio

z

- 23.0

0

Fuel injection timing

~

(FlO, b.T.D.C.)

deg 14±1 16±1

()

Compression pressure MPa

iL:

3.43±O.1 (35±1), at 250 rpm

(3 (kgf/cm')

UJ

Fuel injection pressure MPa

11.8·'g (120·'g)

"-

(/)

kgf/cm')

Recommended diesel gas oil - ISO 8217 DMA, BS 2869 Alar A2 (Cetane No.: 45 min.)

Lubrication system

-

Forced lubrication with trochoid pump

Lubricating oil capacity

f! 2.411.0 3.311.4

Max/Effective

Recommended lubricating oil - API grade CC class or higher

Cooling system - Liquid coolinQ/Radiator

Coolil1g water capacity f! 0.9 (for engine only)

Cooling fan

mm Pusher type, 5 x ~310 Pusher type, 6 x ~335

No. of blade x dia.

Crank V·pulley dia.!

mm ~110/<1>8S ~110/~97

Fan V·pulley dia.

Governor - Mechanical centrifugal governor LAII speed type)

Starting system - Electrical

*1 Dimensions L x W x H

469.1 x 440 x S02/476.6 x 440 x S02 476.6 x 440 x 502

469.1 x 440 x S021

mm

476.6x 440 x 502

*1 Dry weight kg 8SI102 100 8SI100

Transient speed

% $12 $10 ,;12

difference

UJ Governing

Steady state

,,9 I ,,8

I

()

perform·

% ,;7 ,,6

"S

,,8

z speed band

..:

ance

~

(full speed

Recovery time ,,6

0: sec

rr

range)

0:

Fluctuation of

,,30 ,;20 ,,30

UJ

revolution

rpm

"-

Rated operation

MPa ~:2S±0.~~ I

0.29±O.05

1

0.34±O.OS

L.O. press. 2.S+0.S . (3.0±O.S) (3.S±O.S)

Idling

(kgf/cm')

>0.06 (;'0.6)

*1. Designation of engine dimension and dry weight in numerals.

CUCH application: engine with flywheel housing

VMNH application: engine with back plate/with flywheel hausing

1-3

1. Specincations and Performance

1-4 3TNE78A

* Output conditions: Intake back pressure ~ 250 mmAq, Exhaust back pressure ~ 550 mmAq,

other conditions complying with JIS D 1005-1986. After minimum 30 hou(s run-in.

Model

3TNE78A

item Unit

Application - CL VM

I

CH VH

Type - Vertical, 4-cycle water-cooled diesel engine

Combustion system - Direct injection system

No. of cylinders - Bore x Stroke mm 3-78x84

Displacement t!

1.204

Firing order - 1-3-2-1

Revolution speed rpm 1500 1800 2000 2200 2400 2600 2800 3000 3000 3600 3200 3400 3600

Continuous

kW(HP)

9.1 10.8

- - - - - -

18.0 21.0

- -

-

Output*

rating (12.2) (14.5) (24.1) (28.2)

Max. rating kW(HP)

9.9 11.9 13.2 14.6 15.9 17.2 18.5 19.9 19.9 23.2 20.5 21.6 23.2

(13.3 (16.0) (17.7) (19.6) (21.3) (23.1) (24.8) (26.7) (26.7) (31. t) (27.5) (29.0) (31.1)

Max. revolution speed at

1575~ 1870~ 2180~ 2375'~ 2570'~ 2780~

,.

3180'~ 3150~ 3745~

..,

3670~

3800+~

no load

2970 0 3455 ,

Min. revolution speed at

rpm

no load

~1200 ~800 ~1500 ~800

Direction of rotation

- Counterclockwise (viewed from fly~heel)

Power take off

- Flywheel

en

Compression ratio

z

- 18.0

0

Fuel injection timing

~

(FID, b.T.D.C.)

deg 10±1 12±1 14±1 16±1 24±1 18±1 20±1 24±1

()

Compression pressure MPa

u::

3.14±O.1 (32±1), at 250 rpm

U

(kgf/cm')

w

Fuel injection pressure MPa

a.

19.6+'g (200+'g )

en

I (kgf/cm')

Recommended diesel gas oil - ISO 8217 DMA, BS 2869 Al or A2 (Cetane No.: 45 min.)

Lubrication system

- Forced lubrication with trochoid pump

Lubricating oil capacity

t! 3.6/1.3 5.0/1.7

Max/Effective

Recommended lubricating oil - API grade CC class or higher

Cooling system

- Liquid cooling/Radiator

Cooling water capac~y t! 1.8 (for engine only)

Cooling fan

mm Pusher type, 6 x ~335

No. of blade x dia.

Crank V-pulley dia.!

mm ~120/~90 ~110/~110

Fan V-pulley dia.

Governor

-

Mechanical centrifuQal Qovernor (All speed type)

Starting system - Electrical

*1 Dimensions L x W x H mm 553x489x565 520.5 x 489 x 565/528 x 489 x 565 528 x 4a9 x 565

520.5 x 489 x 565/

528 x 489 x 565

*1 Dry weight

kg 138 1121128 124 112/124

Transient speed

% S10 S8 ~12 ~10 ~8 ,,12

difference

w

Governing

Steady state

,,91

S8

1

1

()

perform- % ,,5 S4

g

,,6 S5 S4 s8

z speed band

c(

ance

::0

(full speed

Recovery time ,,5 ~6 ,,5 ,,6 cr: sec

0 range)

"-

Fluctuation of

cr:

S15 525· S30

w

revolution

rpm

a.

Rated operation

0.29±O.05

O.34±O.OS

L.O. press.

MPa

(3.0±0.5)

(3.S±O.5)

Idling

(kgf/cm')

>0.06 (?0.6)

*1. Designation of engine dimension and dry weight in numerals.

CUCH application: engine with flywheel housing

VMNH application: engine with back plateiwith flywheel hausing

1-4

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 16 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

- This complete factory service repair workshop manual is available for instant access on your computer, tablet, or smartphone.

- It covers all repairs, servicing, and troubleshooting procedures with detailed photos and diagrams.

- Professional mechanics and technicians use this manual, which contains step-by-step instructions and highly detailed exploded diagrams and pictures.

- You have the option to print out a single page or the entire manual.

- This manual can be used on multiple computers without any limitations or trial periods.

- There is no expiry date or renewal fee; you can use this manual for life.

- It is fully compatible with Windows and MAC computers.

For more information, please click on the button.